Patents

Literature

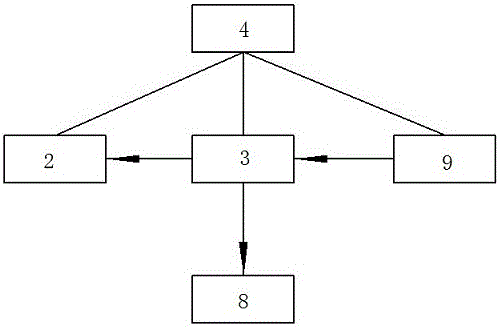

75results about How to "Improve wax removal effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

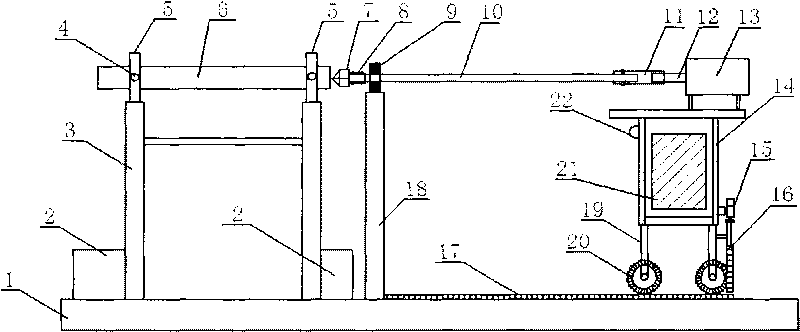

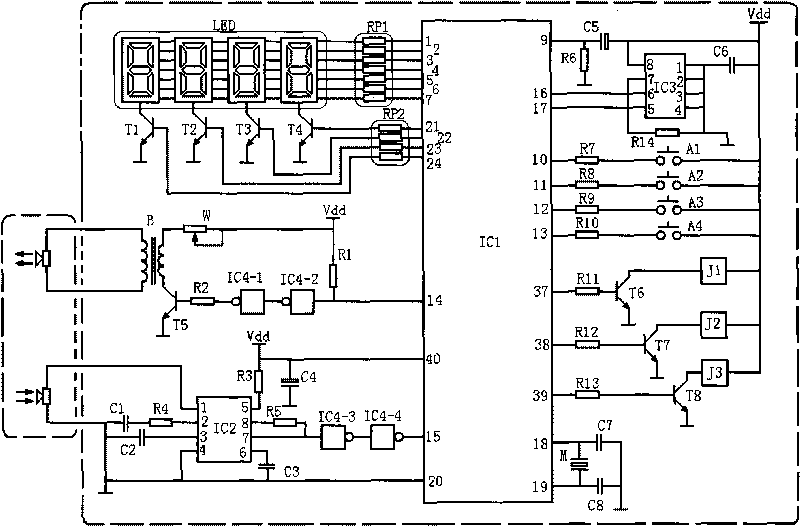

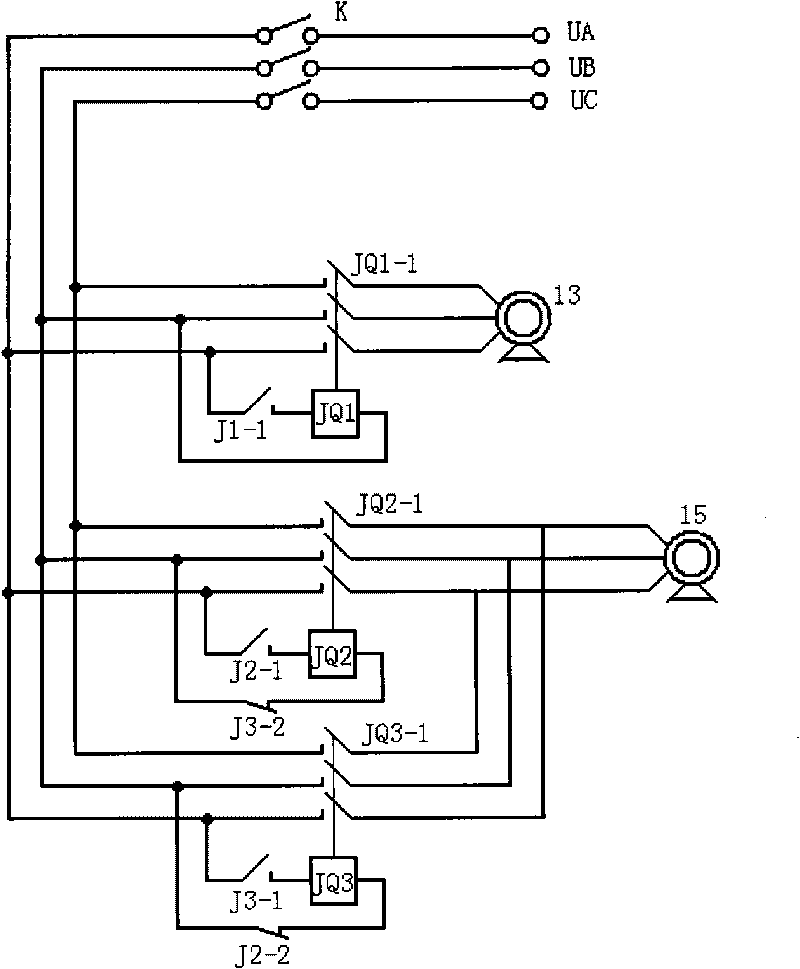

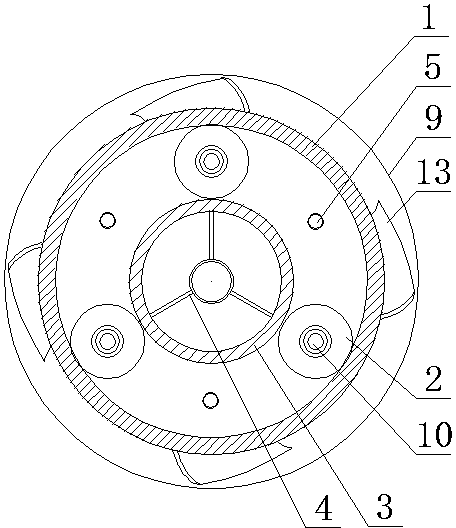

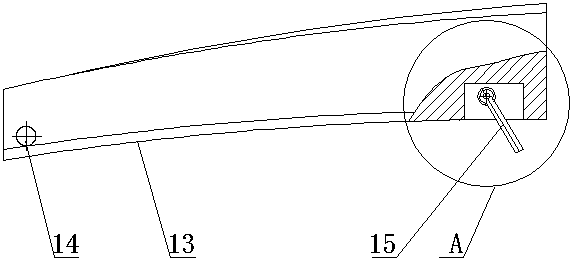

Automatic-control oil pipe dry-type paraffin removal unit

InactiveCN101722163AImprove wax removal effectRapid wax removalComputer controlSimulator controlAutomatic controlDrive motor

The invention relates to an automatic-control oil pipe dry-type paraffin removal unit which comprises a base, an oil pipe fixing support, a bracing frame, a drill bit, a drill stem, a propulsion motor, a drive motor, a rack slide rail, a worktable, a worm, gears, an oil storage box and an automatic controller. Compared with the prior art, the invention has the following advantages: 1. high paraffin removal efficiency and wide application range: the paraffin removal unit is driven by the motors and uses the special paraffin bit and doctor blades, and thus having obvious paraffin removal effect and high speed; due to the simple mechanism of the paraffin removal unit, the paraffin removal effect is obvious and is suitable for small operating zones of oil production plants and self application of mine groups; 2. environmental protection and energy saving: the paraffin removal unit saves substantive water resources and reduces the environmental pollution of dirty oil and paraffin; 3. automatic control: the paraffin removal unit is controlled by an automatic electronic circuit, thereby simplifying the operation and greatly reducing the labor intensity for workers.

Owner:张少波

Soluble chemical paraffin removal ball and preparation method and use method of soluble chemical paraffin removal ball

ActiveCN108559675APrevent redepositionPlay the role of physical wax removalCationic surface-active compoundsDetergent mixture composition preparationSodium stearateOctadecyltrimethylammonium bromide

The invention provides a soluble chemical paraffin removal ball and a preparation method and a use method of the soluble chemical paraffin removal ball. The soluble chemical paraffin removal ball comprises the following raw materials: 60-104 parts of a surfactant and 7-27 parts of a thickener; the surfactant is one or more of sodium stearate, hexadecyl trimethyl ammonium chloride, hexadecyl trimethyl ammonium bromide, sodium laurate, octadecyl trimethyl ammonium chloride, and octadecy trimethyl ammonium bromide; the thickener comprises 2-10 parts of sodium carboxymethylcellulose, 2-10 parts ofpolyacrylamide and 2-7 parts of sodium polyphosphate. The raw materials are proportionally added into absolute ethyl alcohol, stirred evenly, formed through a mould, and dried to obtain the soluble chemical paraffin removal ball. The paraffin removal ball is added according to the conditions of the pipeline length and the paraffin precipitation. The chemical paraffin removal ball has double effects of physically removing paraffin and chemically preventing paraffin, and the problem of paraffin precipitation in a transportation pipeline of the crude oil is solved.

Owner:XI'AN PETROLEUM UNIVERSITY

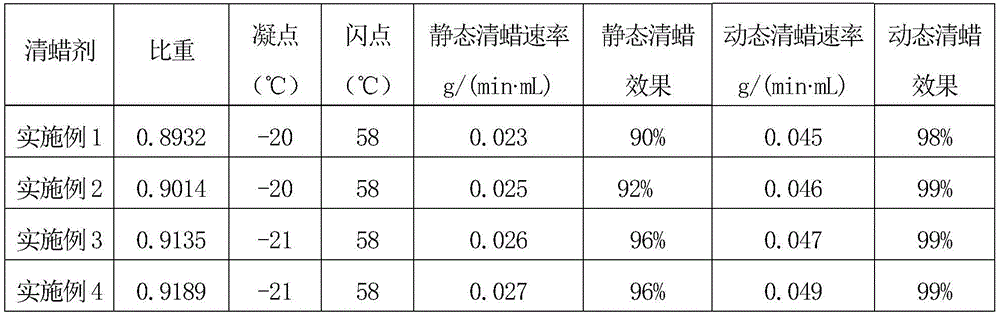

Emulsion type paraffin remover and inhibitor and preparation method thereof

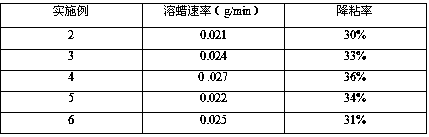

The invention relates to an emulsion type paraffin remover and inhibitor and a preparation method thereof, and belongs to the technical field of oil exploitation. The emulsion type paraffin remover and inhibitor includes, by weight, 45%-60% of 150# solvent oil, 4.5%-6% of octylphenol polyoxyethylene ether, 4.5%-6% of fatty alcohol-polyoxyethylene ether, 2.25%-3% of polyoxyethylene sorbitan monostearate, 3%-4% of ether cosolvent, and the balance water or synthetic brine. According to the emulsion type paraffin remover and inhibitor, the paraffin dissolution rate is more than 0.022 g / min, the paraffin inhibition rate is more than 75%, and oil well paraffinication can be effectively prevented. The emulsion type paraffin remover and inhibitor has good paraffin removing and inhibiting effects.

Owner:CHINA PETROLEUM & CHEM CORP +1

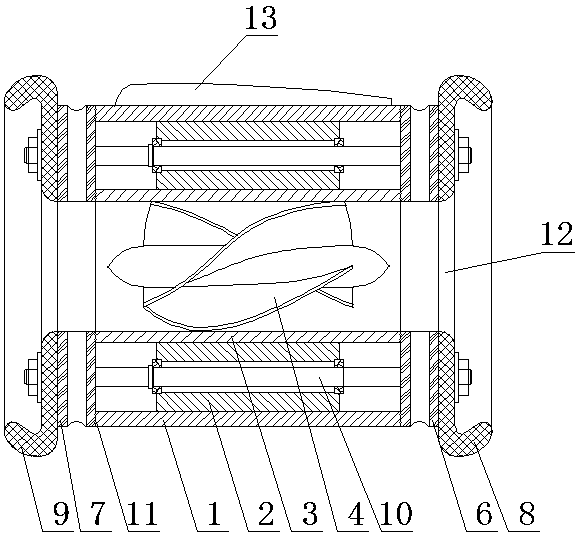

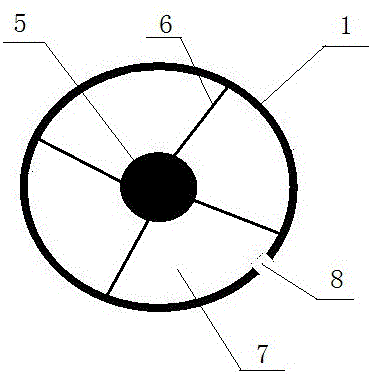

Passive oil conveying pipeline cleaner

InactiveCN103785656AReduce lossesGuaranteed oil delivery efficiencyHollow article cleaningImpellerEngineering

The invention relates to a passive oil conveying pipeline cleaner and belongs to the technical field of oil conveying pipeline dredging equipment. The pipeline cleaner comprises a sun gear, planetary gears, a center gear and an impeller. The two ends of the sun gear are provided with a front sealing plate and a back sealing plate through fixing rods respectively. A planetary gear shaft is arranged between the front sealing plate and the back sealing plate in a triangle shape. The planetary gears are movably arranged on the planetary gear shaft respectively. The center gear is arranged in the sun gear between the planetary gears. The impeller is arranged in the center gear. The planetary gears are in meshed connection with the center gear and the sun gear respectively. Power is provided for the pipeline cleaner through raw oil conveyed in a pipeline, rotating blade cutting design of interference fit of a traditional descaling device and the pipeline is changed, damage on the pipeline is effectively lowered, descaling effect is improved, loss caused by production stopping is lowered, and oil conveying efficiency is effectively guaranteed. According to the pipeline cleaner, through the similarity principle, different sizes can be designed, so that the requirements of washing work of pipelines with different inner diameters are met.

Owner:YANGTZE UNIVERSITY

Emulsion paraffin remover for oil well as well as preparation method and application thereof

The invention provides an emulsion paraffin remover for an oil well as well as a preparation method and application thereof. The emulsion paraffin remover is prepared from the following ingredients inparts by weight: 25 to 45 parts of diesel, 3 to 6 parts of gemini quaternary ammonium salt, 3 to 7 parts of fatty alcohol-polyoxyethylene ether, 1.5 to 2.5 parts of sorbitan monooleate, 2 to 5 partsof mutual solvents, 1 to 3 parts of sodium hydroxide and 35 to 60 parts of water. Three kinds of surfactants can achieve the moisturizing and conversion effects, so that the paraffin forming surface is converted into the hydrophilic surface; the paraffin falling is facilitated; in addition, the three kinds of surfactants achieve the cooperated effects, the ultra-low surface tension effect is generated; the effective viscosity reduction can be realized. The emulsion paraffin remover has the advantages of oil-based paraffin removers and water-based paraffin removers; the defect of high toxicityof the oil-based paraffin remover and the defect of great temperature sensitivity of the water-based paraffin remover are avoided; in addition, no injury is caused on the environment and bodies of workers; the paraffin removing effect is obvious; the paraffin remover conforms to the development trend of the paraffin remover for the oil well in future.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Oil-in-water paraffin remover

The invention relates to an oil-in-water paraffin remover, belonging to the field of oilfield chemistry. The invention is characterized in that the oil-in-water paraffin remover is prepared by mixing the following raw materials in percentage by weight: 10-20% of benzene, 5-15% of toluene, 10-15% of petroleum ether, 3-7% of surfactant, 2-8% of mutual solvent, 1-3% of alkaline matter, 3-10% of emulsifier and the balance of water. The oil-in-water paraffin remover is prepared by combining the advantages of the water-base paraffin remover and oil-base paraffin remover and lowering the harsh requirements for the emulsion-type paraffin remover. The oil-in-water paraffin remover has the advantages of high safety, environment friendliness and excellent paraffin removal effect.

