Patents

Literature

44results about How to "Reduce aluminum consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

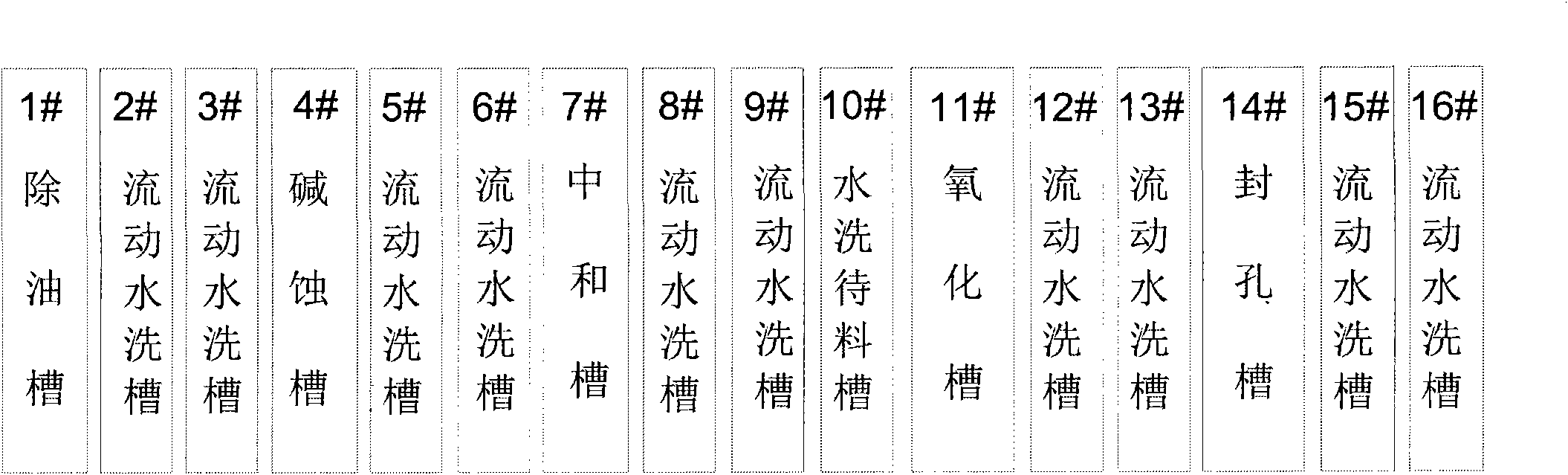

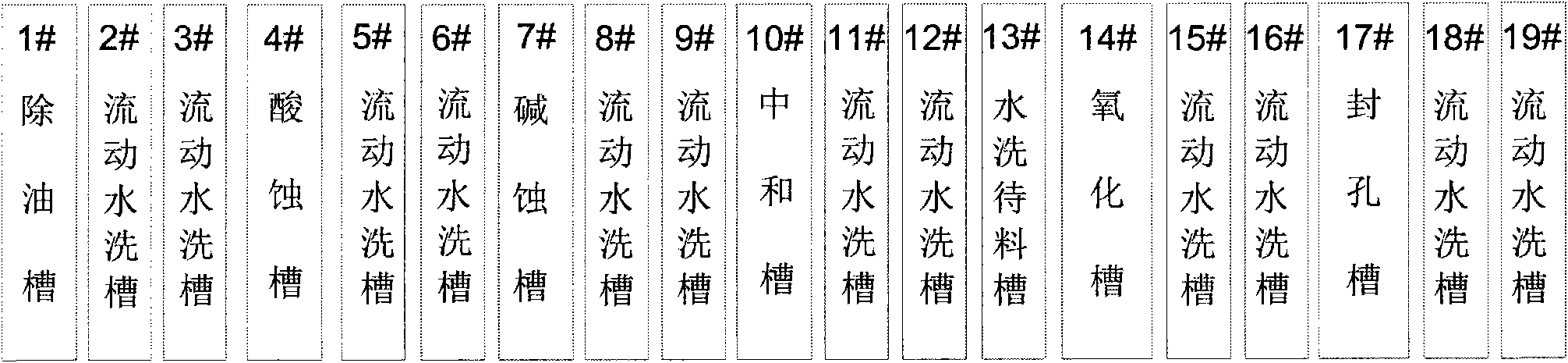

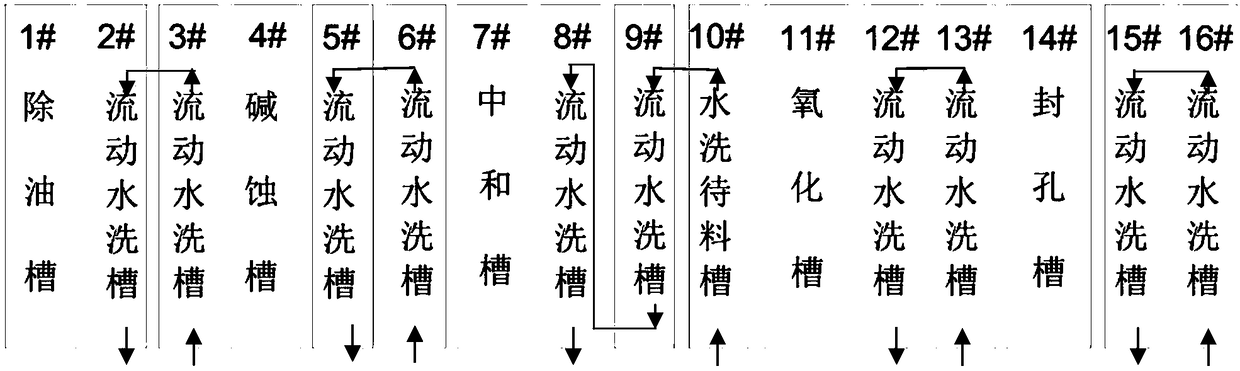

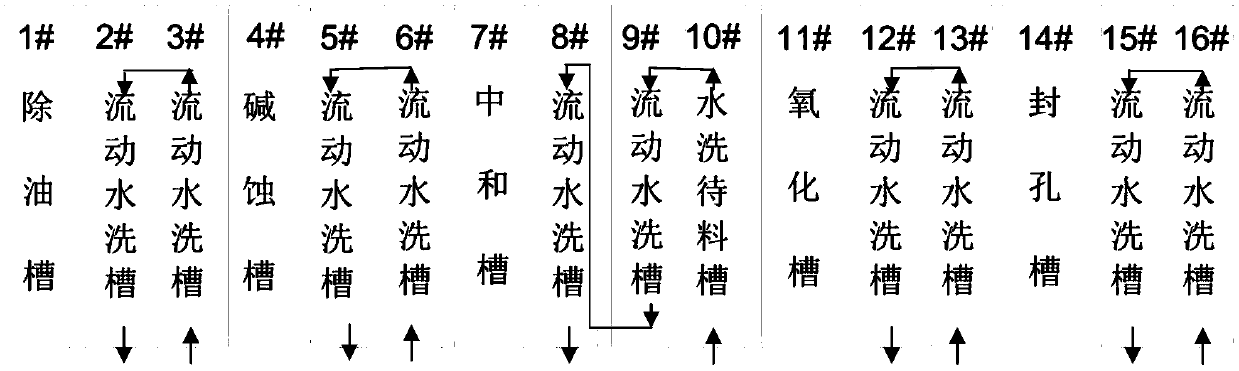

Aluminum alloy anodizing line treatment process

ActiveCN103952741AAchieve large-scale water conservationAvoid pollutionAnodisationAnodizingMaterials science

