Preparation method for hyaluronic acid self-assembled colloidal particle

A technology of hyaluronic acid and colloidal particles, which is applied in the preparation of hyaluronic acid composite colloidal particles, formulation composition, preparation and drying, can solve the problems of easy degradation, short retention time, poor stability, etc., and achieve good hydrophilicity, The effect of excellent safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

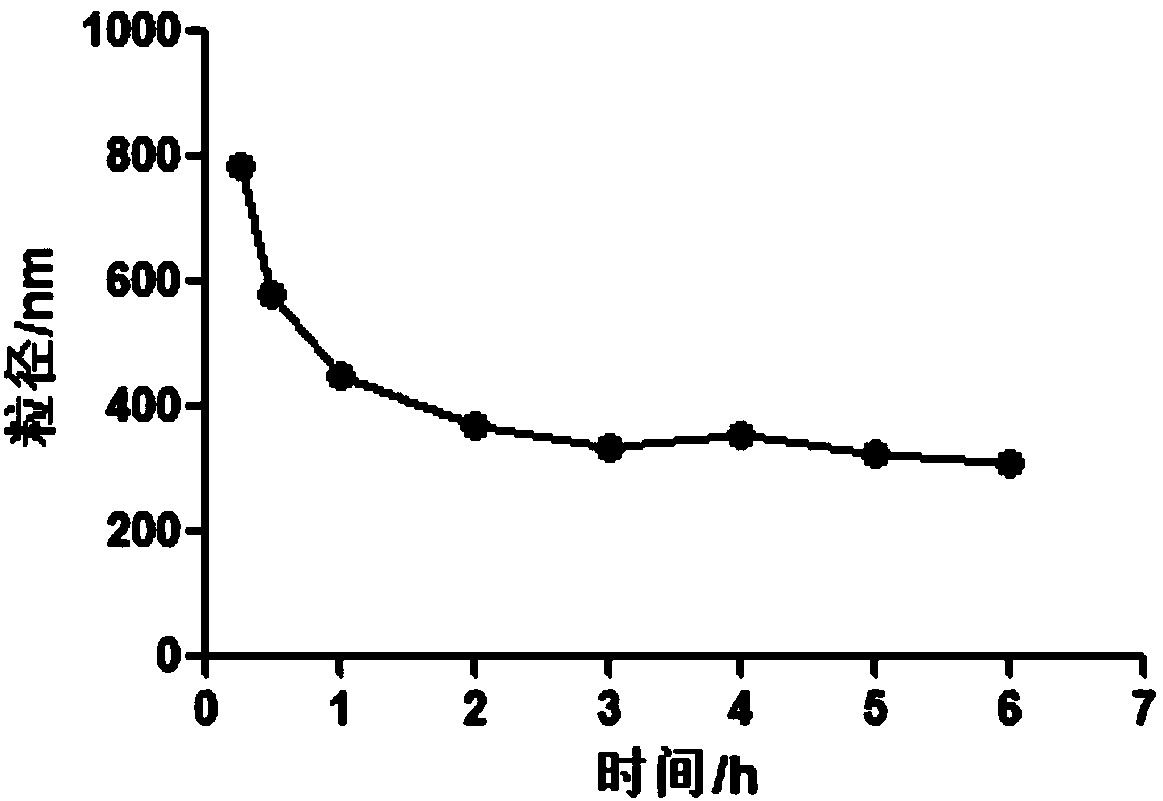

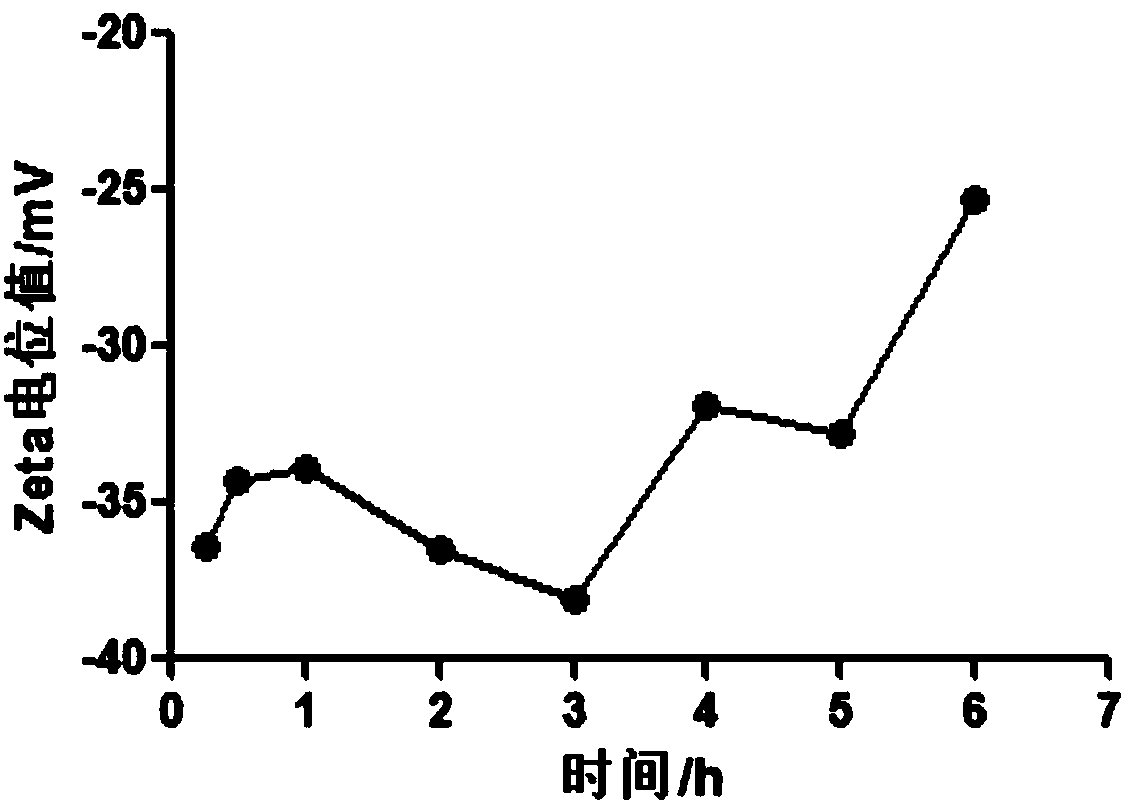

[0033] Embodiment 1: 50kD HA prepares the method for HA-PDM colloidal particle

[0034] Accurately weigh 0.5g of 50kD HA, put it in 50ml of ultrapure water, stir and dissolve, add 300μl of DM and stir for 2h, use dilute hydrochloric acid to adjust the pH of the mixed solution to 6.30, put it in a round bottom flask, add the initiator KPS (2.5%) solution: 1.5ml, feed nitrogen, stir at 1300rpm / min, heat in a water bath at 70°C, condense and reflux, react for 4h, then cool the solution and put it into a dialysis bag (8000Da), in a phosphate buffer with pH 5.0 After dialysis for 72 hours, the solution was taken out and placed in a watch glass, pre-frozen at -20°C (refrigerator), and dried in a freeze dryer for 48-72 hours. Take it out and grind it, and store it at 4°C.

