Packaging shape-stabilizing method of inorganic hydrated salt phase-change heat storage material

A technology of phase-change heat storage materials and inorganic hydrated salts, which is applied in the field of material science and can solve problems such as incomplete adsorption, long time consumption, and unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

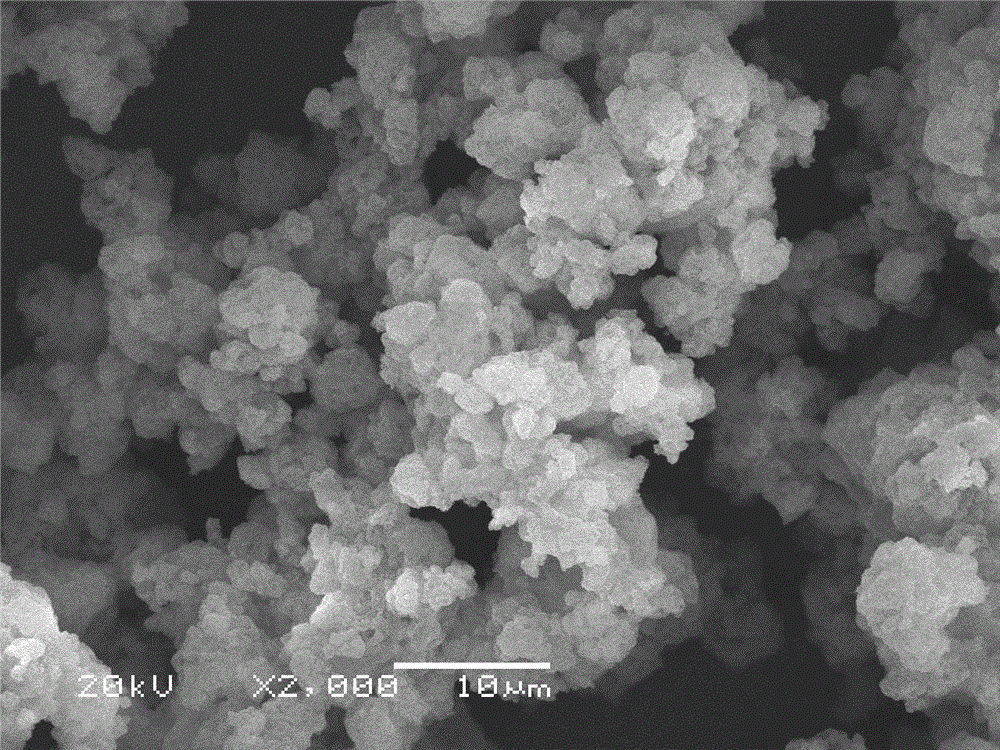

[0014] (1) Take 2g CaCl 2 ·6H 2 O, put it in a beaker, add 0.06 borax, mix evenly, add a small amount of deionized water, seal it with plastic wrap, put it in a constant temperature drying oven at 50 ℃, and heat it for 5 minutes to make it reach a molten state; (2) take 1.0 Porous Al 2 o 3 Added to the molten CaCl 2 ·6H 2 O in a beaker, and stir evenly, put the beaker of the above sample in a vacuum drying oven, vacuumize for 2h, and then put it in the refrigerator for 5h for recrystallization, that is, a new type of CaCl with uniform adsorption is obtained. 2 ·6H 2 O Porous Al 2 o 3 Composite phase change material; (3) The phase change temperature of the obtained composite shape-setting phase change heat storage material is 30.71°C, and the latent heat value of phase change is 99.81 J / g; the SEM photos and DSC test results of this example are as follows Figure 1a , Figure 2a shown.