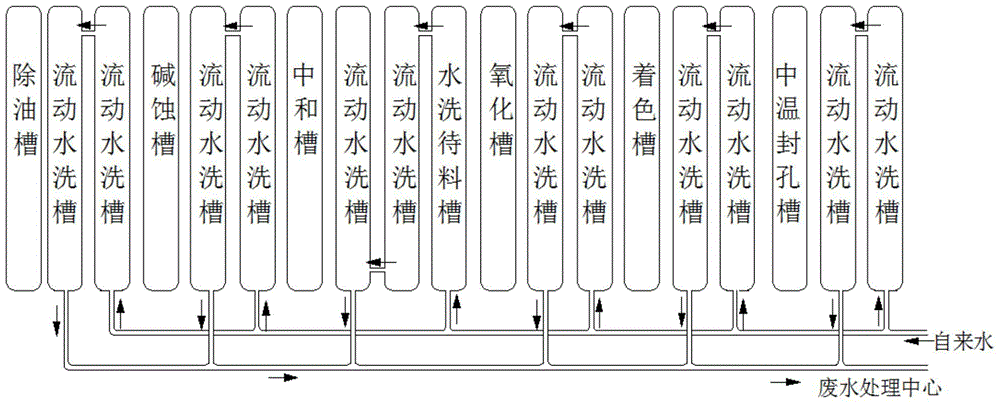

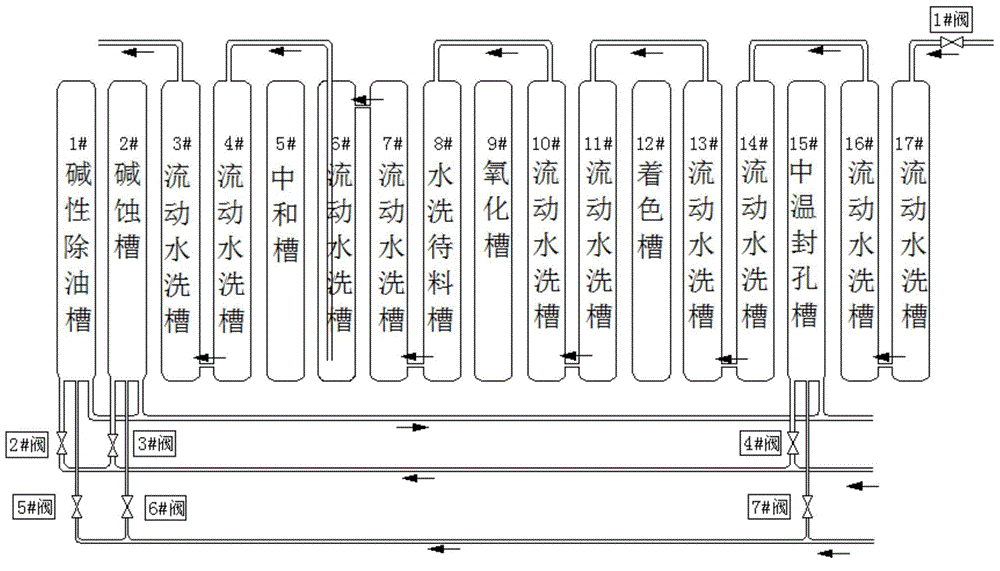

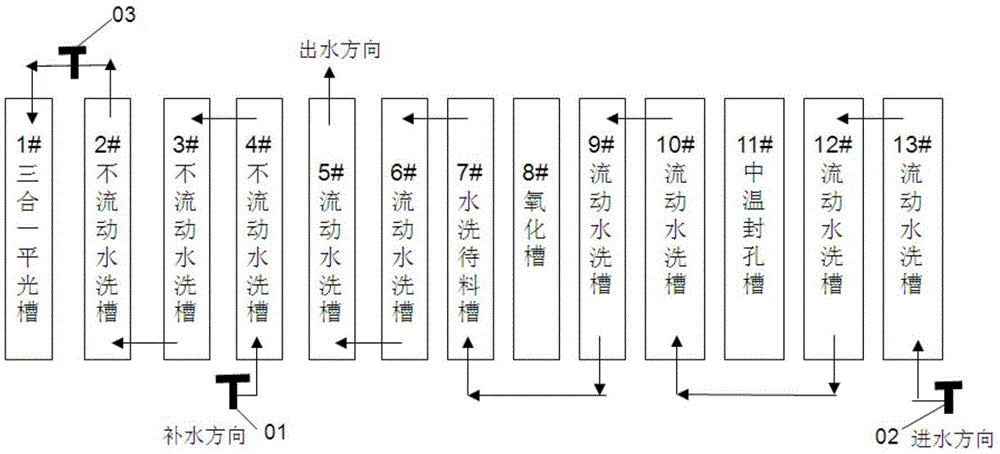

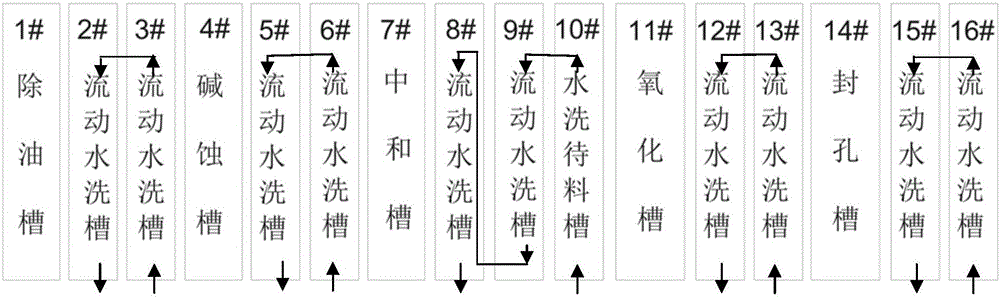

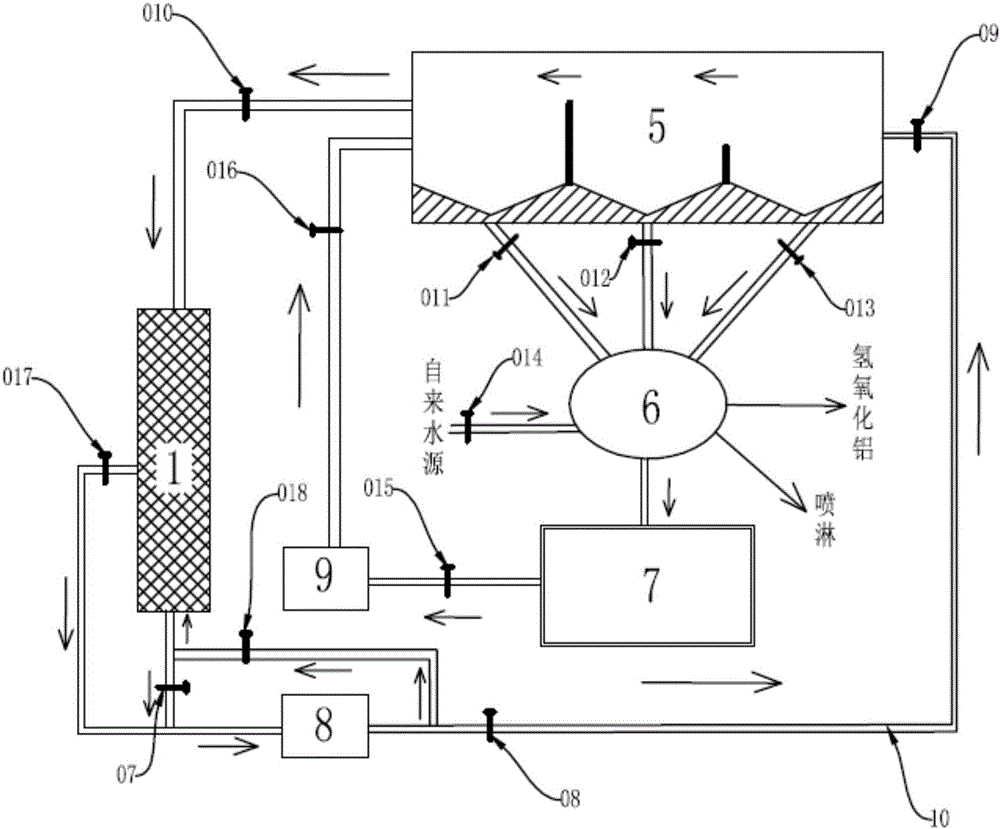

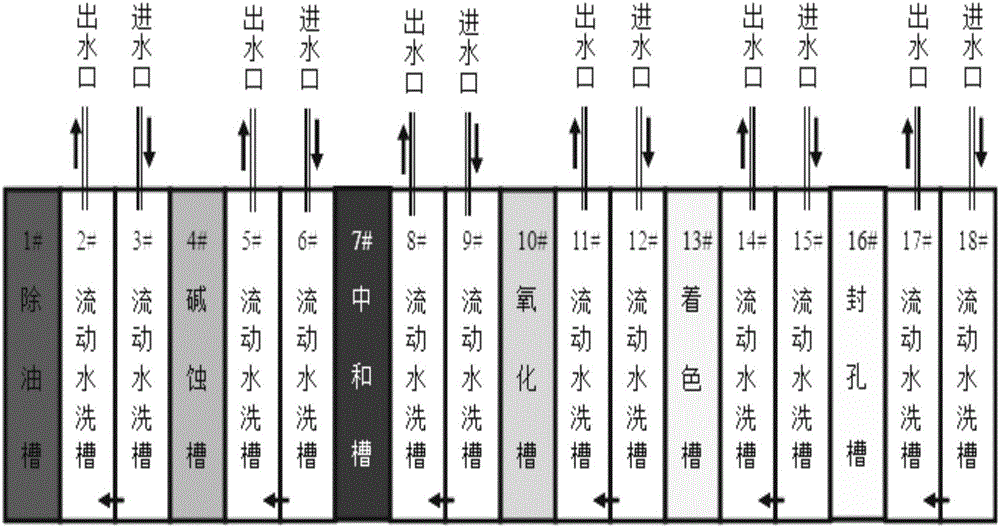

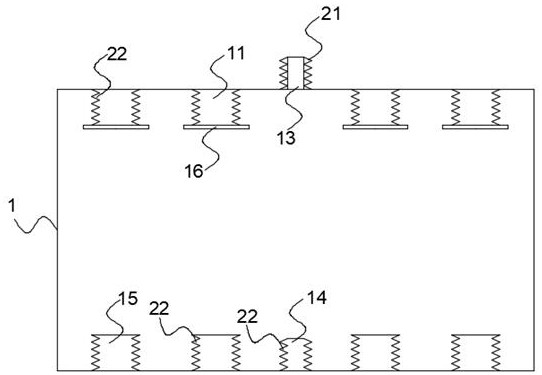

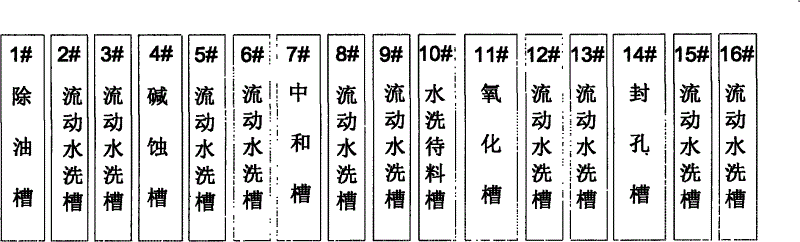

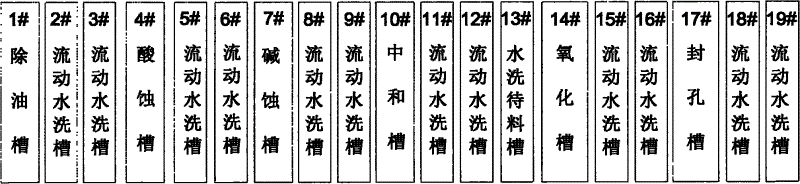

The invention relates to an aluminum alloy anodizing line treatment process. The aluminum alloy anodizing line treatment process comprises a functional trough system and water washing trough systems arranged between functional troughs. The functional trough system is arranged along the flow direction of washing water in a manner that an upstream functional trough is compatible with a downstream functional trough, and the water washing trough systems are arranged in an overall phase-reversing in-series-connection manner. According to the aluminum alloy anodizing line treatment process, a mode in which a flowing water washing tank is separately configured for each functional trough in the traditional anodizing line is changed. Since all water washing troughs are connected in series in a phase-reversing manner, the number of the water inlets and outlets is greatly reduced and the water consumption is decreased from 25.0-35.0 tons per ton material to 5.0-6.0 tons per ton material and the water is saved by more than 80%. The treatment process disclosed by the invention has the advantages of low production cost, high efficiency and environmental friendliness and is suitable for industrial application.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

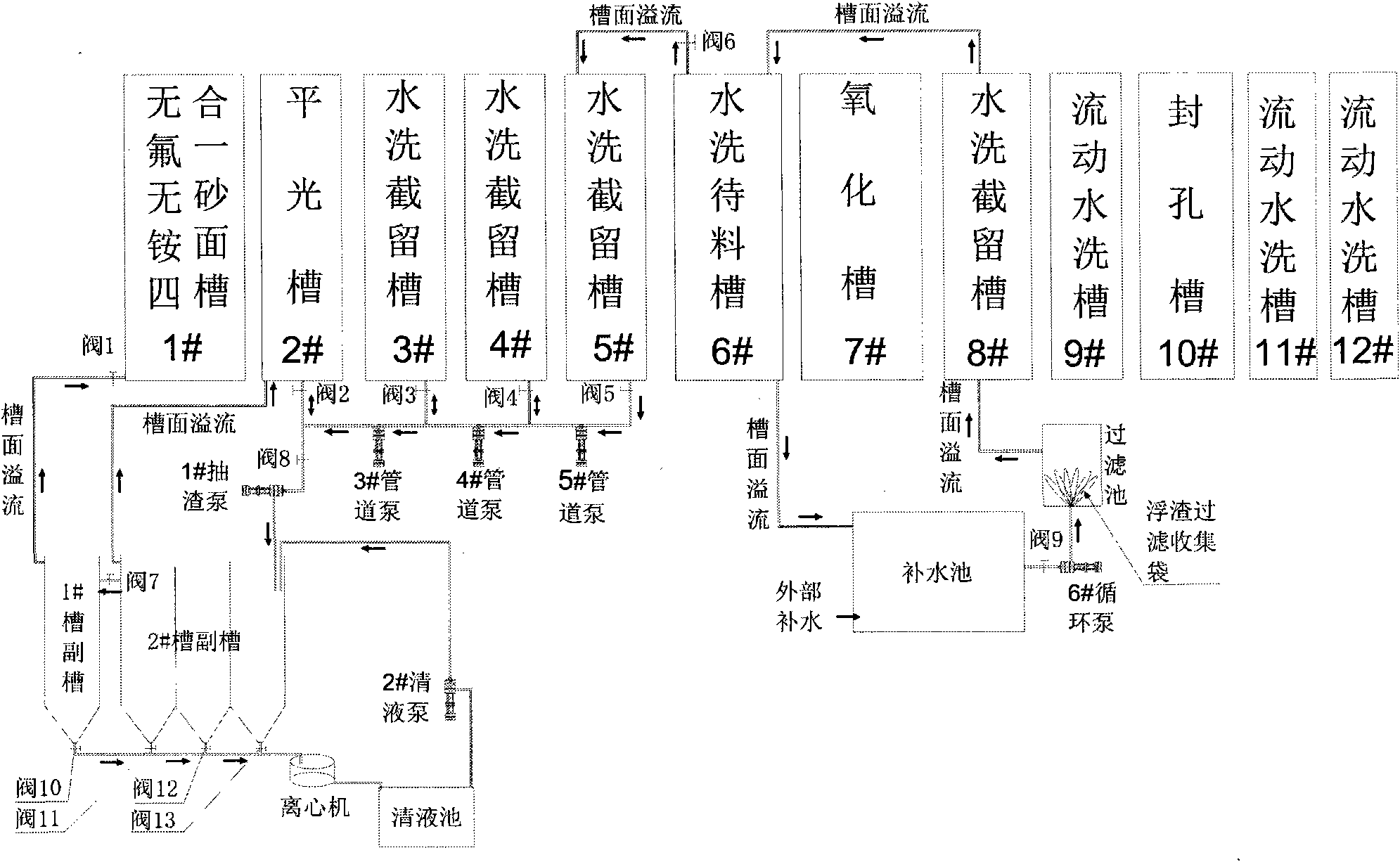

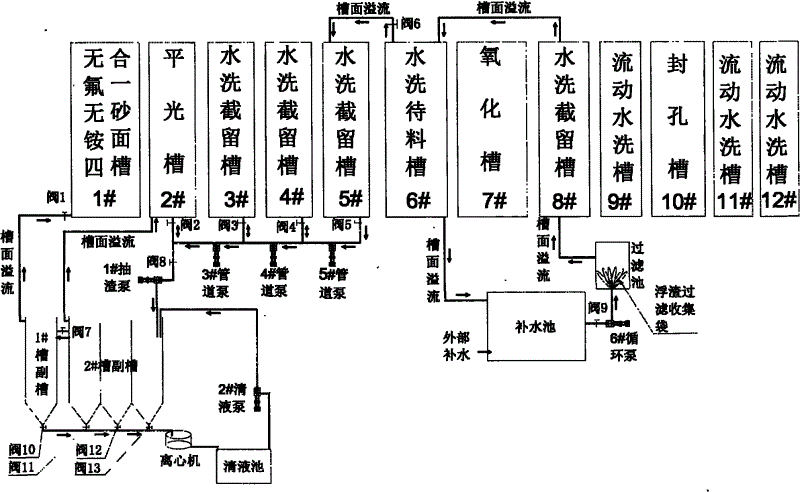

Surface pre-treatment system combining four aluminum alloy working grooves into whole for full recovery of medicament and zero emission of wastewater

