Patents

Literature

42results about How to "Good atomization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Benzene-free spray paint and preparation method thereof

The invention relates to a benzene-free spray paint. The spray paint is characterized by comprising the following components by weight percent: 21-25% of acrylic resin, 4-10% of pigment, 0.5-1% of dispersing agent, 0.3-0.8% of flatting agent, 0.5-1% of bentonite, 5-10% of ethylene glycol monobutyl ether, 4-8% of n-butyl acetate, 8-18% of acetic ether, 10-15% of acetone, and 38-42% of dimethyl ether. The spray paint is prepared from raw materials which are completely free of harmful substances like benzene and heavy metals through a certain production method, thus avoiding harm of benzene and heavy metals to human health, and effectively protecting environment and safety of people.

Owner:ZHONGSHAN DATIAN CAR CARE IND

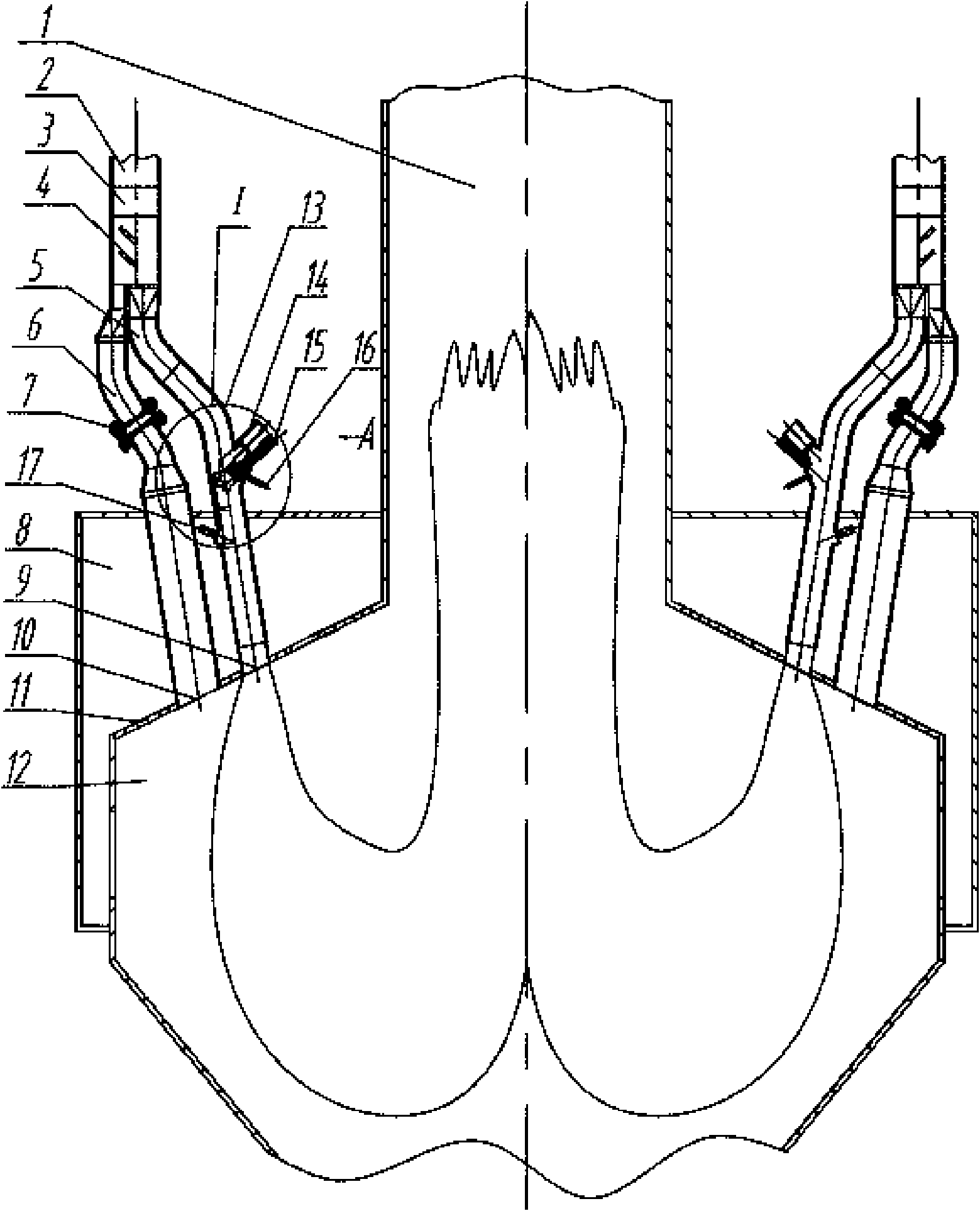