Owner:山东聚鑫化工有限公司

Metal cleaning agent added with functional modified graphene and preparing method of metal cleaning agent

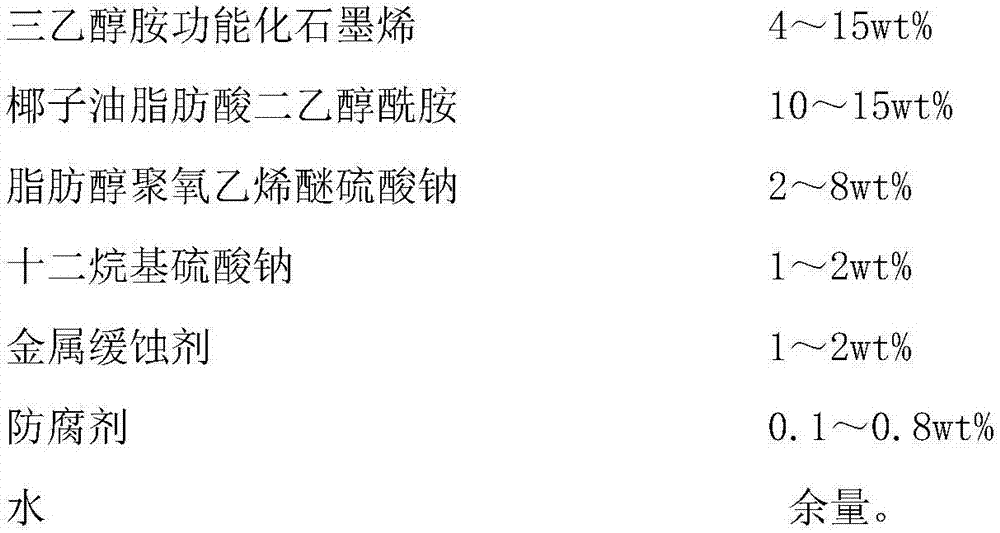

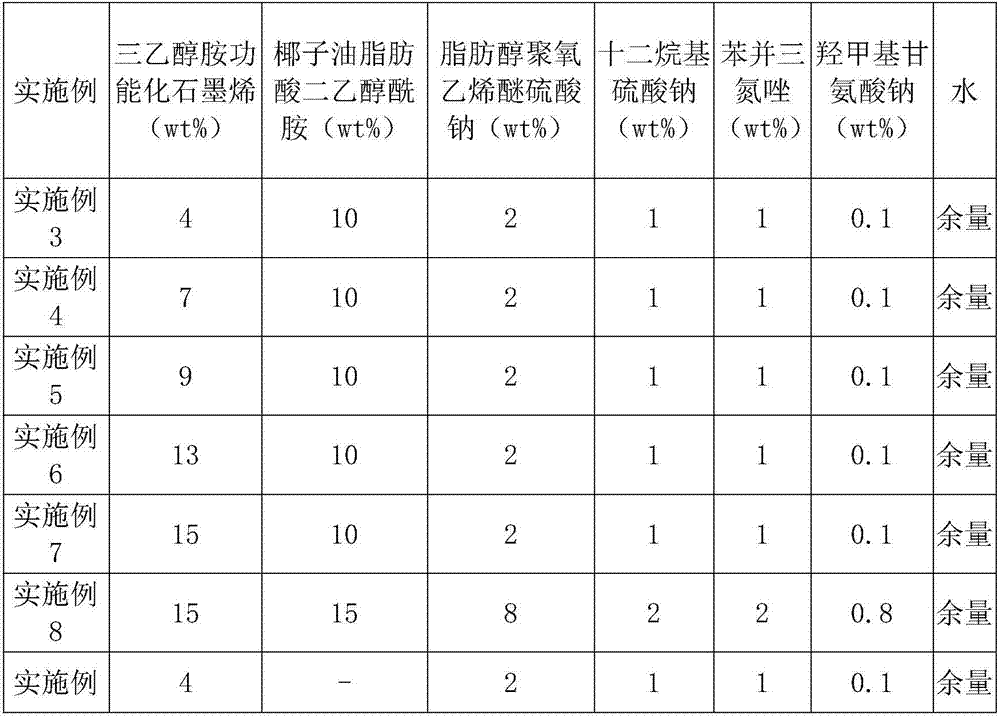

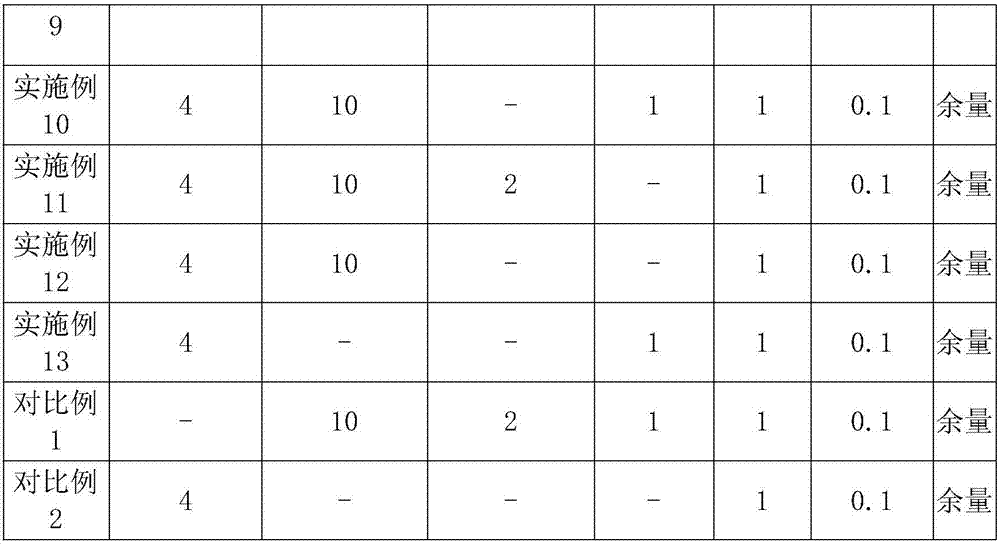

The invention relates to a metal cleaning agent, and discloses a metal cleaning agent added with functional modified graphene and a preparing method of the metal cleaning agent. The metal cleaning agent is composed of 4-15wt% of triethanolamine functional graphene, 13-25wt% of surfactant, 1-2wt% of metal corrosion inhibitor, 0.1-0.8wt% preservative and the balance water. According to the metal cleaning agent, the triethanolamine functional graphene is creatively used to be added into the metal cleaning agent, triethanolamine of the triethanolamine functional graphene and the graphene are bonded as covalent bond, and the surface of the metal cleaning agent contains a large amount of tertiary amine nitrogen and hydroxyl active functional groups; and amino ionic liquid functional graphene achieves graphene modification through the non-covalent interaction between imidazole rings and graphite rings, the graphene has the super large specific surface area, the strong complexing effect is achieved after the grapheme and the triethanolamine are functionalized, so that the strong adsorption capacity is achieved, the hydrophilic and lipophilicity of the triethanolamine are retained, the strong adsorption capacity also can be achieved, and the metal cleaning agent is used without matching of an additional complexing agent.

Owner:郴州国盛新材科技有限公司

High-effective environment-friendly oil-based wax removal agent

The invention discloses a high-effective environment-friendly oil-based wax removal agent which is prepared with n-octyl alcohol, isoamyl alcohol and a penetrating agent JFC as additives, span-80 and polyethylene glycol monononylphenyl ether as surfactants, and n-heptane, cyclohexane, n-hexane and petroleum ether as solvents without organic chlorine, carbon disulfide and benzene-series solvents, so that the wax removal agent is greatly eliminated in toxicity and reduces damage on operators. The wax removal agent is toxic-free on a catalyst used in a crude oil refining process and is free of corrosion on oil recovery devices and refining devices. The oil-based wax removal agent is higher than 0.90 in specific gravity, not only has wax removal effect but also has viscosity reducing effect with viscosity reducing rate being higher than 35%, is higher than commercial wax removal agents in wax removal rate by 30% and in was removal effect by 10%, is lower than -20 DEG C in condensation point and is suitable in cold weather.

Owner:陕西延安石油天然气有限公司 +1

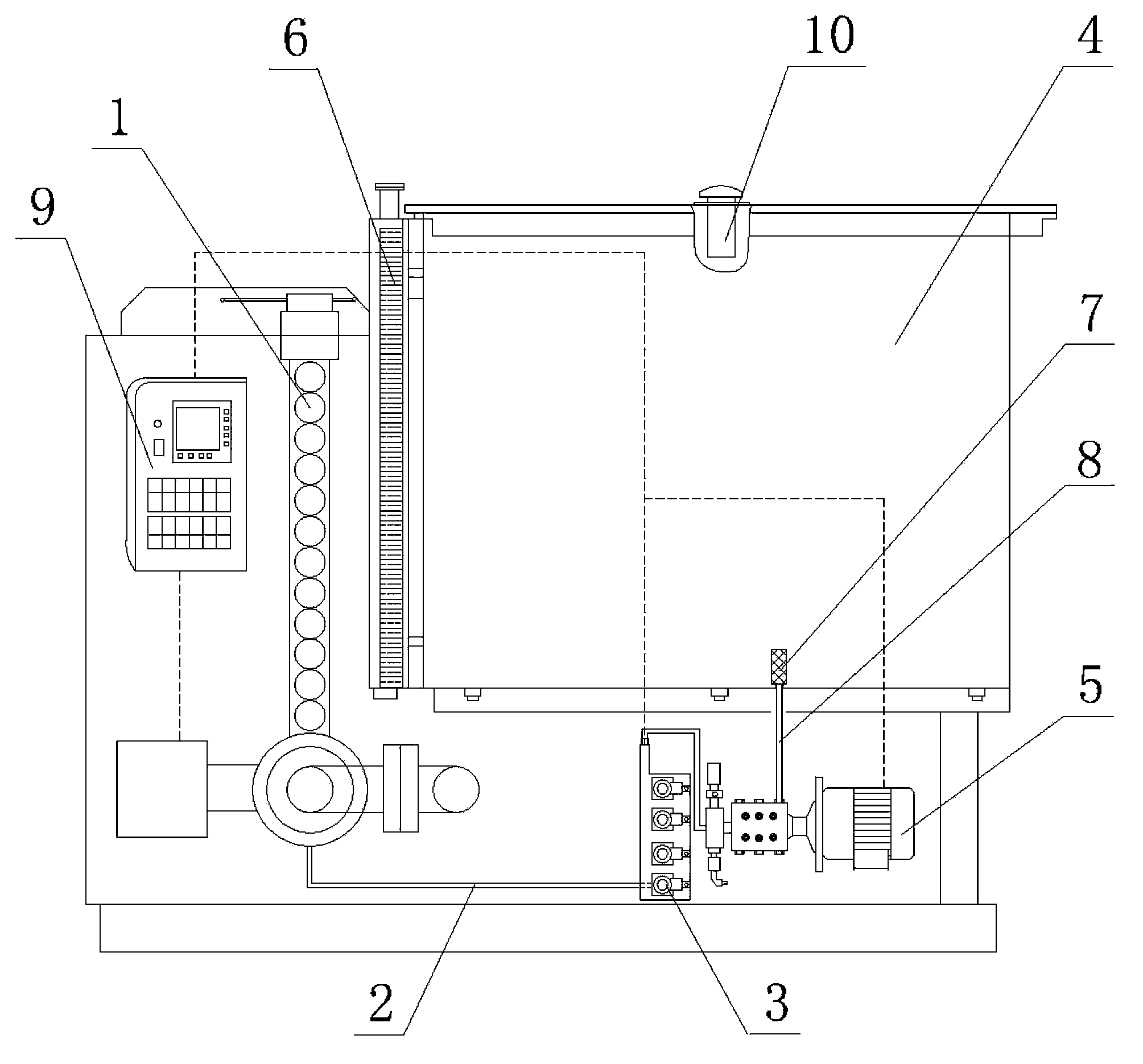

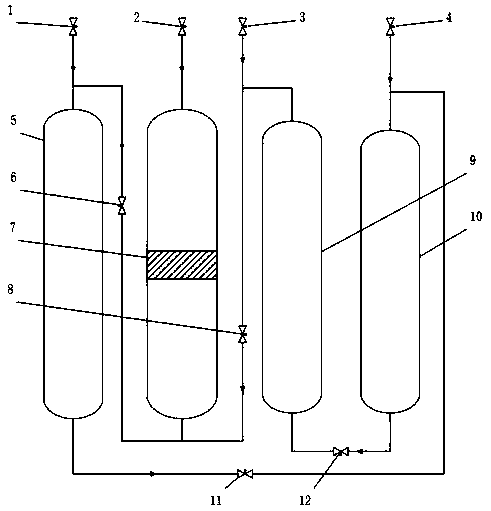

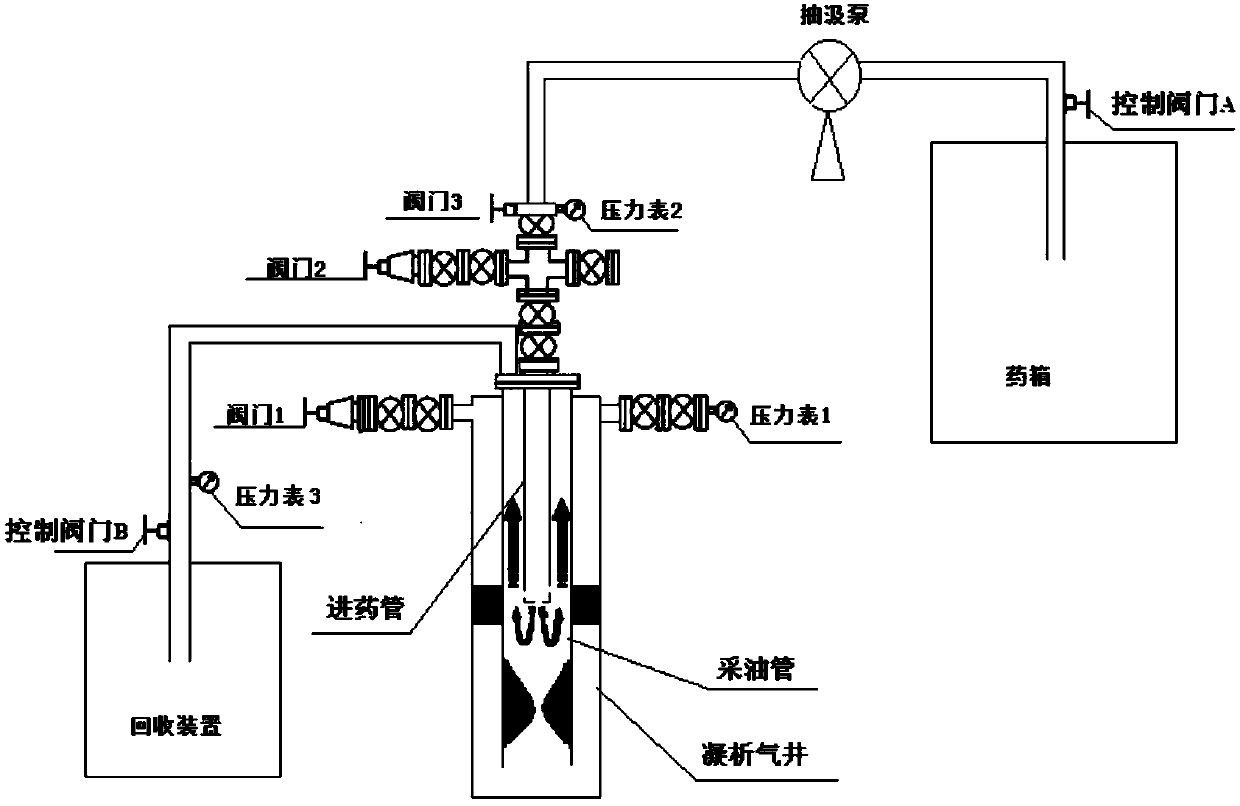

Paraffin removal device of oil gathering pipeline

ActiveCN103696736AImprove wax removal effectImprove oil delivery capacityCleaning apparatusWaxParaffin oils