Embodiment 2

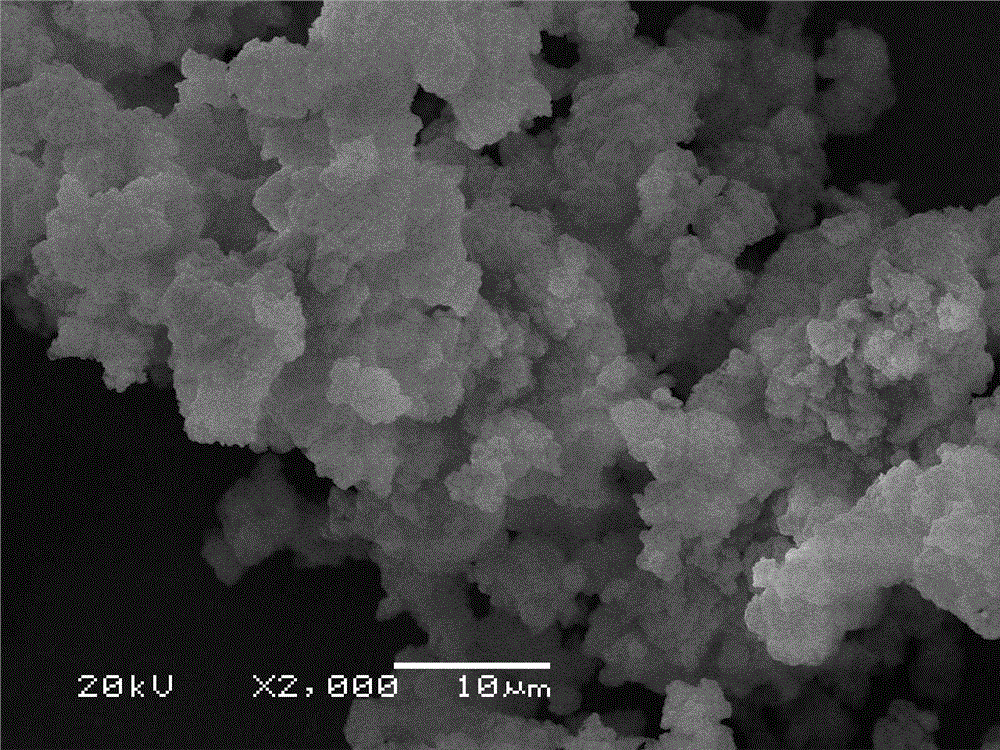

[0016] (1) Take 2g CaCl 2 ·6H 2 O, put it in a beaker, add 0.06 borax, mix evenly, add a small amount of deionized water, seal it with plastic wrap, put it in a constant temperature drying oven at 50 ℃, and heat it for 5 minutes to make it reach a molten state; (2) take 1.2 Porous Al 2 o 3 Added to the molten CaCl 2 ·6H 2 O in a beaker, and stir evenly, put the beaker of the above sample in a vacuum drying oven, vacuumize for 2h, and then put it in the refrigerator for 5h for recrystallization, that is, a new type of CaCl with uniform adsorption is obtained. 2 ·6H 2 O Porous Al 2 o 3 Composite phase change material; (3) The phase change temperature of the obtained composite shape-setting phase change heat storage material is 29.95°C, and the latent heat value of phase change is 86.42 J / g; the SEM photos and DSC test results of this example are as follows Figure 1b , Figure 2b shown.

Embodiment 3

[0018] (1) Take 2g CaCl 2 ·6H 2 O, put it in a beaker, add 0.06 borax, mix well, add a small amount of deionized water, seal it with plastic wrap, put it in a constant temperature drying oven at 50 ℃, and heat it for 5 minutes to make it reach a molten state; (2) Take 1.4 Porous Al 2 o 3 Added to the molten CaCl 2 ·6H 2 O in a beaker, and stir evenly, put the beaker of the above sample in a vacuum drying oven, vacuumize for 2h, and then put it in the refrigerator for 5h for recrystallization, that is, a new type of CaCl with uniform adsorption is obtained. 2 ·6H 2 O Porous Al 2 o 3 Composite phase change material; (3) The phase change temperature of the obtained composite shape-setting phase change heat storage material is 28.34°C, and the latent heat value of phase change is 70.61J / ; the SEM photos and DSC test results of this embodiment are as follows Figure 1c , Figure 2c shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com