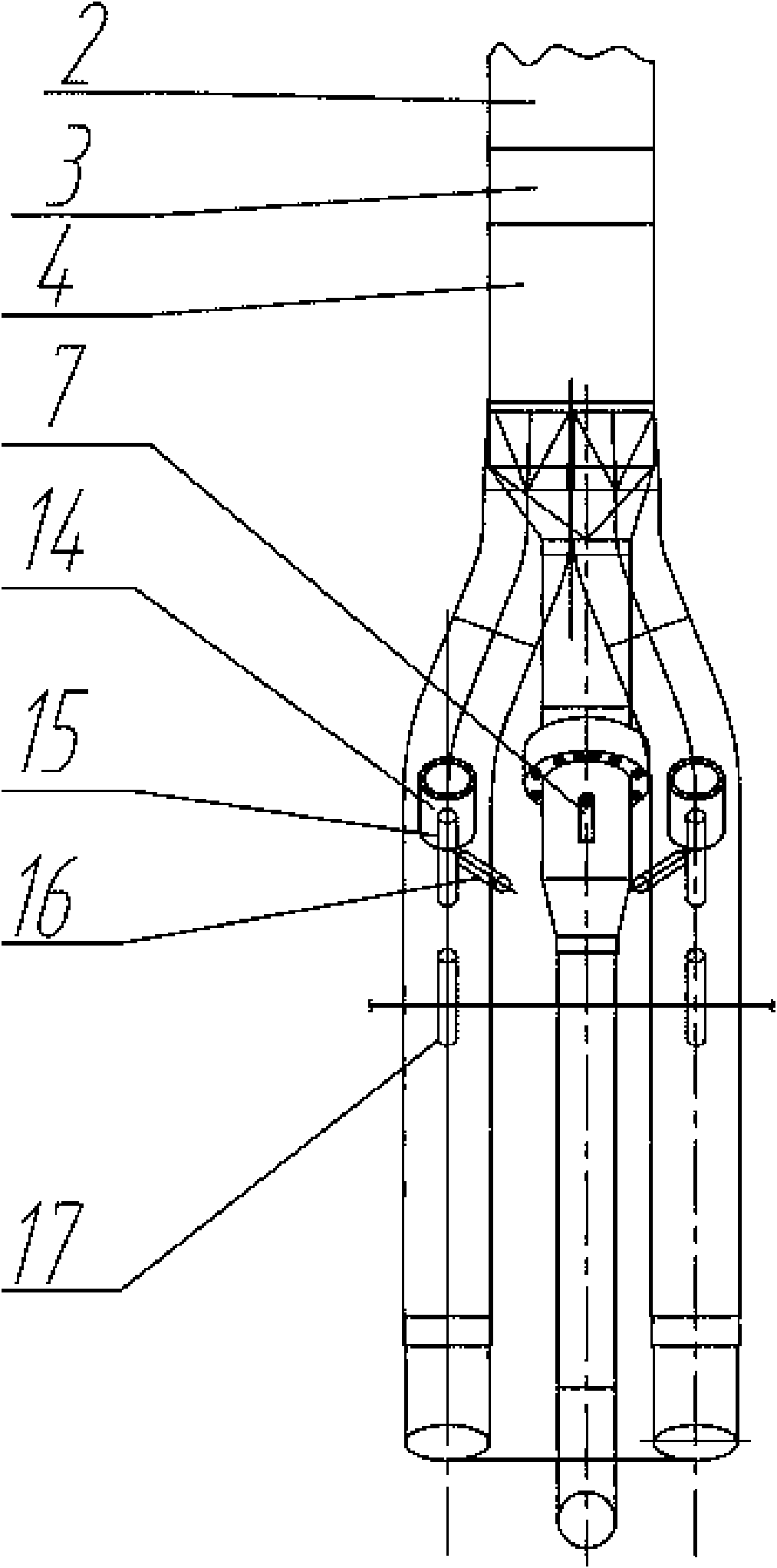

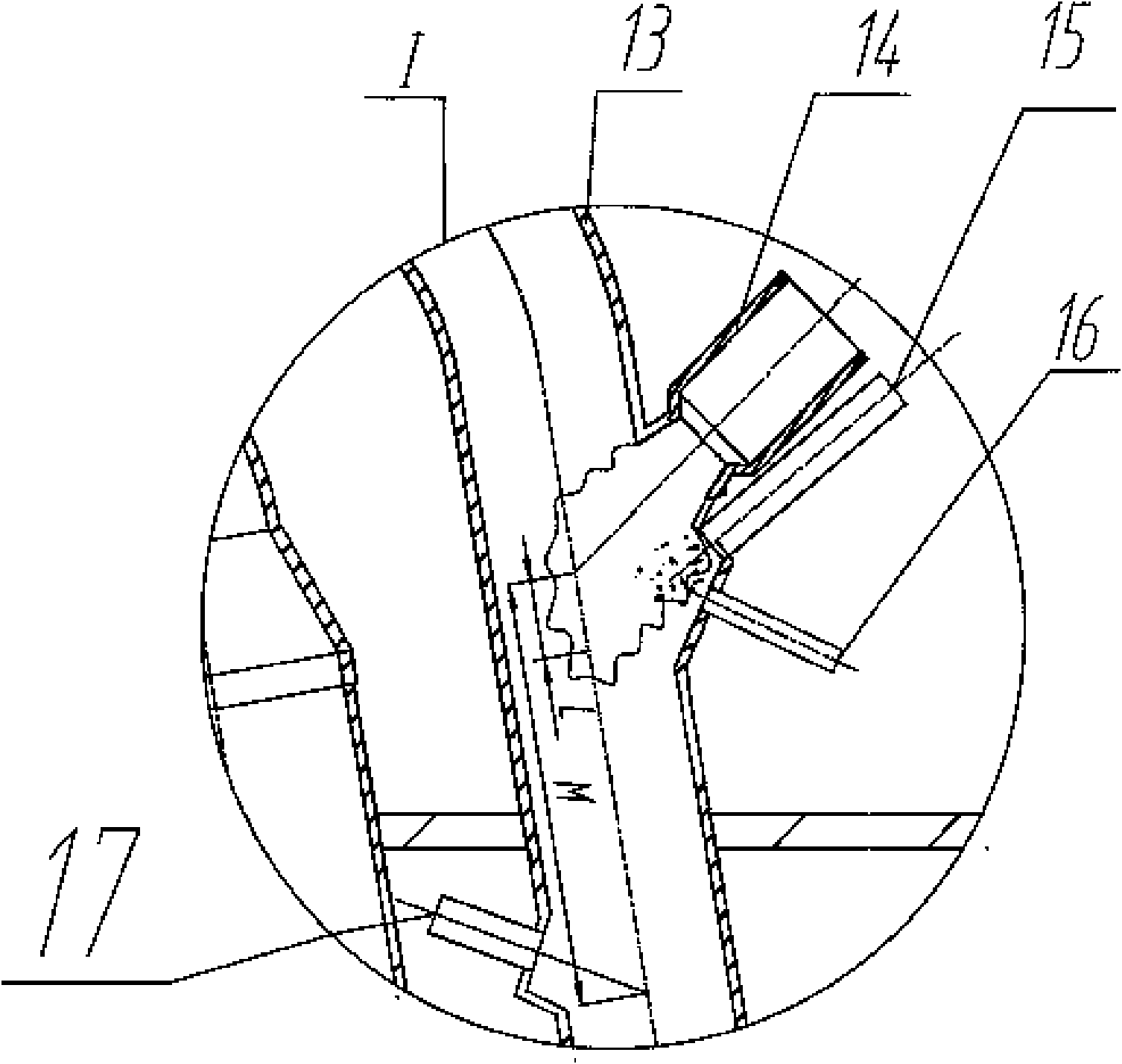

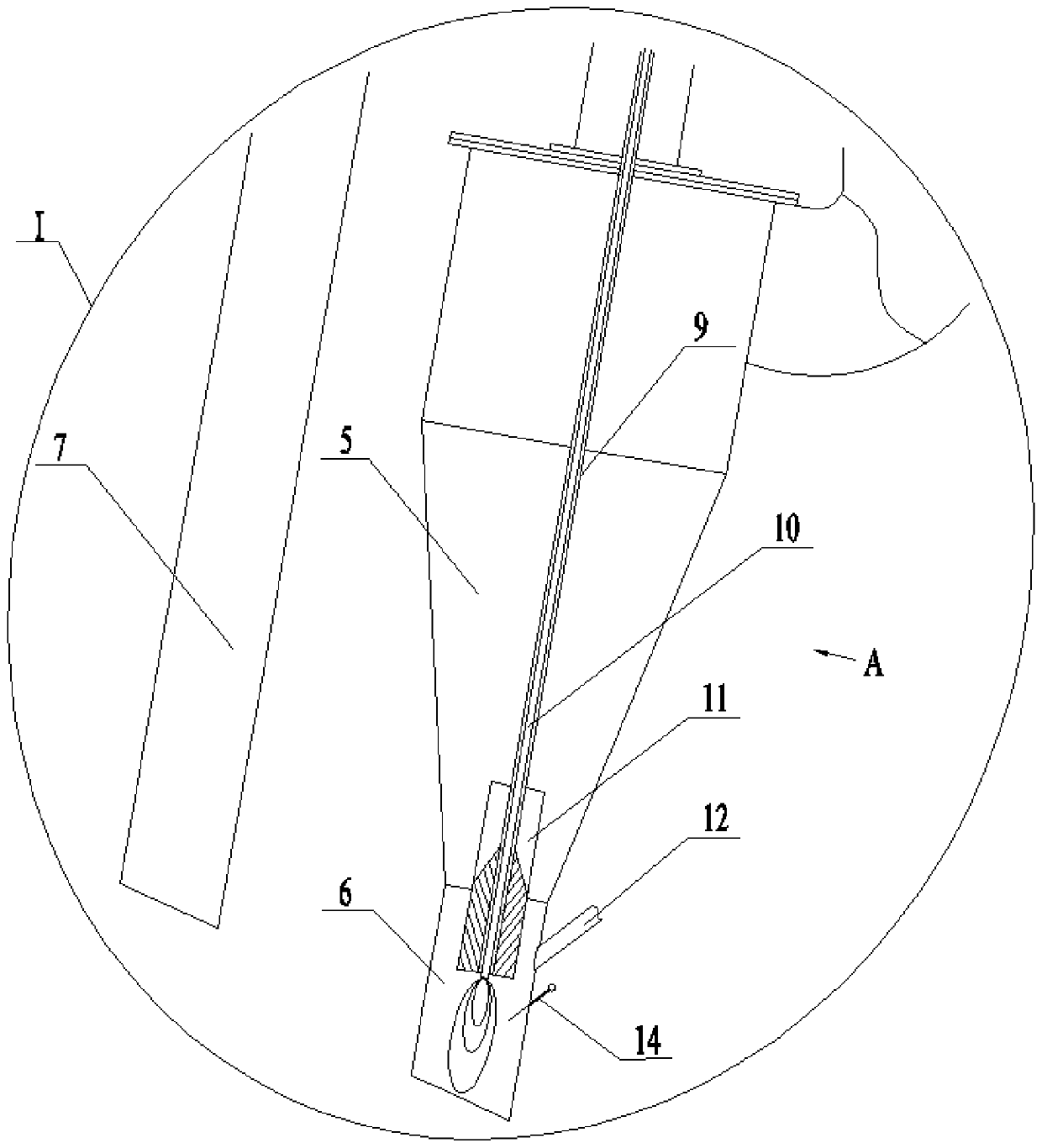

Trace oil igniting coal dust firing device for multiple oil guns

InactiveCN101603684AEasy to igniteNot easy to ignitePilot flame ignitersPulverulent fuel combustion burnersCoal dustHigh heat

The invention provides a trace oil igniting coal dust firing device for multiple oil guns, relates to a firing device, and solves the problem of easily failed ignition due to the fact that distance between a main oil gun and an auxiliary oil gun on the same side is large, and the main oil gun and an auxiliary oil gun on the opposite side are not alternately arranged in the prior firing device. The main oil gun and the auxiliary oil gun on the opposite side are alternately and oppositely arranged on side walls of a concentrated coal dust pipeline; distances of crossing points among the central line of the main oil gun, the central line of the auxiliary oil gun on the same side and the central line of the concentrated coal dust pipeline are between 80 and 100mm; and distances of the crossing points of the central line of the main oil gun, the central line of the auxiliary oil gun on the opposite side and the central line of the concentrated coal dust pipeline are between 500 and 700mm. The distance between the main oil gun and the auxiliary oil gun on the same side is close so as to ensure that fuel which is sprayed from the auxiliary oil gun and has excellent atomization can be directly sprayed into high temperature flame generated by ignition of the main oil gun for fierce firing, and the flame generated after fuel sprayed from the main oil gun and the auxiliary oil gun is fired can support each other to form whole flame which has large length and roughness and good rigidity and can ignite high concentrated coal dust.

