Lithium battery module for replacing lead-acid storage battery of automobile

A lead-acid battery, battery module technology, applied in the direction of batteries, secondary batteries, battery pack components, etc., can solve problems such as improper use and safety, and achieve the effects of long service life, space saving, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

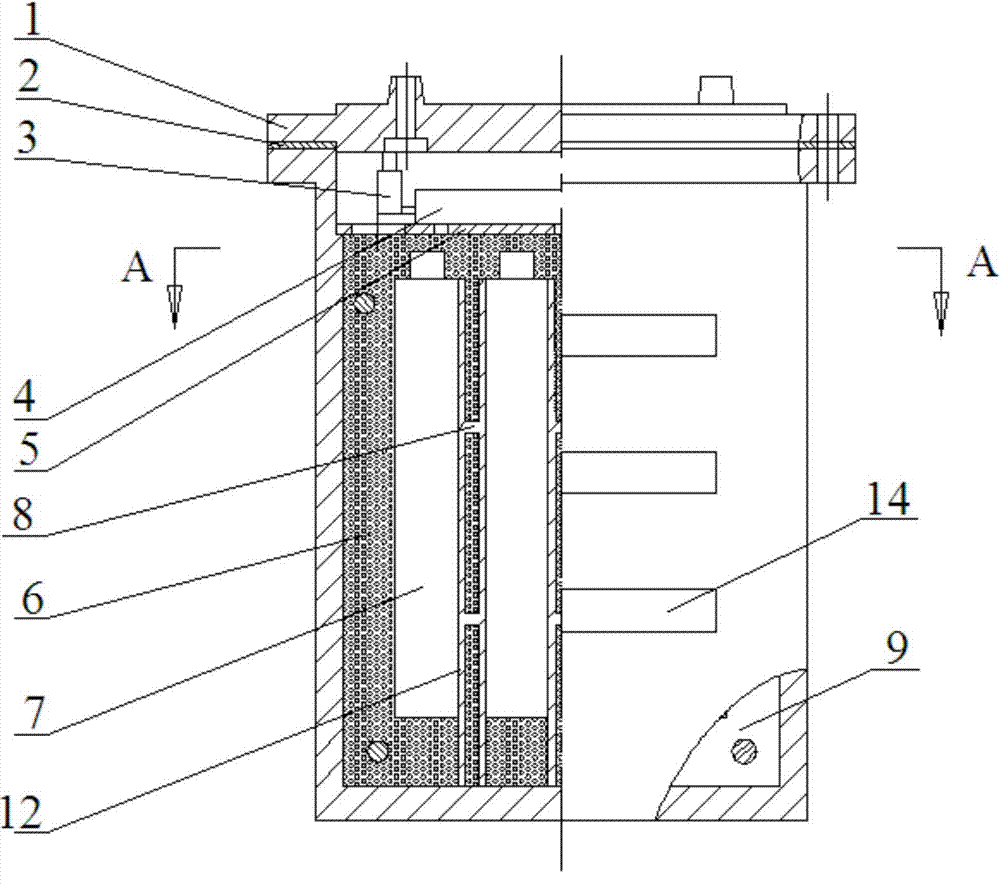

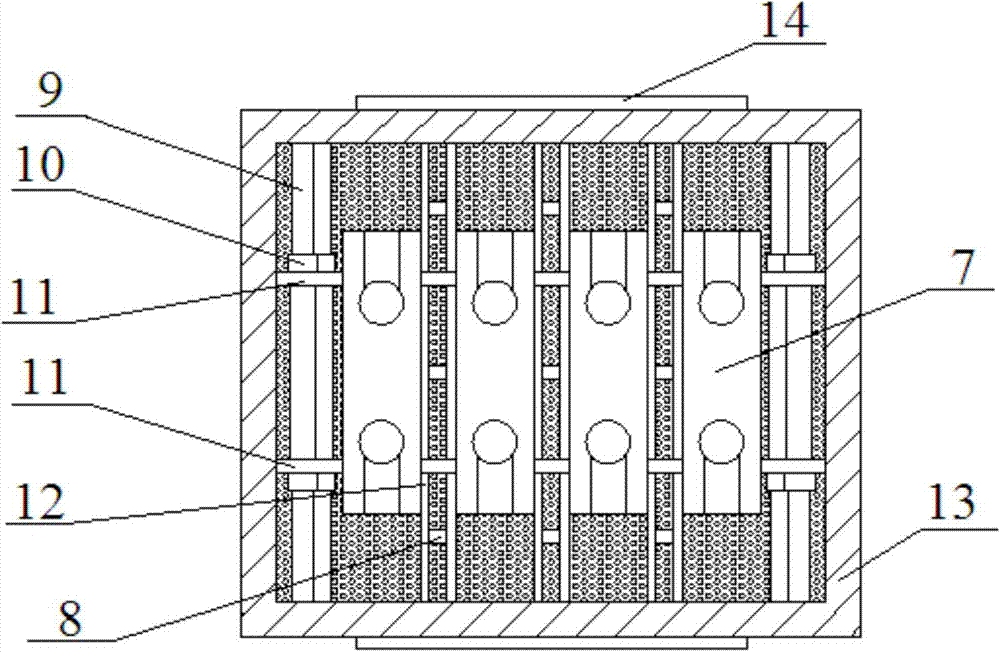

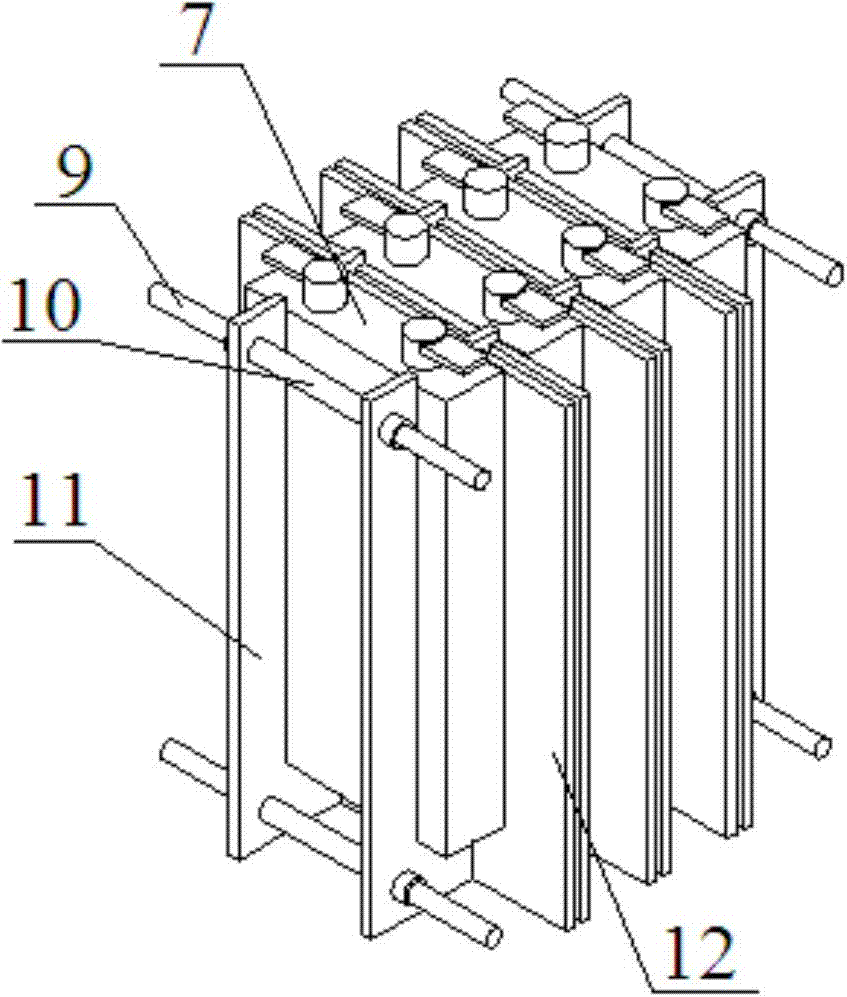

[0053] A lithium battery module that replaces lead-acid batteries for automobiles, such as Figure 1 ~ Figure 2 , including an upper cover 1, a housing 13, a sealed grid 5, a lithium battery 7, an insulating phase change material 6, a battery holding component, a heat conduction rib, a battery protection plate 4 and a self-recovery circuit protector 3, the upper cover 1 and the shell The body 13 is mechanically connected to form a sealed cavity, and the sealed grid 5 is arranged in the housing 13. The sealed grid 5 divides the sealed cavity into an upper half cavity and a lower half cavity, and an insulating phase change material 6 is filled in the lower half cavity. , the lithium battery 7 is provided with a plurality, and the plurality of lithium batteries are connected and fixed through the battery holding assembly, and are arranged in the insulating phase change material 6, and the heat conduction ribs are arranged between the adjacent lithium batteries 7, and the battery p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com