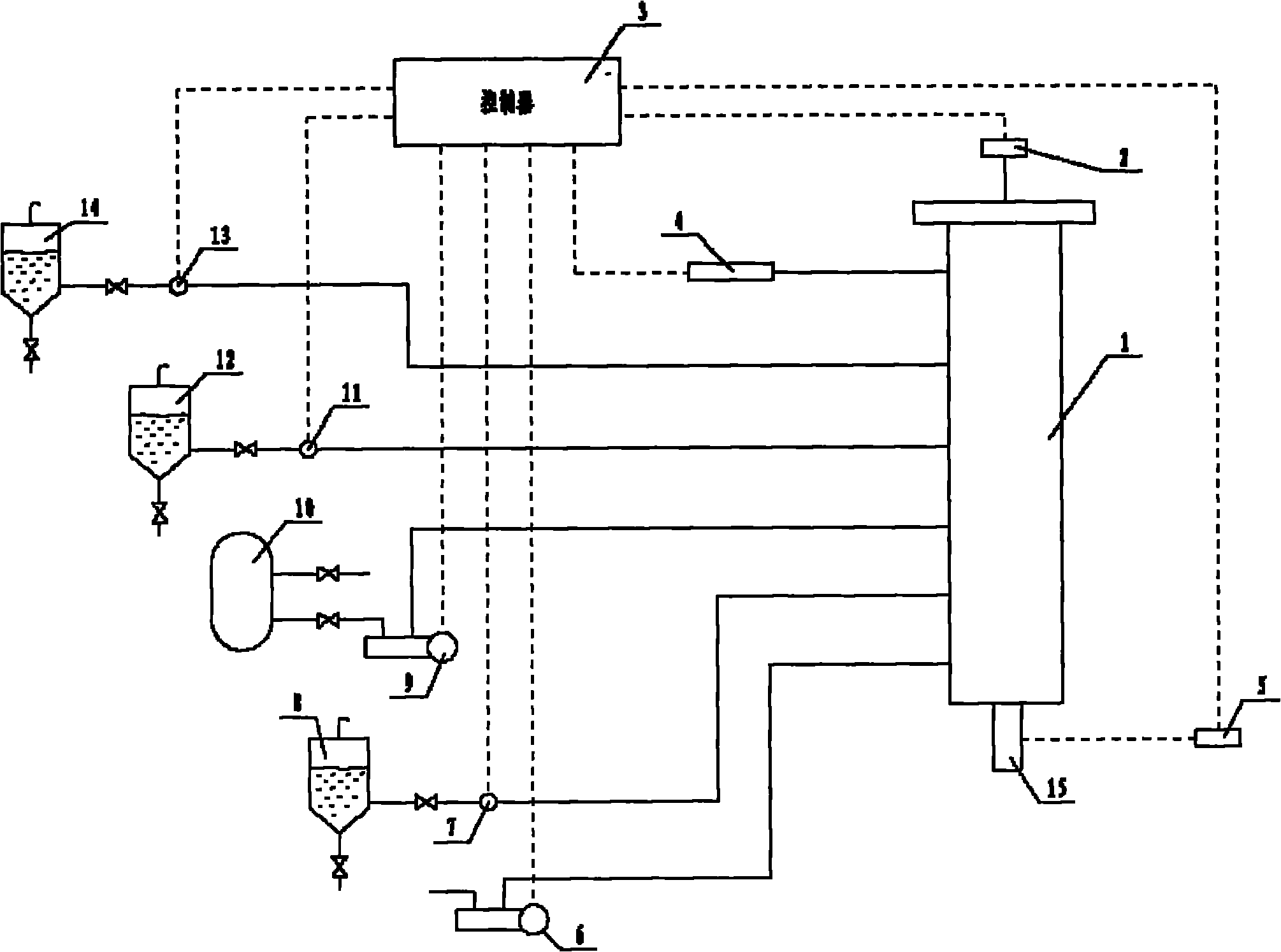

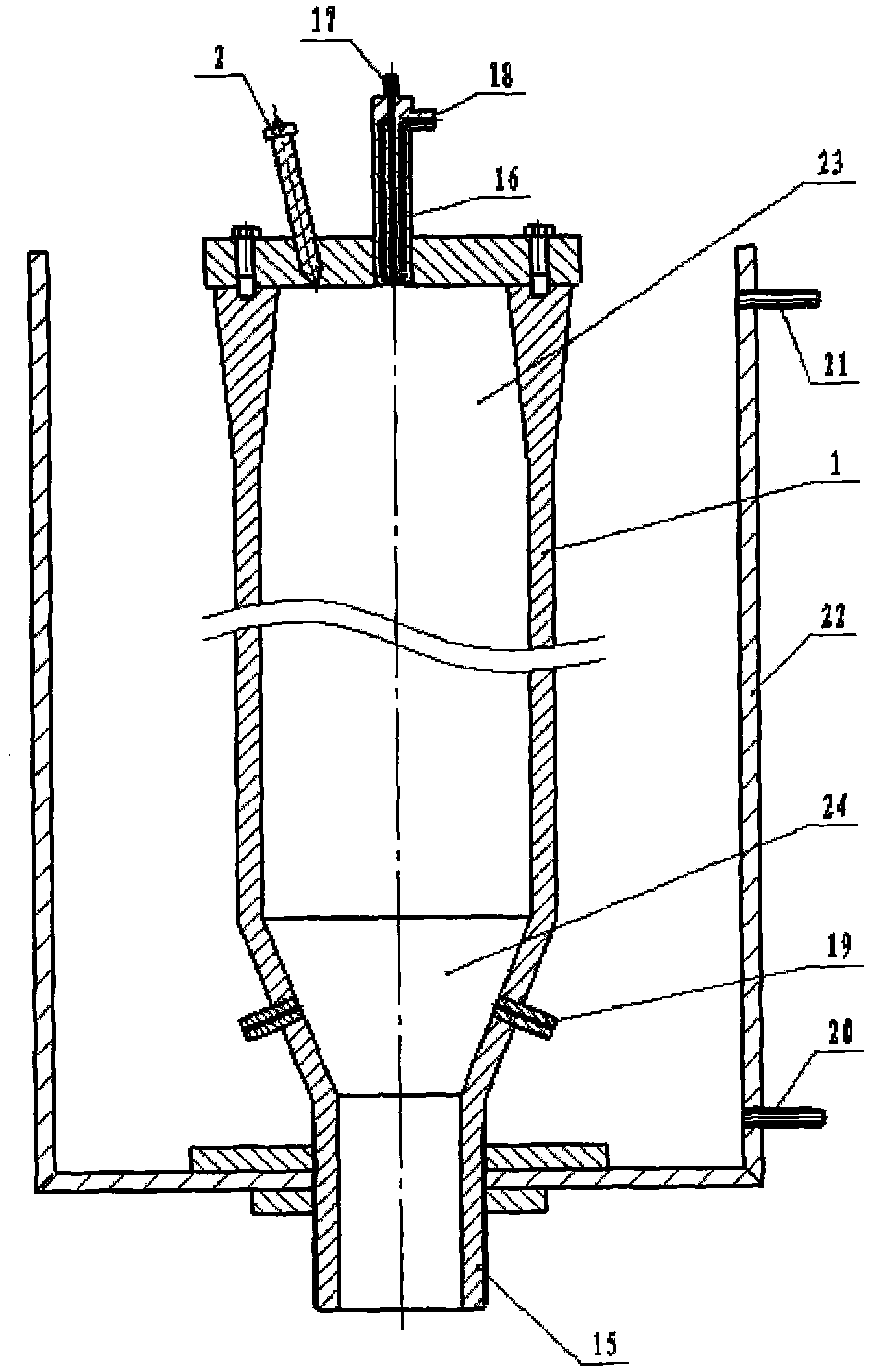

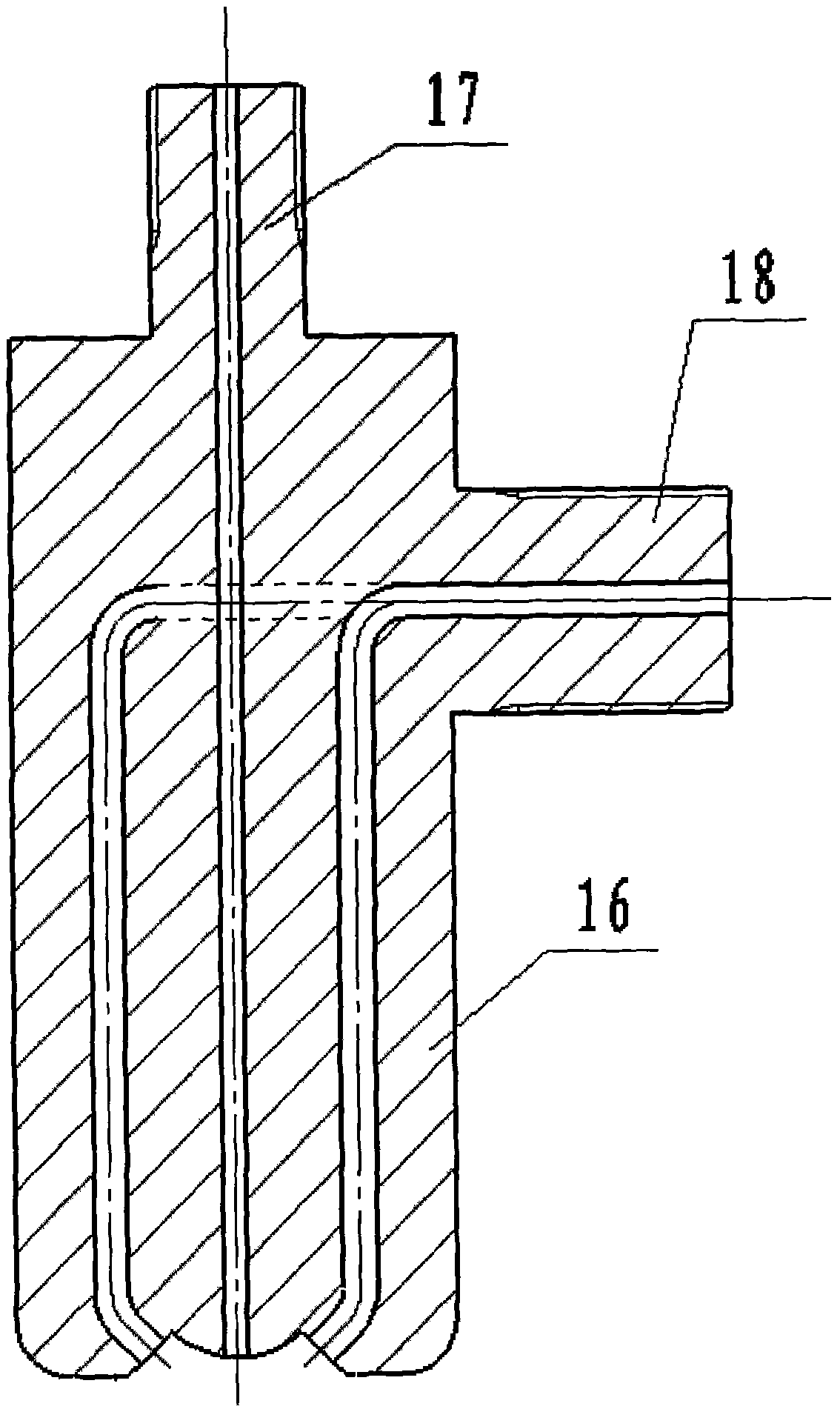

The invention discloses a paraffin removal device of an oil gathering pipeline. The paraffin removal device comprises a ball casting device (1), a medicine box (4), a measuring pump (5), an electromagnetic valve (3) and an intelligent control system (9), wherein the medicine box (4) is connected with the measuring pump (5) through a measuring pump medicine feeding pipe (8); the measuring pump (5) is connected with an oil pipe medicine feeding pipe (2) through the electromagnetic valve (3); the ball casting device (1) is arranged outside the medicine box (4) and is communicated with the oil pipe medicine feeding pipe (2); the intelligent control system (9) is in circuit connection with the ball casting device (1), the measuring pump (5) and the electromagnetic valve (3) respectively. According to the paraffin removal device, the functions of medicine feeding paraffin melting and ball casting paraffin removal are integrated on the same equipment, the paraffin removal capacity of the oil gathering pipeline is effectively improved, return pressure at a well opening can be effectively reduced, and production pollution and loss caused by ball casting plugging of the oil gathering pipeline are avoided.

Owner:PETROCHINA CO LTD

Gathering and transportation pipeline wax-removing intelligent ball and wax-removing method

The invention belongs to the field of oil gathering pipeline wax removal, and in particular relates to a gathering and transportation pipeline wax-removing intelligent ball and a wax-removing method, which are mainly applied to an automatic ball throwing device. The gathering and transportation pipeline wax-removing intelligent ball provided by the invention can automatically vibrate up and down when being blocked by wax to be detained under compulsion, and wax blocks are loosened or melted through vibration and heat generated by vibration, so that the wax removing and preventing effect is achieved; and the intelligent ball can spray a certain dose of wax-removing agent during vibration, so that the intelligent ball can directly reach to the blocking position through two approaches, the effective wax removing and preventing effect is achieved, and waste of the agent caused by the fact that the wax removing agent is added at the mouth of a well is avoided.

