Instant-dry type thermal sublimation transfer printing PET membrane

A dye-sublimation and digital technology, applied in printing, printing devices, copying/marking methods, etc., can solve the problem that the drying speed cannot meet the printing and production speed requirements, and achieve the effect of maintaining size and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

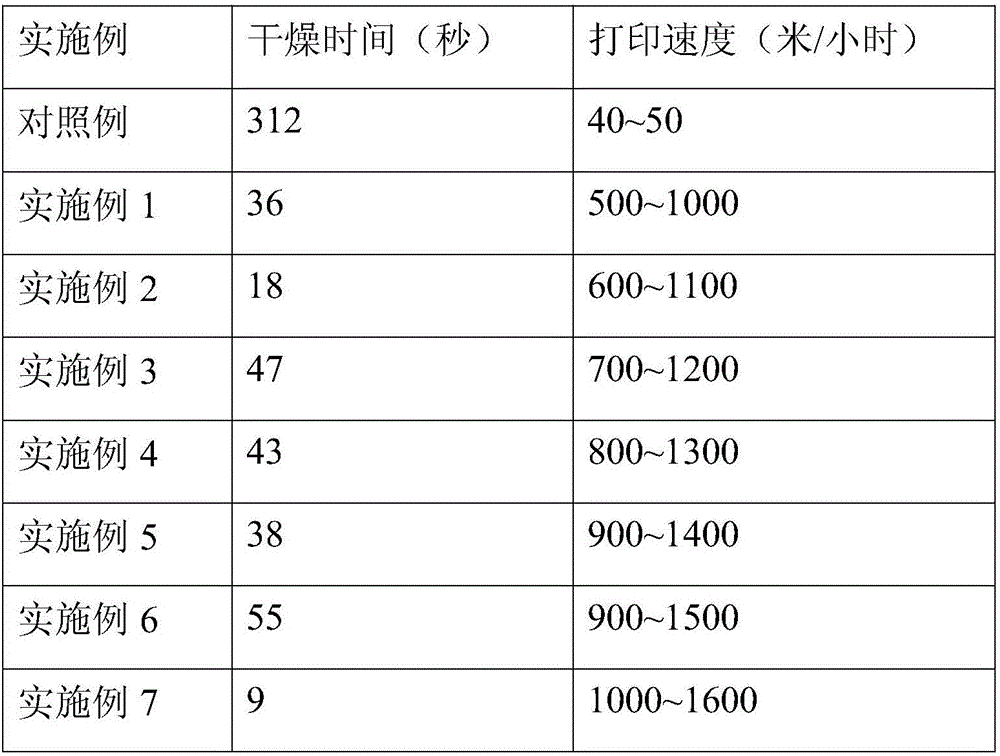

Examples

Embodiment 1

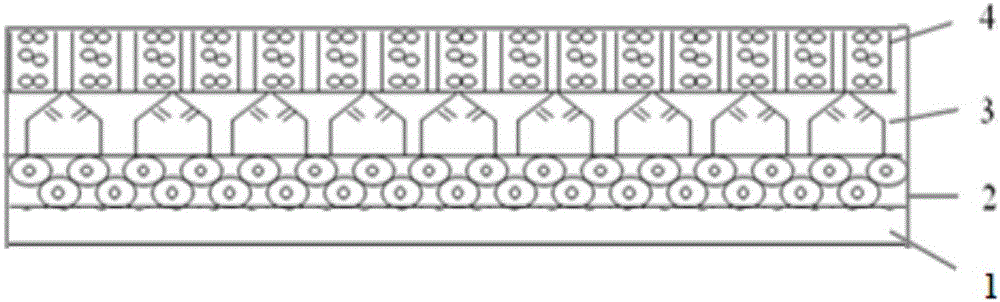

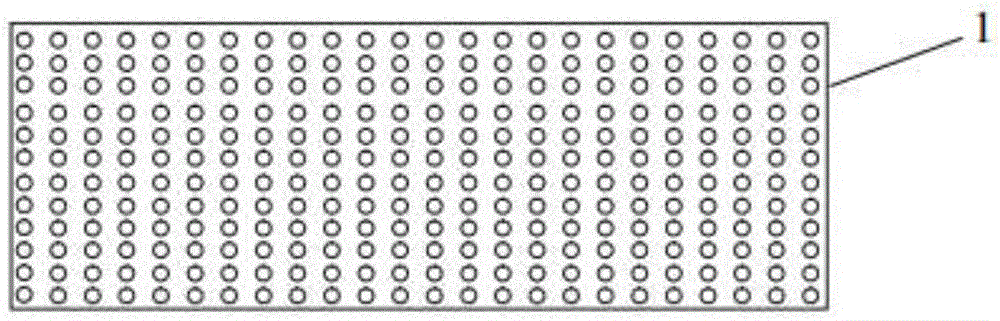

[0033] Instant dry sublimation transfer digital PET film, such as figure 1 As shown, it includes a perforated PET film layer 1, a water-absorbing and water-permeable layer 2, a porous layer 3, and a surface channel layer 4 from bottom to top.

[0034] The water-absorbing and permeable layer 2 is calculated by mass percentage, and the components and contents are as follows:

[0035] Resin composition 40%;

[0036] Porous inorganic matter 60%;

[0037] Wherein, the resin composition is composed of 45% by mass percent of simethicone modified acrylic resin and 55% by mass of water-absorbent resin; the water-absorbent resin is composed of 60% by mass of acrylic acid-sodium acrylate copolymer and It is composed of 40% acrylamide-sodium acrylate copolymer. The mass of the water-absorbing and water-permeable layer 2 on the perforated PET film layer 1 per square meter is 2.4 g.

[0038] The porous layer 3 is made of 62% by mass of cellulose, 30% by mass of cationic modified polyacr...

Embodiment 2

[0044] Instant dry sublimation transfer digital PET film, such as figure 1 As shown, it includes a perforated PET film layer 1, a water-absorbing and water-permeable layer 2, a porous layer 3, and a surface channel layer 4 from bottom to top.

