Method for detecting organic matters in packaging material

A technology for packaging materials and organic matter, applied in the field of analysis and detection, to achieve high accuracy, simple method, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

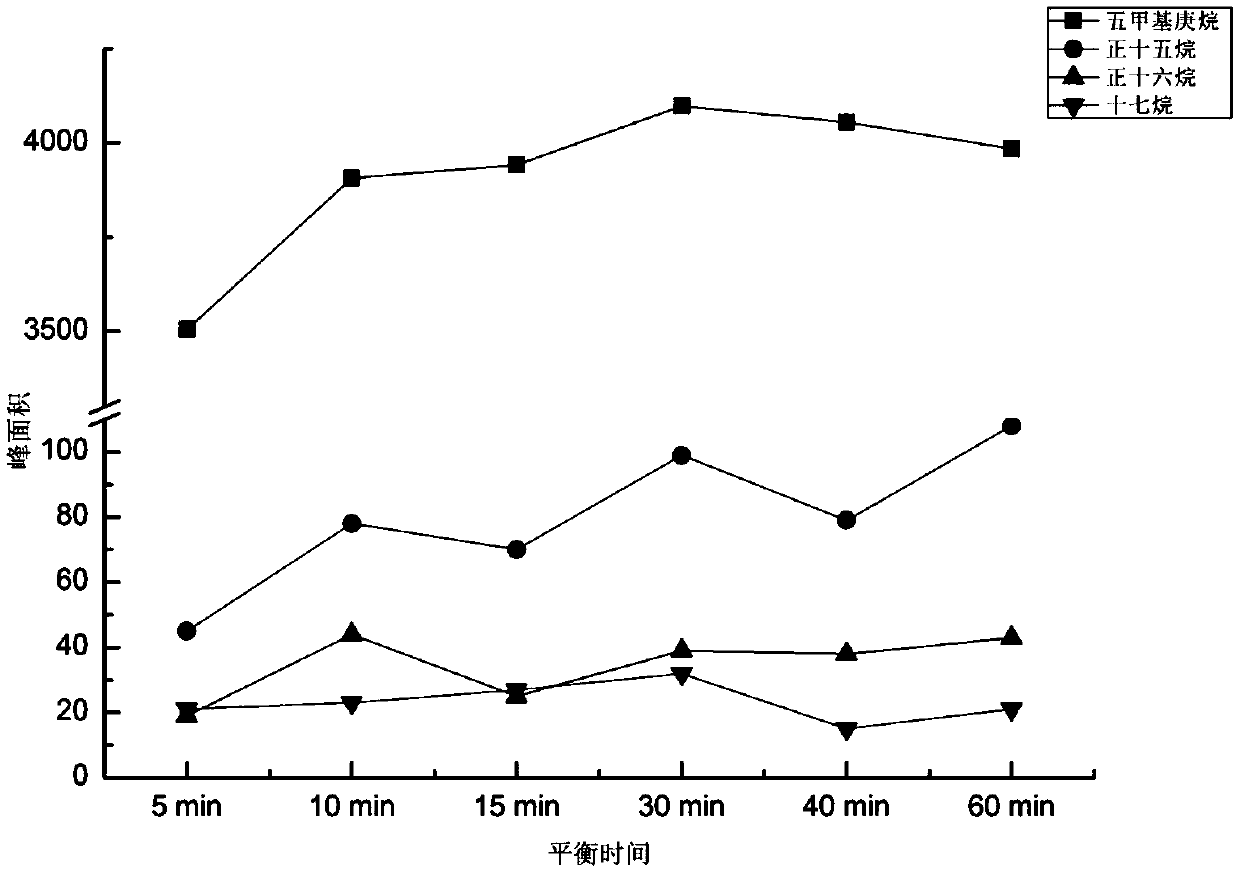

[0051] In this embodiment, the static headspace balance is determined by gas chromatography-mass spectrometry at different balance times.

[0052] Among them, the condition of static headspace equilibrium is as follows:

[0053] Sample equilibrium temperature: 110°C; sample loop temperature: 120°C; transfer line temperature: 140°C; sample bottle pressurization pressure: 35psi; carrier gas pressure: 40psi; pressurization time: 2.0min; inflation time: 0.20min; sample loop balance Time: 0.05min; injection time: 0.1min.