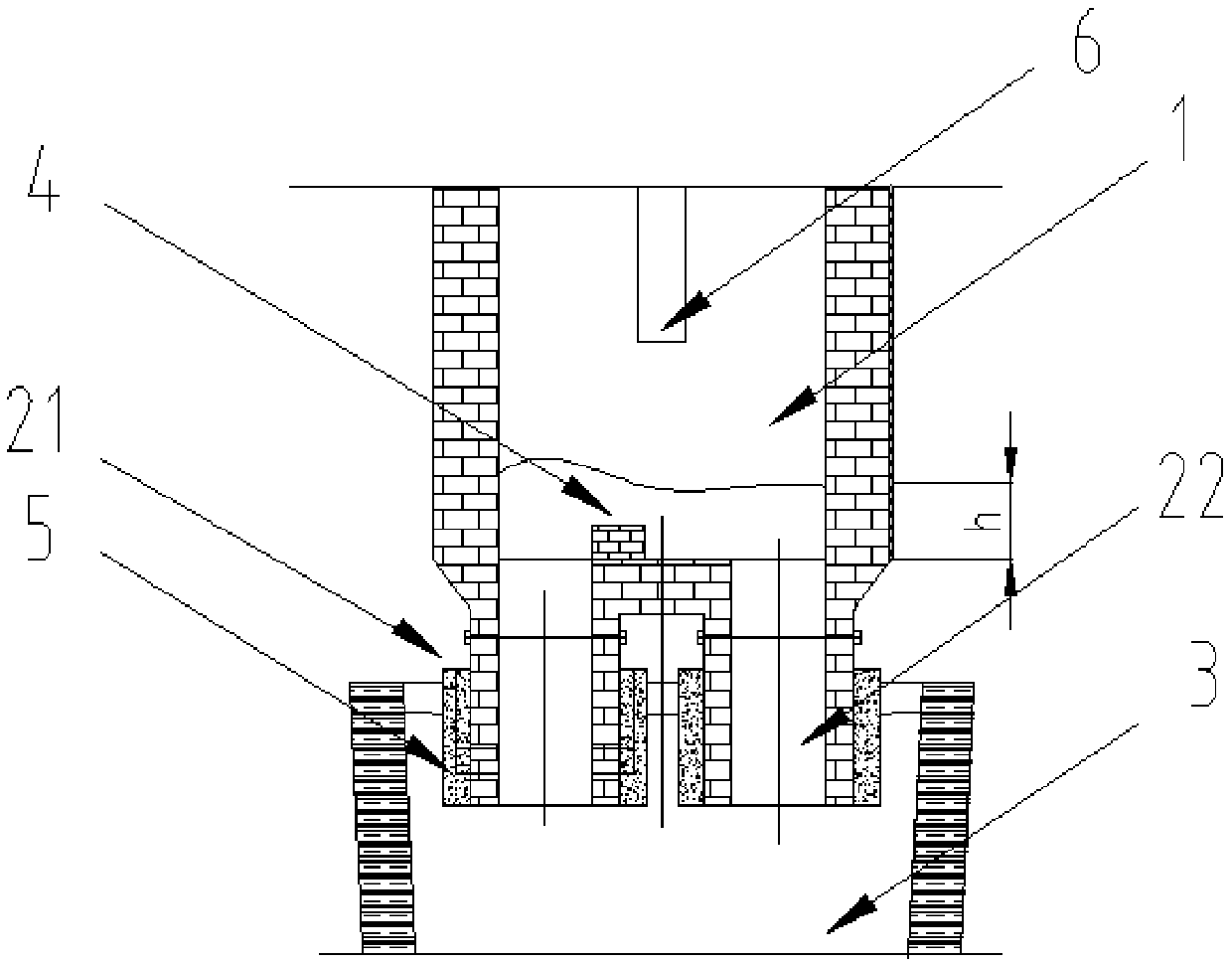

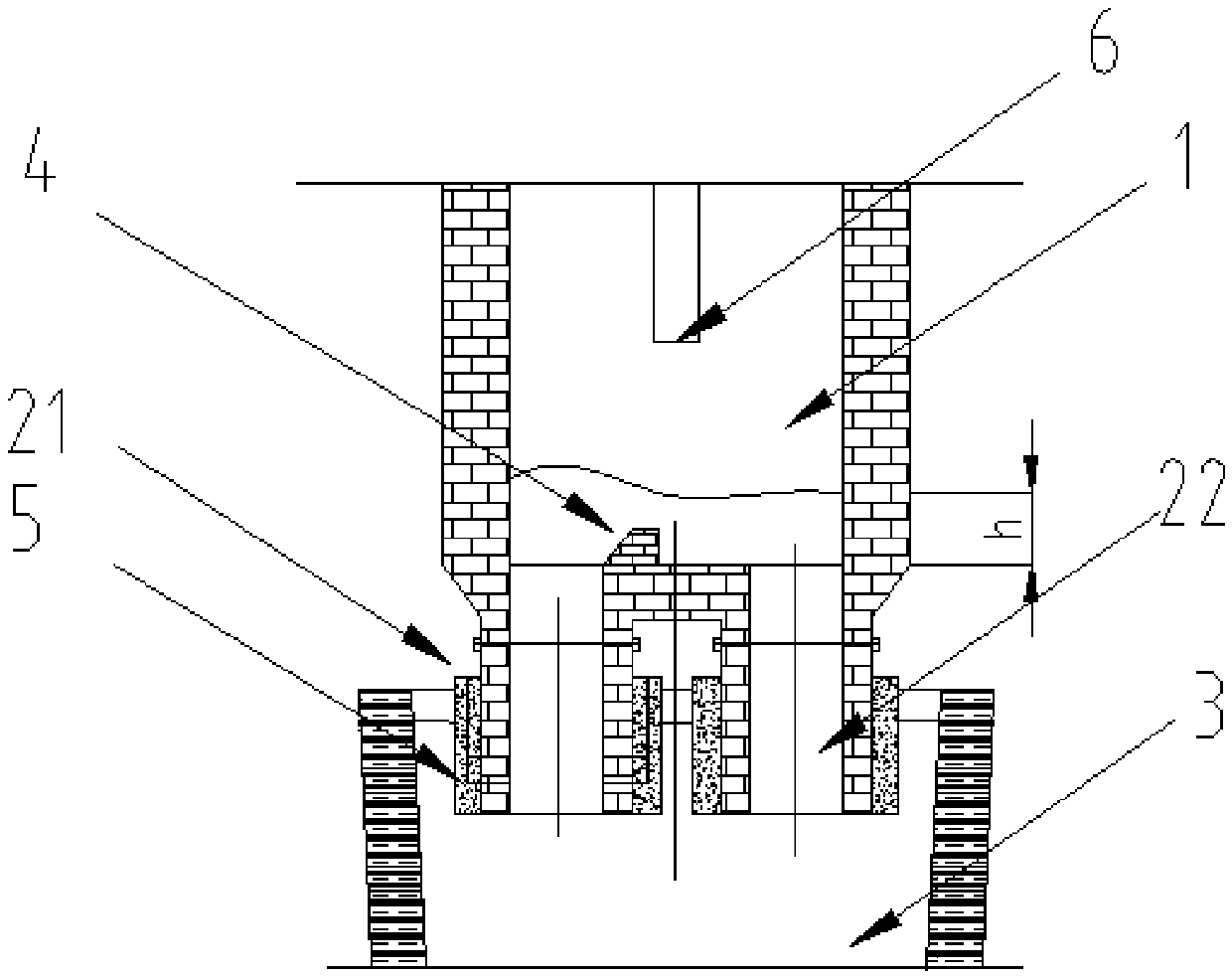

The invention relates to a surface pre-treatment system combining four aluminum alloy working grooves into a whole for full recovery of medicament and zero emission of wastewater. The surface pre-heated system comprises a No.1 four-in-one sand surface groove, a No.2 matte tank, a No.3 water washing interception groove, a No.4 water washing interception groove, a No.5 water washing interception groove, a No.6 water washing material waiting groove, a No.7 oxidation groove and a No.8 water washing interception groove, as well as a matching slag pumping system, a medicament recovery system, a water circulation purification processing system and a reverse water replenishing neutralization system. As the four working grooves are combined into a whole, and the technical scheme is simultaneously equipped with the full recovery of the medicament and the zero emission of the wastewater, the pollution of fluorine and ammonium in the oxidation pre-treatment of an aluminum alloy anode can be effectively solved, the full recovery of the wastewater in the aluminum alloy surface pre-treatment can be realized, the pollution control of a company can be greatly reduced, and the production cost can be reduced.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

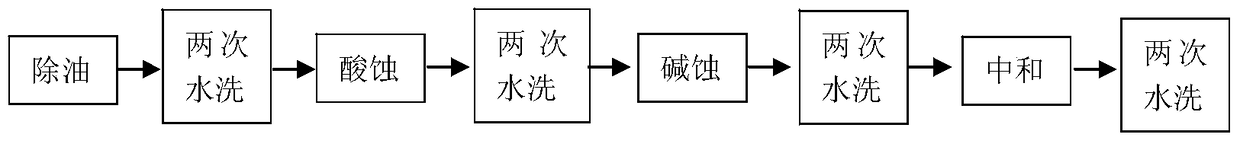

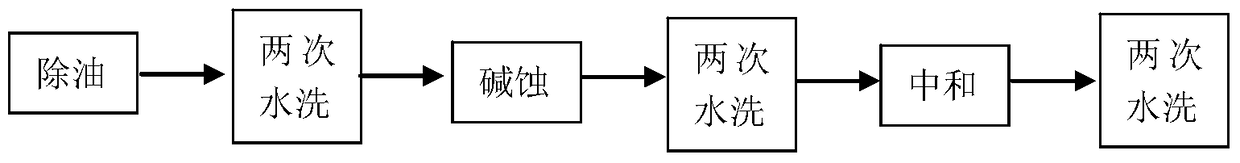

Anode oxidation pretreatment method for aluminium alloy

InactiveCN1654714ASand fastReduce aluminum consumptionSurface reaction electrolytic coatingWaxPretreatment method

The processing method of aluminum alloy part before anode oxidizing includes the following steps: eliminating oil and wax, water washing, brightening acid pickling, low temperature polishing, water washing, eliminating ash, and water washing. The said method has the advantages of powerful mechanical ripple eliminating ability, low aluminum loss, complete elimination of acid pickling ash, etc. and can make the processed surface have no ripple, ash and fine sand and be bright.

Owner:熊映明

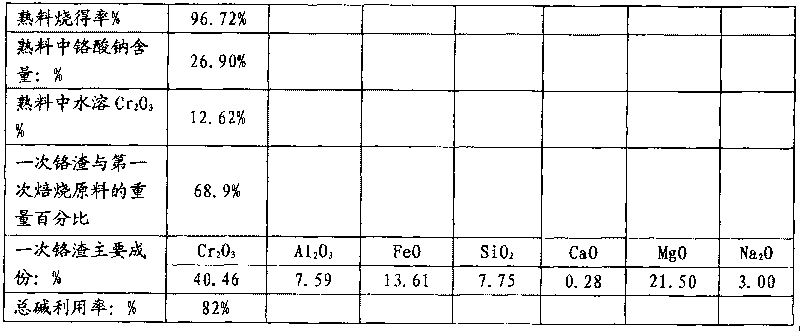

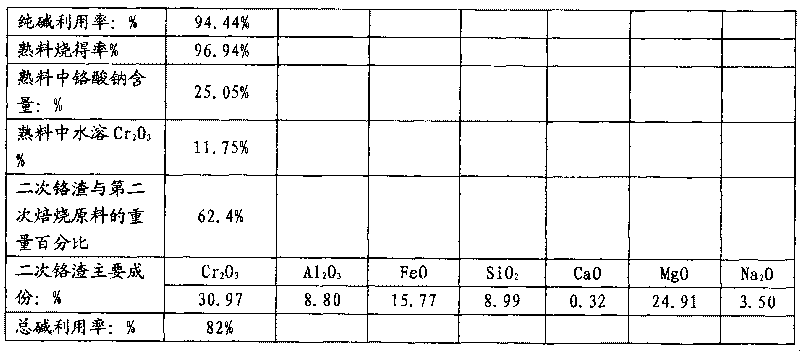

Method for producing sodium chromate by roasting chromium ore and small amount of soda

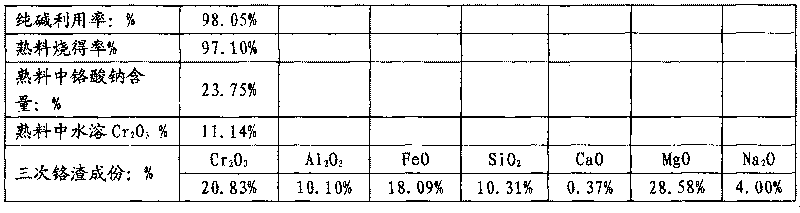

The invention discloses a method for producing sodium chromate by roasting chromium ore and a small amount of soda. The method is characterized in that chromium ore and calcined soda are mixed, wherein the added quantity of the calcined soda is 35% to 45% of theoretical required amount for complete reaction with dichromium trioxide in the chromium ore; then the mixture is added to a rotary kiln for first roasting, the temperature of materials at a hot space in the kiln is 1000 DEG C to 1050 DEG C, wrought materials are cooled and leached to obtain a sodium chromate leaching solution and first chromium dregs; the first chromium dregs are dried and crashed for second roasting with newly added calcined soda, the use amount of the calcined soda is 30% to 50% of theoretical required amount for complete reaction with the dichromium trioxide in the first chromium dregs; the sodium chromate leaching solution and second chromium dregs can be obtained through roasting and leaching processes, the second chromium dregs, limestone and newly added calcined soda are roasted for the third time, the use amount of the calcined soda in the third roasting is 35% to 75% of theoretical required amount for complete reaction with the dichromium trioxide in the second chromium dregs, and the use amount of the limestone is 2% to 5% of the sum of weight of three raw materials of the second chromium dregs, the calcined soda and the limestone; and the sodium chromate leaching solution and third chromium dregs are obtained after leaching. By adopting method of the invention, the utility ratio of the calcined soda is also enhanced greatly.

Owner:XINJIANG SING HORN GRP CO LTD

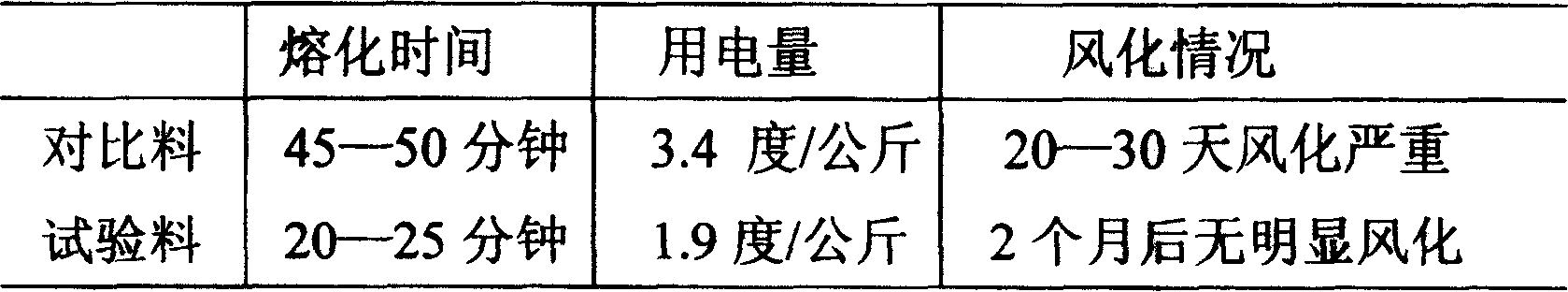

Aluminum or aluminum alloy melt slag removal agent

The invention discloses an aluminum or aluminum alloy melt slag removal agent and belongs to the technical field of metal liquid impurity removal. The aluminum or aluminum alloy melt slag removal agent comprises the following component formulas in percentage by weight: 25-30 percent of sodium chloride, 25-30 percent of potassium chloride, 5-10 percent of sodium carbonate, 5-10 percent of sodium sulfate, 1-5 percent of sodium fluoroaluminate, 5-10 percent of sodium fluosilicate, 5-10 percent of calcium fluoride, 1-5 percent of potassium nitrate and 5-10 percent of potassium fluosilicate. The aluminum or aluminum alloy melt slag removal agent is high in heating property, the aluminum in the slag can be fully separated, the alumina components are decomposed, and the aluminum consumption is reduced, so that the aluminum slag is dry and loose and is easily removed; the treated aluminum liquid purity is greatly improved, and the metal performance is improved; and moreover, the slag attached to the furnace wall and the furnace hearth is reduced, the furnace body is damaged, the service life of the smelting furnace is prolonged, and the prepurging cost is reduced.

Owner:XINCHANG COUNTY GUOWEI ALUMINUM PROD AUXMATERIALS

Production method of ferrotitanium

InactiveCN102392133AGranularity requirements are relaxedDoes not affect reactivitySmelting processFerrosilicon

The invention relates to a production method of ferrotitanium. The production method is characterized by comprising the following steps: carrying out arc strike by using ferrum-contained raw material to form a molten pool; putting titanium-containing raw material and lime into a refined electric furnace; carrying out electric-arc heating; in the melting process, adding ferrosilicon into the refined electric furnace to prepare slag and iron; adding the ferrum-containing raw material, lime and aluminum into the refined electric furnace to react with the slag, wherein the alloy generated in the reaction process sink and the slag floats up in the reaction process, and slag and iron are separated until reaction is finished; deslagging, and continuously smelting to finish the whole smelting process; and cutting off power supply, cooling and finishing to obtain the ferrotitanium. The production method has the advantages that requirement on the granularity of each raw material is not strict, processing procedures are reduced, the labor intensity of workers is lowered, the safety coefficient in the ferrotitanium production can be improved, the product recovery rate is improved, aluminum consumption is lowered, and production cost is lowered; and different models of ferrotitanium are produced, thereby breaking through a pattern that a single method can be used for smelting limited models of ferrotitanium.

