Environment-friendly electrostatic spraying antirust oil and preparation method thereof

A technology of electrostatic spraying and anti-rust oil, which is applied in the petroleum industry, base materials, additives, etc. It can solve the problems of anti-humidity and heat, salt spray ability to be improved, and difficulty in meeting environmental protection requirements, etc., to achieve outstanding anti-rust performance and meet anti-rust requirements Performance requirements, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

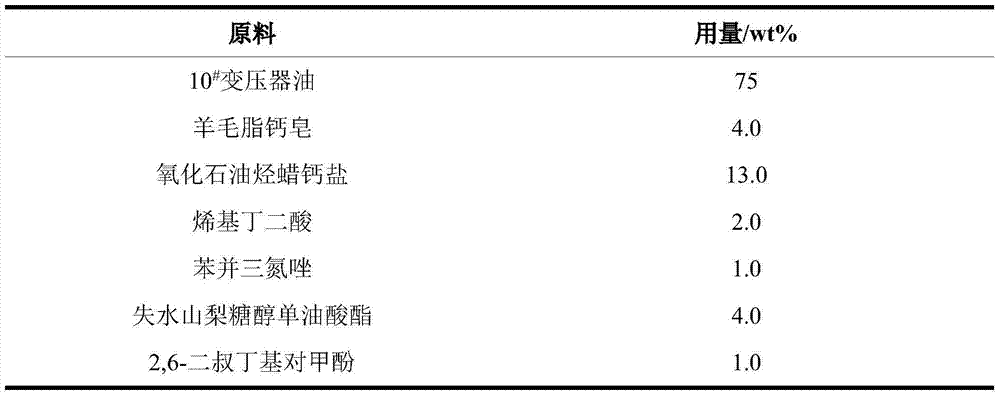

Embodiment 1

[0032] An environment-friendly electrostatic spray anti-rust oil, its formula composition is as follows:

[0033] Table 1: Formula composition of environmentally friendly electrostatic spraying antirust oil

[0034]

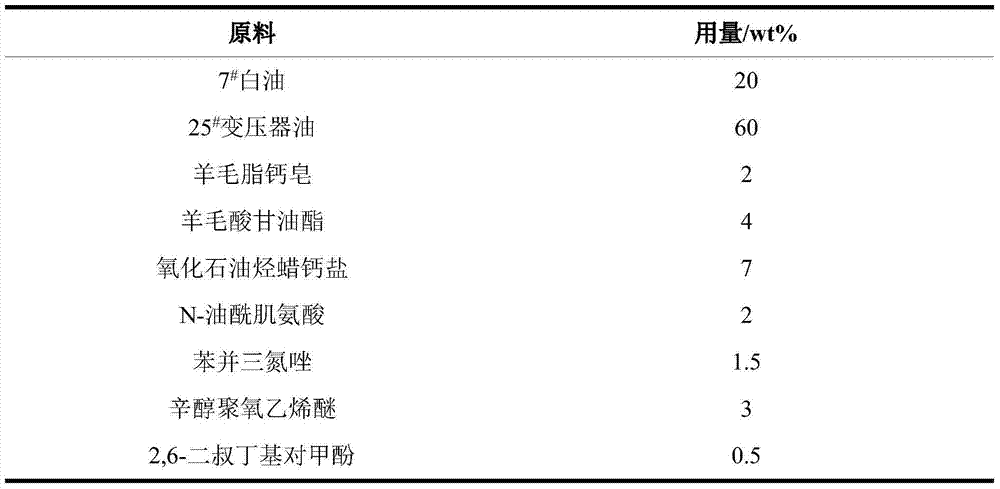

Embodiment 2

[0036] An environment-friendly electrostatic spray anti-rust oil, its formula composition is as follows:

[0037] Table 2: Formula composition of environmentally friendly electrostatic spraying antirust oil

[0038]

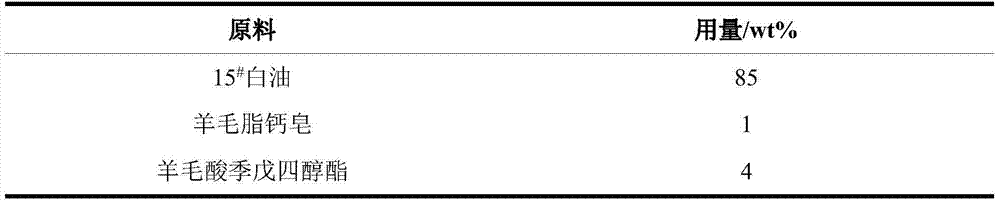

Embodiment 3

[0040] An environment-friendly electrostatic spray anti-rust oil, its formula composition is as follows:

[0041] Table 3: Formula composition of environmentally friendly electrostatic spraying antirust oil

[0042]

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com