Waterborne furniture primer and preparation method thereof and wood finishing construction technology

A water-based, primer technology, used in coatings, polyurea/polyurethane coatings, devices for coating liquids on surfaces, etc., can solve problems such as poor penetration, poor penetration of primers, and harm to human health, reducing Environmental pollution, excellent stability, good transparency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

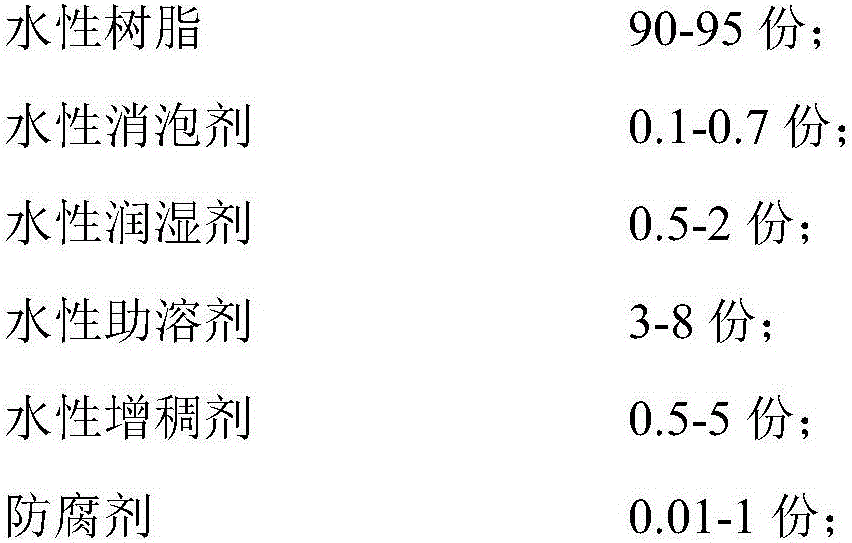

[0035] The present invention also provides a preparation method of water-based furniture primer, comprising the following steps: adding water-based resin, water-based defoamer, water-based wetting agent, water-based co-solvent, preservative, and pH assistant in a low-speed stirring state , slowly add a water-based thickener, then adjust the stirring speed to 1000-1200r / min, and stir for 20-30min to obtain a water-based furniture primer.

[0036] During the preparation of water-based furniture primer, the stirring speed needs to be controlled. Because the stirring speed will affect the compactness of the primer coating film. Different stirring speeds will cause density changes, and the stirring speed will increase the gas content, resulting in a decrease in the density of the coating film, thereby reducing the compactness of the coating film. Therefore, when the stirring speed reaches 1000-1200r / min, the stirring time should be controlled.

[0037] The invention provides a wo...

Embodiment 1

[0050] Under the stirring state of 400r / min, add 90kg water-based resin (KT300A and ESC-4907), 0.1kg water-based defoamer (TEGO902W), 0.7kg water-based wetting agent (SP-994), 3.5kg ethylene glycol, 0.1 kg preservative (CI-15HS), 0.1kg pH additive (AMP-95), slowly add 1kg water-based thickener (RM2020), then adjust the stirring speed to 1000r / min, and stir for 30min to obtain a water-based furniture primer.

Embodiment 2

[0052] Under the stirring state of 400r / min, add 91kg water-based resin (KT302 and XK12), 0.2kg water-based defoamer (QX-600), 1kg water-based wetting agent (TEGO270), 4.5kg ethylene glycol, 0.1kg preservative (CI-15HS), 0.1kg pH additive (AMP-95), slowly add 1.5kg water-based thickener (RM2020), then adjust the stirring speed to 1000r / min, and stir for 25min to obtain a water-based furniture primer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com