Owner:HARBIN INST OF TECH

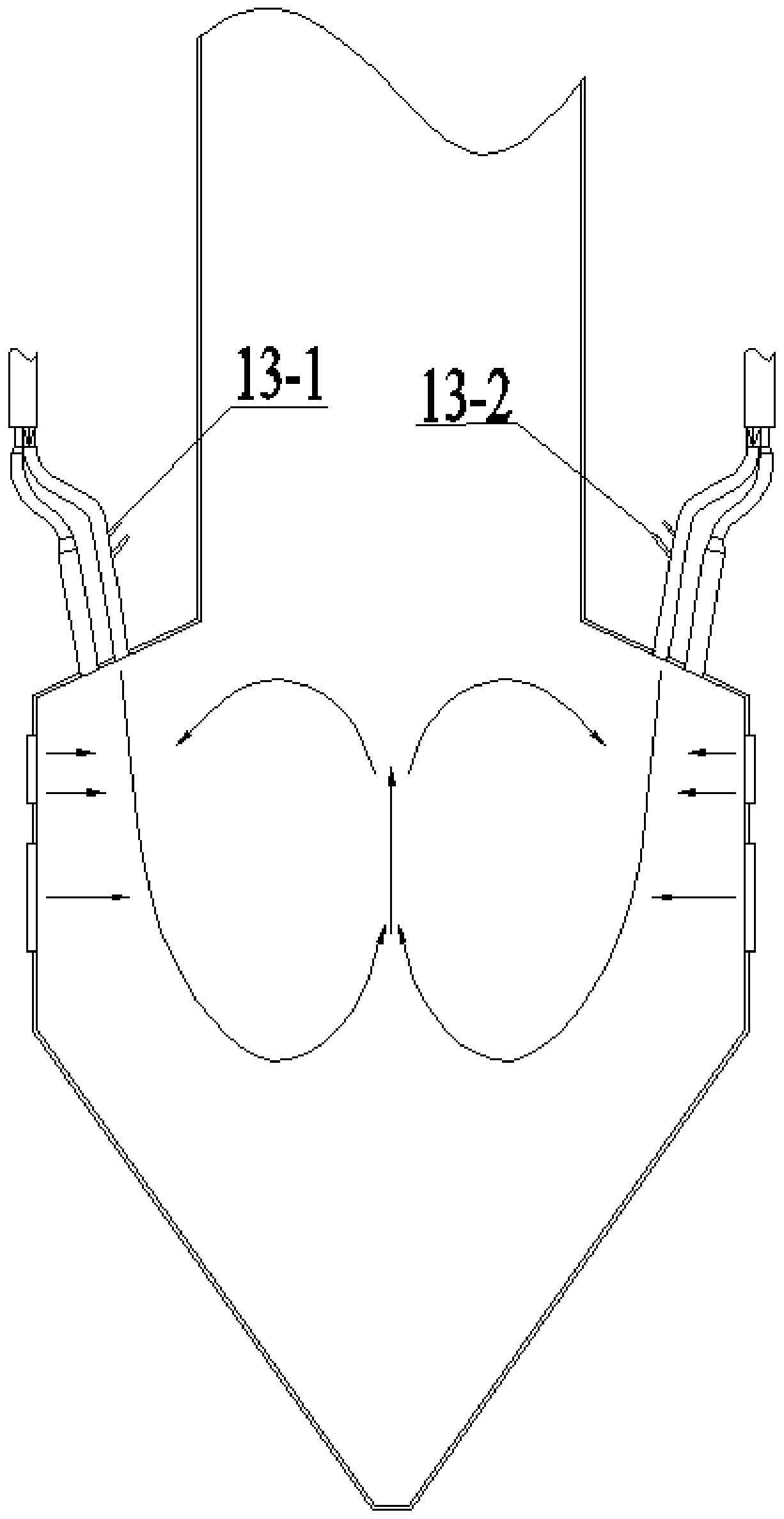

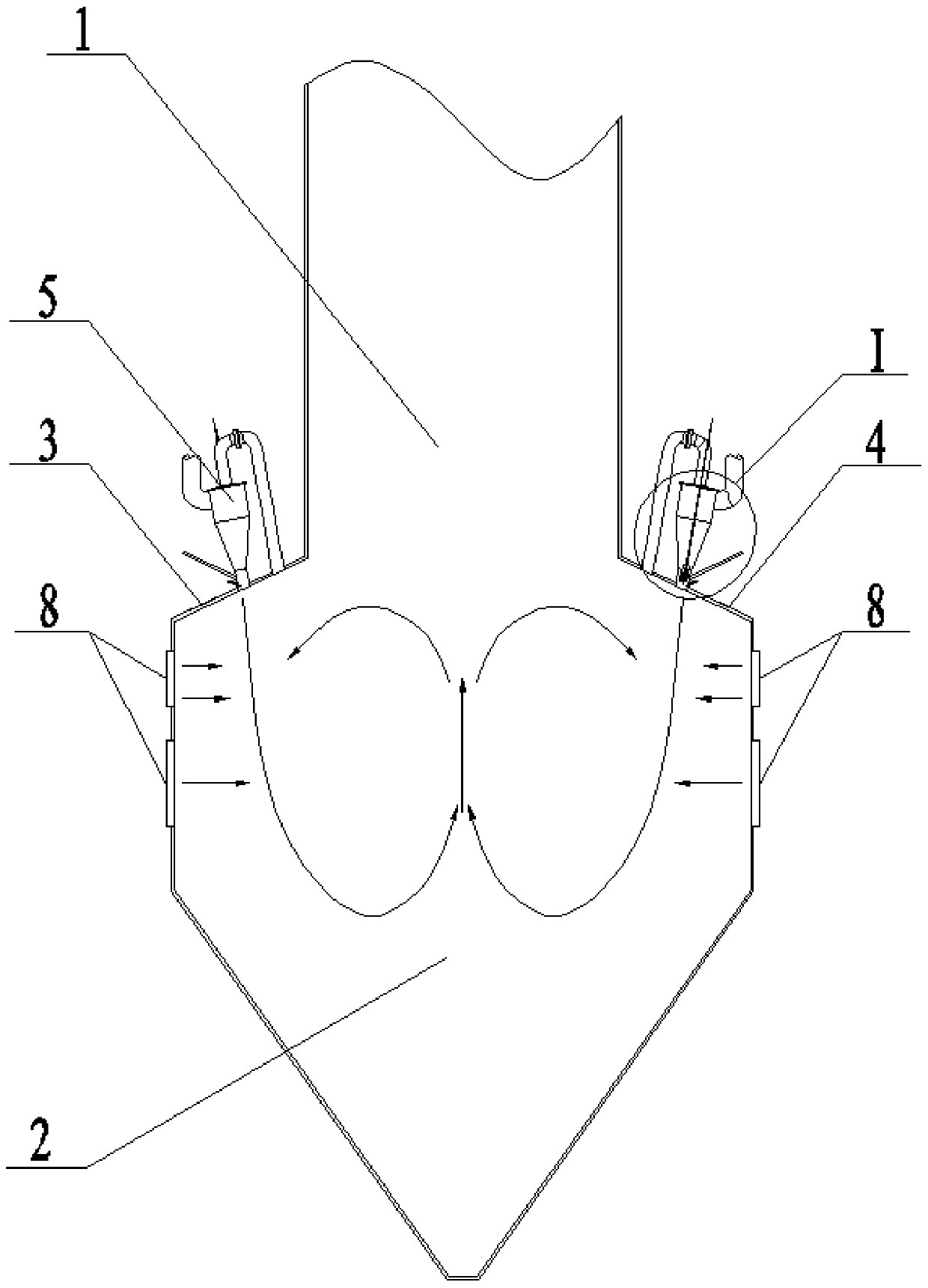