[0054] The gas chromatography conditions are as follows:

[0055] Chromatographic column: HP-5 capillary column (30m×0.32mm×0.25μm); furnace temperature: initial 50°C (2min), 5°C / min to 150°C (1min), then 10°C / min to 240°C (3min); inlet temperature: 150°C, split ratio: 10:1; carrier gas: high-purity helium, purity ≥ 99.999%; constant flow mode, column flow: 1.0mL / min.

[0056] Heating program: the initial temperature is 50°C, keep it for 2 minutes, raise it to...

Embodiment 2

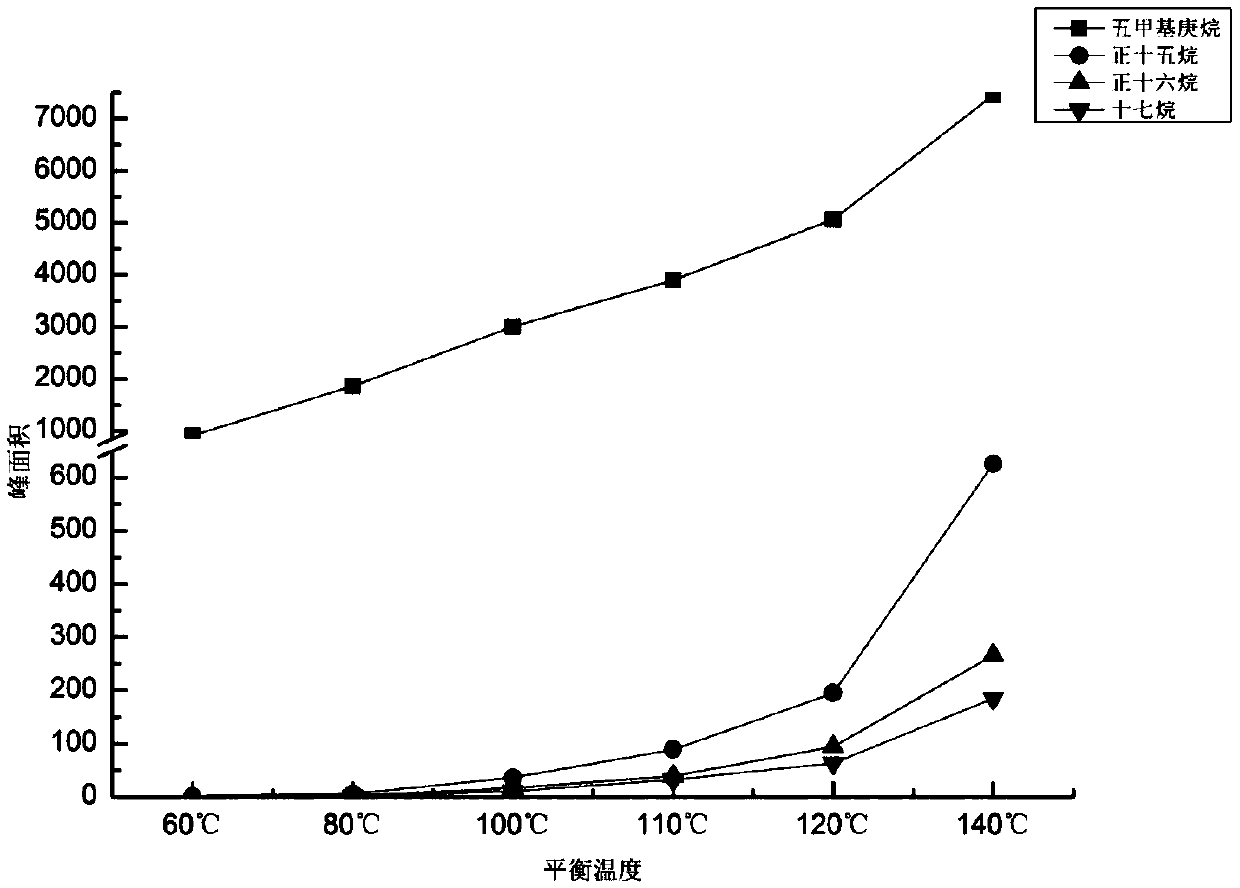

[0061] In this embodiment, the static headspace equilibrium is determined by gas chromatography-mass spectrometry at different equilibrium temperatures.

[0062] Among them, the condition of static headspace equilibrium is as follows:

[0063] Sample equilibration time: 30min; Sample loop temperature: 120°C; Transfer line temperature: 140°C; Sample bottle pressurization pressure: 35psi; Carrier gas pressure: 40psi; Pressurization time: 2.0min; Gas filling time: 0.20min; Sample loop equilibrium time : 0.05min; injection time: 0.1min.

