Novel aluminum product wax removing agent and preparation method thereof

A wax removal agent and aluminum material technology, which is applied in the field of new aluminum material wax remover and its preparation, can solve the problems of only wax removal function, slow wax removal speed, and high cost, and achieve remarkable wax removal effect and wax removal speed Fast, energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

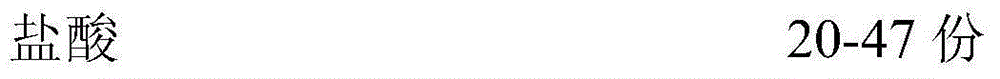

[0016] A novel aluminum material wax remover, its composition is calculated by weight, comprising:

[0017]

[0018] Among them, hydrochloric acid is used to etch the aluminum material to remove the natural oxide film on the surface of the aluminum material. Fatty alcohol polyoxyethylene ether is a non-ionic surfactant, which acts as emulsification and penetration, fully contains oil stains and wax stains, and emulsifies into 0 / W type; Peel off the natural oxide film and moisten oil stains and wax stains, and at the same time play a brightening effect; Ethylene glycol monobutyl ether acts as a solvent, which acts as a solubilizer, that is, a bridging effect, which can not only dissolve wax stains, but also dissolve in water. Knead several substances that are not compatible with each other completely to form a clear and thorough solution. The effect of each component of the wax remover provided by the invention and the synergistic effect between them make the invention have...

Embodiment 2

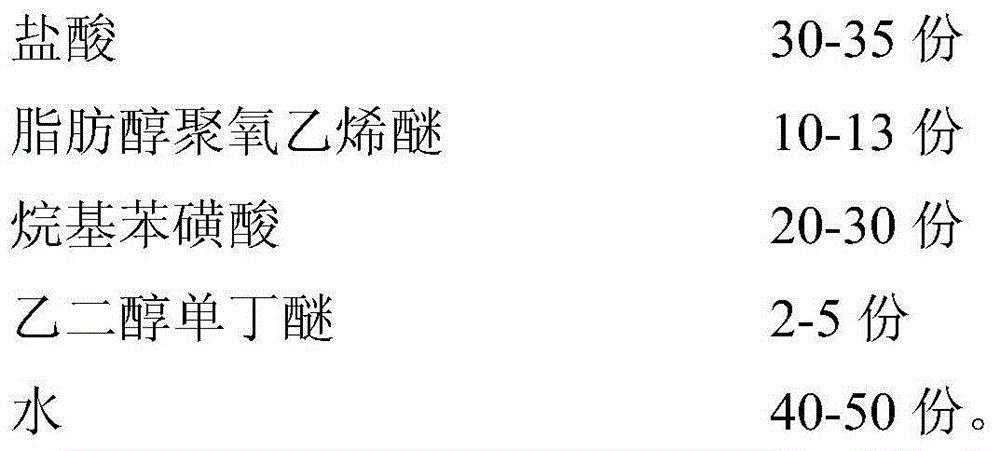

[0023] A novel aluminum material wax remover, its composition is calculated by weight, comprising:

[0024]

[0025] The preparation method steps are as follows:

[0026] First put 2 / 3 parts by weight of water in the reactor, then add hydrochloric acid and stir evenly, the concentration of hydrochloric acid is 10%, then add fatty alcohol polyoxyethylene ether, alkylbenzenesulfonic acid and ethylene glycol monobutyl ether, Stir to dissolve, raise the temperature to 75°C, add water to the full amount, and mix well to obtain the product.

Embodiment 3

[0028] A novel aluminum material wax remover, its composition is calculated by weight, comprising:

[0029]

[0030] The preparation method steps are as follows:

[0031] First put 1 / 3 parts by weight of water in the reactor, then add hydrochloric acid and stir evenly, the concentration of hydrochloric acid is 13%, then add fatty alcohol polyoxyethylene ether, alkylbenzenesulfonic acid and ethylene glycol monobutyl ether, Stir to dissolve, raise the temperature to 85°C, add water to the full amount, and mix well to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com