Owner:PETROCHINA CO LTD

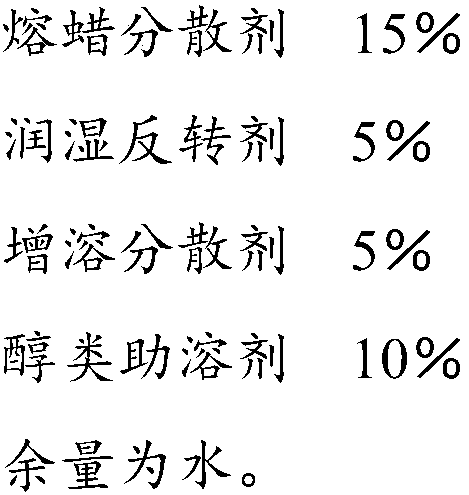

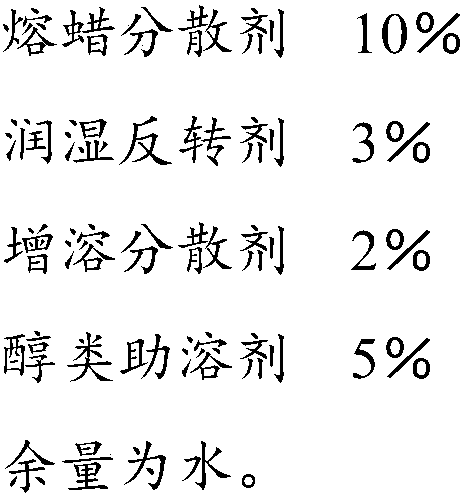

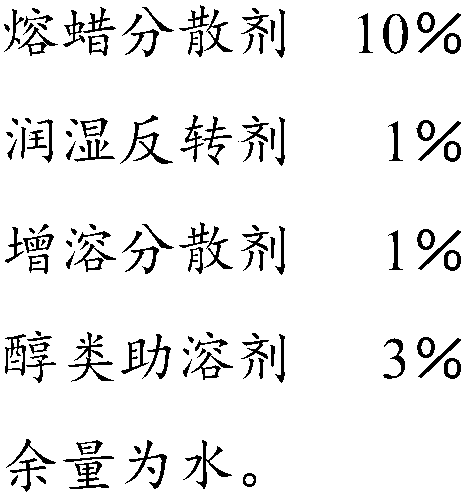

Water-based antiwax remover and preparation method thereof

The invention discloses a water-based antiwax remover and a preparation method thereof. The water-based antiwax remover consists of a wax melting dispersant, a reverse wetting agent, a solubilizationdispersant, an alcohol cosolvent and water or simulated salty water, wherein the wax melting dispersant, the reverse wetting agent, the solubilization dispersant and the alcohol cosolvent account for15-35% of the water-based antiwax remover. The preparation method of the water-based antiwax remover comprises the following steps: uniformly mixing the wax melting dispersant, the reverse wetting agent and the solubilization dispersant, adding the alcohol cosolvent, mixing, and adding the water or the simulated salty water, thereby obtaining the water-based antiwax remover. The invention relatesto the water-based antiwax remover and the preparation method thereof, the water-based antiwax remover is capable of both preventing and cleaning wax, and compared with a conventional emulsion-type antiwax remover, the water-based antiwax remover is relatively safe, efficient, odorless, free of pollution and high in flash point.

Owner:威海翔泽新材料科技有限公司

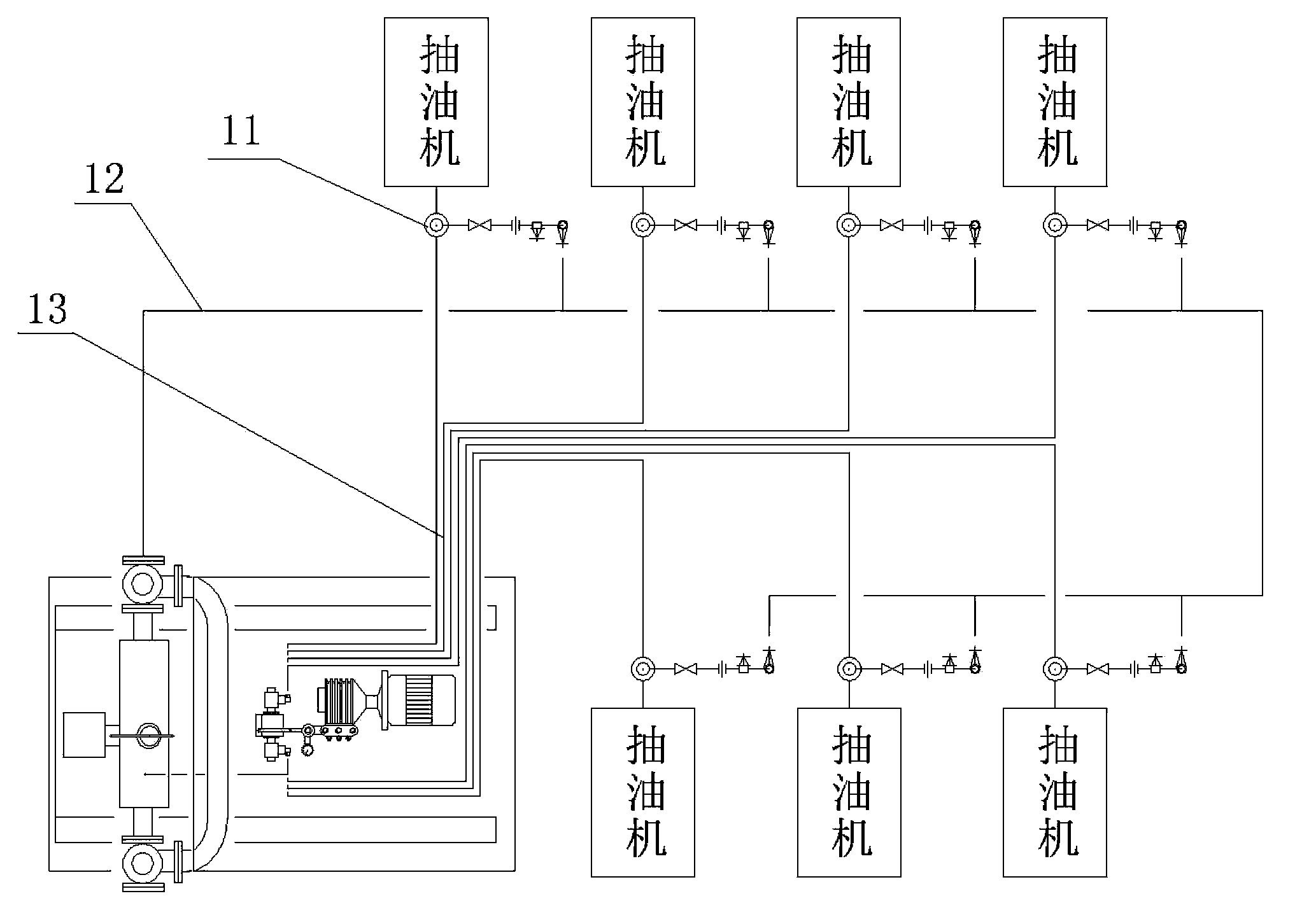

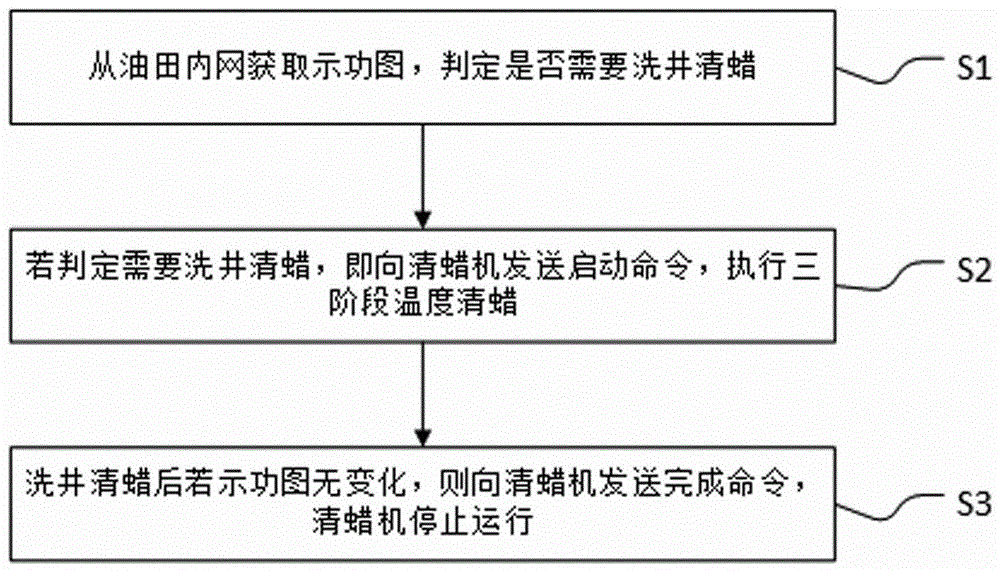

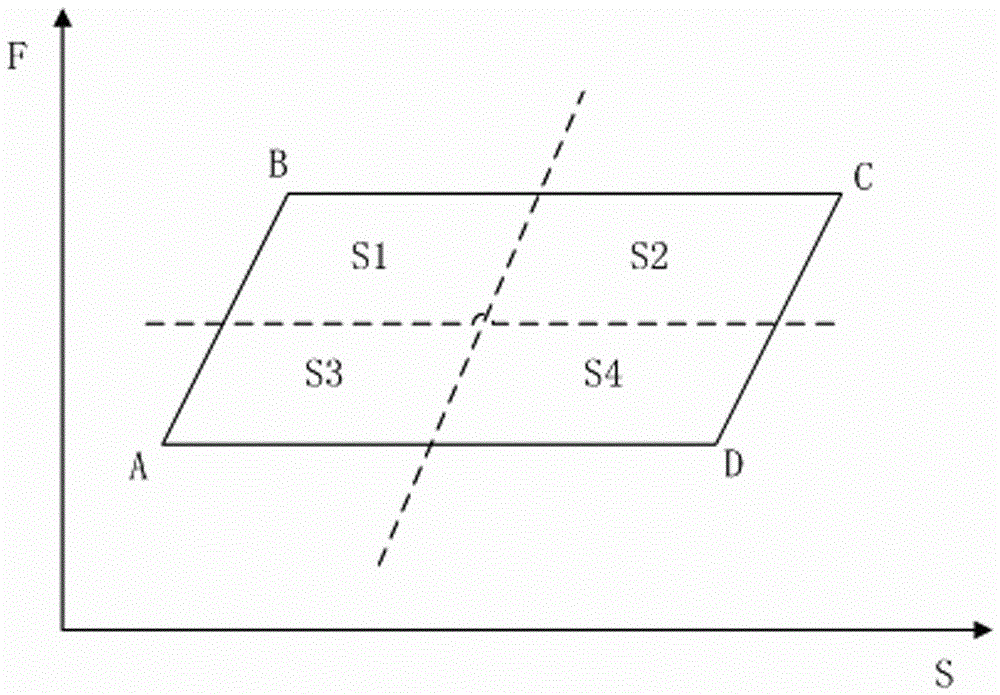

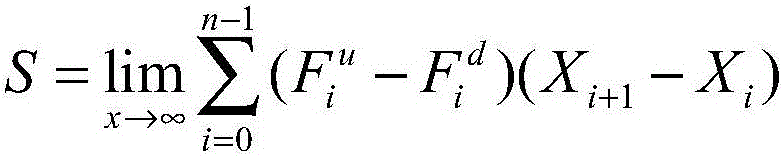

Method and system for intelligently thermally washing and removing paraffin by aid of internet of things

ActiveCN105735942ARealize intelligent controlHigh control precisionConstructionsCleaning apparatusWaxInformatization

The invention discloses a method and a system for intelligently thermally washing and removing paraffin by the aid of an internet of things. The method includes acquiring indicator diagrams from internal networks of oil fields and judging whether well flushing and paraffin removing are required or not; transmitting starting commands to paraffin removing machines if well flushing and paraffin removing are required and executing three-stage temperature paraffin removing; transmitting completion commands to the paraffin removing machines if the indicator diagrams are not changed after well flushing and paraffin removing are completely executed, stopping the paraffin removing machines from running, monitoring paraffin removing data and oil well data by the aid of the system in real time and feeding the paraffin removing data and the oil well data to intelligent paraffin removing network control platforms. The method and the system have the advantages that well flushing and paraffin removing can be intelligentized, processes are simple, obvious paraffin removing effects can be realized, and damage to oil wells due to the traditional paraffin removing modes can be prevented; intelligentization, informatization, the internet of things and big data processing technologies are applied, accordingly, paraffin removing equipment can be remotely digitally operated and monitored, oil well paraffin deposit can be warned, automatic paraffin removing and well flushing can be carried out according to well flushing strategies, and unattended operation can be implemented.