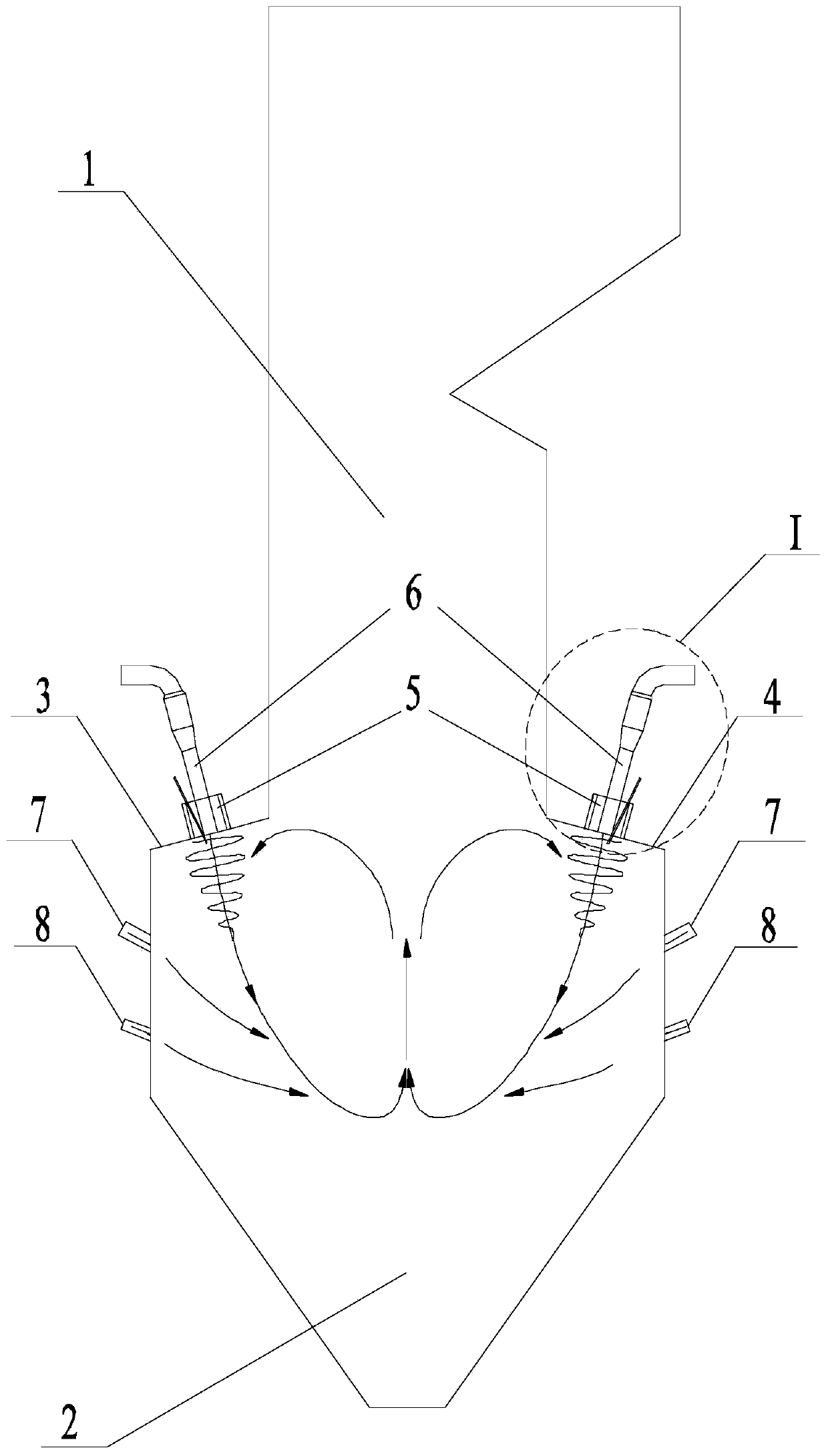

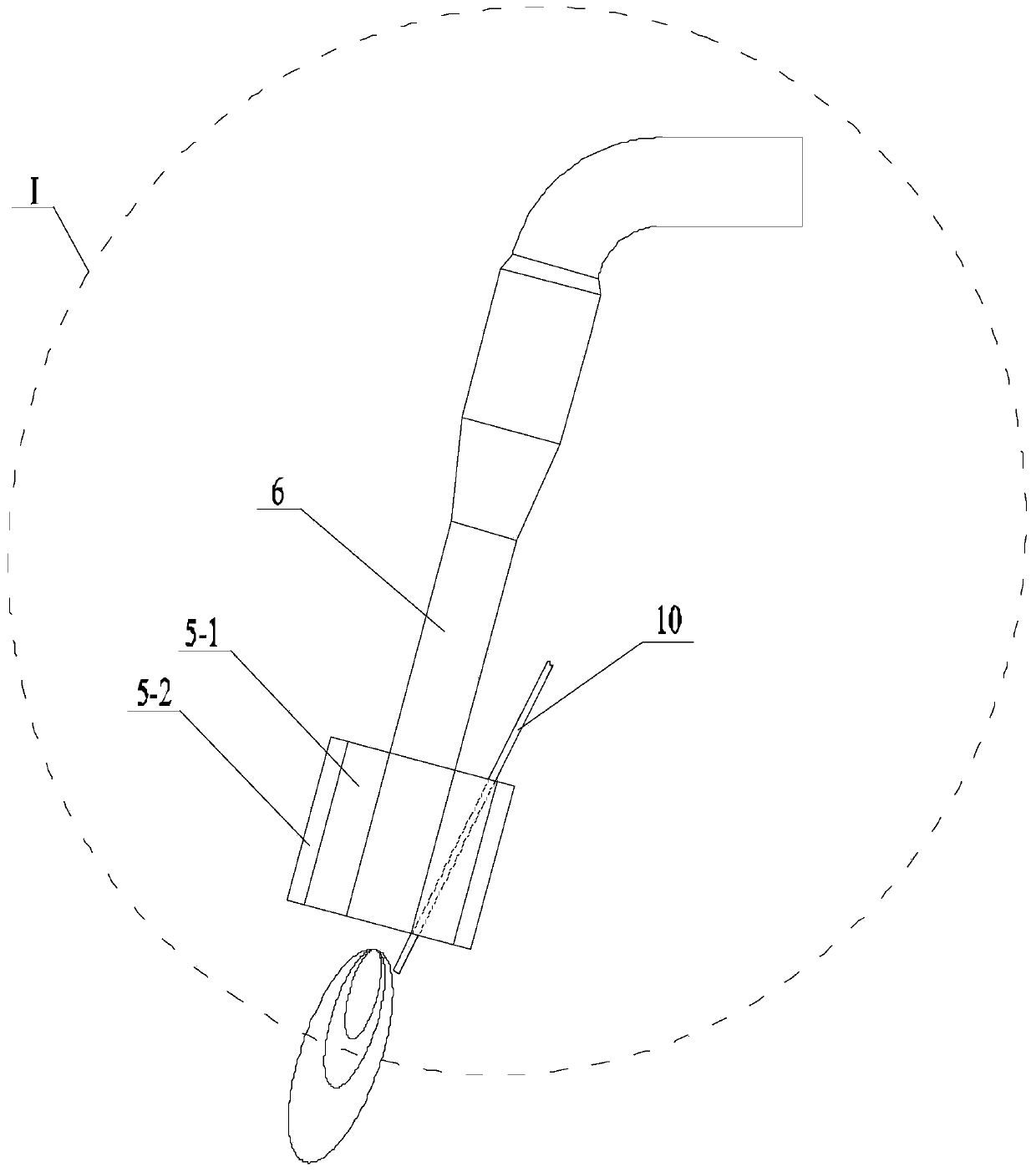

