Master-slave point-by-point correcting method for LED display screen

An LED display, point-by-point correction technology, applied in static indicators, instruments, etc., can solve problems such as unsatisfactory correction results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

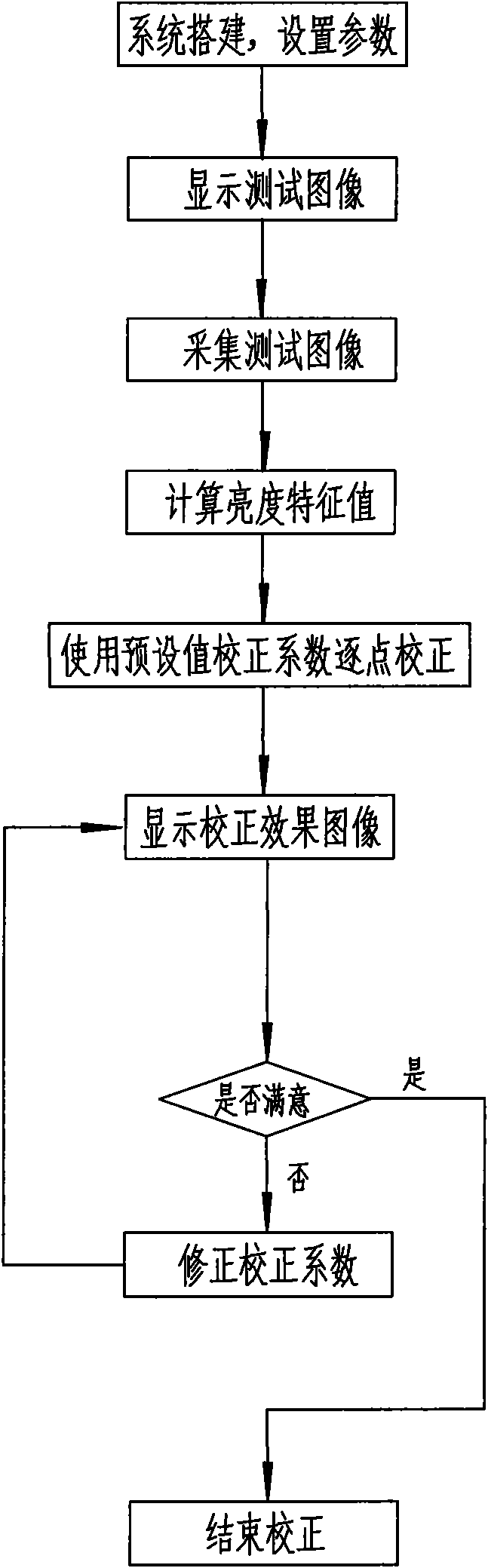

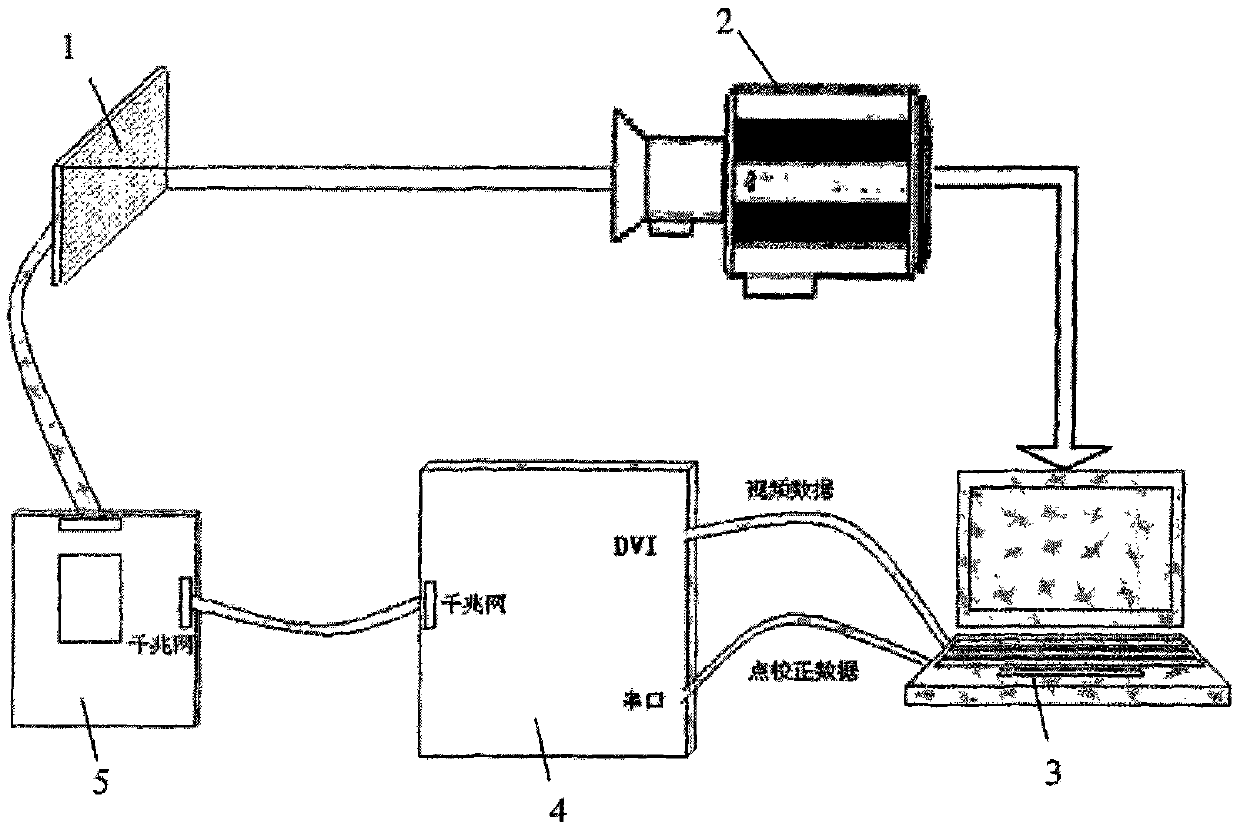

[0036] Such as Figure 4 Shown is the flow chart of the method of the present invention, the present embodiment provides a kind of LED display screen point-by-point correction method of master-slave mode, first combines figure 2 The point-by-point correction system of the LED display screen in the master-slave mode is described in detail. The system structure includes: a master control module 10, a slave control module 14, an image acquisition device 12, a wireless transmitting module 11, a wireless receiving module 13 and an LED display screen 15; the main control module 10 is connected with the image acquisition device 12 and the wireless transmission module 11, the main control module 10 controls the image acquisition device 12 to collect the test image displayed on the LED display screen 15, and obtains each LED light point in the test image According to the brightness characteristic value of the system preset correction coefficient, the adjusted lamp point brightness dat...

Embodiment 2

[0051] Yet another example, such as image 3 As shown, in the above-mentioned point-by-point correction system, the main control module 10 also includes an image acquisition control unit 103, a data processing unit 101 and a wireless transmission control unit 104 connected in sequence; the image acquisition control unit 103 is connected with the image acquisition device 12 for Collect the test image by controlling the image acquisition device 12; the data processing unit 101 is used to receive the test image, process the test image to obtain the brightness data of the lamp point; the wireless transmission control unit 104 is connected with the wireless transmission module 11, and uses To control the wireless transmitting module 11 to send commands and the brightness data of the lamps to the wireless receiving module 13 .

[0052] Yet another example, such as image 3 As shown, the main control module 10 also includes a user input unit 105 for inputting parameters of the LED d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com