Owner:RENQIU NORTH CHINA OILFIELD RELIANCE IND

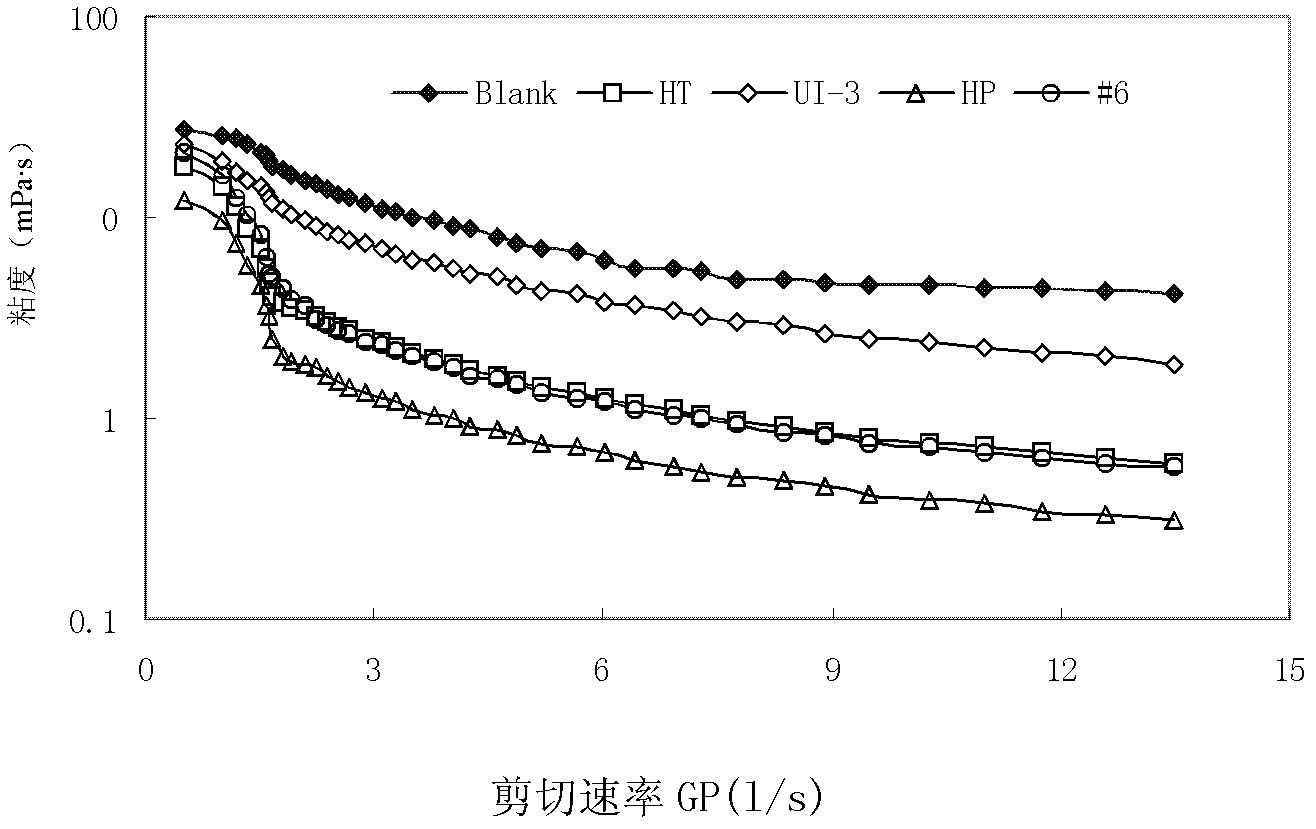

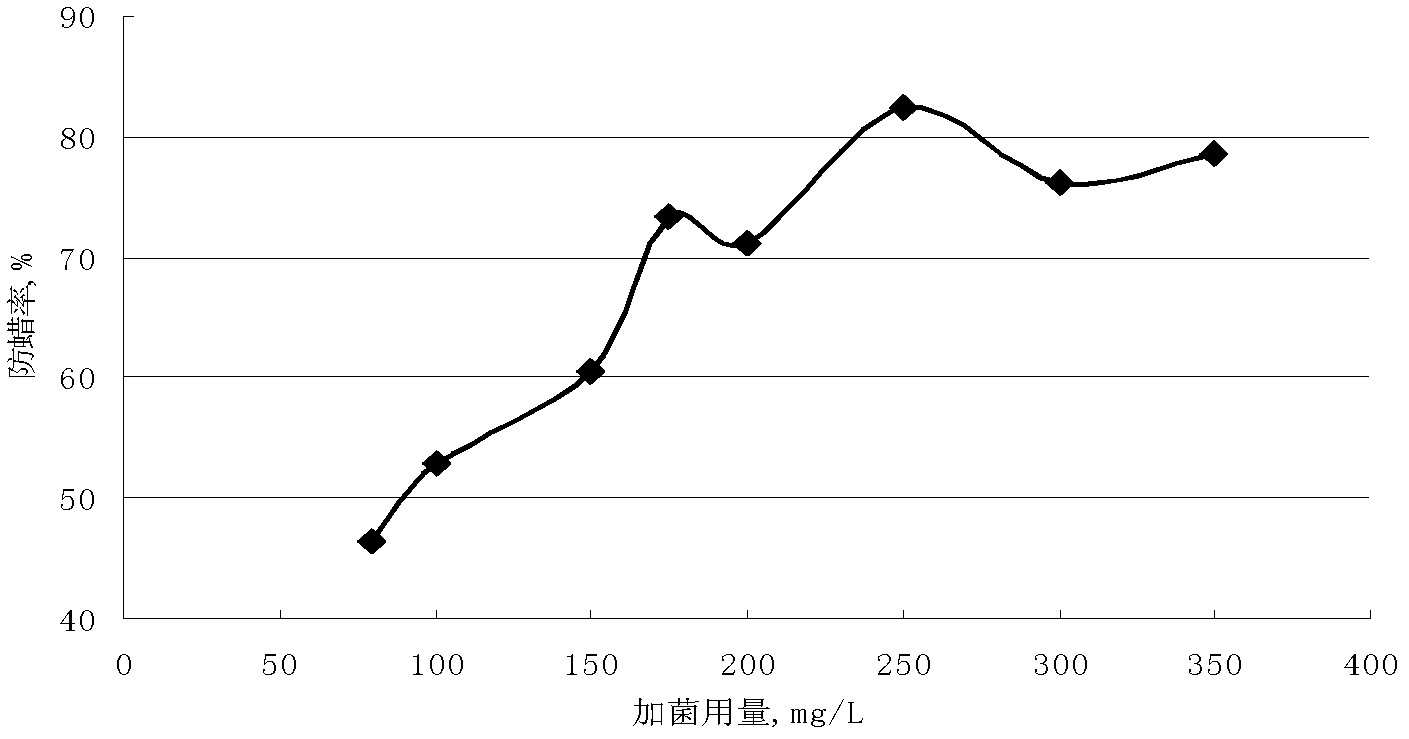

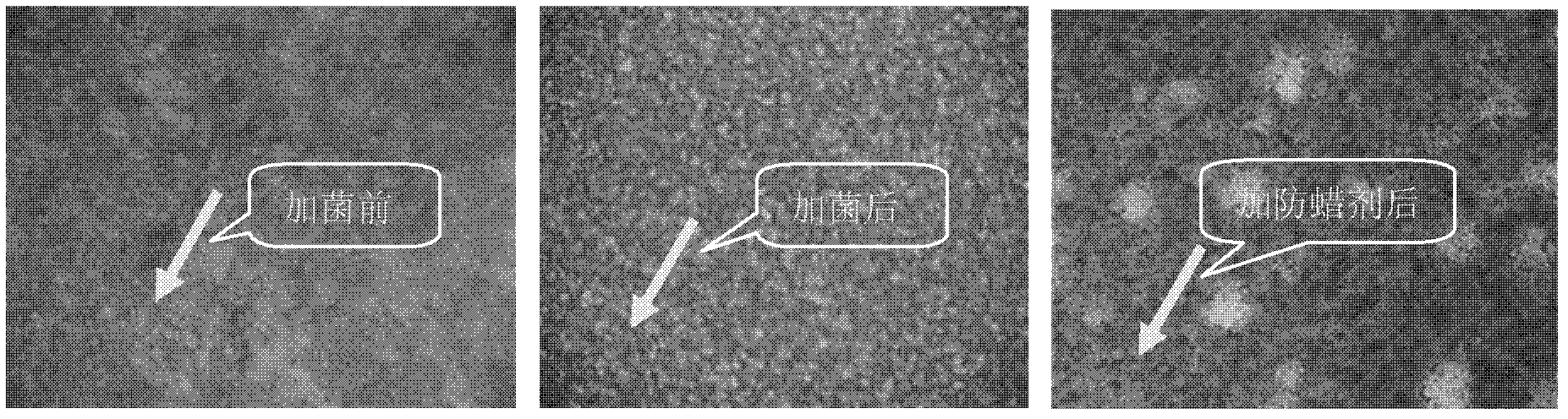

A kind of anti-wax agent and its application

ActiveCN102277318AImprove wax removal effectImprove liquidityBacteriaMicroorganism based processesWaxMicrobiology

The invention discloses a wax cleaning and preventing bacterial agent and use thereof. The bacterial agent is prepared by combining wax clearing bacteria HP and L-510 and wax preventing bacteria UI-3, HT, Po and No.6. Experiments prove that the bacterial agent has good wax clearing and preventing effects and that when the medicine concentration is higher than 100mg / L, the wax preventing rate reaches over 50 percent; and the results of wax cleaning and preventing experiments of 4 wells on site prove the effective rate of the bacterial agent reaches 100 percent, that the medicine administrationperiod is prolonged to 10 to 28 days from 5 days, that the construction process is simple, small in dose, low in cost, economic and efficient, that the application of the bacterial agent to waxed wells are wide, and that the bacterial agent is applicable to almost all waxed wells. The bacterial agent is expected to play a great role in cleaning and preventing wax in field of oil exploitation and has a bright prospect.

Owner:PETROCHINA CO LTD +1

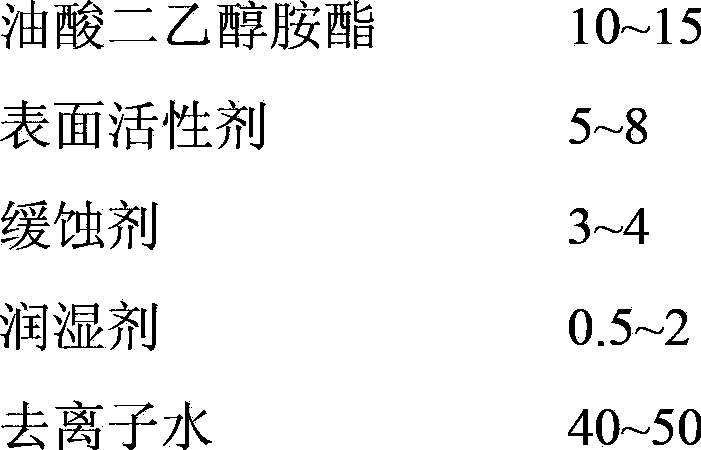

Industrial dewaxing agent

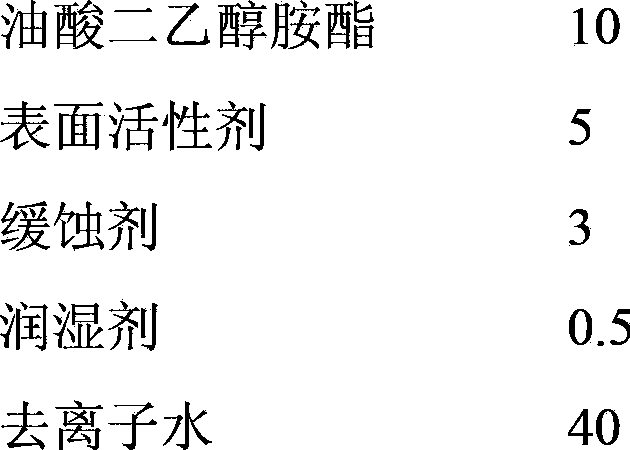

The invention provides an industrial dewaxing agent. The industrial dewaxing agent is prepared by dissolving oleic acid diethanolamine ester, a surfactant, a corrosion inhibiter and a wetting agent in deionized water and then uniformly mixing. The industrial dewaxing agent consists of the following ingredients in parts by mass: 10-15 parts of oleic acid diethanolamine ester, 5-8 parts of the surfactant, 3-4 parts of the corrosion inhibiter and 40-50 parts of deionized water, wherein the oleic acid diethanolamine ester is a reaction product of oleic acid and diethanolamine according to the molar ratio of 1:2; the surfactant comprises span 20, span 60, span 80, tween 40 and tween 60; the corrosion inhibiter is one of benzotriazole, petroleum sulfonate and alpha-hydroxybenzotriazole.

