White wood finishing paint cured under UV (ultraviolet)-LED (light-emitting diode) light sources and preparation method of finishing paint

A UV-LED, wood lacquer technology, applied in the field of coatings, can solve the problem of no good solution for white wood lacquer, and achieve the effects of good hiding power, high whiteness and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

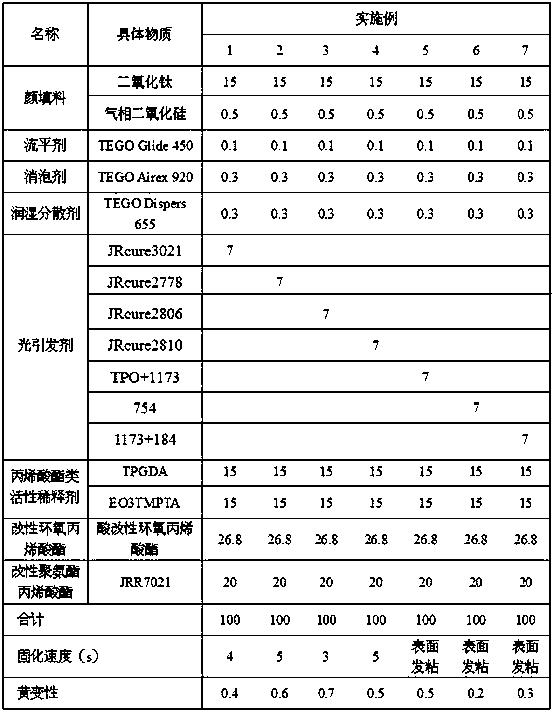

[0024] The invention will be further illustrated by the following non-limiting examples.

[0025] Preparation method of coating:

[0026] Step 1, under the condition of avoiding sunlight or ultraviolet light irradiation, weigh each component in sequence according to the proportion;

[0027] Step 2: Mix the modified epoxy acrylate, modified urethane acrylate, and 70% acrylate reactive diluent evenly, keep the temperature of the mixed material lower than 50°C during the stirring process, and the stirring speed is 500-8000 rpm / min, last 5min;

[0028] Step 3: Put the remaining 30% acrylate active diluent and titanium dioxide into a high-speed disperser and mix them. During the mixing process, the material should be less than 50 degrees, and the stirring speed should be 800-1000 rpm. After 5 minutes, add additives , after stirring at 800-1000 rpm for 5 min, the prepared material was ground with a three-roll mill. To fineness below 10μm;

[0029] Step 4, put the white slurry p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Light intensity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com