[0064] The gas chromatography conditions are as follows:

[0065] Chromatographic column: HP-5 capillary column (30m×0.32mm×0.25μm); furnace temperature: initial 50°C (2min), 5°C / min to 150°C (1min), then 10°C / min to 240°C (3min); inlet temperature: 150°C, split ratio: 10:1; carrier gas: high-purity helium, purity ≥ 99.999%; constant flow mode, column flow: 1.0mL / min.

[0066] Heating program: the initial temperature is 50°C, keep it for 2 min...

Embodiment 3

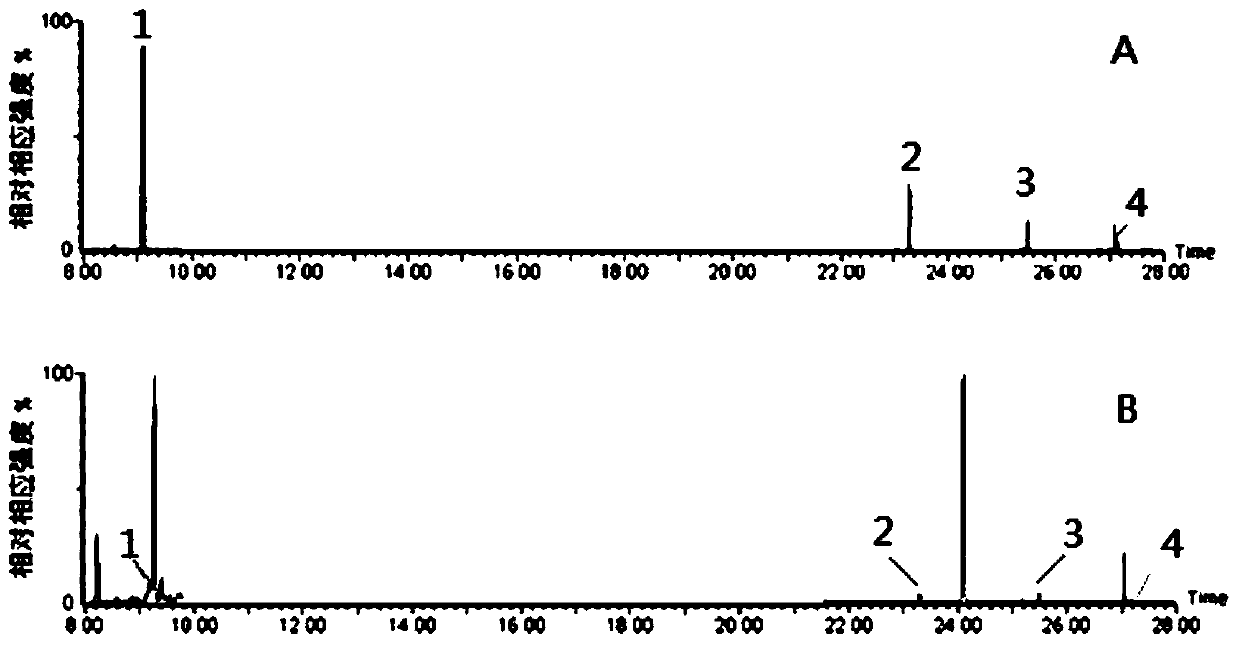

[0071] In this example, pentamethylheptane, n-pentadecane, n-hexadecane and n-heptadecane are detected by static headspace equilibrium and gas chromatography-mass spectrometry.

[0072] Among them, the condition of static headspace equilibrium is as follows:

[0073] Sample equilibration temperature: 110°C; sample equilibration time: 30min; sample loop temperature: 120°C; transfer line temperature: 140°C; sample bottle pressurization pressure: 35psi; carrier gas pressure: 40psi; 0.20min; sample loop equilibration time: 0.05min; injection time: 0.1min.

[0074] The gas chromatography conditions are as follows:

[0075] Chromatographic column: HP-5 capillary column (30m×0.32mm×0.25μm); furnace temperature: initial 50°C (2min), 5°C / min to 150°C (1min), then 10°C / min to 240°C (3min); inlet temperature: 150°C, split ratio: 10:1; carrier gas: high-purity helium, purity ≥ 99.999%; constant flow mode, column flow: 1.0mL / min.

[0076] Heating program: the initial temperature is 50°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com