Owner:季爱英

Wax remover used for metal polishing part and preparation process thereof

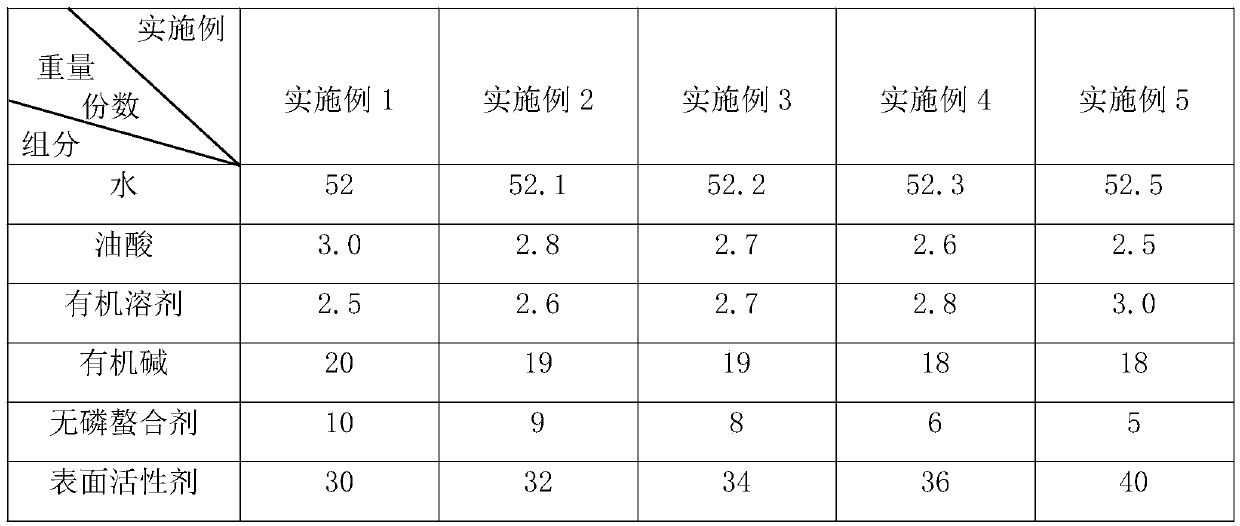

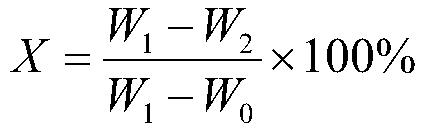

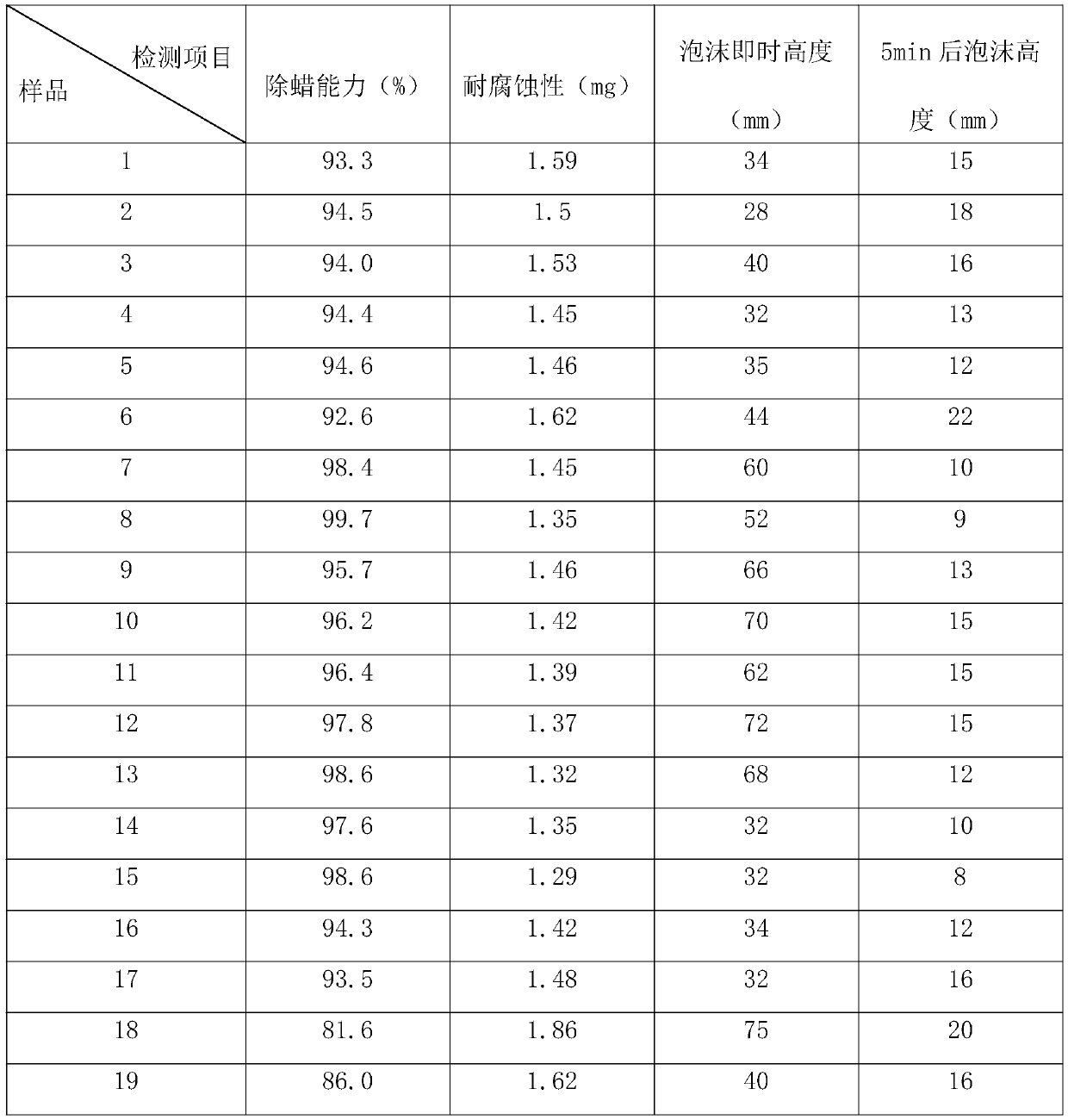

The invention discloses a wax remover used for a metal polishing part and a preparation process thereof, and relates to the technical field of metal cleaning agents. According to the technical scheme,the key point is that the wax remover used for the metal polishing part comprises the following components in parts by weight: 52-52.5 parts of water, 2.5-3.0 parts of oleic acid, 2.5-3.0 parts of anorganic solvent, 18.0-20.0 parts of organic alkaline, 5.0-10.0 parts of a non-phosphorus chelating agent and 30-40 parts of a surfactant, wherein the surfactant is compounded from polyether modifiedpolysiloxane and heterogeneous alcohol oleic acid soap. The wax remover disclosed by the invention has the advantages of good wax removal effect, high safety and environment friendliness.

Owner:厦门普诺尔新材料科技有限公司

Dewaxing fluid for cleaning metal product

The invention relates to a dewaxing fluid for cleaning a metal product. The dewaxing fluid comprises, by weight, 18-25 parts of coconut diethanol amide phosphate, 5-10 parts of sodium dodecyl sulfate, 3-6 parts of fatty alcohol polyoxyethylene ether, 5-8 parts of citric acid, 1-3 parts of nonylphenol polyoxyethylene ether, 10-15 parts of stearic acid, 15-20 parts of oleic acid and the balance water. The dewaxing fluid has the advantages of less use amount, excellent dewaxing effects and high stability.

Owner:WUXI QIBAO CLEANING AGENT CO LTD

Efficient oil well paraffin remover

InactiveCN109897617AIncrease hydrationImprove the lubrication effectDrilling compositionWaxBlock structure

The invention discloses an efficient oil well paraffin remover, and belongs to the technical field of oilfield exploitation. Hydrophilic components such as mercaptoethanol are led in and matched to form a water protective film, hydration and lubrication properties of oil paraffin are improved, paraffin dispersion effects are improved, entanglement among a hole structure formed in the preparation process and components such as composite paraffin removal basic materials and composite accessories is achieved, affinity effects on the paraffin in using is improved, and paraffin removal effects areimproved. Added phospholipid has good emulsification functions, so that polar groups in components can extend into the paraffin, phospholipid molecules have more negative charges, local charges can beunbalanced and excluded each other, a blocking structure formed by paraffin accumulation in an oil well is broken, an open area cannot be reduced, an oil pipe cannot be blocked by the paraffin, and dredging effects are improved. The paraffin remover solves the problems that a current frequently-used paraffin remover has low liquidity at low temperature, paraffin remover speed is low, the open area is reduced, and the oil pipe is blocked by the paraffin.

Owner:杭州攻守道贸易有限公司

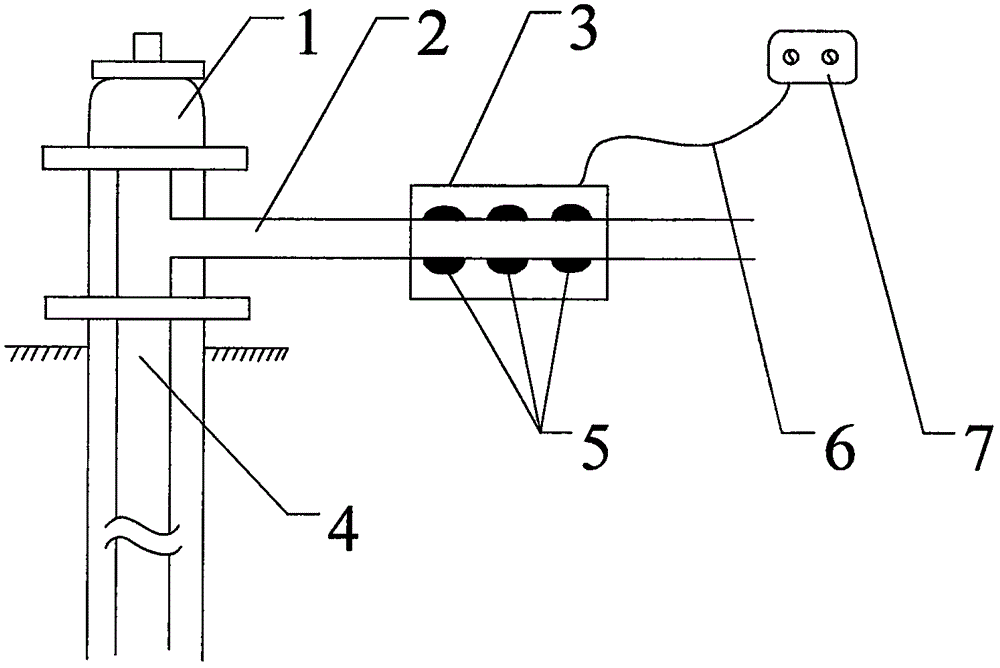

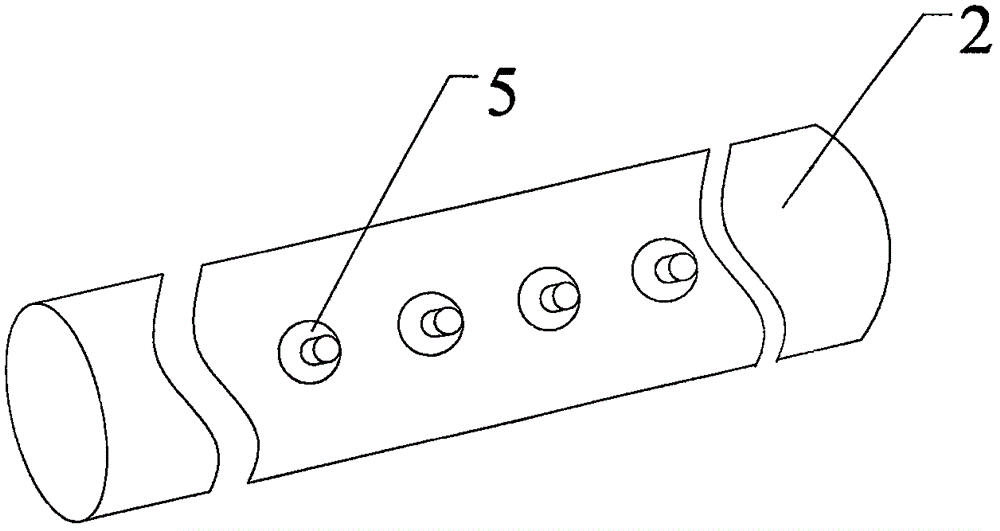

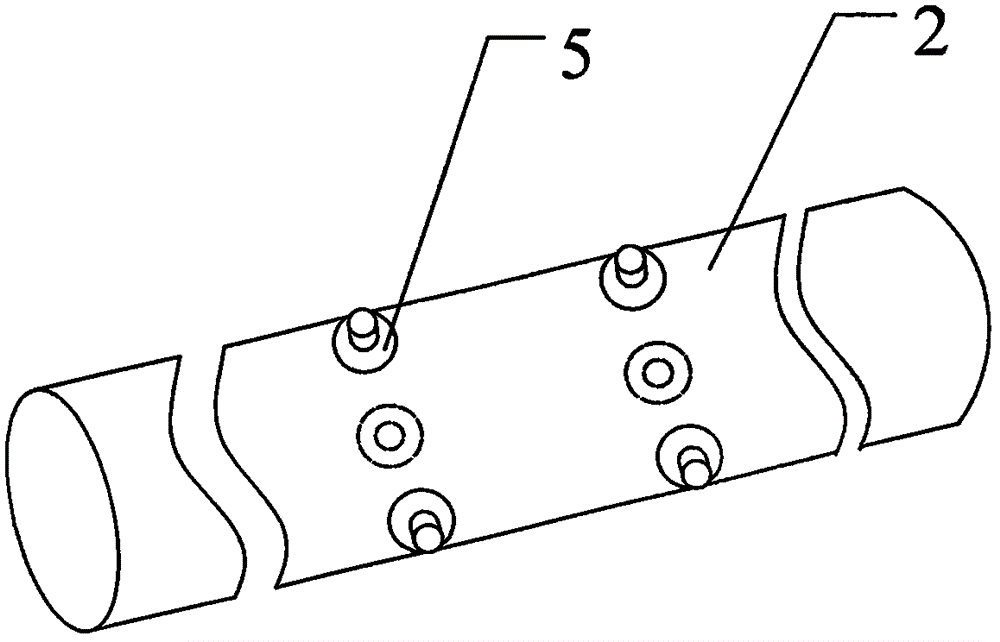

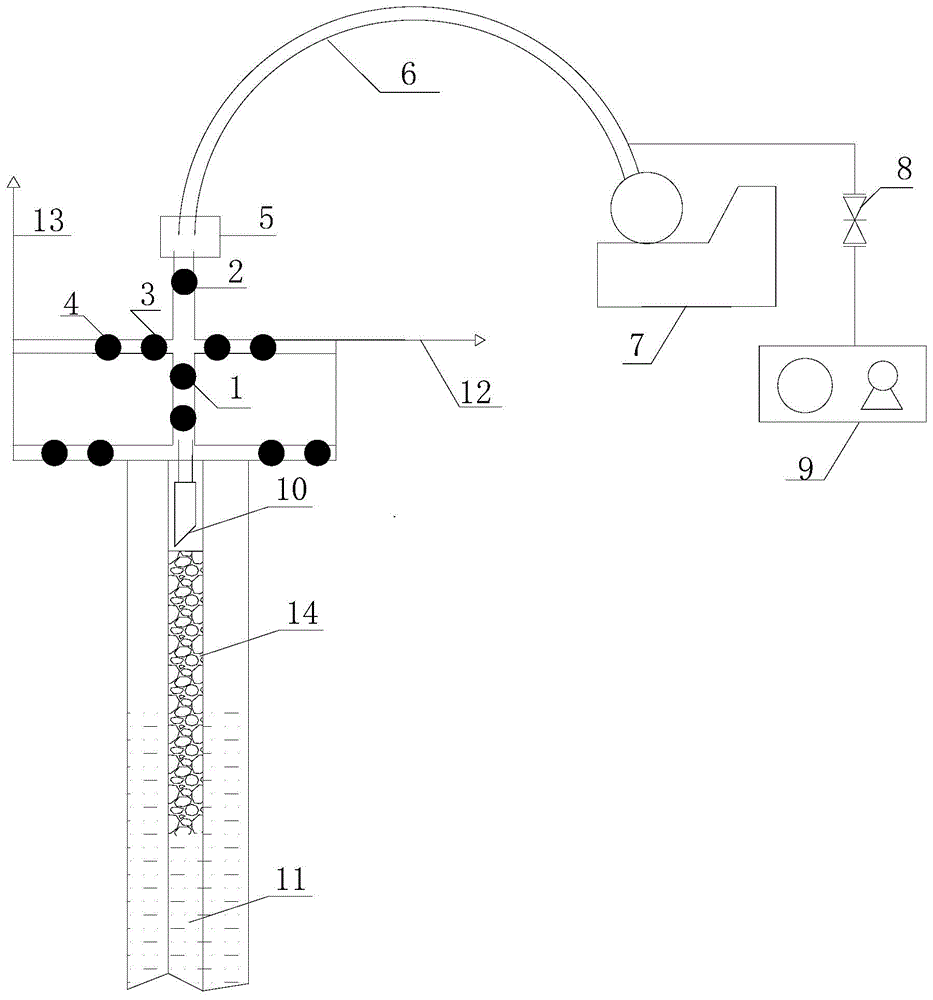

Array type ultrasonic vibration oil well paraffin removal & control device

InactiveCN106351609ASimple structureEasy to useCleaning apparatusVibration devicesParaffin oilsEngineering

The invention discloses an array type ultrasonic vibration oil well paraffin removal & control device which comprises an ultrasonic signal generator, an explosion-proof cable, an ultrasonic transducer, and a protective housing. The array type ultrasonic vibration oil well paraffin removal & control device is characterized in that: the ultrasonic signal generator is connected with the ultrasonic transducer through the explosion-proof cable; the protective housing is arranged outside the ultrasonic transducer; the ultrasonic transducer is fixedly connected to the external wall of the outlet pipe of the oil well; distance between the ultrasonic transducers is an integral multiple of the wavelength thereof; the ultrasonic transducers are arranged in an array type on the external wall of the outlet pipe of the oil well. The array type ultrasonic vibration oil well paraffin removal & control device with the mentioned structure has the advantages of a simple structure, simple use method, good paraffin removal & control effects, and strong suitability, and can be used conveniently and effectively for paraffin removal and control in oil wells.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

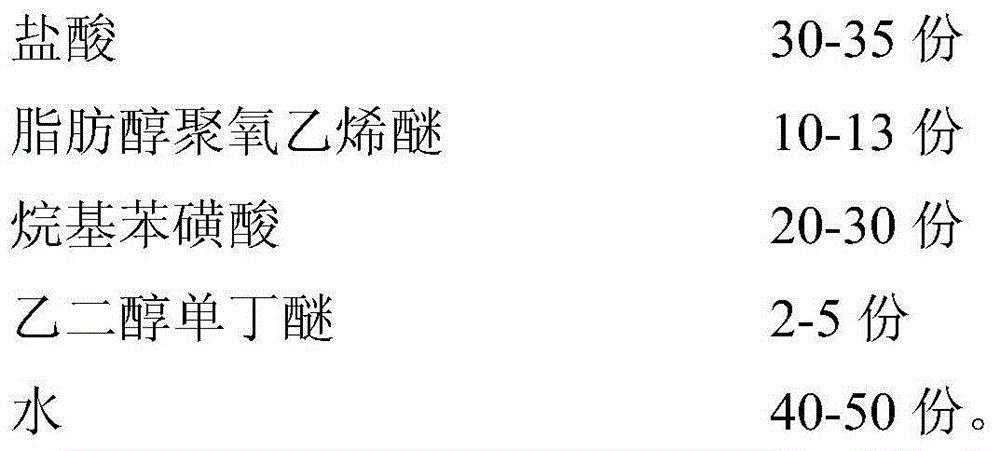

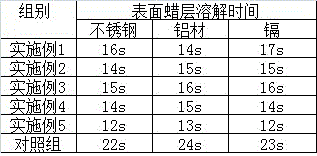

Novel aluminum product wax removing agent and preparation method thereof

The invention proposes a novel aluminum product wax removing agent. The novel aluminum product wax removing agent comprises the following components in parts by weight: 20-47 parts of hydrochloric acid, 5-20 parts of fatty alcohol-polyoxyethylene ether, 10-30 parts of alkyl benzene sulfonic acid, 1-5 parts of ethylene glycol monobutyl ether and 15-90 parts of water. The novel aluminum product wax removing agent is acid liquid, is prominent in wax removing effect and quick in wax removing speed, can effectively remove polishing paste, polishing wax, oil, dirt and natural oxide films on surfaces of aluminum products, and is free of harm to the aluminum products.