[0045] The water-absorbing and permeable layer 2 is calculated by mass percentage, and the components and contents are as follows:

[0046] Resin composition 65%;

[0047] Porous inorganic matter 35%;

[0048] Wherein, the resin composition is composed of acrylic resin modified by methyl ethyl silicone oil of 70% by mass and a water-absorbent resin of 30% by mass; the water-absorbent resin is composed of acrylic acid-sodium acrylate copolymer, mass percent of 35%, It is composed of 25% of acrylamide-sodium acrylate copolymer and 40% of carboxymethyl cellulose-acrylate copolymer. The mass of the water-absorbing and water-permeable layer 2 on the perforated PET film layer 1 per square meter is 3.0 g.

[0049] The porous layer 3 is mad...

Embodiment 3

[0055] Instant dry sublimation transfer digital PET film, such as figure 1 As shown, it includes a perforated PET film layer 1, a water-absorbing and water-permeable layer 2, a porous layer 3, and a surface channel layer 4 from bottom to top.

[0056] The water-absorbing and permeable layer 2 is calculated by mass percentage, and the components and contents are as follows:

[0057] Resin composition 53%;

[0058] Porous inorganic matter 47%;

[0059] Wherein, the resin composition is composed of 60% by mass percent of vinyl silicone oil modified acrylic resin and 40% by mass of water-absorbent resin; the water-absorbent resin is composed of 55% by mass of acrylamide-sodium acrylate copolymer and Composed of 45% carboxymethyl cellulose-acrylate copolymer. The mass of the water-absorbing and water-permeable layer 2 on the perforated PET film layer 1 per square meter is 2.2 g.

[0060] Porous layer 3 is made by the reaction of 7% diisocyanate by mass percent of 68% sodium car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com