Metal cleaning agent added with functional modified graphene and preparing method of metal cleaning agent

A metal cleaning agent and graphene technology, applied in the field of metal cleaning agents, can solve problems such as high cost, incomplete cleaning, complex formula, etc., and achieve the effects of reducing surface tension, good wax removal effect, and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

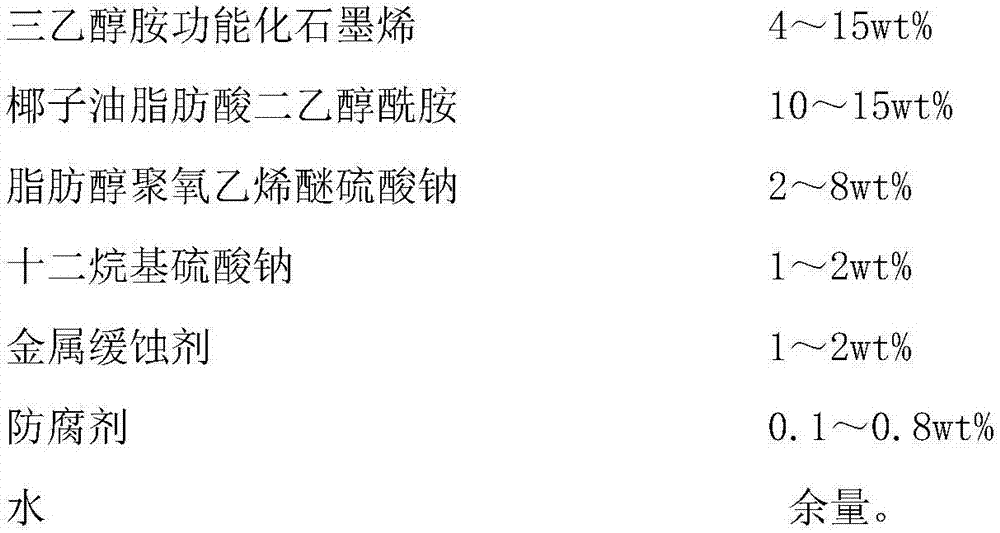

Method used

Image

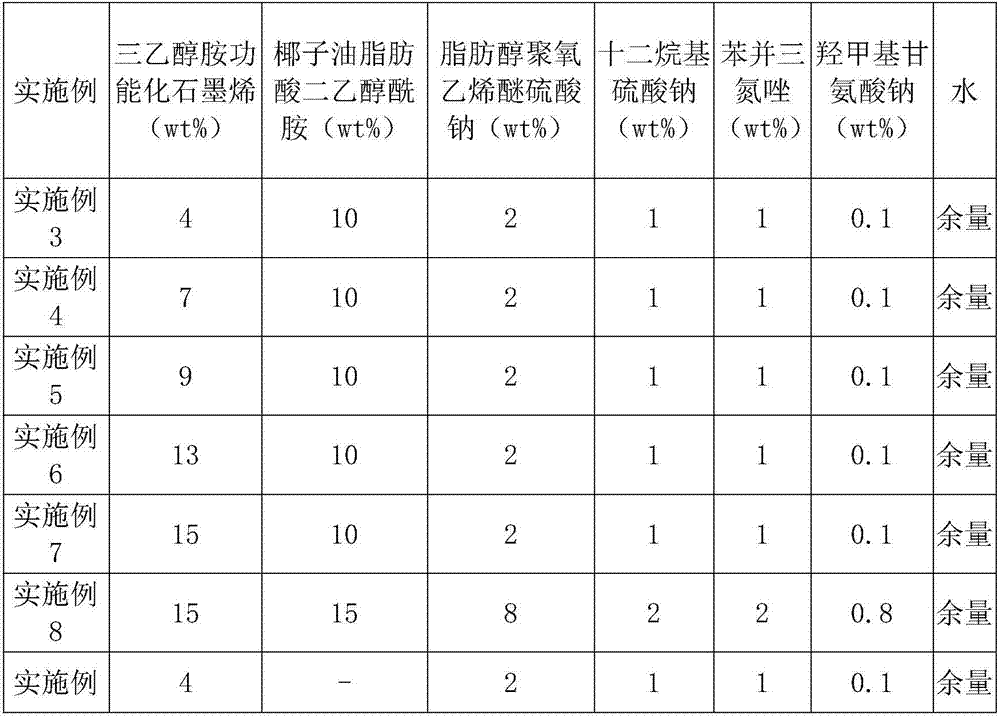

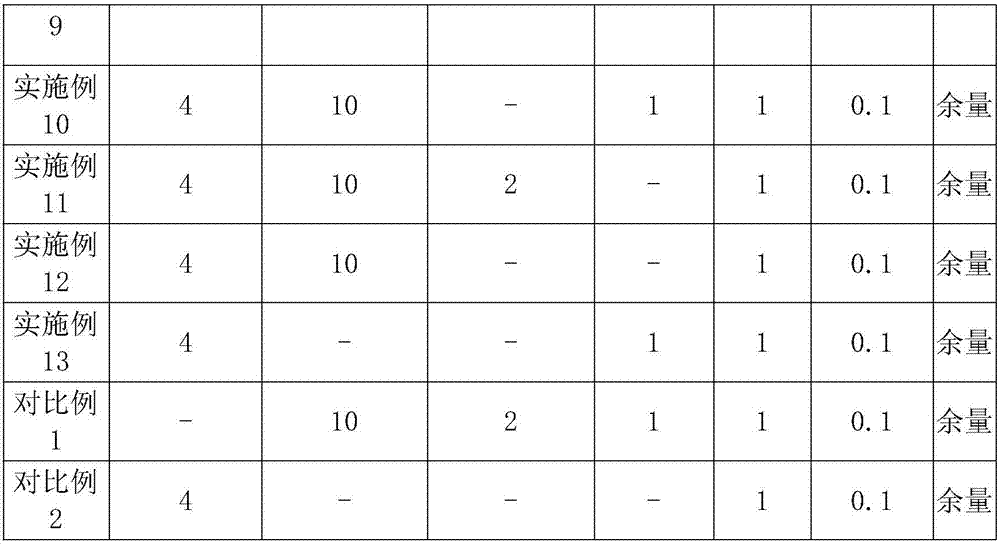

Examples

Embodiment 1

[0035] The present embodiment provides a kind of preparation method of triethanolamine functionalized graphene, comprises the following steps:

[0036] S1. Preparation of triethanolamine functionalized graphene:

[0037] S11. Adopt graphene oxide as raw material, be dissolved in deionized water, concentration is 2mg / L, pH is 1, ultrasonic dispersion 30min, obtain uniform dispersion liquid, uniform dispersion liquid and triethanolamine are mixed by volume ratio 20:1, obtain mixed solution;

[0038] S12. Heat the mixed solution in step S11 in a water bath at 70°C for 2 hours, centrifuge the reacted suspension, wash with absolute ethanol and deionized water until neutral, and dry at 60°C to obtain triethanolamine functionalized Graphene.

Embodiment 2

[0040] The present embodiment provides a kind of preparation method of triethanolamine functionalized graphene, comprises the following steps:

[0041] S1. Preparation of triethanolamine functionalized graphene:

[0042] S11. Adopt graphene oxide as raw material, be dissolved in deionized water, concentration is 3mg / L, pH is 2, ultrasonic dispersion 30min, obtain uniform dispersion liquid, uniform dispersion liquid and triethanolamine are mixed by volume ratio 25:1, obtain mixed solution;

[0043] S12. Heat the mixed solution in step S11 in a water bath at 90°C for 5 hours, centrifuge the reacted suspension, wash with absolute ethanol and deionized water until neutral, and dry at 70°C to obtain triethanolamine functionalized Graphene.

Embodiment 3

[0045] The present embodiment provides a kind of preparation method that adds the metal cleaning agent of functionalized modified graphene, comprises the following steps:

[0046] S1. adopt the triethanolamine functionalized graphene prepared by embodiment 1 as raw material;

[0047] S2. Add 4wt% triethanolamine functionalized graphene, 10t% coconut oil fatty acid diethanolamide, 2wt% fatty alcohol polyoxyethylene ether sodium sulfate, 1wt% ten dialkyl sodium sulfate, 1wt% of benzotriazole, 0.1wt% of sodium hydroxymethylglycinate and the rest of water, stirred for 1-2 hours at a stirring speed of 80-100r / min, to a black uniform liquid, and finally obtained functionalized modified graphite Alkene metal cleaner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com