Owner:CITIC JINZHOU METAL

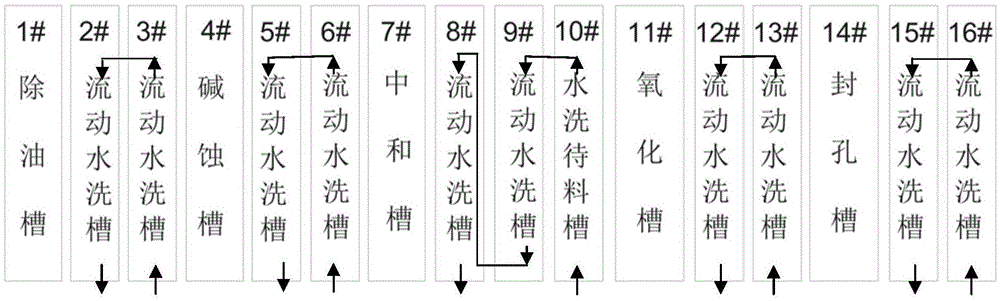

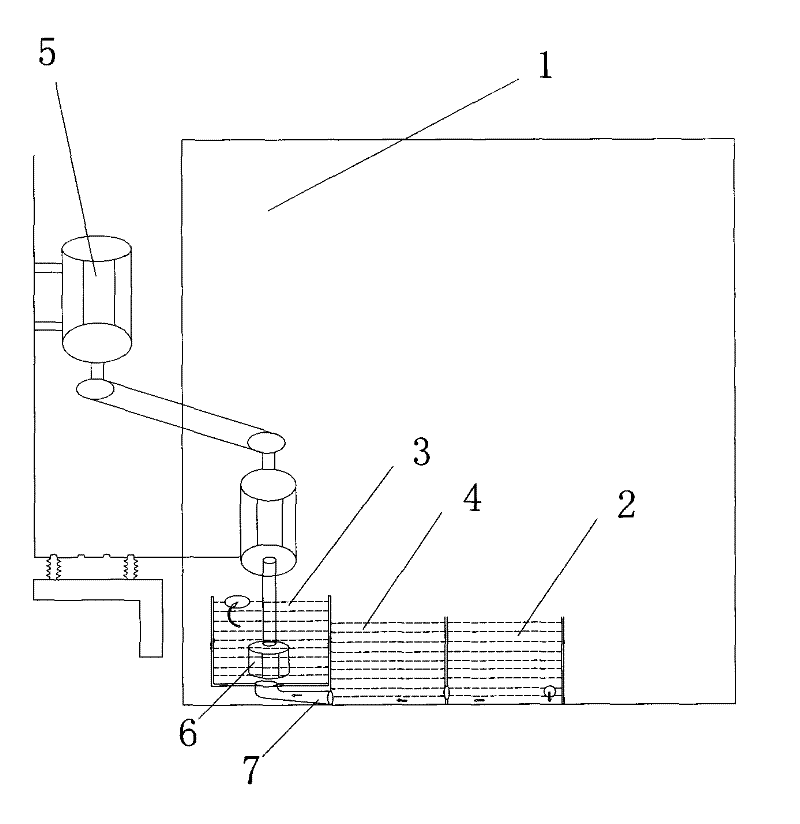

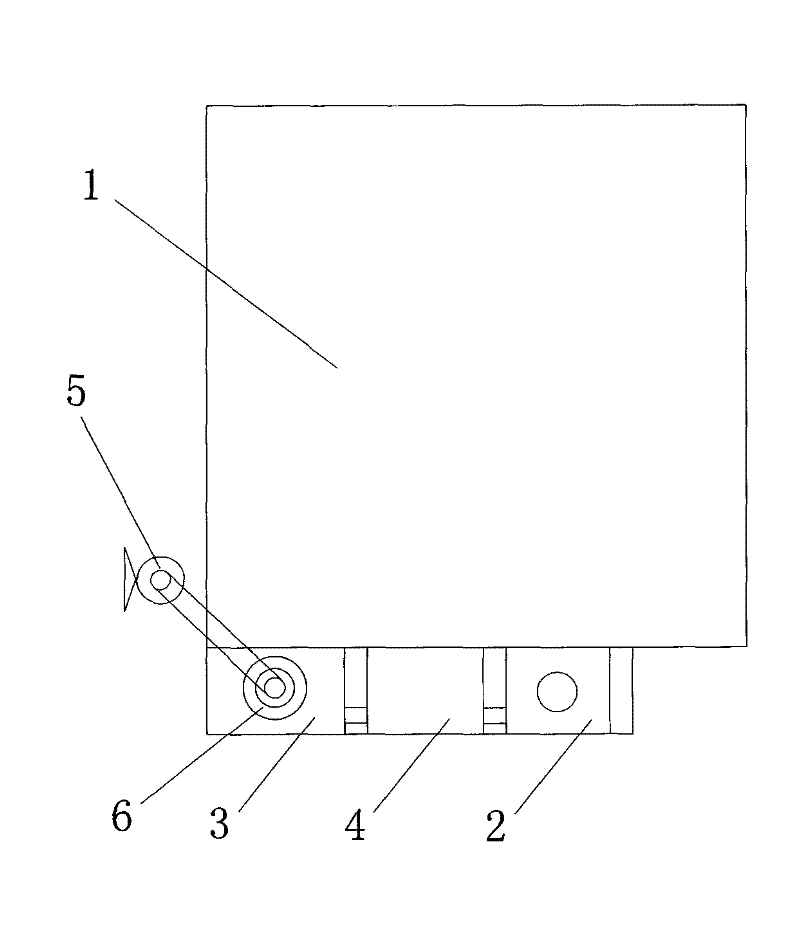

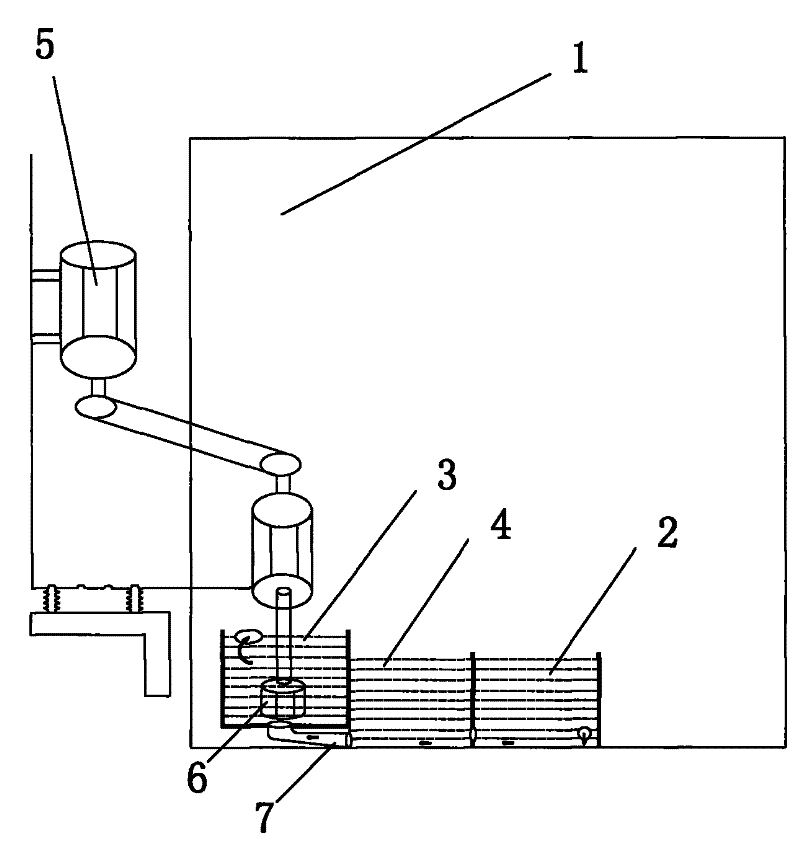

Fluorine-free COD-free three-in-one zero-diopter pretreatment process for aluminum alloy

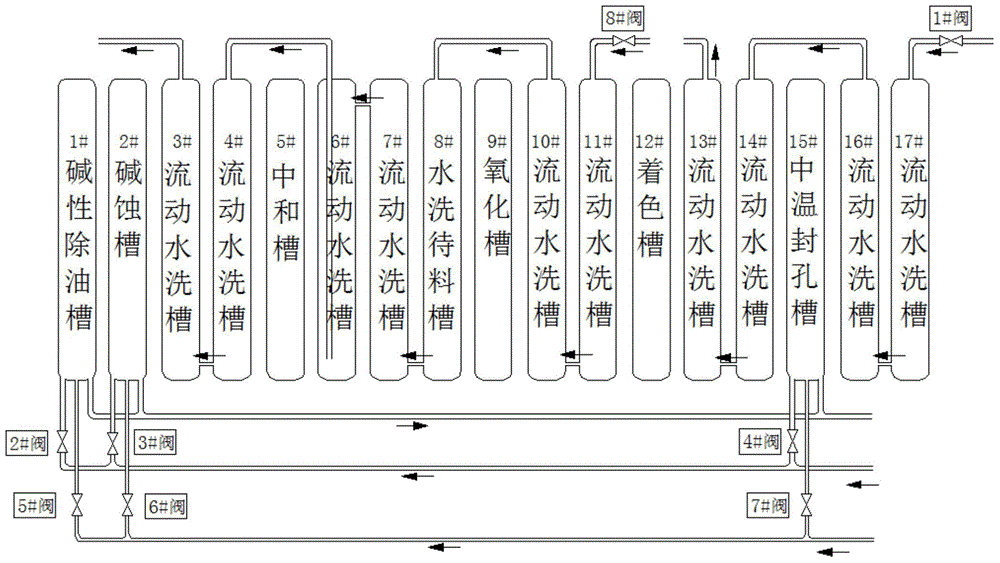

ActiveCN105624760AReduce consumptionReduce aluminum consumptionSurface reaction electrolytic coatingWater savingWater flow

The invention relates to a fluorine-free COD-free three-in-one zero-diopter pretreatment process for an aluminum alloy, namely a fluorine-free COD-free three-in-one zero-diopter treatment and medicament compatibility and series-opposing water saving system for the aluminum alloy. The system comprises a medicament recovery system and a series-opposing water saving system; the medicament recovery system comprises a three-in-one zero-diopter groove and a non-flowing water washing groove subsystem, and the overall non-flowing water washing groove subsystem is arranged in a series-opposing manner; in addition, a first water inlet is formed in the initial end of the water flowing direction of the non-flowing water washing groove subsystem, and a water outlet in the terminal end of the non-flowing water washing groove subsystem is connected to a water supplementation opening of the three-in-one zero-diopter groove through a water supplementation one-way valve; and the series-opposing water saving system comprises a function groove subsystem and a flowing water washing groove subsystem arranged between function grooves. By means of the fluorine-free COD-free three-in-one zero-diopter pretreatment process for the aluminum alloy, the quality of the surface of the aluminum alloy is greatly improved; the process is an updating technology for an existing common alkaline degreasing process; the problems of fluorine pollution and COD standard exceeding of anodic oxidation pretreatment of the aluminum alloy can be effectively solved; and high-degree water saving of an anodic oxidation line is achieved.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