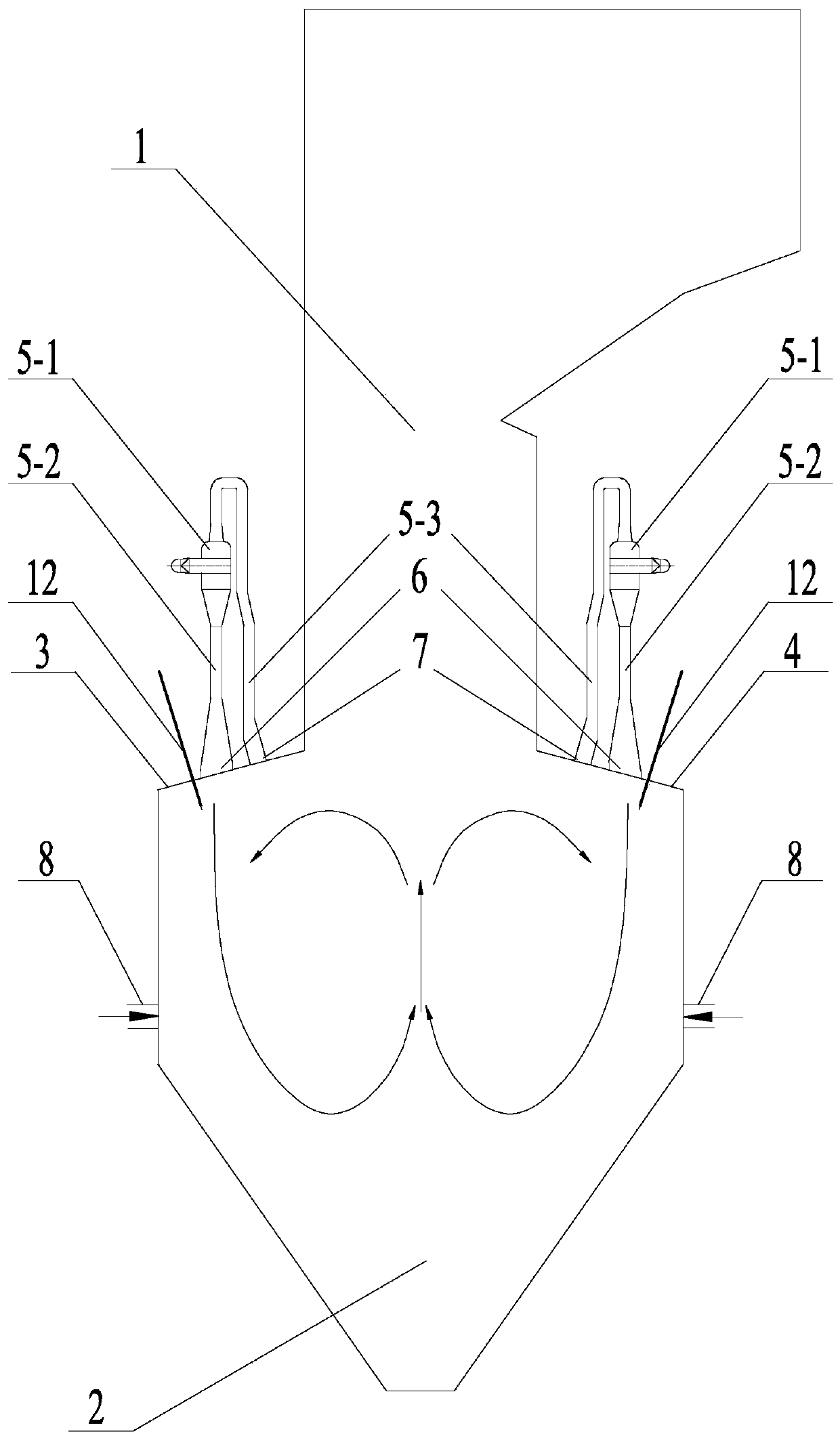

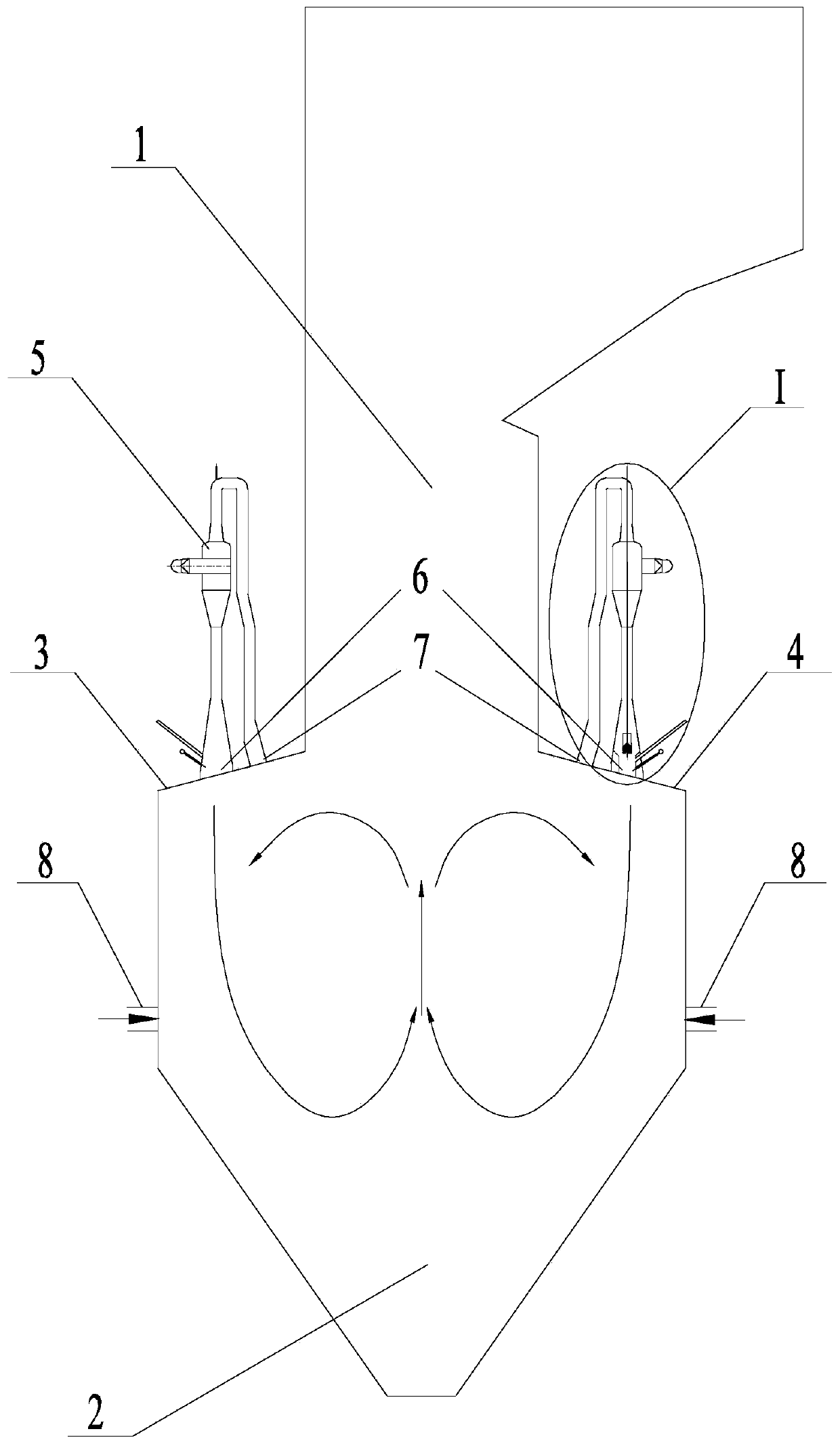

W flame boiler with double-cyclone-barrel thick and thin pulverized coal separation type combustors

