Epoxy modified polyurethane cryogenic adhesive

A technology of epoxy modification and polyurethane, which is applied in the field of ultra-low temperature resistant adhesives and epoxy modified polyurethane ultra-low temperature resistant adhesives. The effect of constant mechanical properties and high bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

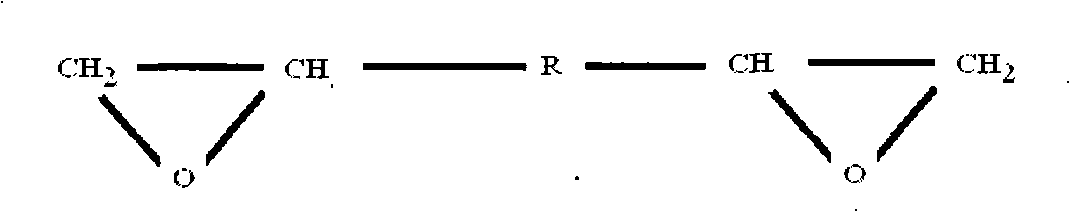

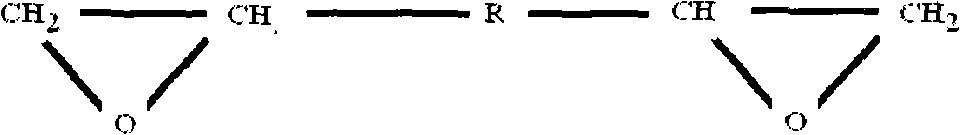

Image

Examples

Embodiment 1

[0022] The adhesive is prepared according to the following composition ratio (mass percentage):

[0023] Polyurethane modified prepolymer 30%

[0024] Epoxy 5%

[0026] Chain extender 1,4 butanediol 15%

[0027] Expanded Vermiculite 2%

[0028] SiO 2 18%

[0029] CaCO 3 12%

[0030] CaCl 2 8%

[0031] The preparation method of this adhesive is:

[0032] 1. Mix the polyurethane modified prepolymer and the solvent and stir evenly in the reaction kettle, and pack it as component A;

[0033] 2. Add the above-mentioned mixed filler, chain extender and appropriate solvent to the epoxy resin, and gradually stir evenly, and pack it as component B;

[0034] 3. When bonding materials, add B to component A in proportion, and stir evenly, then apply and bond.

Embodiment 2

[0036] The adhesive is prepared according to the following composition ratio (mass percentage):

[0037] Polyurethane modified prepolymer 40%

[0038] Epoxy 5%

[0040] Chain extender 1,4 butanediol 15%

[0041] Expanded Vermiculite 1%

[0042] SiO 2 5%

[0043] CaCO 3 14%

[0044] CaCl 2 10%

[0045] The preparation method of this adhesive is the same as in Example 1.

Embodiment 3

[0047] The adhesive is prepared according to the following composition ratio (mass percentage):

[0048] Polyurethane modified prepolymer 35%

[0049] Epoxy 12%

[0050] Solvent (methyl ethyl ketone) 15%

[0051] Chain extender MOCA 8%

[0052] Vermiculite 3%

[0053] SiO 2 15%

[0054] CaCO 3 10%

[0055] CaCl 2 2%

[0056] The preparation method of this adhesive is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com