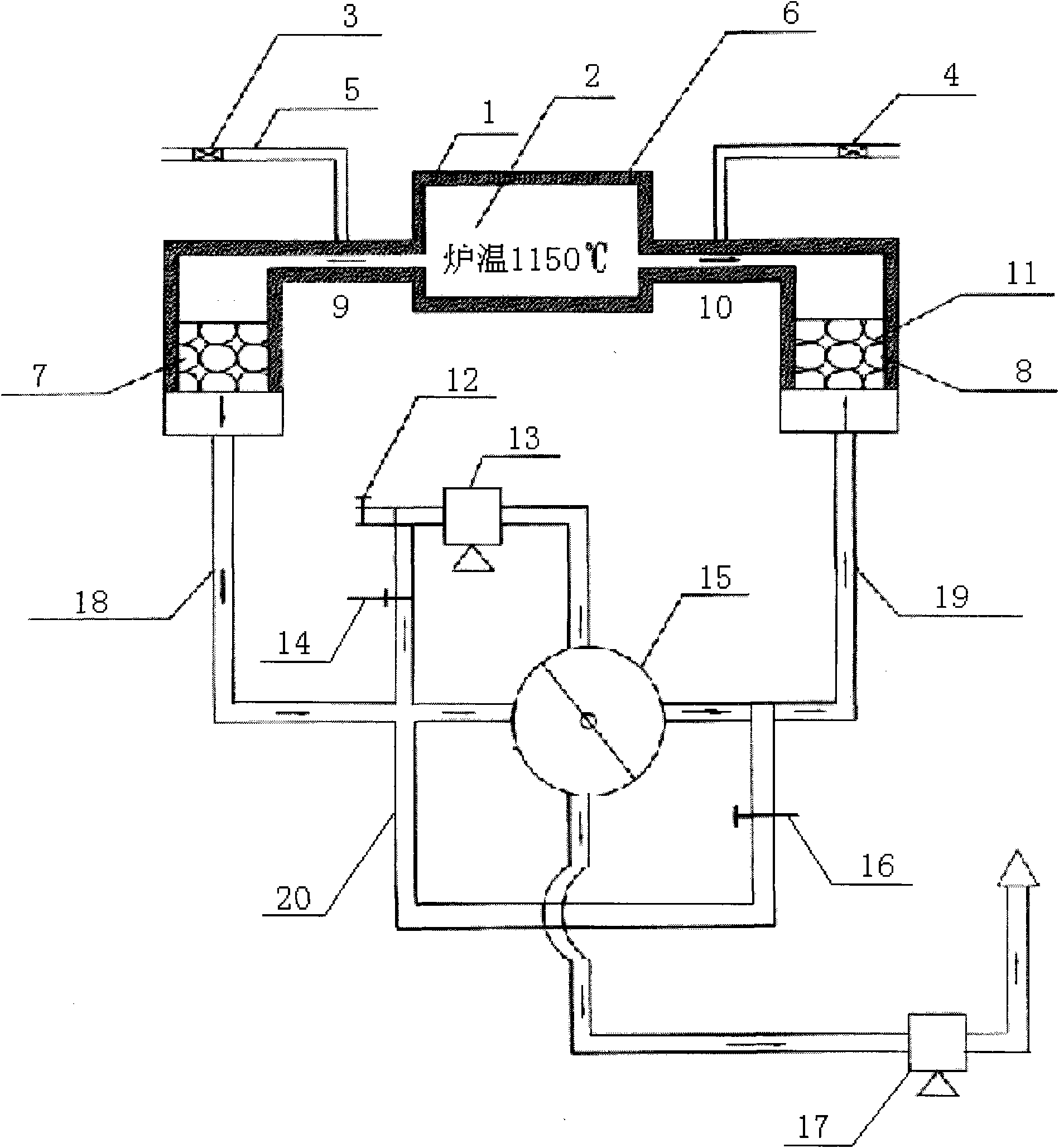

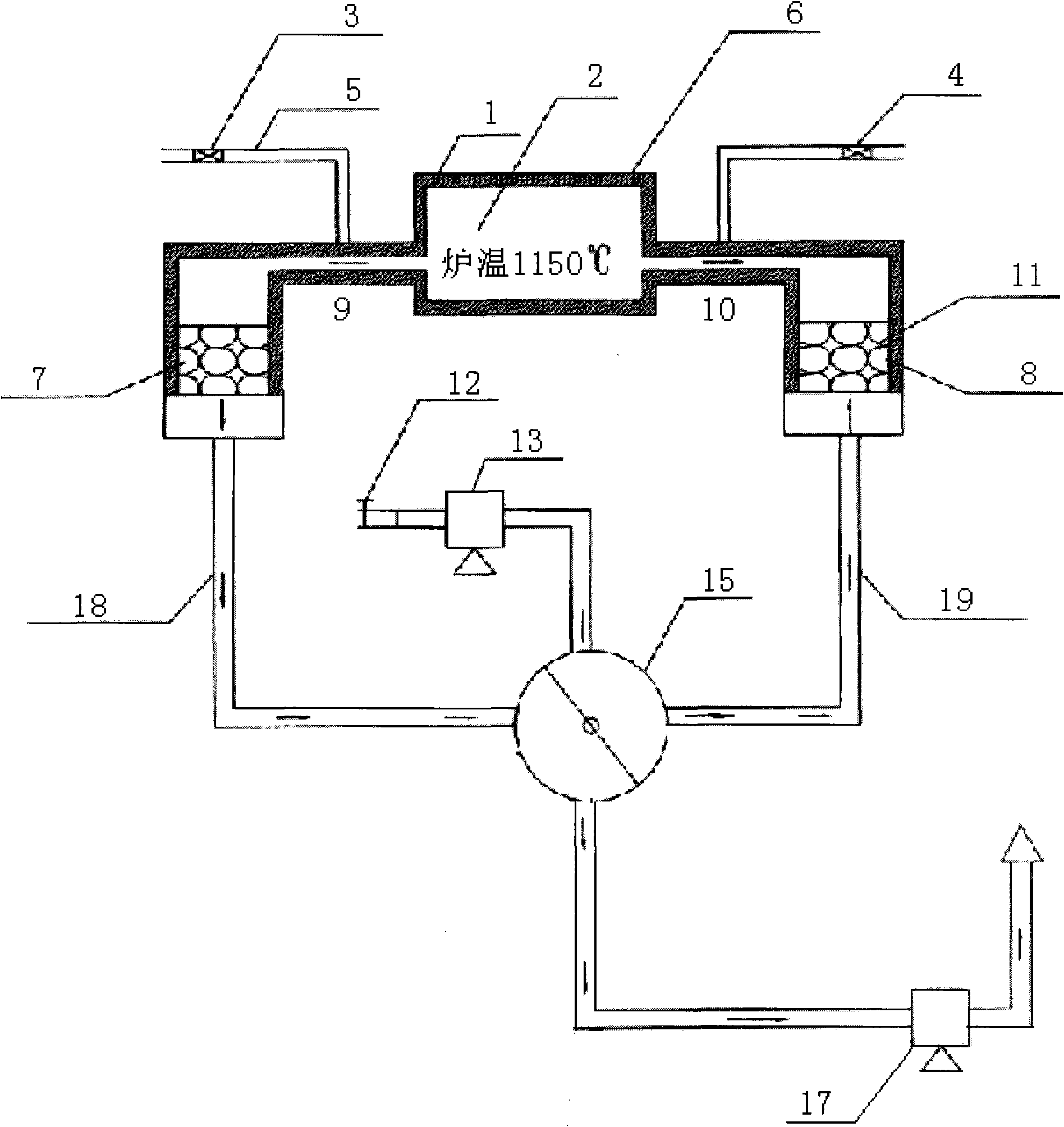

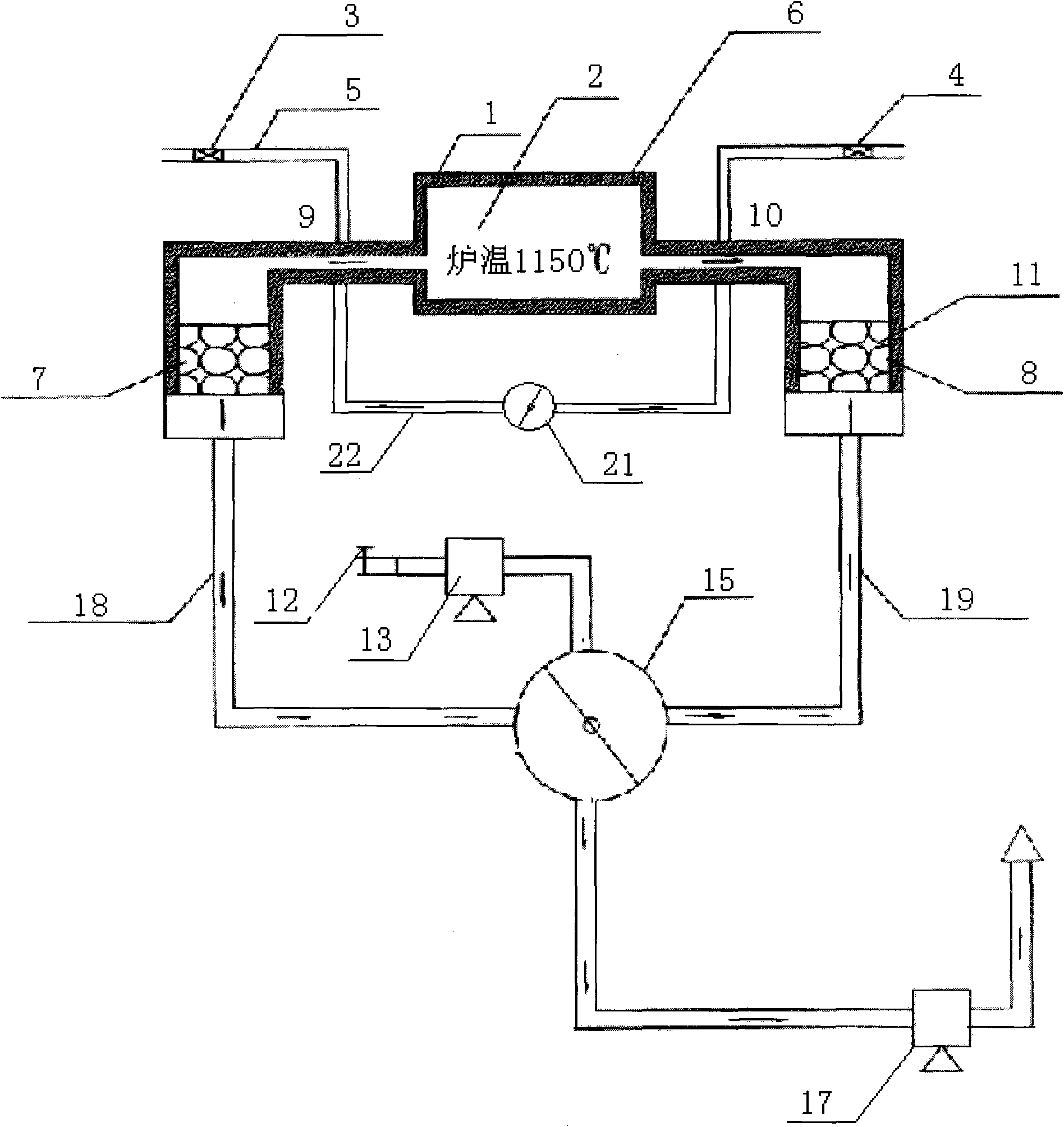

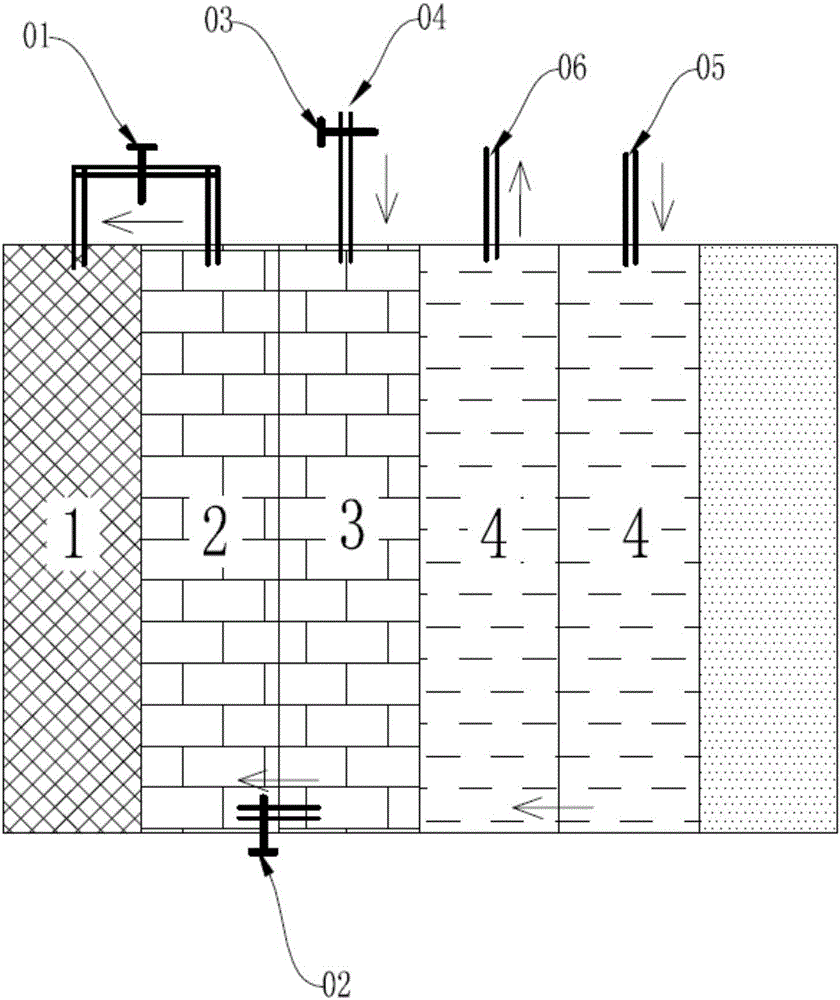

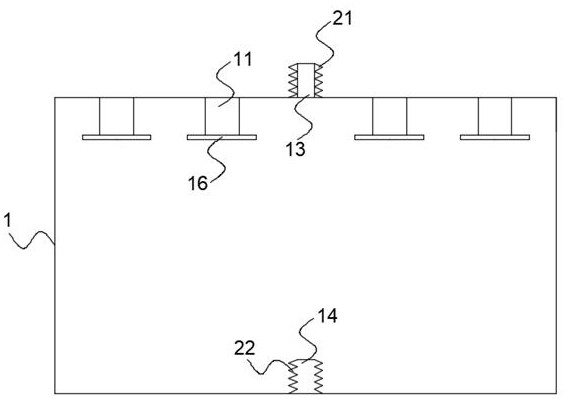

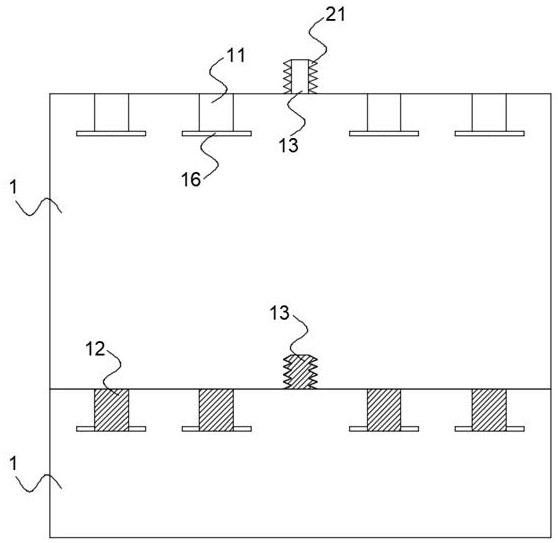

Method for regulating oxygen atmosphere in fuel oil (gas) reverberatory furnace by using recovered fume

InactiveCN101915502AReduce burning lossReduce production efficiencyLighting and heating apparatusCombustion chamberProcess engineering

The invention relates to a method for regulating oxygen atmosphere in a fuel oil (gas) reverberatory furnace by using recovered fume. The method is implemented by a reverberatory furnace regulating the fuel oil (gas) by using the recovered fume. The reverberatory furnace regulating the fuel oil (gas) by using the recovered fume comprises a furnace body 1, a nozzle, heat accumulators (7 and 8), fume pipelines (18 and 19), a reversing adjusting valve 15, an air blower 13 and the like, and is characterized in that: a fume recovering pipeline with a fume adjusting valve is arranged between a heat accumulator A (7) and a heat accumulator B (8) and regulates the oxygen atmosphere in a combustion chamber of a reaction furnace by using the recovered fume to ensure that the oxygen is fully burned; a pipeline arranged between low-temperature pipelines below the heat accumulators is a low-temperature fume recovering pipeline (20); a pipeline arranged between high-temperature pipelines above the heat accumulators is a high-temperature fume recovering pipeline; and the oxygen atmosphere in the combustion chamber can be regulated by one of the low-temperature fume recovering pipeline and the high-temperature fume recovering pipeline as required.

