A kind of preparation method of hydrophilic porous shaped activated carbon

An activated carbon and pore forming technology, applied in the field of functional materials, can solve the problems of poor hydrophilicity, water resistance and stability, limited performance and application range, and achieve cost-effective advantages, convenient operation, and high economic value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A preparation method of hydrophilic porous shaped activated carbon, comprising the following steps:

[0026] Step 1) According to the difference of water-soluble hydroxyl polymers, prepare an aqueous solution with an appropriate concentration: weigh a certain amount of water-soluble hydroxyl-containing polymers, dissolve them in an appropriate amount of distilled water to swell and dissolve, and wait for cooling before use.

[0027] Step 2) Add 2wt% NaOH aqueous solution to alkalize for half an hour, and add an appropriate amount of activated carbon to the glue system to control the glue / charcoal ratio.

[0028] Step 3) adding an appropriate amount of cross-linking agent epichlorohydrin to control the mass ratio of polymer to epichlorohydrin.

[0029] Step 4) Add foaming agent ammonium bicarbonate accounting for 0.1%-0.3% of the total weight of the system, and stir evenly.

[0030] Step 5) Stir the reaction for 1-2 hours under a constant temperature water bath at 65°C....

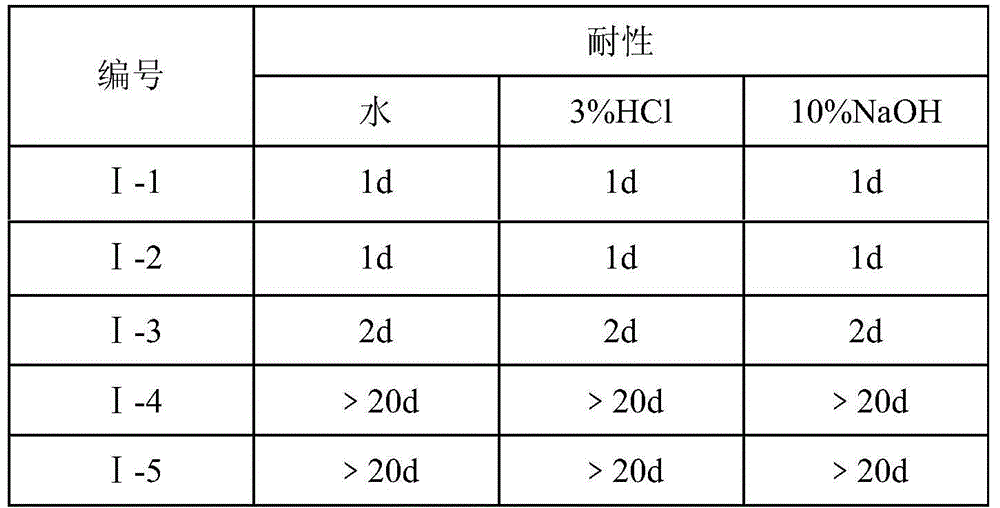

Embodiment 1

[0034] Implementation of Polyvinyl Alcohol-Epichlorohydrin Bonded Activated Carbon

[0035] Accurately weigh 2g of polyvinyl alcohol, dissolve in 23g of distilled water, and swell and dissolve in an oven at 93°C. Add 5ml of 2wt% NaOH aqueous solution to alkalize for half an hour. Add an appropriate amount of powdered activated carbon to the glue system to make the glue / charcoal ratio 1:1. Added 0.133g, 0.2g, 0.25g, 0.4g, 0.67g of epichlorohydrin respectively, so that the mass ratio of polyvinyl alcohol to epichlorohydrin was 15:1, 10:1, 8:1, 5:1, 3:1, the numbers are Ⅰ-1, Ⅰ-2, Ⅰ-3, Ⅰ-4, Ⅰ-5. Put it in a constant temperature water bath at 65° C., stir and heat for 1 hour, then stop stirring, and place it under the constant temperature water bath at this temperature for 45 minutes. After the reaction, neutralize to neutral with acetic acid. Pour the mixture into molds and dry them in an oven at 110°C. After it is completely dried and solidified, it is soaked in water, 3wt% ...

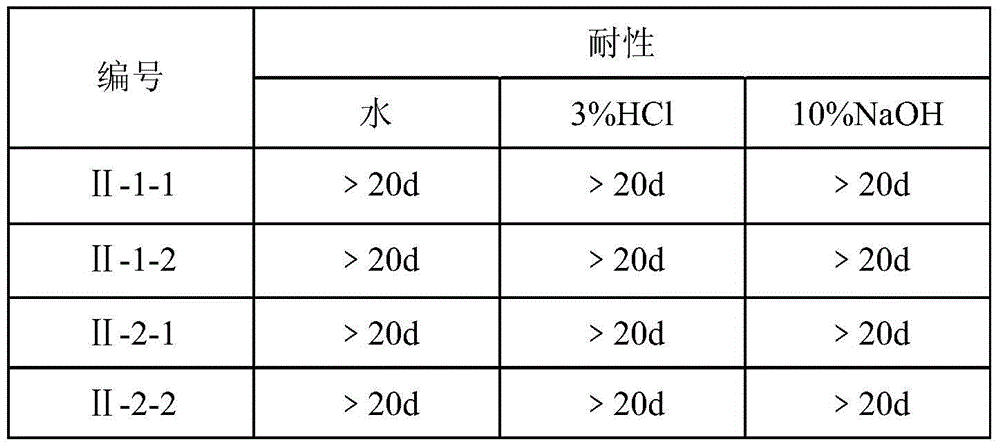

Embodiment 2

[0042] Implementation of Carboxymethyl Cellulose-Epichlorohydrin Bonded Activated Carbon

[0043]Accurately weigh 2g of carboxymethylcellulose, dissolve in 23g of distilled water, swell and dissolve under stirring. Add 5ml of 2wt% NaOH solution to alkalize for half an hour. Add an appropriate amount of powdered activated carbon to the glue system to make the glue / charcoal ratio 2:1, 1:1, and the numbers indicate Ⅱ-1, Ⅱ-2. Add 0.4g and 0.67g of epichlorohydrin respectively, so that the mass ratio of carboxymethyl cellulose and epichlorohydrin is 5:1 and 3:1, and the numbers are respectively II-1-1 and II-1-2 , II-2-1, II-2-2. Put it in a constant temperature water bath at 65° C., stir and heat for 1 hour, then stop stirring, and place it under the constant temperature water bath at this temperature for 45 minutes. After the reaction, neutralize the pH to neutral with acetic acid. Pour the mixture into molds and dry them in an oven at 110°C. After it is completely dried and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com