Owner:夏良文 +1

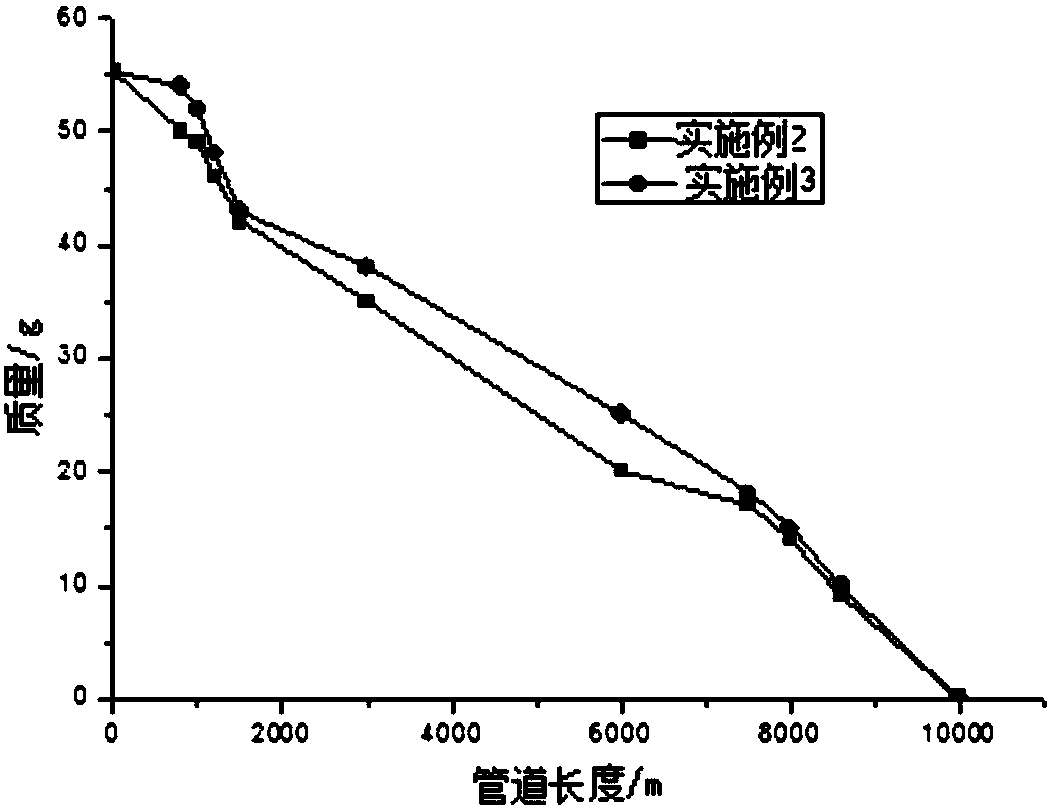

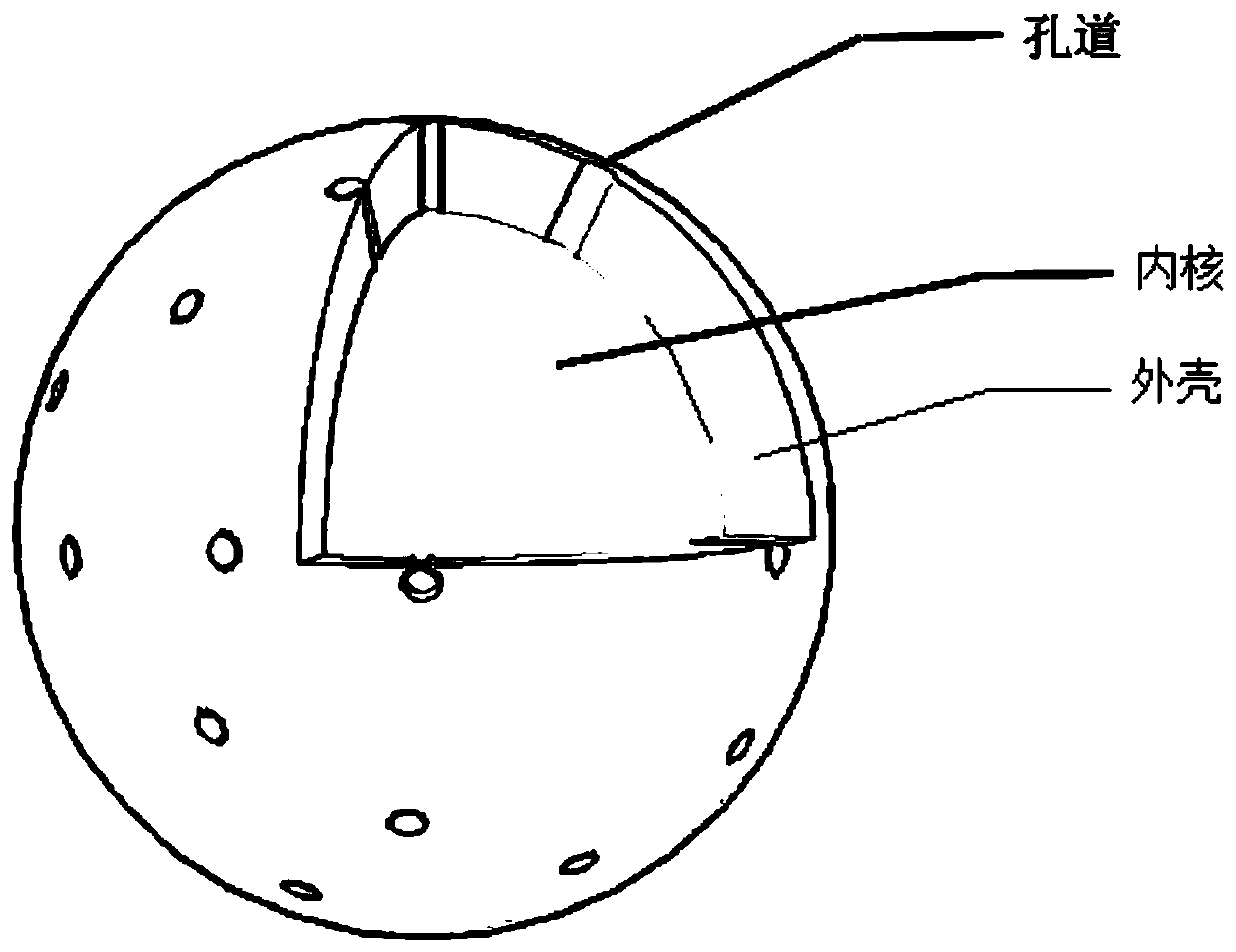

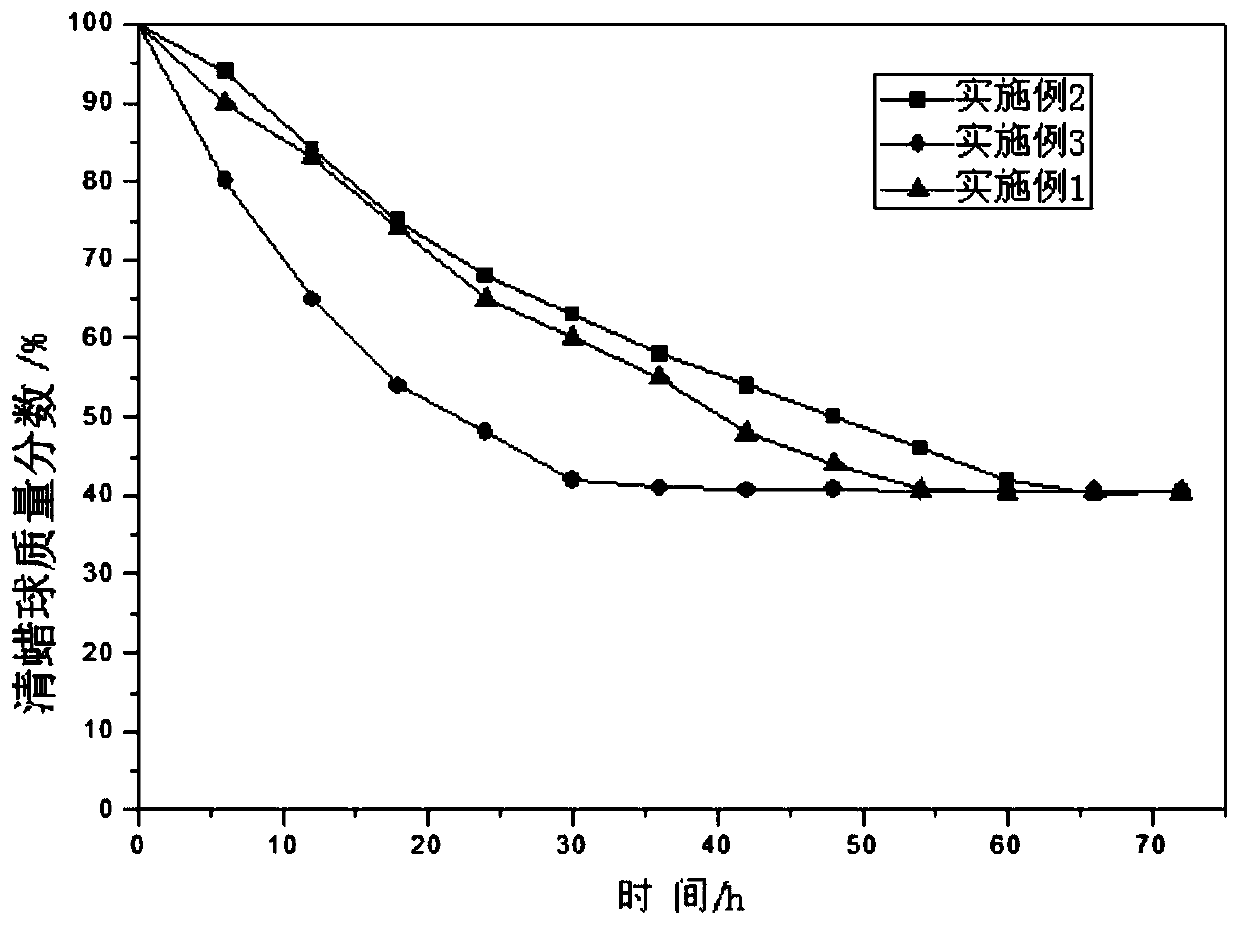

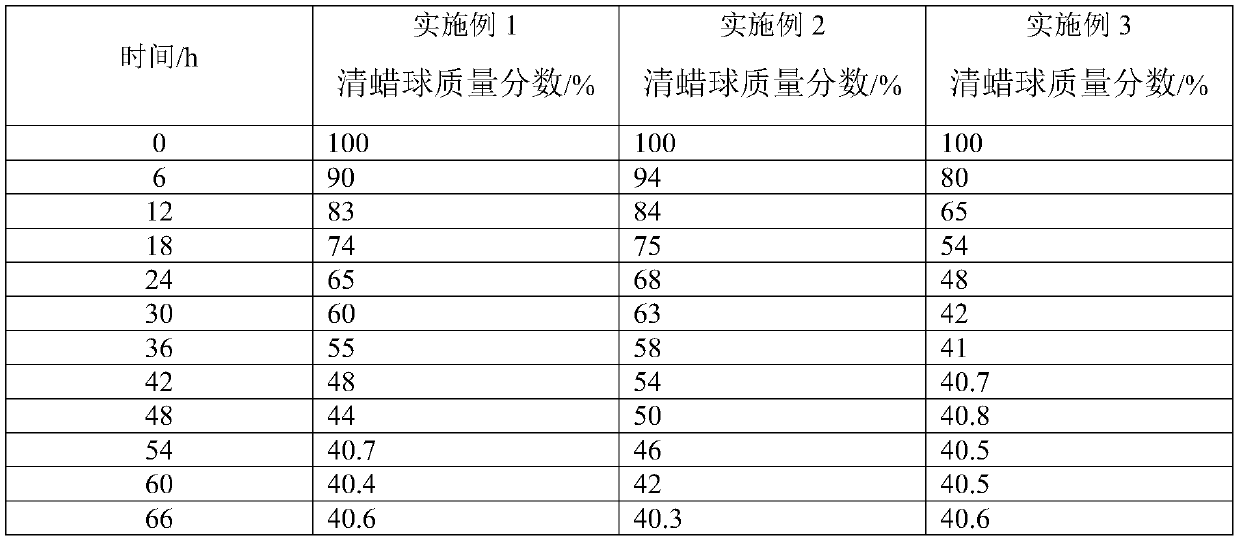

Embedded-type chemical wax removing ball as well as preparation method and application thereof

InactiveCN109868127AImprove mechanical propertiesImprove wax removal effectPipeline systemsDrilling compositionWaxChemistry

The invention provides an embedded-type chemical wax removing ball as well as a preparation method and application thereof. The wax removing ball comprises an inner core prepared from an anti-wax agent and an outer shell prepared from EVA, and the outer shell is provided with a plurality of through holes in a radial direction; the anti-wax agent comprises sodium stearate, sodium benzoate, a geminisurfactant and sodium laurate; and the wax removing ball comprises the following components, in parts by mass: 40-50 parts of the EVA, 35-40 parts of the sodium stearate, 3-8 parts of a preservative,5-8 parts of the sodium laurate and 4-5 parts of the gemini surfactant. According to the wax removing ball provided by the invention, the EVA outer shell has the mainly effects of increasing the mechanical properties of the wax removing ball, and has a physical wax removing effect; the outer shell of the wax removing ball is provided with the plurality of through holes in the radial direction, the through holes are only channels of connection between the outside and the anti-wax agent in the wax removing ball, and when the wax removing ball flows in oil transmission pipelines, the anti-wax agent is released through the pipelines to play a chemical anti-wax effect.