Owner:江西宏成铝业有限公司

Method for preparing aluminum-titanium-carbon intermediate alloy

One Al-Ti-C intermediate alloy preparation method, involves a kind to use in the aluminum alloy production crystal grain thin Al-Ti-C intermediate alloy production method. Its characteristic lies in with the calcium carbide does carbon source, the production craft completely dissolves after the aluminum, melts the body fever to join the electricity stone powder hydrofluotitanic acid armor the mixture, elevates temperature to 950deg.C~~1000deg.C, guarantees the wet 10~~30 minute, after melt body surface liquid state dregs casting.The invention characteristic is the raw material unites is easy, alloy production craft simple, production cost low, produces the alloy thin medicinal preparation thin crystal grain with this craft is incubation period short, specially suits outside the stove is continuously thin.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

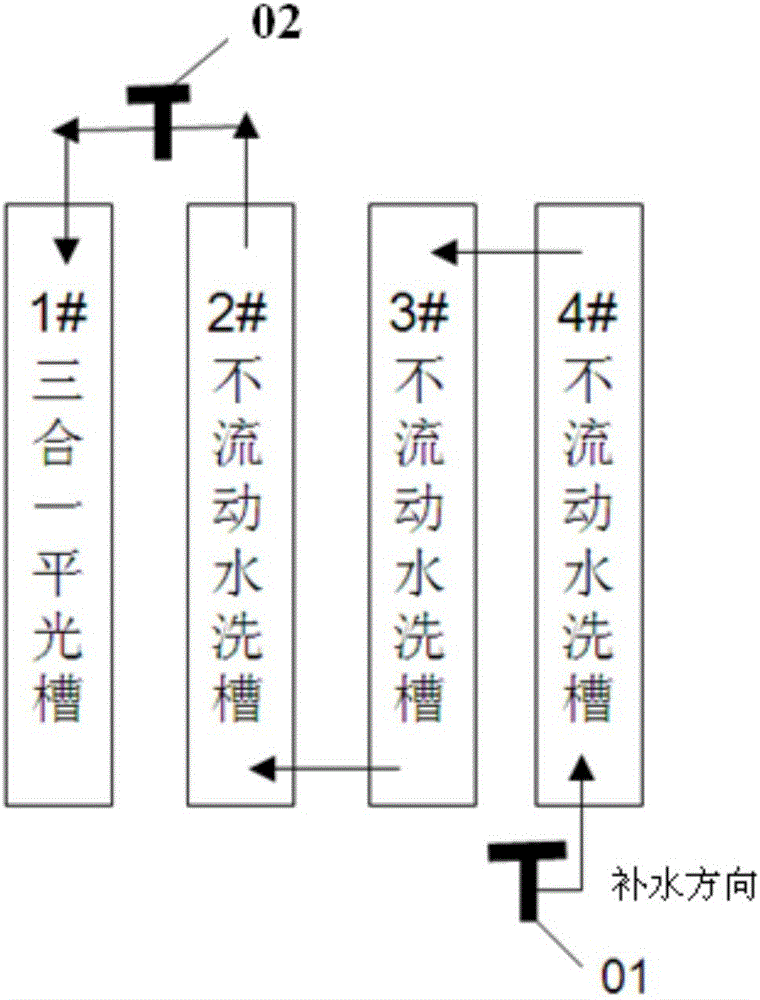

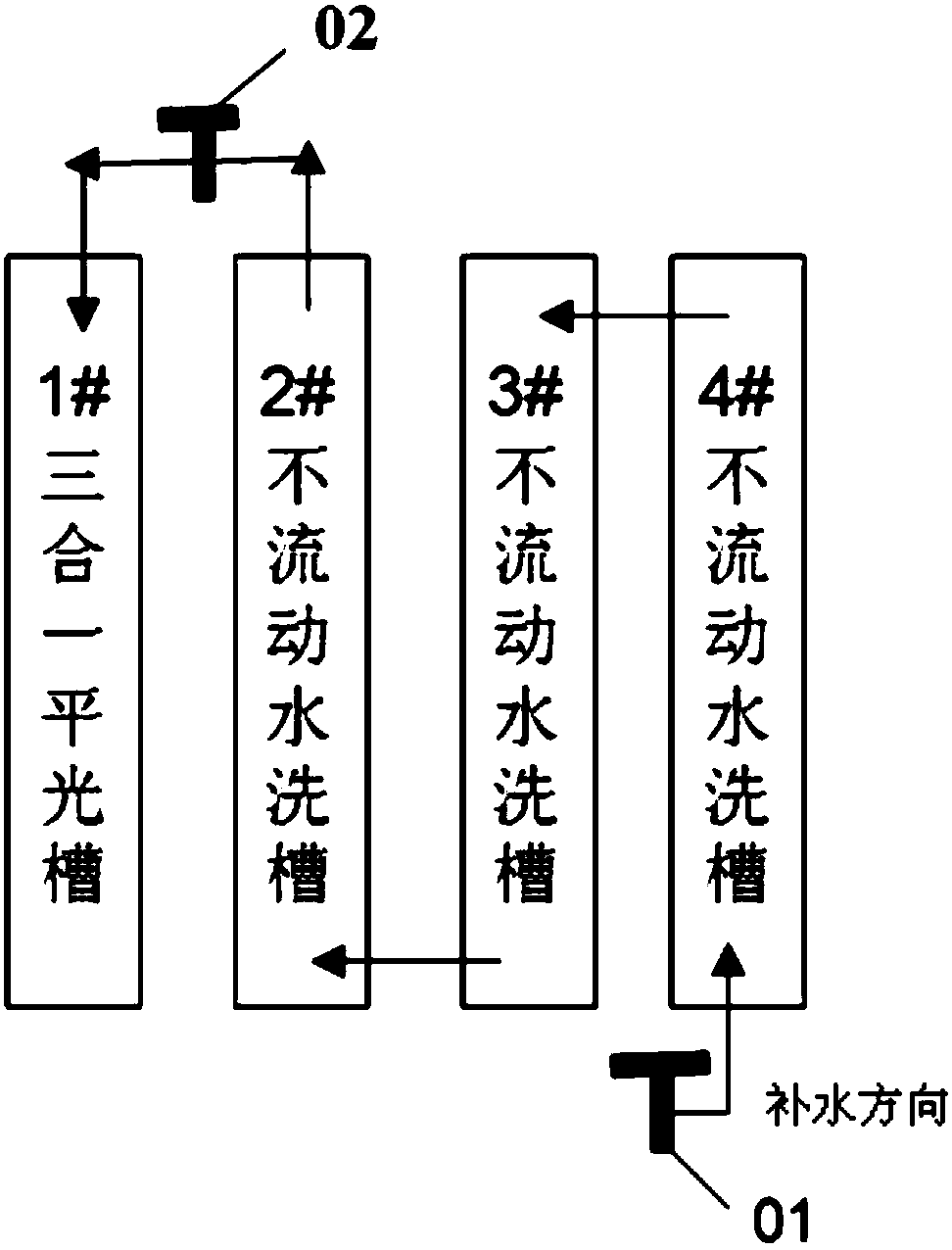

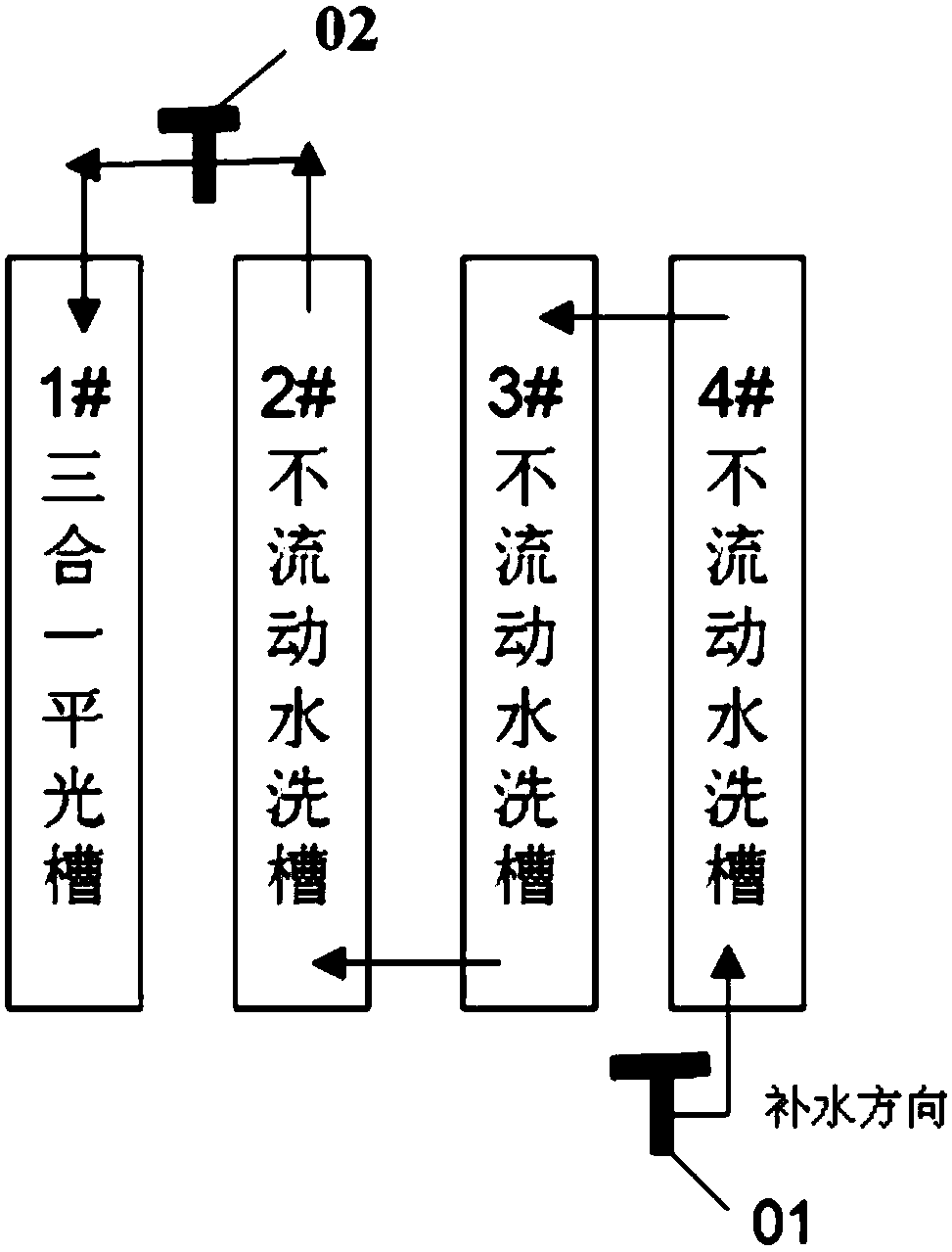

Aluminum alloy fluorine-free and COD-free three-in-one plain glass pretreatment drug recovery system

Aluminum alloy fluorine-free and COD-free three-in-one plain glass pretreatment drug recovery system, comprises a three-in-one plain glass tank and a non-flow tank subsystem. The non-flow tank subsystem is arranged in reverse series arrangement, a begin end of water flow is provided with a water inlet, a terminal outlet is connected to a water replenishing port of the three-in-one plain glass tank through a one-way valve device. The aluminum alloy fluorine-free and COD-free three-in-one plain glass pretreatment drug recovery system retains and reuses the drug, and reduces the unnecessary waste of the drug.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

Rapid and efficient sanding process for aluminium profile

InactiveCN104878390AReduced surface pretreatment processEasy to handleSurface reaction electrolytic coatingOrganic acidTherapeutic effect

The invention relates to an aluminium profile surface treatment production process, in particular to a rapid and efficient sanding process for an aluminium profile. The rapid and efficient sanding process for the aluminium profit has the benefits as follows: the aluminium profile is pretreated through an alkali etching agent using Na2CO3 as a main component, and sulfuric acid electrolyte added with organic acid is used for anodic oxidation, so that an oxidizing temperature range is broadened and the oxidation speed is increased. The surface pretreatment process of the aluminium profile is reduced while the surface treatment effect of the aluminium profile is not lowered, and aluminium consumption is reduced.

Owner:HUZHOU JULI ALUMINUM

Novel aluminum product wax removing agent and preparation method thereof

The invention proposes a novel aluminum product wax removing agent. The novel aluminum product wax removing agent comprises the following components in parts by weight: 20-47 parts of hydrochloric acid, 5-20 parts of fatty alcohol-polyoxyethylene ether, 10-30 parts of alkyl benzene sulfonic acid, 1-5 parts of ethylene glycol monobutyl ether and 15-90 parts of water. The novel aluminum product wax removing agent is acid liquid, is prominent in wax removing effect and quick in wax removing speed, can effectively remove polishing paste, polishing wax, oil, dirt and natural oxide films on surfaces of aluminum products, and is free of harm to the aluminum products.

Owner:夏良文 +1

Alkaline three-in-one grinding process capable of integrating pretreatment of aluminum with on-line recycle of aluminum hydroxide

ActiveCN106367791AFull recoveryReduce processing costsSurface reaction electrolytic coatingAluminium hydroxideEngineering

The invention discloses an alkaline three-in-one grinding process capable of integrating pretreatment of aluminum with on-line recycle of aluminum hydroxide. The process comprises a medicament recycling system and two flowing water washing tanks, wherein the medicament recycling system comprise an alkaline three-in-one grinding tank and a stagnant water washing tank subsystem which are connected in series oppositely; the liquid in the alkaline three-in-one grinding tank is alkaline liquid and contains sodium nitrate of which the concentration is 40g / L to 80g / L; the ratio of the concentration of sodium nitrate to the concentration of free alkali is equal to 1; the stagnant water washing tank subsystem comprises a first stagnant water washing tank and a second stagnant water washing tank which are connected in series oppositely; the start end, along the water flowing direction, of the second stagnant water washing tank is also provided with a water replenishing hole and a third valve; the two flowing water washing tanks are connected in series oppositely. The alkaline three-in-one grinding process capable of integrating pretreatment of aluminum with on-line recycle of aluminum hydroxide, disclosed by the invention, has the characteristics that the aluminum alloy surface quality is improved, a grinded surface is uniform and smooth, grains are grinded completely, few industrial waste residues are generated, medicament consumption is low, scale formation and blocking are prevented, on-line recycle of the alkaline liquid and the aluminum hydroxide is realized and the like.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

RH refining device and method for promoting deep decarburization of molten steel

PendingCN109576447AIncrease vacuumGood carbon-oxygen reaction mass transfer conditionsProcess efficiency improvementMetallurgyOxygen

The invention relates to an RH refining device and method for promoting deep decarburization of molten steel, and relates to the technical field of refining outside a molten steel furnace. The devicecomprises a vacuum chamber, an ascending dip tube, a descending dip tube, a ladle, a weir wall, an argon blowing tube and a top blowing oxygen gun. The top of the vacuum chamber is equipped with the top blowing oxygen gun, the bottom of the vacuum chamber is connected to the ascending dip tube and the descending dip tube, and the weir wall is installed at an outlet of the ascending dip tube at thebottom of the vacuum chamber. The ascending dip tube is provided with an argon blowing tube and communicates with gas. The ascending dip tube and the descending dip tube are inserted into the moltensteel in the ladle, and the molten steel is circulated between the vacuum chamber and the ladle through the ascending dip tube and the descending dip tube. The RH refining device and method have the advantages that implementation is facilitated, the weir wall is conveniently maintained, the RH refining device and method can be used and promoted in a factory, and has good practical significance.

