Modified aqueous glaze, preparation method, and wood finishing construction technology

A water-based and modified technology, applied in the field of wood lacquer, can solve the problems of peeling off the top coat, weak penetration, easy color fading, etc., and achieve the effects of reduced drying speed, good transparency and permeability, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

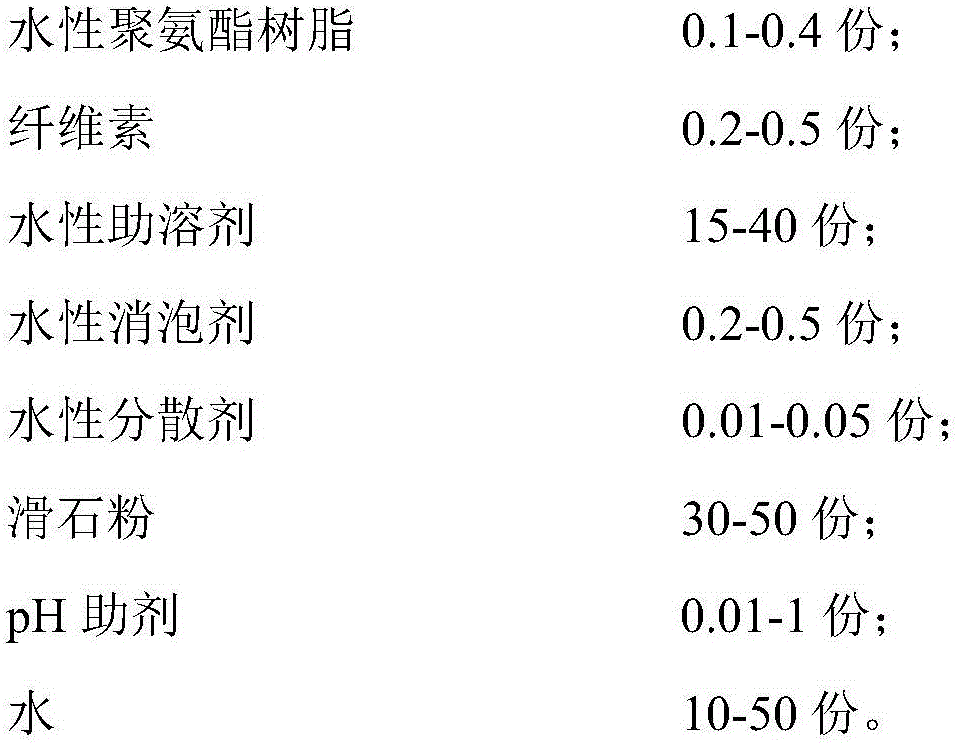

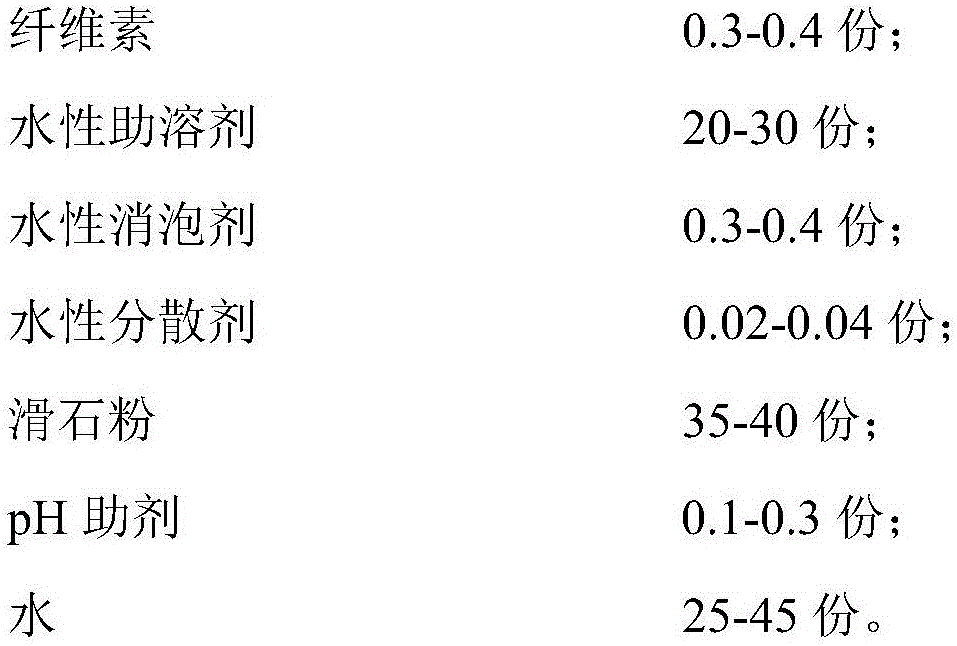

Method used

Image

Examples

preparation example Construction

[0039] The invention provides a kind of preparation method of the modified water glas, comprising the following steps:

[0040] 1) Under low-speed stirring, add water and cellulose in sequence according to the weight of each component of Waterglass, adjust the stirring speed to 400-600r / min, slowly add PH additives, stir for 10-15min, then stir uniform.

[0041] 2) Add water-based defoamer, water-based dispersant, water-based co-solvent and water-based polyurethane resin in sequence according to parts by weight, stir for 30-40 minutes, and then stir evenly.

[0042] 3) Slowly add talcum powder, adjust the stirring speed to about 1000-1200r / min, stir for 20-30min, and stir evenly to obtain the modified water gelis.

[0043] In steps 1), 2), and 3), the stirring speed and stirring time are very important in the preparation process of the Water Gris, because the stirring speed will affect the compactness of the Water Gris coating film. Different stirring speeds will cause densi...

Embodiment 1

[0058] A kind of preparation method of modified water glas comprises the following steps:

[0059] 1) Under low-speed stirring, add 29kg of water and 0.3kg of hydroxymethylcellulose agent to the mixer in turn, increase the speed to 400r / min, slowly add 0.08kg of amine assistant (AMP-95), stir for 10min, and stir evenly;

[0060] 2) Then add 0.3kg of water-based defoamer (SP-994), 0.02kg of water-based dispersant (A168), 40kg of water-based co-solvent and 0.3kg of water-based polyurethane resin (KT300A) into the mixer, and stir evenly;

[0061] 3) Slowly add 30kg of talcum powder (HTP05), adjust the rotation speed to about 1200r / min, stir evenly, and obtain modified water glas.

Embodiment 2

[0063] A kind of preparation method of modified water glas comprises the following steps:

[0064] 1) Under low-speed stirring, add 30.3kg of water and 0.3kg of hydroxymethyl cellulose to the mixer in turn, increase the speed to 400r / min, slowly add 0.09kg of amine additive (AMP-95) and stir evenly;

[0065] 2) Then add 0.2kg of water-based defoamer (SP-994), 0.01kg of water-based dispersant (A168), 34kg of water-based co-solvent and 0.1kg of water-based polyurethane resin (KT300A) into the mixer, and stir evenly;

[0066] 3) Slowly add 35kg of talcum powder (HTP05), adjust the rotation speed to about 1200r / min, stir evenly, and obtain modified water glas.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com