Intrinsically safe type sample gas processing system

A sample gas processing system, intrinsically safe technology, applied in the field of intrinsically safe sample gas processing systems, can solve the problems of toxic gas leakage, sample gas flow meter exposed water, easy damage, etc., to achieve good safety, simple structure, easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

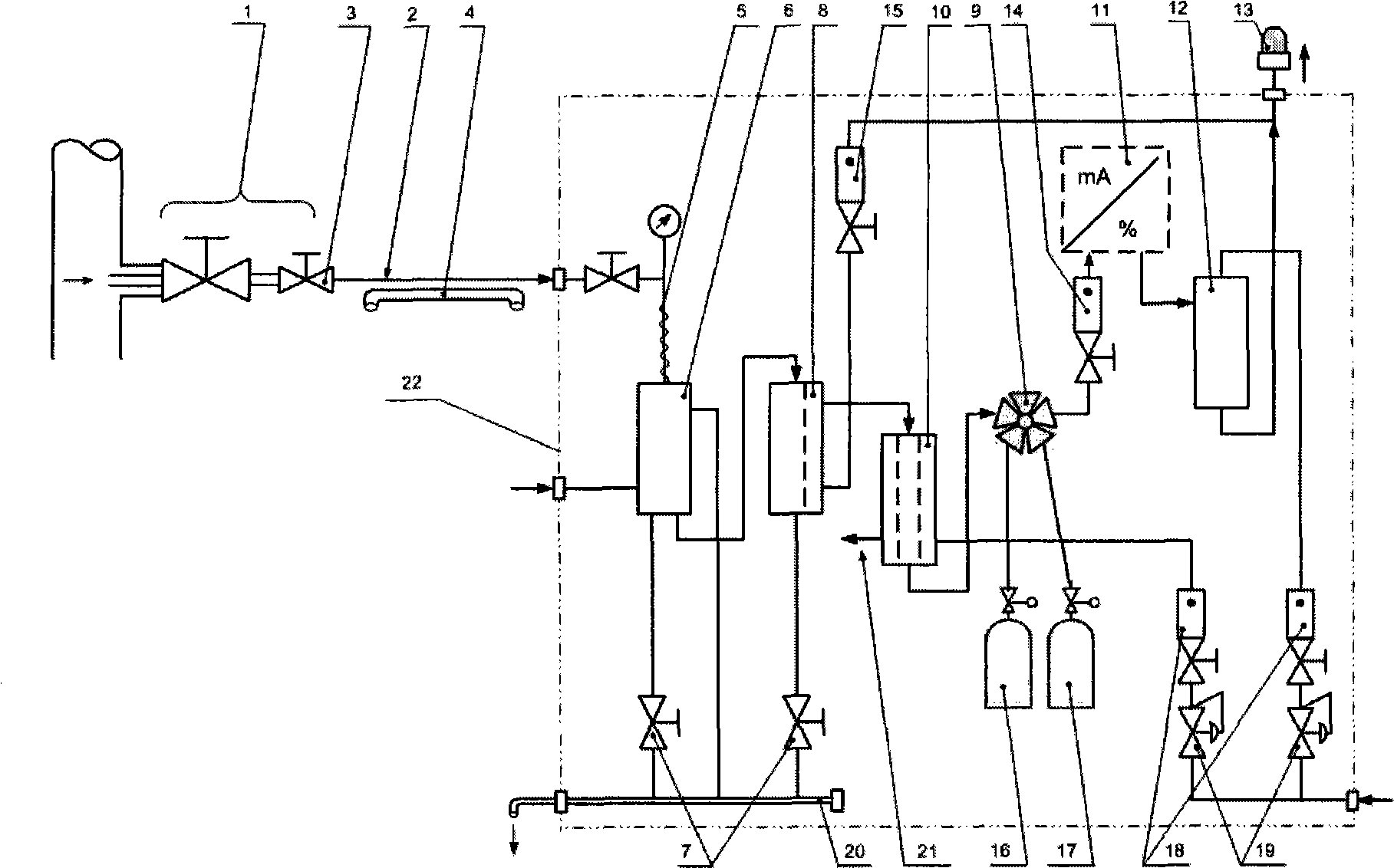

[0031] figure 1 It is a schematic diagram of the connection structure of the sample gas processing system of the present invention. like figure 1 As shown, the intrinsically safe sample gas processing system of the present invention includes a sample gas collection device and a sample gas processing device. The sample gas collection device includes a detachable sampling probe 1 and a pneumatic sampling pump 12. The sample gas processing device It includes sample gas pre-cooling pipe 5, water cooling and water removal device 6, self-cleaning sample gas filter 8 and permeation sample gas dryer 10. The sample gas processing system is then connected to the gas analyzer 11 shown by the dotted line in the figure to form an online analysis system. In practical applications, different online analysis systems can be formed by connecting different gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com