Owner:CENT IRON & STEEL RES INST

Multi-station automatic piezoelectric machine for cast-aluminum rotor and method thereof

Provided is a multi-station automatic piezoelectric machine for a cast-aluminum rotor and a method thereof. A pressure-casting device of a multi-station pressure-casting device is connected and fixedwith a mold-closing mechanism of an oil cylinder. A multi-station device is arranged onto a rotary servo mechanism and connected and fixed with the rotary servo mechanism. The rotary servo mechanism can rotate at 360 degrees. When the mechanism rotates at every 90 degrees, four stations are arranged. The center line of the rotary servo mechanism is deviated from the hole center line of a four-station template at the distance of fixed value. Additionally, the center line of the pressure-casting device, the center line of the four-station template and the center line of an injection mechanism are vertical and collinear. The mold-closing mechanism of the oil cylinder drives the pressure-casting device to vertically and downwardly move and tightly press the cast-aluminum rotor. The mold-closing mechanism, the pressure-casting device and the cast-aluminum rotor are integrally formed. The machine is simple in operation and high in work efficiency and reduces the potential safety hazard, relieves labor intensity of workers and achieves automated, intelligent and integrated production. An air pore, a broken strip and insufficient pouring of the cast-aluminum rotor are avoided. Aluminum losses and stray losses are reduced in order to increase efficiency of a motor. Energy is saved. The labor condition is improved.

Owner:JIANGSU DAZHONG ELECTRIC MOTOR

Anode oxidation pretreatment method for aluminium alloy

InactiveCN100334258CSand fastReduce aluminum consumptionSurface reaction electrolytic coatingWaxPretreatment method

Owner:熊映明

Aluminum profile rapid and efficient sanding process

InactiveCN108220966AReduced surface pretreatment processEasy to handleAnodisationOrganic acidTherapeutic effect

The invention relates to an aluminum profile surface treatment production process, in particular to an aluminum profile rapid and efficient sanding process. The aluminum profile rapid and efficient sanding process has the following beneficial effects of carrying out pretreatment on the aluminum profile by adopting an alkaline etching agent taking Na2Co3 as a main component; and widening oxidationtemperature range by adopting a sulfuric acid electrolyte added with organic acid to speed up the oxidation speed. The surface pretreatment process of the aluminum profile is reduced while the sand surface treatment effect of the aluminum profile is not reduced, and the aluminum consumption is reduced.

Owner:谢正芬

Aluminum liquid backwater circulating device of smelting heat-holding furnace

InactiveCN102384647ASmall temperature differenceReduce the temperatureFurnace typesEngineeringTemperature difference

An aluminum liquid backwater circulating device of a smelting heat-holding furnace comprises a heat holding chamber, a deaerating chamber, a static chamber and a using chamber which are communicated with each other and further comprises a lifting device. The lifting device comprises a backwater chamber, a motor and a graphite rod, and the backwater chamber is communicated with the using chamber through a first pipeline. The backwater chamber is communicated with the heat holding chamber through a second pipeline which is slantly arranged from top to bottom, the upper end of the second pipeline is connected with a water outlet hole of the backwater chamber, the lower end of the second pipeline is connected with a water inlet hole of the heat holding chamber, and the water outlet hole of the backwater chamber and the water inlet hole of the heat holding chamber are respectively located above the surface of aluminum liquid in corresponding chamber. The tail end of the graphite rod is arranged in the backwater chamber, and the upper end of the graphite rod is connected with an output shaft of the motor. The lifting device is added, temperature difference between the using chamber and the heat holding chamber is shortened by quickening flow of the aluminum liquid. Under the condition of unchanging the temperature of the using chamber, the temperature of the heat holding chamber is lowered, service life of the heat holding chamber is prolonged, aluminum consumption is reduced, and fuel is saved.

Owner:浙江曙光实业有限公司

Out-of-furnace smelting method of ferrovanadium alloy

InactiveCN113151730AReduce aluminum consumptionReduce energy consumptionRefining (metallurgy)High energy

The invention relates to the technical field of metallurgy, in particular to an out-of-furnace smelting method of ferrovanadium alloy. In order to solve the technical problems of long process period, high energy consumption, low vanadium recovery rate and unstable quality of ferrovanadium alloy smelting at the present stage, the invention provides the out-of-furnace smelting method of the ferrovanadium alloy. The out-of-furnace smelting method specifically comprises the following steps of a, treating a furnace barrel by adopting a dry-method furnace barrel knotting process; b, uniformly mixing smelting furnace charge, putting into a smelting furnace, and starting smelting; c, blowing and refining, specifically, after the reaction is finished, electrically heating and then blowing and refining, and electrically heating again after the blowing and refining is finished; and d, after electric heating is finished again, and standing and water quenching to obtain a FeV80 alloy product. The obtained ferrovanadium alloy product meets the national standard GB / T 4139-2012, and the vanadium recovery rate is kept to be 98% or above; and meanwhile, the method also has the characteristics of low aluminum consumption, low energy consumption, simple process flow and stable product quality, and has good economic benefits and application prospects.

Owner:BEIHAI SPECIAL IRON ALLOY PANGANG GROUP

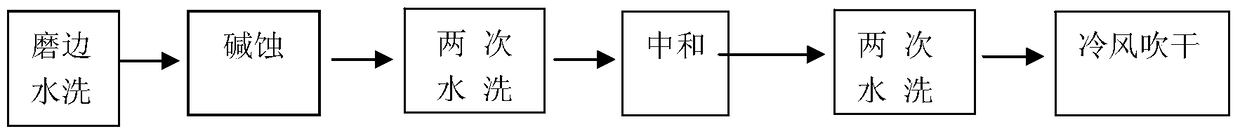

Aluminum alloy surface pretreatment method

The invention relates to a low-pollution, low-water-consumption and alkali-etching oil-removing integrated aluminum alloy surface pretreatment method. The method comprises the following steps: 1) placing aluminum alloy into an alkali-etching agent solution and performing alkali-etching oil-removing treatment; 2) washing; 3) placing into a neutralizing solution and performing neutralizing treatment; 4) washing; 5) blow-drying. Compared with the traditional acid etching process, the method has the advantages that fluorine and ammonia nitrogen pollution is avoided, aluminum consumption is similar and water consumption is greatly reduced. Compared with the traditional alkali etching process, the method has the advantages of low aluminum consumption, low water consumption, short process flow and high efficiency. The method not only eliminates the fluorine and ammonia nitrogen pollution from the source of the process, but also has the advantages of low aluminum consumption, low water consumption, short flow and high efficiency, and has the characteristics of environmental friendliness and resource saving.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

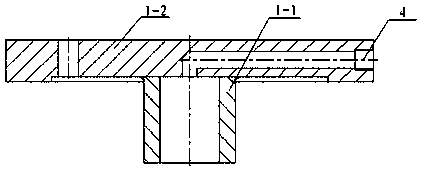

Novel anode carbon block for continuous prebaking

The invention provides a novel anode carbon block for continuous prebaking. The novel anode carbon block is characterized in that a carbon bowl is arranged at the top of a carbon block body; a carbon bowl filling block is movably arranged in the carbon bowl; a bump is arranged on the top surface of the carbon block body; a groove is formed in the bottom surface of the carbon block body and corresponds to the bump; a plurality of protrusions are arranged on one side face of the bump and distributed in the length direction of the bump, a plurality of recesses are formed in one side wall of the groove and distributed in the depth direction of the groove, the protrusions are matched with the recesses, and the distribution directions of the protrusions and the recesses are consistent, so that after the bump is inserted into the groove and the protrusions and the recesses are embedded in a one-to-one correspondence mode, the new carbon block body is connected with the old carbon block body. The continuous use of a prebaked anode is realized, the time for connecting new anode carbon block is short, the labor intensity is low, the use is convenient, the bonding area of the new and old carbon blocks is increased, the connection strength of the carbon blocks is improved, the service life of a single carbon block is prolonged, the production cost is low, the production efficiency is improved, and the product percent of pass is improved.