Owner:XI'AN PETROLEUM UNIVERSITY

Device for removing paraffin and washing well by gas heat carrier

InactiveCN101858205ADoes not affect productivityDoes not affect other jobsCleaning apparatusInsulationGas analysisHeat carrier

The invention provides a device for removing paraffin and washing well. The device comprises a high-temperature gas generator, and an air compressor, a high-pressure fuel injection pump, a gas analysis system, a high-pressure fuel injection pump, a gasification water injection pump and a cooling water pump which are controlled by a controller, wherein the high-temperature gas generator comprises a cylinder block, a cooling water tank, an air-fuel mixer, a compressed air inlet, a cooling water inlet, a cooling water outlet, an igniter, a combustion chamber, a gasification blending chamber, a gasification water injection inlet and a high-temperature gas spout formed at the lower end of the gasification blending chamber. The device has the advantages of capability of burning diesel oil and accompanying natural gas generated by burning oil wells directly, environmental protection, energy conservation, low operation cost, convenient fuel sources, small volume, light weight, flexibility andconvenience, and excellent application prospect in the aspects of paraffin removal and dirt washing of the oil wells.

Owner:辽阳华路催化技术研发有限公司

Environment-friendly wax removing agent

InactiveCN104031754ANon-irritatingImprove wax removal effectNon-ionic surface-active compoundsDetergent compounding agentsWaxSulfate

The invention relates to the technical field of daily chemicals, and particularly relates to an environment-friendly wax removing agent. The wax removing agent is composed of the following materials in parts by weight: 5-10 percent of sodium citrate, 1-3 percent of polyether sulfate, 1-3 percent of iso-tridecyl alcohol polyoxyethylene ether, 1-3 percent of oleic acid and 60-80 percent of deionized water. The invention aims at providing a safe and environment-friendly wax removing agent which is convenient to use.

Owner:梁晓

Long-distance pipeline wax-cleaning agent and wax-cleaning conveying technology method

ActiveCN103421625AEasy operating conditionsImprove wax removal effectHollow article cleaningNon-surface-active detergent solventsSolventWax

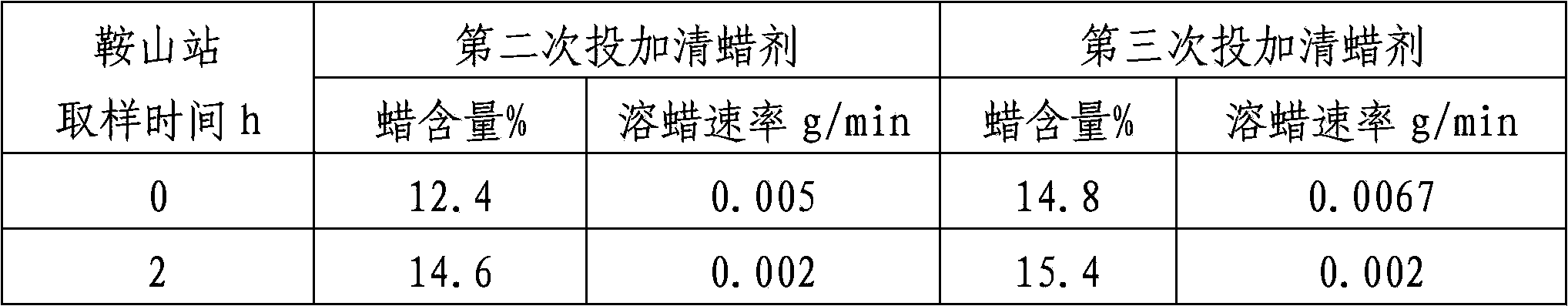

The invention discloses a long-distance pipeline wax-cleaning agent and a wax-cleaning conveying technology method. The wax-cleaning agent is prepared by complex formulation of crude oil, 0 # diesel oil and solvent oil 90 #, wherein the crude oil comprises lower than 6% of wax and has a solubility parameter of 7.0-8.0, and the weight ratio of crude oil: 0 # diesel oil: solvent oil 90 # is 6-8:3-1:1. The wax-cleaning conveying technology method comprises the following steps: 1) estimating the effective volume of a pipeline for wax cleaning; 2) mixing the 0 # diesel oil and the solvent oil 90 # in a weight ratio of 3-1:1, and then mixing the crude oil and a diesel oil and solvent oil mixed solution in a weight ratio of 6-8:1; 3) heating to enable the output temperature to be 50-70 DEG C; 4) pumping a wax-cleaning agent mixed solution into the pipeline from a first station in three times with the dosage for each time being the effective pipeline volume, when oil head arrives a terminal station, testing the wax content of the wax-cleaning agent, and stopping pipeline conveying for 3 days; 5) in sixth and ninth day later, repeating the steps of 2) to 4), and performing the second and third addition of the wax cleaning agent, testing the wax content of the wax-cleaning agent at the terminal station in every 2 hours, and calculating the wax dissolving rate; and 6) outputting from the terminal station.

Owner:PIPECHINA SOUTH CHINA CO

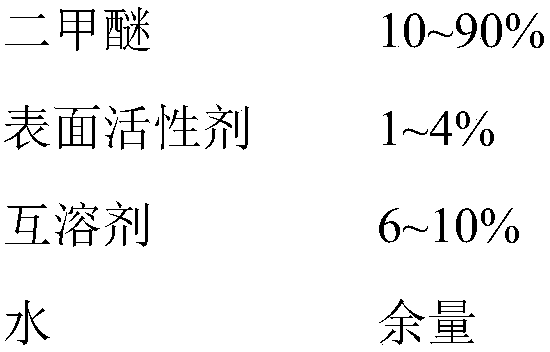

Novel paraffin remover having recycling ability and preparation and recycling method thereof

The invention relates to a chemical product used in an oil field, and provides a novel paraffin remover having recycling ability and a preparation and a recycling method thereof. The novel paraffin remover comprises the following components by mass percentage: 10 to 90% of a main component dimethyl ether, 6 to 10% of a mutual solvent, 1-4% of a surfactant, and the balance is water. The invention also provides the preparation and the recycling method thereof. The paraffin remover has the advantages that the main component and water are mixed and dissolved in any ratio when the mutual solvent content is 6% or more, and complex formulation is carried out according to the requirements; the paraffin remover has the characteristics of recycling and reusing; the dissolving performance is excellent; the paraffin remover is a benzene-free organic solvent, which is green and non-toxic; the paraffin remover has certain paraffin inhibition effect while paraffin removing, and is suitable for oil wells with different salinity, temperatures and oil sample density; and the product is neutral and does not corrode oil pipes.

Owner:SOUTHWEST PETROLEUM UNIV

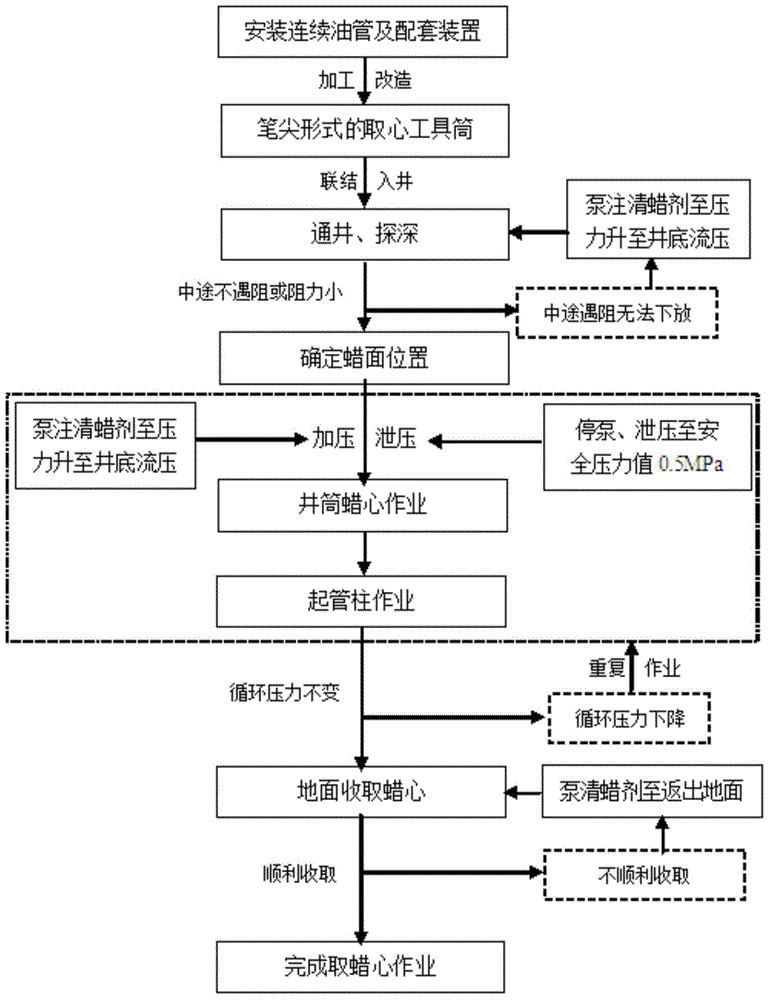

Novel coring and paraffin-removing method for coiled tubing in low-pressure low-yield oil-gas well

ActiveCN104948137AGuide follow-up productionMake up for low pressure (≤5.0MPa)Cleaning apparatusWaxAlcohol

The invention provides a novel coring and paraffin-removing method for coiled tubing in a low-pressure low-yield oil-gas well. The method includes the steps of modifying the tail end of the coiled tubing into a coring tool in the form of a 45 degrees angled nib; connecting parts, slowly putting the coiled tubing and the coring tool in the well, and performing coring and paraffin removal; observing interior pressure of the coiled tubing, and if the interior pressure is stable, slowly lifting up the coiled tubing and the coring tool to the surface; after lifting the coiled tubing and the coring tool to the surface, building the pressure with an alcohol injection pump or through residual pressure in the coiled tubing, and collecting a paraffin core. According to the technical features of mechanical paraffin removal and chemical paraffin removal and to the principle of drilling coring, the coring and wax-removing method combining paraffin remover injection by pumping and the coiled tubing is used; the problem that paraffin blockage under low pressure and low yield is better solved, the blocking paraffin in the tubing is cleared, a paraffin-removing profile of a shaft is established, and following production of the oil-gas well is better guided.

Owner:CHINA PETROLEUM & CHEM CORP +1

Nanometer paraffin removal and inhibition agent for high-water content oil product

InactiveCN105086974AExtend hot wash cycleLow viscosityDrilling compositionThermal insulationDissolution

The invention discloses a nanometer paraffin removal and inhibition agent for a high-water content oil product. A preparation method of the nanometer paraffin removal and inhibition agent comprises selecting an appropriate traditional paraffin removal and inhibition agent, selecting an appropriate nano-material, determining a mixing ratio of the paraffin removal and inhibition agent to the nano-material, processing the materials to form axiolitic or cylindrical particles or carrying out refrigeration crushing to obtain powder, selecting an appropriate dispersant, cosolvent and stabilizing agent, carrying out heating dissolution to obtain a uniform solution, transporting the solution to a place, and in necessity, forming a high-liquidity uniform liquid by heating and thermal insulation. The nanometer paraffin removal and inhibition agent can reduce a wax precipitation point of oil wells, gas wells and gathering and transportation pipes with high water content and reduces oil product viscosity and condensation point. When the addition amount is higher than a certain value (ppm), paraffin inhibition efficiency is generally 40% or more and paraffin removal effects are obvious. The nanometer paraffin removal and inhibition agent can prolong an oil well hot washing period, has effects of demulsification and viscosity reduction, and can be used as a well washing solution and a viscosity reducer.

Owner:BEIJING LANDY GREAT EXPLOIT SCI & TECH DEV

Environment-friendly type wax removal agent and preparation method thereof

InactiveCN106434012AEfficient removalEasy to useInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSalicylic acidFatty alcohol

The invention discloses an environment-friendly type wax removal agent and a preparation method thereof. The environment-friendly type wax removal agent is prepared from the following raw materials in parts by weight: 40 to 52 parts of polyacrylamide, 16 to 28 parts of fatty alcohol-polyoxyethylene ether, 10 to 16 parts of sodium citrate, 12 to 18 parts of cocoanut oil diethan olamide, 14 to 20 parts of ethyl alcohol, 15 to 21 parts of calcium carbonate, 8 to 14 parts of salicylic acid, 3 to 9 parts of glyceryl laurate, 6 to 12 parts of gleditsia sinensis extracting liquid, 4 to 10 parts of syzygium aromaticum extracting liquid, 2 to 8 parts of penetrant, and 1 to 7 parts of defoaming agent, wherein the defoaming agent is a mixture of tributyl phosphate and organic silicon. The environment-friendly type wax removal agent has the advantages that the wax removal effect is obvious, the wax removal speed is high, the polishing cream, polishing wax, oil, dirt and the like on the surface of the material are effectively removed, the harm to material is avoided, and the corrosion to metal is avoided; by adding natural extracts of gleditsia sinensis and syzygium aromaticum, the dirt removal effect of the wax removal agent is improved, the poison and irritation are avoided, and the safety, environment-friendly and pollution-free effects are realized when the wax removal agent is used; the preparation method is simple, is suitable for industrialized production, and has great popularizing meaning.

Owner:肇庆市高新区创客科技有限公司

Environment-friendly wax removing agents and preparation method thereof

The invention discloses environment-friendly wax removing agents and a preparation method thereof. The environment-friendly wax removing agents comprise, by weight, 50-60 parts of polyacrylamide, 6-11 parts of diglycidyl ether, 6-8 parts of ethylenediaminetetraacetic acid Tetrasodium, 5-8 parts of isocaprylic acid glycidyl ether, 4-6 parts of boron silicic acid, 3-6 parts of tween, 2-4 parts of metasilicic acid trimethy phosphate, 1-3 parts of glyceryl laurate and 1-2 parts of sodium citrate. The invention further provides the preparation method for the environment-friendly wax removing agents.

Owner:苏州书瑞环保科技有限公司

Wax clearing agent, preparation method and applications thereof

The invention provides a wax clearing agent, a preparation method and applications thereof, wherein the wax clearing agent comprises, by weight, 0.1-3% of an ethylene-vinyl acetate copolymer, 1-2% ofdichloroethane, 0.5-0.8% of polyacrylate, 1-2% of styrene, 0.1-0.5% of a dispersant, 0.1-0.3% of a penetrant, 0.1-1% of a pour point depressant, and the balance of C9 aromatic hydrocarbons. In the prior art, the clogging of the ultra-deep condensate gas well is difficult to clear. According to the present invention, the wax clearing agent is used for solving the technical defect in the prior art.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com