Thin film type sodium ion secondary battery and preparation method thereof

A technology of secondary batteries and sodium ions, which is applied in the direction of secondary batteries, electrolyte battery manufacturing, battery electrodes, etc., to achieve the effects of improving safety performance, avoiding shedding, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

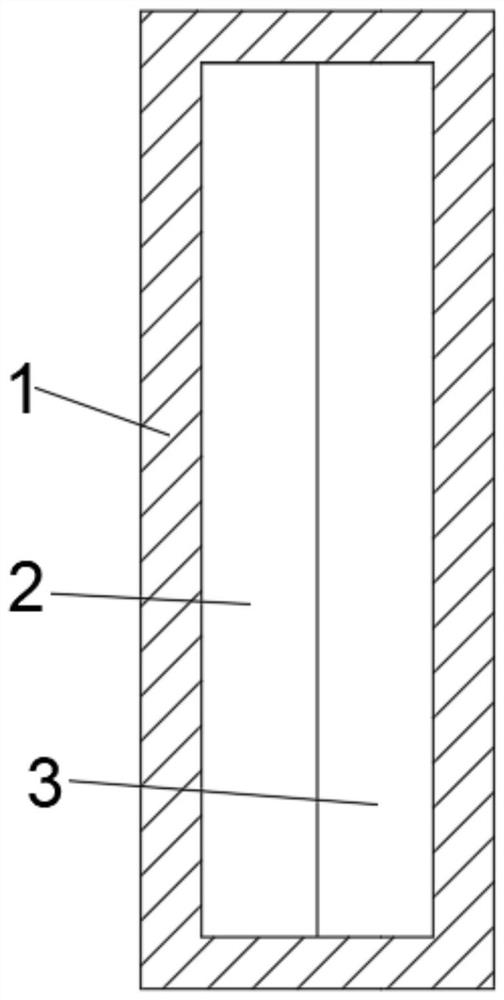

Image

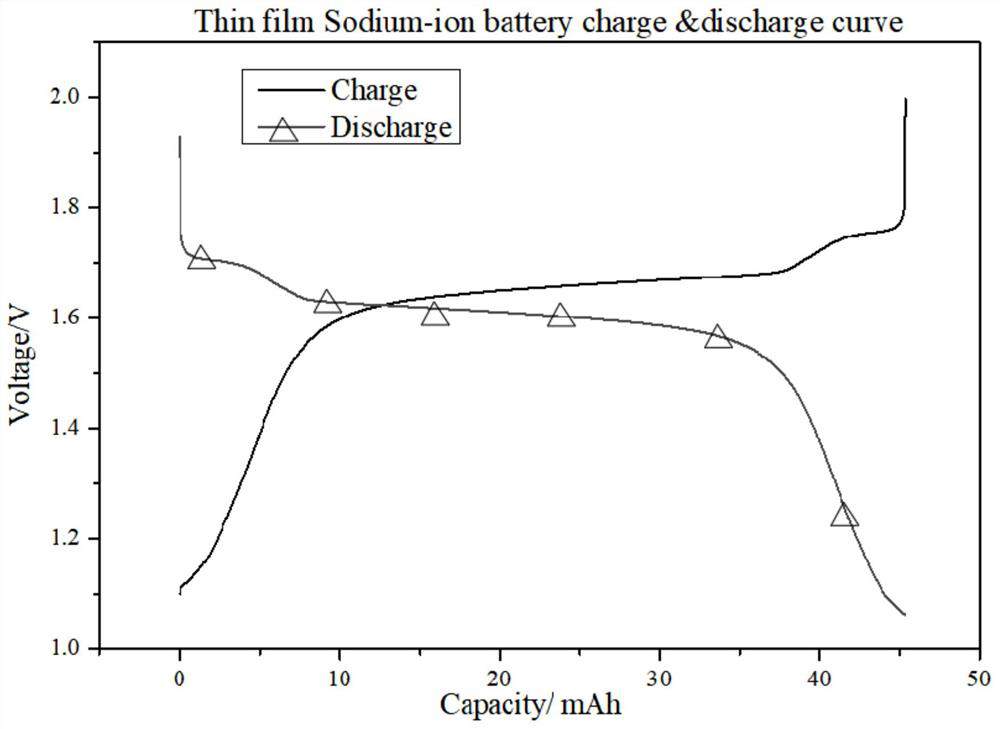

Examples

Embodiment 1

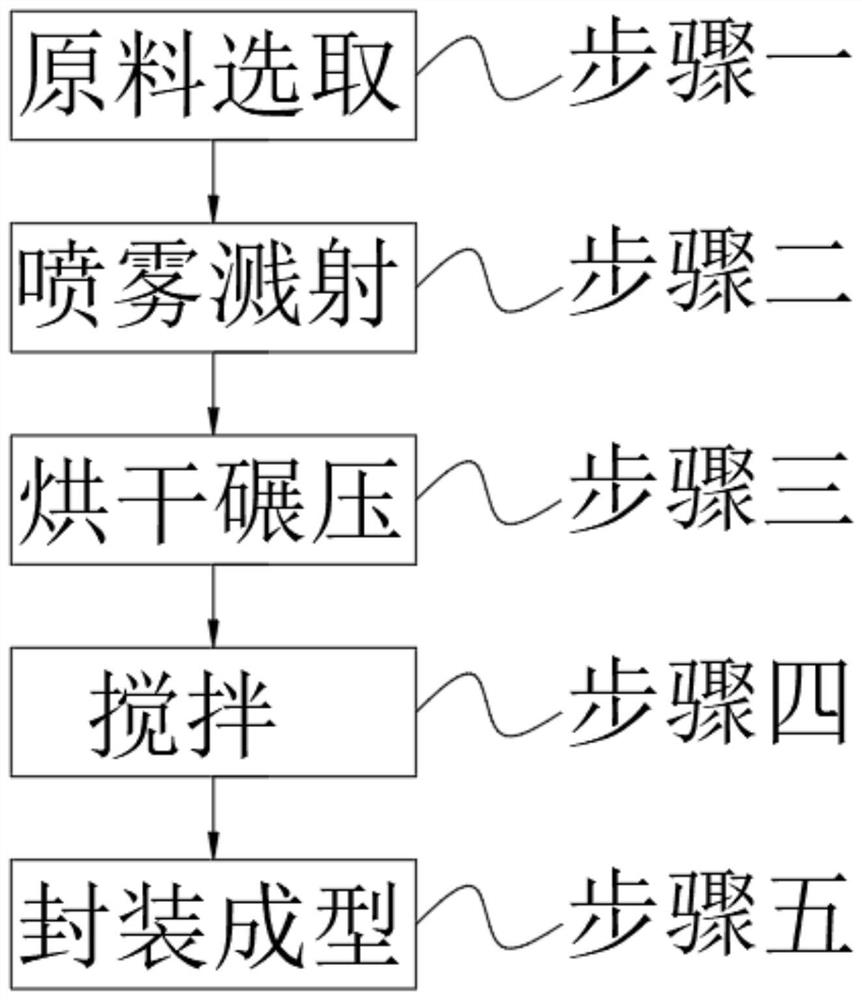

[0028] A method for preparing a thin-film sodium ion secondary battery, comprising step 1, selecting raw materials; step 2, spraying and sputtering; step 3, drying and rolling; step 4, stirring; step 5, packaging and molding;

[0029] In the above step 1, a certain amount of active material, conductive agent, binder, NMP solvent, current collector, sodium salt, mixed solvent, PEO polymer and PVDF are first selected for use, and the active material is carbon-coated sodium Fast ion conductor material sodium vanadium phosphate, the conductive agent is one or more mixtures of superconducting carbon black, carbon nanotubes and acetylene black, and the binder is one or more of PVDF, PTFE, polyaniline and polyurethane A variety of mixtures, and the current collector is an aluminum foil current collector or a nickel foil current collector;

[0030] Wherein the above-mentioned step two, take by weight 80% of the active material, 10% of the conductive agent and 10% of the binding agent ...

Embodiment 2

[0035] A method for preparing a thin-film sodium ion secondary battery, comprising step 1, selecting raw materials; step 2, spraying and sputtering; step 3, drying and rolling; step 4, stirring; step 5, packaging and molding;