Owner:阿坝铝厂

Al-Si-Mn alloy and its preparing process

Owner:GEBREIER ALLOY CHANGZHOU

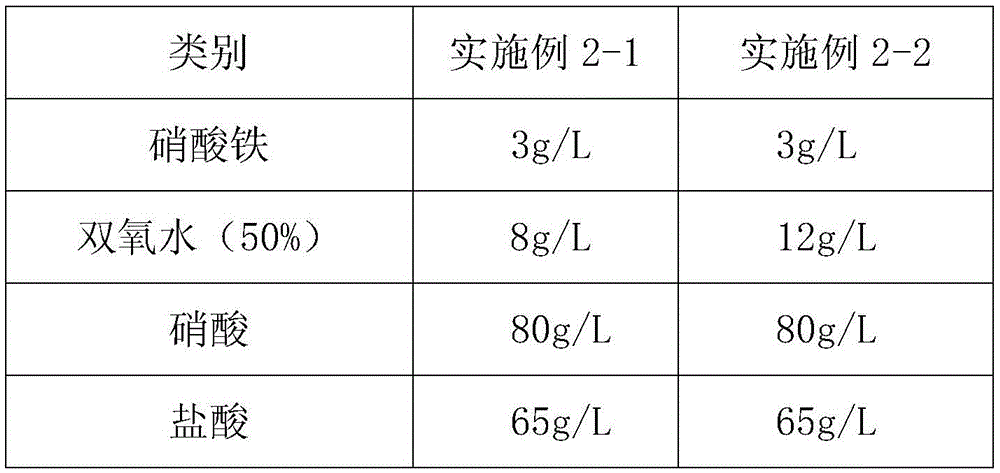

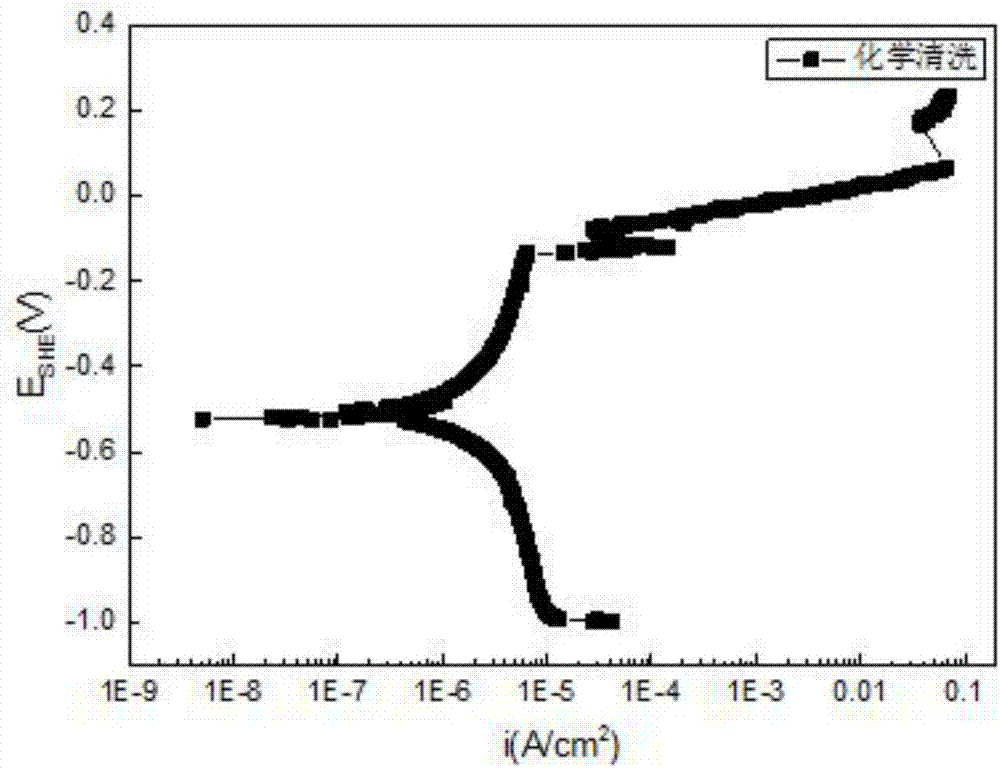

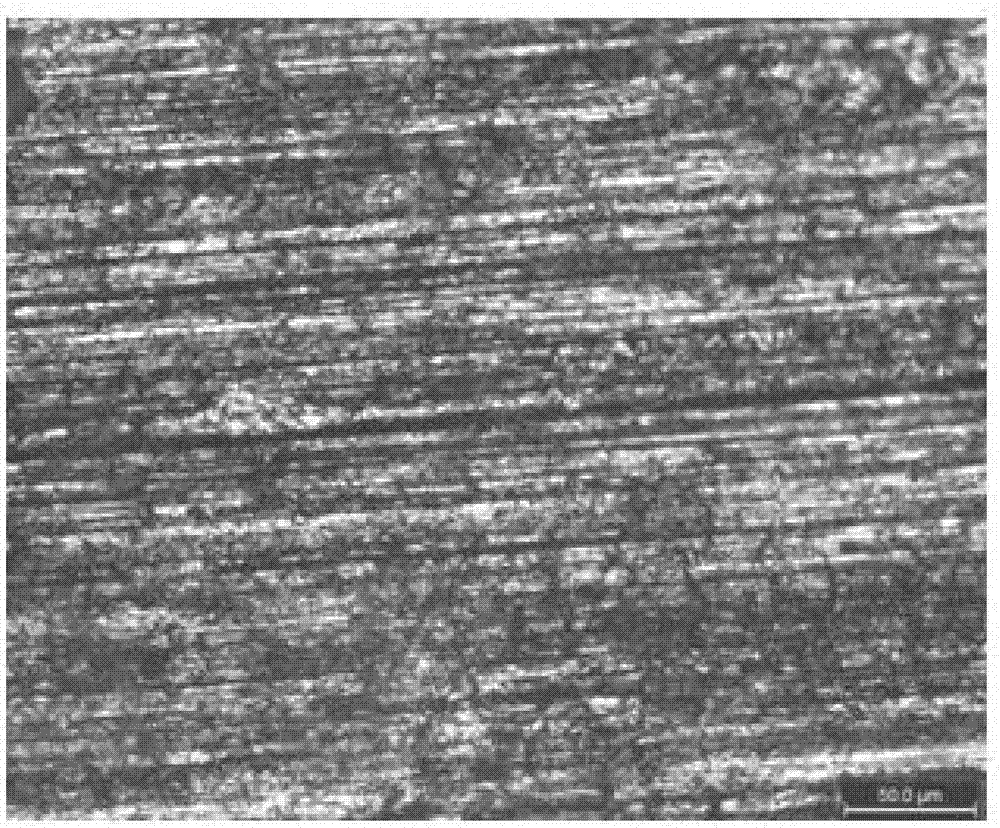

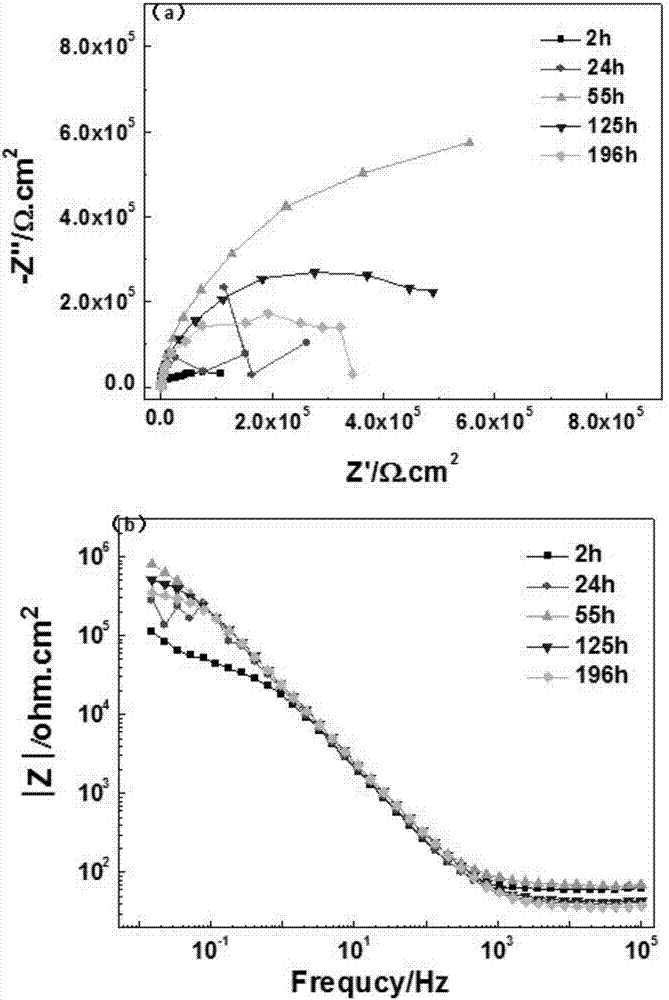

Photochemical treating fluid for pretreatment of aluminum or aluminum alloy surface, and chemical cleaning method

A photochemical treating fluid for pretreatment of aluminum or aluminum alloy surface, and a chemical cleaning method belong to the technical field of aluminum alloy surface pretreatment. The invention aims to solve the technical problems of environmental pollution, low production efficiency, high water consumption and unsatisfactory corrosion resistance of coating in the existing aluminum alloy chemical cleaning method. The photochemical treating fluid comprises phytic acid, NaHF<2>, Fe(NO)<3>, RC5820 and triethanolamine oleate. The chemical cleaning method comprises the steps: firstly, wiping the aluminum or aluminum alloy surface with gasoline to remove oil and dry; secondly, washing with hot water; thirdly, alkaline washing; fourthly, washing with hot water; fifthly, photochemical treatment; sixthly, natural drying. In the invention, through treating the aluminum alloy surface with the chemical cleaning method, the corrosion resistance of the aluminum alloy surface is improved, and aluminum consumption is not much different; water consumption is reduced greatly, and the technological process is short; and the efficiency is high.

Owner:哈尔滨哈船新材料科技有限公司 +1

High-strength aluminum and magnesium alloy material for mold

The invention discloses a high-strength aluminum and magnesium alloy material for a mold. The high-strength aluminum and magnesium alloy material comprises, by weight percentage, 1.1-1.2% of Cu, 5.3-5.6% of Mg, 0.2-0.25% of Si, 0.1-0.15% of Zn, 0.1-0.2% of Fe, 1.2-1.6% of Mn, 0.6-0.7% of Ti, 0.03-0.06% of W, 0.02-0.04% of Cr, 0.07-0.12% of Zr, 0.06-0.08% of La, 0.05-0.07% of Sm, 0.05-0.06% of Nd,0.05-0.07% of Y, 0.02-0.04% of Pr, 0.01-0.03% of Gd and the balance Al and inevitable impurities. The aluminum and magnesium alloy material is high in strength, hardness and corrosion resistance, andthe service life can be prolonged.

Owner:SUZHOU HAOYAN PRECISION MOLD CO LTD

Aluminum or aluminum alloy melt slag removal agent

Owner:XINCHANG COUNTY GUOWEI ALUMINUM PROD AUXMATERIALS

Aluminum alloy fluoride-free no-COD three-in-one flat-light pretreatment reagent recovery system

InactiveCN109423678AReduce consumptionReduce aluminum consumptionCellsSurface reaction electrolytic coatingAlloyEngineering

An aluminum alloy fluoride-free no-COD three-in-one flat-light pretreatment reagent recovery system comprises a three-in-one flat-light tank and a non-flowing water-washing tank subsystem, the non-flowing water washing tank system is in an integral and reverse in-series connection manner, and a water inlet is formed in the initial end of the water flowing direction, and a water outlet of the terminal is connected to a water supplementing opening of the three-in-one flat light tank through a water supplementing single-way valve device. The aluminum alloy fluoride-free no-COD three-in-one flat-light pretreatment reagent recovery system is used for intercepting and reusing a reagent, so that unnecessary waste of the reagent can be reduced.

Owner:梁肆生

Aluminum alloy fluorine-free and cod-free three-in-one flat-gloss pre-treatment chemical recovery system

Aluminum alloy fluorine-free and COD-free three-in-one plain glass pretreatment drug recovery system, comprises a three-in-one plain glass tank and a non-flow tank subsystem. The non-flow tank subsystem is arranged in reverse series arrangement, a begin end of water flow is provided with a water inlet, a terminal outlet is connected to a water replenishing port of the three-in-one plain glass tank through a one-way valve device. The aluminum alloy fluorine-free and COD-free three-in-one plain glass pretreatment drug recovery system retains and reuses the drug, and reduces the unnecessary waste of the drug.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

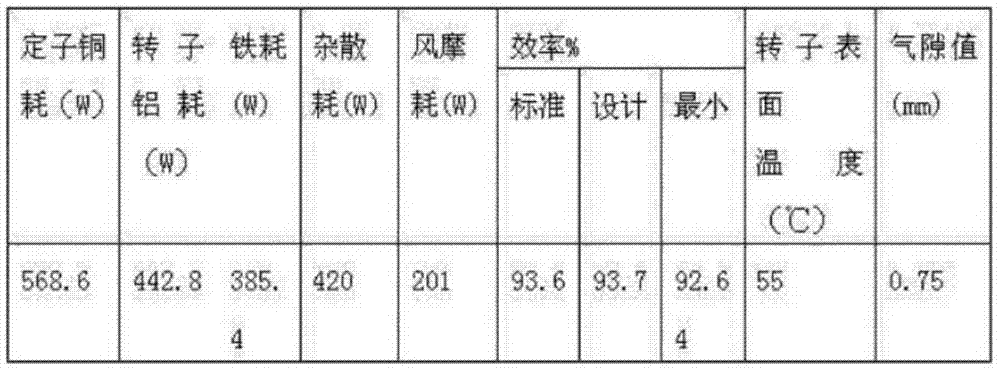

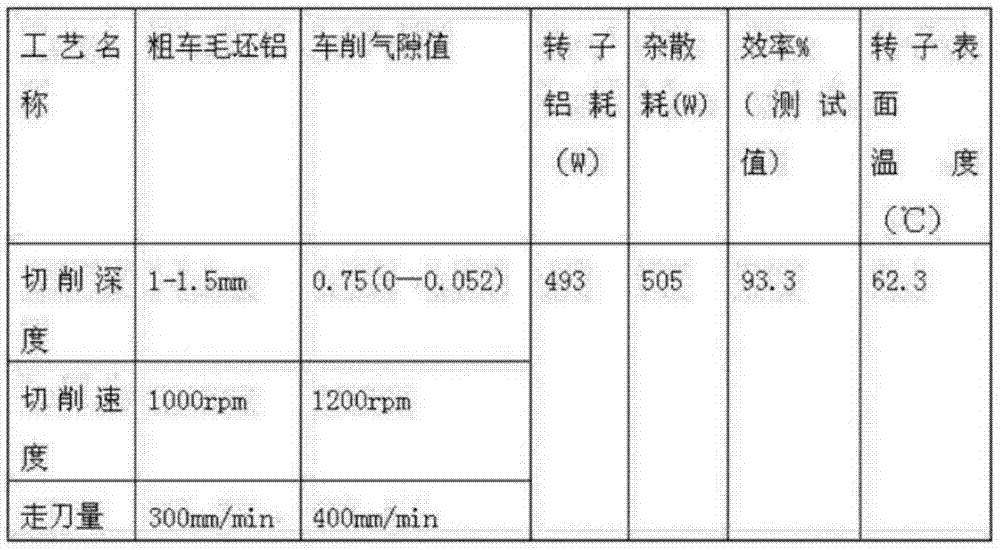

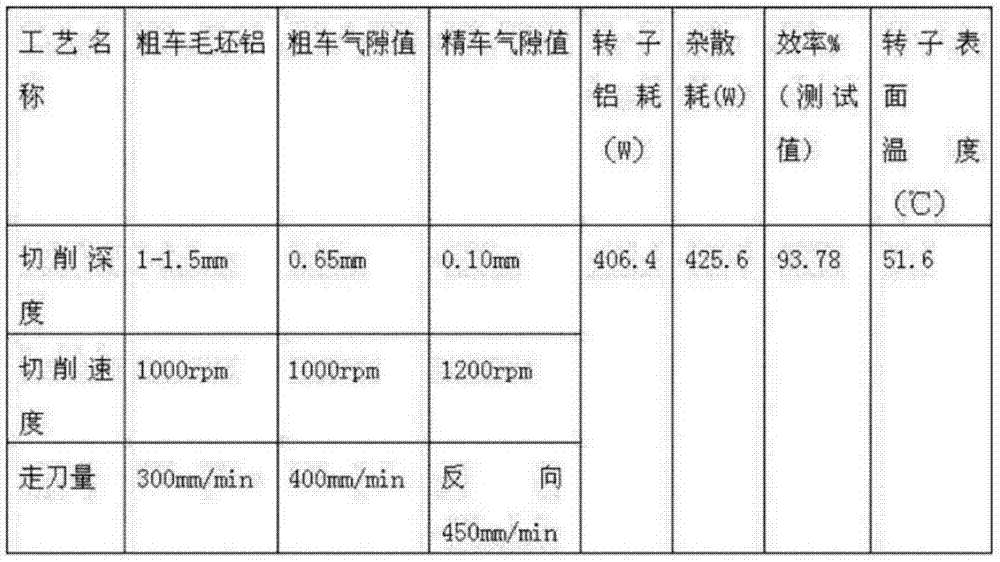

A processing method for reducing aluminum consumption of ultra-high-efficiency motor rotor

ActiveCN103633791BImprove efficiencyReduce the temperatureManufacturing stator/rotor bodiesTwo stepControl theory

The invention discloses a machining method capable of reducing the aluminum consumption of an ultra-efficient motor rotor. The method comprises the following steps of 1) turning off blank aluminum on the surface of the rotor according to specified process parameters; 2) performing turning to reduce an air gap value of the outer circle of the rotor by 3 / 5-9 / 10 of a specified value according to specified process parameters; 3) performing turning to eliminate the finish turning machining allowance of 1 / 5 -1 / 10 of the air gap value of the outer circle of the rotor according to specified process parameters, wherein a feeding travel direction is opposite to rough machining directions in the first two steps. The method is convenient to machine, the efficiency of a motor is improved, the surface temperature of the rotor is reduced, and the aluminum consumption of the rotor is reduced. The method is applied to the field of motors.

Owner:JIANGSU DAZHONG ELECTRIC MOTOR

Iron core aluminum-iron composite deoxidizing agent

The composite aluminum-iron deoxidizing agent with iron core consists of Al 85-95 wt% and Fe 5-15 wt% and has one iron core accounting for 35-45 wt%. The composite aluminum-iron deoxidizing agent with iron core is superior to available aluminum deoxidizing agent and composite aluminum-iron deoxidizing agent, and has raised molten steel deoxidizing effect, capacity of forming easily floating oxide, lowered aluminum consumption, and capacity of raising steel quality and lowering steel producing cost.

Owner:KUNMING IRON & STEEL GRP CO LTD

Surface pre-treatment system combining four aluminum alloy working grooves into whole for full recovery of medicament and zero emission of wastewater

The invention relates to a surface pre-treatment system combining four aluminum alloy working grooves into a whole for full recovery of medicament and zero emission of wastewater. The surface pre-heated system comprises a No.1 four-in-one sand surface groove, a No.2 matte tank, a No.3 water washing interception groove, a No.4 water washing interception groove, a No.5 water washing interception groove, a No.6 water washing material waiting groove, a No.7 oxidation groove and a No.8 water washing interception groove, as well as a matching slag pumping system, a medicament recovery system, a water circulation purification processing system and a reverse water replenishing neutralization system. As the four working grooves are combined into a whole, and the technical scheme is simultaneously equipped with the full recovery of the medicament and the zero emission of the wastewater, the pollution of fluorine and ammonium in the oxidation pre-treatment of an aluminum alloy anode can be effectively solved, the full recovery of the wastewater in the aluminum alloy surface pre-treatment can be realized, the pollution control of a company can be greatly reduced, and the production cost can be reduced.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com