Finishing method of wood

A wood and mold technology, applied in wood treatment, wood treatment details, wood compression, etc., can solve the problems of low board yield, waste, and impact on use effects, and achieve easy adjustment, good effect, and good correction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

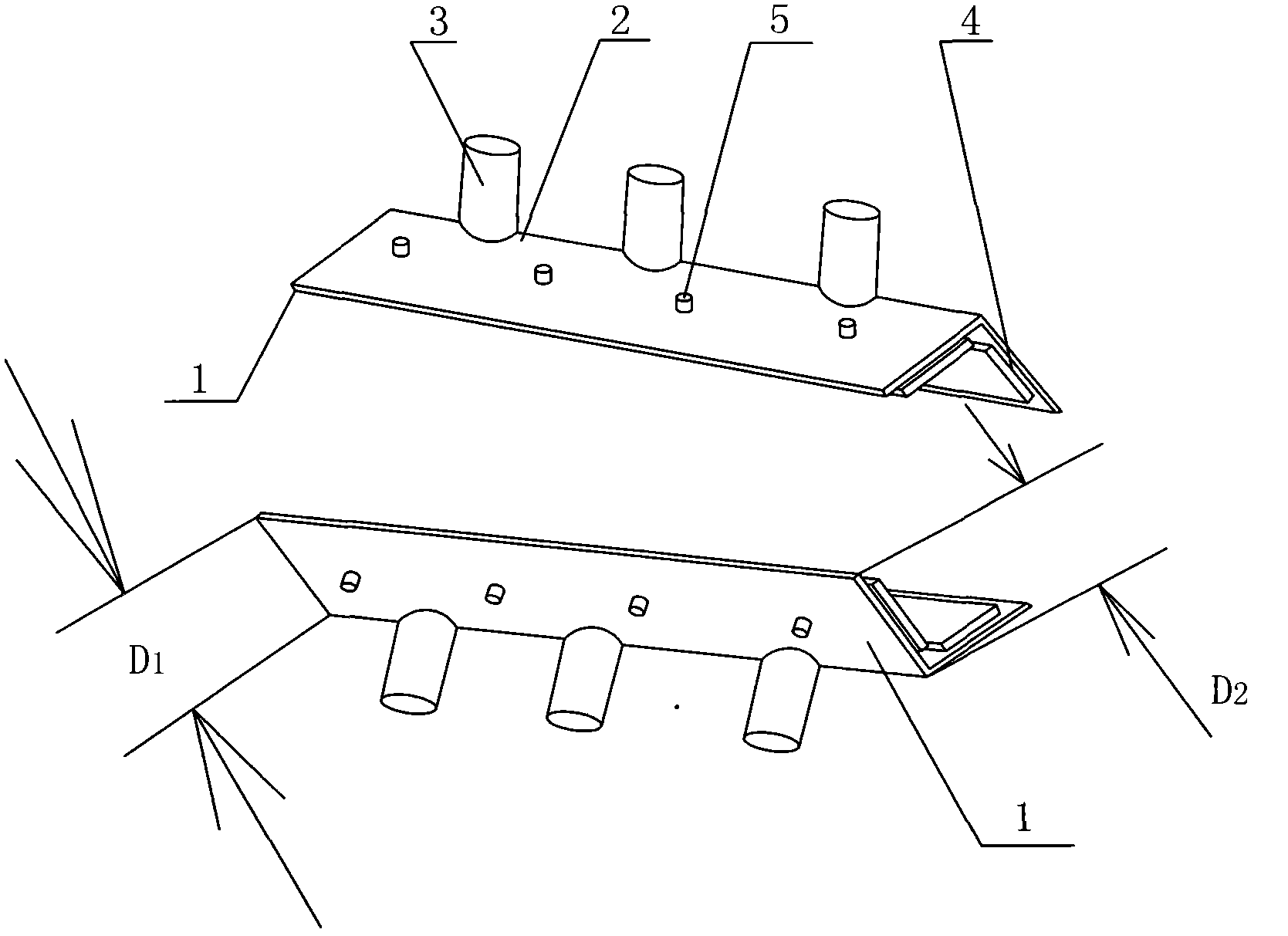

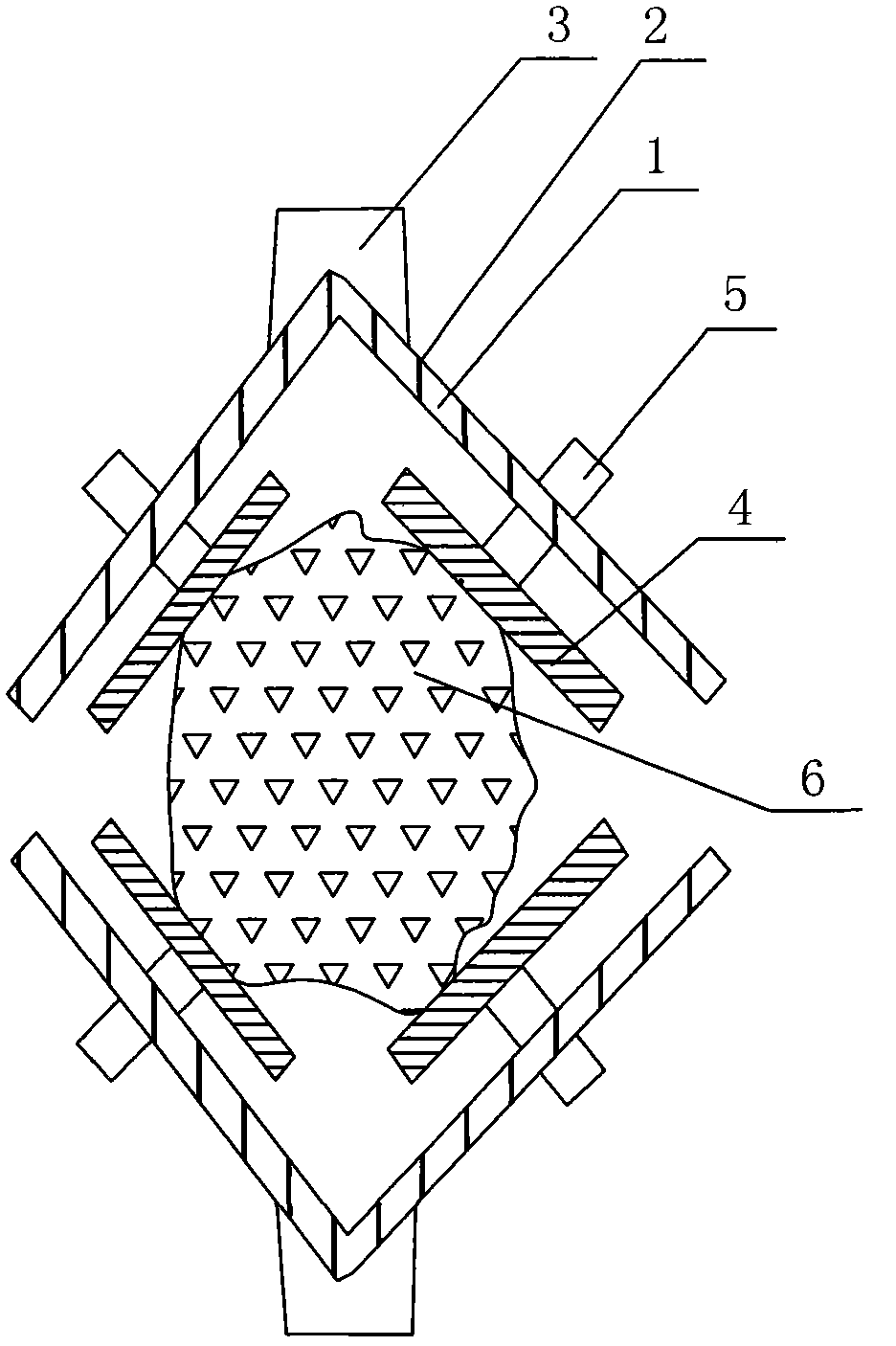

Method used

Image

Examples

Embodiment 1

[0027] a. Take a 2.5-meter-long, irregular cypress, place it in a heating room and heat it to 105 degrees for a period of time. The temperature inside the cypress is 85 degrees.

[0028] During the heating process of cypress wood, the internal temperature rises slowly. If the internal temperature is brought closer to 105 degrees, it will take a long time. The internal temperature can reach 85 degrees to meet the requirements of the present invention.

[0029] A log with a diameter of 20 cm can meet the requirements in 60 minutes when the surrounding environment is 300 degrees, and a log with a diameter of 25 cm can meet the requirements in 65 minutes when the surrounding environment is 300 degrees. Those in the field can easily rely on it. Master of experience, the same below.

[0030] b. Use a press to flatten the cypress in the above a, and slowly lower the temperature to room temperature, the cooling process is 60 minutes.

[0031] The pressing and flattening is pressing the arched...

Embodiment 2

[0034] a. Take a 2.5-meter long, irregular cypress, place it in the heating room and heat it to 95 degrees for a period of time. The temperature inside the cypress is 80 degrees.

[0035] b. Use a press to flatten the cypress in the above a, and slowly lower the temperature to room temperature for 70 minutes.

[0036] The cypress prepared in this embodiment can improve the utilization rate and the product has the advantages of not being easily deformed. Compared with Example 1, the recovery deformation is slight. It can be considered that the heating temperature in this embodiment is lower, but this still meets the requirements.

Embodiment 3

[0038] a. Take a 2.5-meter-long, irregular cypress, place it in a heating room and heat it to 100 degrees for a period of time. The internal temperature of the wood is 92 degrees.

[0039] b. Use a press to flatten the wood in a, and slowly lower the temperature to room temperature. The cooling process is 80 minutes.

[0040] The wood finished in this embodiment can improve the utilization rate, and the product has the advantages of not being easily deformed. In general, among Examples 1, 2, and 3, Example 3 is the best, because it can ensure the effect, and can also reduce the temperature. , To achieve the lowest cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com