[0036] In the above step 1, a certain amount of active material, conductive agent, binder, NMP solvent, current collector, sodium salt, mixed solvent, PEO polymer and PVDF are first selected for use, and the active material is carbon-coated sodium Fast ion conductor material sodium vanadium phosphate, the conductive agent is one or more mixtures of superconducting carbon black, carbon nanotubes and acetylene black, and the binder is one or more of PVDF, PTFE, polyaniline and polyurethane A variety of mixtures, and the current collector is an aluminum foil current collector or a nickel foil current collector;

[0037] Wherein the above-mentioned step two, take by weight respectively 95% active material, 2% conductive agent and 3% binder from the spare ma...

Embodiment 3

[0042] A method for preparing a thin-film sodium ion secondary battery, comprising step 1, selecting raw materials; step 2, spraying and sputtering; step 3, drying and rolling; step 4, stirring; step 5, packaging and molding;

[0043] In the above step 1, a certain amount of active material, conductive agent, binder, NMP solvent, current collector, sodium salt, mixed solvent, PEO polymer and PVDF are first selected for use, and the active material is carbon-coated sodium Fast ion conductor material sodium vanadium phosphate, the conductive agent is one or more mixtures of superconducting carbon black, carbon nanotubes and acetylene black, and the binder is one or more of PVDF, PTFE, polyaniline and polyurethane A variety of mixtures, and the current collector is an aluminum foil current collector or a nickel foil current collector;

[0044] Wherein the above-mentioned step two, take by weight 90% active material, 5% conductive agent and 5% binding agent respectively according ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com