Gas totally-drying purifying dust-collecting process of blast-furnace

A blast furnace gas, fully dry technology, applied in blast furnaces, dust collectors, blast furnace details, etc., can solve problems such as poor system reliability, uneconomical operation, and many process pipelines, and achieve the effect of increasing power generation rate and increasing latent heat of gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

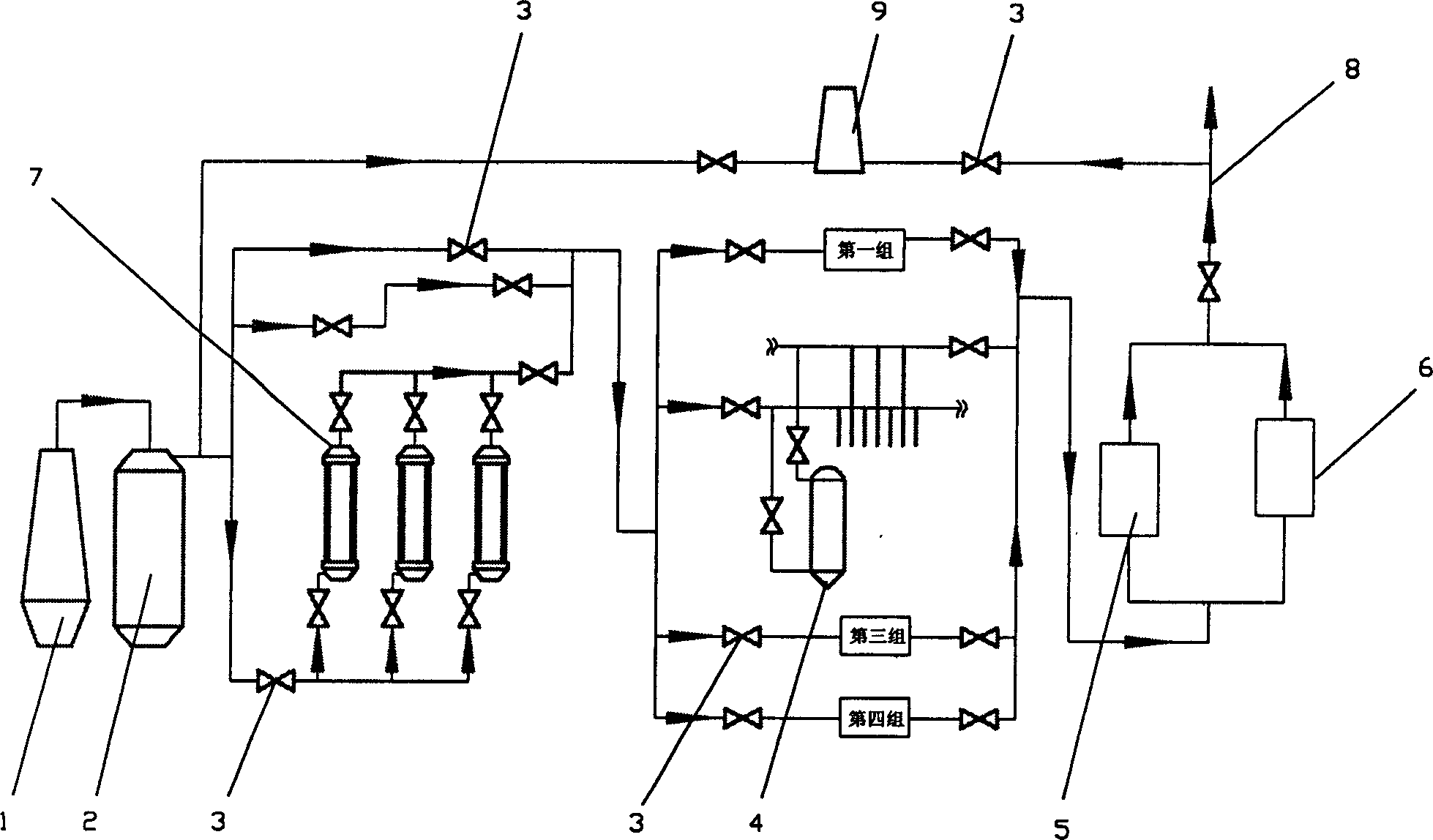

[0016] see figure 1 , the dusty gas from the blast furnace 1 first enters the gravity dust collector 2 for rough dust removal, and the raw gas after rough dust removal enters the raw gas supervisors of each dust removal subsystem through the raw gas supervisor of the system, and then enters the 4 boxes of each bag filter for further dedusting. Fine dust removal, the clean hot gas after fine dust removal enters the clean gas main pipe of the system through the clean gas main pipes of each subsystem, and then enters the external clean gas main network 8 after passing through the dry turbine 6 or the pressure reducing valve group. The 4 boxes of each dust collector in the dust removal system are divided into four to six groups according to the total number of boxes, that is, four to six dust removal subsystems, each dust removal subsystem contains more than five dust removal boxes, and each dust removal subsystem (each group) A reliable cut-off valve group 3 is added on the inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com