Embodiment 2

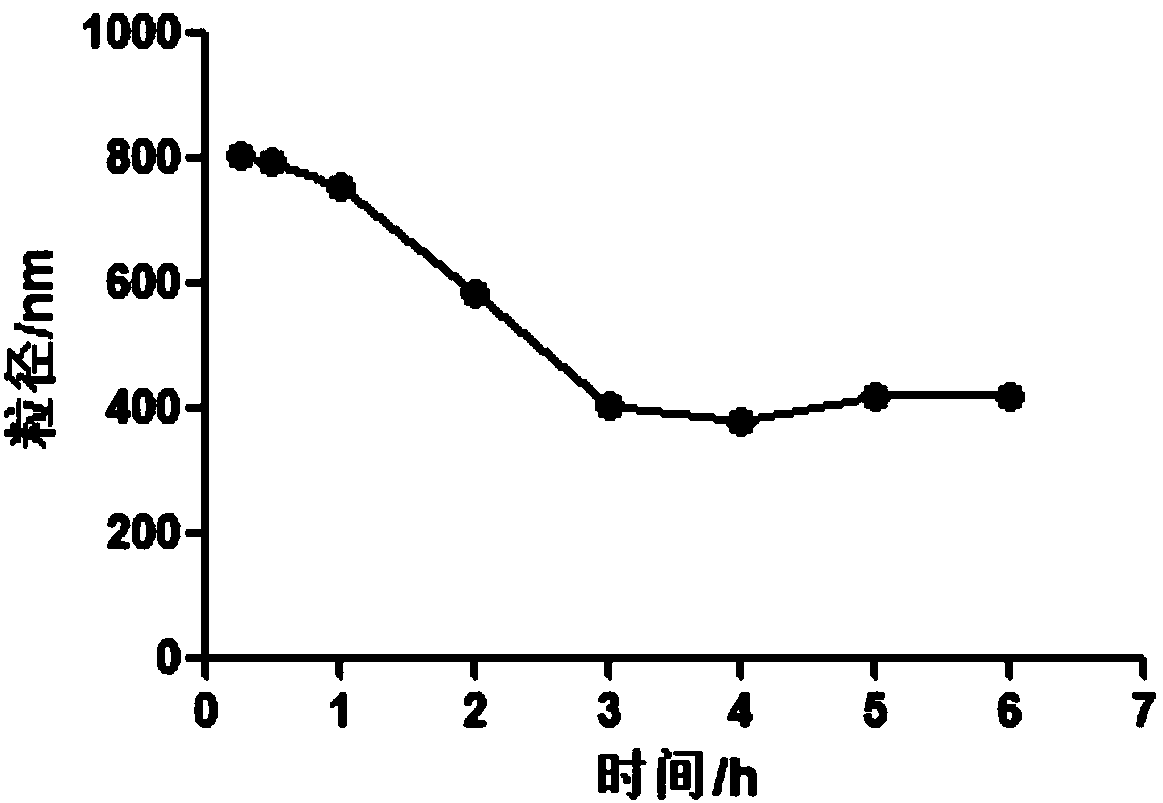

[0035] Embodiment 2: 500kD HA prepares the method for HA-PDM colloidal particle

[0036] Precisely weigh 0.5g of 500kD HA, put it in 50ml of ultrapure water, stir and dissolve, add 500μl of DM and stir for 2h, use dilute hydrochloric acid to adjust the pH of the mixed solution to 6.30, put it in a round bottom flask, add the initiator KPS (2.5%) solution: 2.5ml, feed nitrogen, stir at 1560rpm / min, heat in a water bath at 70°C, condense and reflux, react for 4h, then cool the solution and put it into a dialysis bag (8000Da), in a phosphate buffer with pH 5.0 After dialysis for 72 hours, the solution was taken out and placed in a watch glass, pre-frozen at -20°C (refrigerator), and dried in a freeze dryer for 48-72 hours. Take it out and grind it, and store it at 4°C.

Embodiment 3

[0037] Embodiment 3: 1200kD HA prepares the method for HA-PDM colloidal particle

[0038] Precisely weigh 0.5g of 1200kD HA, put it in 50ml of ultrapure water, stir and dissolve, add 300μl of DM and stir for 2h, use dilute hydrochloric acid to adjust the pH of the mixed solution to 6.30, put it in a round bottom flask, add the initiator KPS (2.5%) solution: 2.5ml, feed nitrogen, stir at 1560rpm / min, heat in a water bath at 70°C, condense and reflux, react for 4h, then cool the solution and put it into a dialysis bag (8000Da), in a phosphate buffer with pH 5.0 After dialysis for 72 hours, the solution was taken out and placed in a watch glass, pre-frozen at -20°C (refrigerator), and dried in a freeze dryer for 48-72 hours. Take it out and grind it, and store it at 4°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com