InactiveCN111023084APromote fireImprove featuresPulverulent fuel combustion burnersIndirect carbon-dioxide mitigationCombustorPower station

The invention provides a W flame boiler with double-cyclone-barrel thick and thin pulverized coal separation type combustors, and relates to a power station boiler which adopts the flexible peak regulation technology. The W flame boiler with the double-cyclone-barrel thick and thin pulverized coal separation type combustors is used for solving the problems that a W flame boiler is poor in ultralowload stable combustion and operation capacity, and the flexible peak regulation load cannot be 20%. The W flame boiler comprises an upper combustion chamber, a lower combustion chamber, a front boiler arch, a rear boiler arch, a front wall, a rear wall, the multiple double-cyclone-barrel thick and thin pulverized coal separation type combustors and multi-layer arch bottom secondary air nozzles. Each double-cyclone-barrel thick and thin pulverized coal separation type combustor comprises two thick pulverized coal airflow nozzles and two exhaust air nozzles. The upper combustion chamber, the front boiler arch, the front wall, the lower combustion chamber, the rear wall and the rear boiler arch are combined to form a boiler body. The multi-layer arch bottom secondary air nozzles are arrangedon the front wall and the rear wall in sequence from top to bottom. The double-cyclone-barrel thick and thin pulverized coal separation type combustors are installed on the front boiler arch and therear boiler arch in a linear mode, and the corresponding thick pulverized coal airflow nozzles and the corresponding exhaust air nozzles of each double-cyclone-barrel thick and thin pulverized coal separation type combustor communicate with the boiler body. The invention belongs to the field of boilers.

Owner:HARBIN INST OF TECH

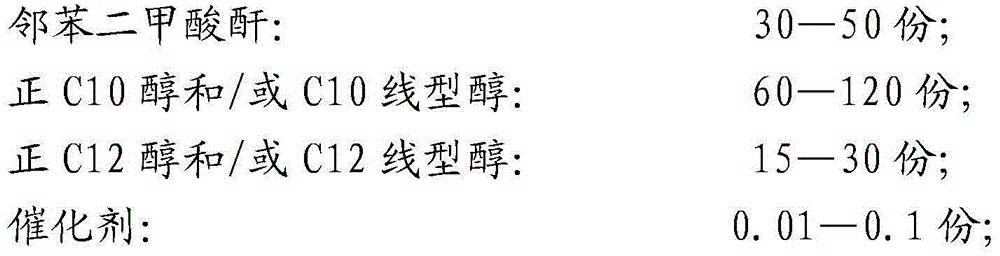

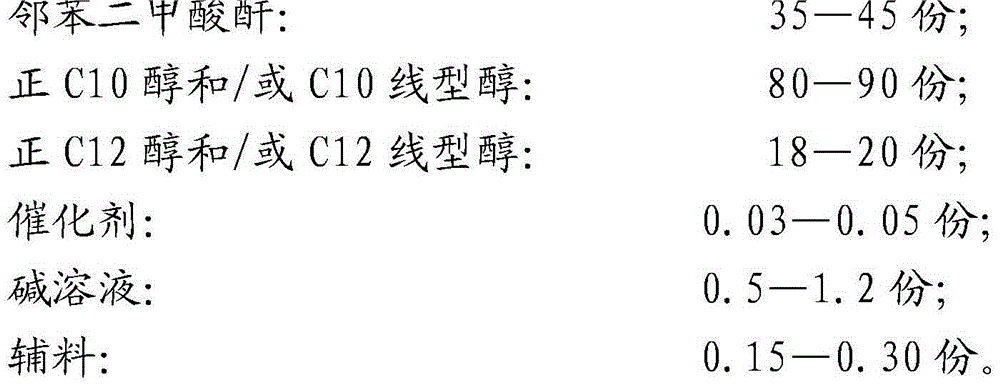

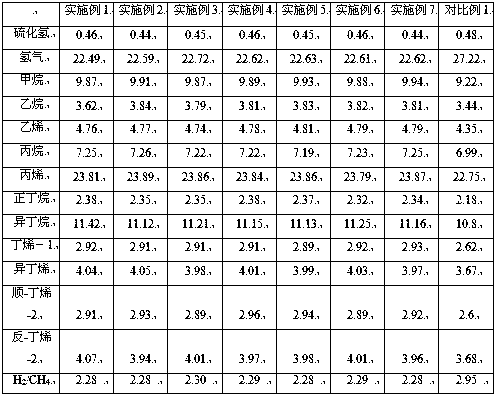

High and low temperature-resistant low-fogging degree functional environment-friendly plasticizer

InactiveCN105272850APromote environmental protectionHigh plasticizing efficiencyOrganic compound preparationCarboxylic acid esters preparationAlcoholPlasticizer

The invention discloses a high and low temperature-resistant low-fogging degree functional environment-friendly plasticizer, comprising phthalic anhydride, n-C10 alcohol, C10 linear alcohol, n-C12 alcohol, C12 linear alcohol, a catalyst, an alkali solution and an accessory material. The phthalic anhydride undergoes an esterification reaction with fatty alcohol and produces phthalic acid fatty ester under the action of the catalyst, and the phthalic acid fatty ester is subjected to dealcoholization, neutralization and refining so as to obtain the finished plasticizer. A formula for the plasticizer comprises 30 to 50 parts of the phthalic anhydride, 60 to 120 parts of n-C10 alcohol and / or C10 linear alcohol, 15 to 30 parts of n-C12 alcohol and / or C12 linear alcohol, 0.01 to 0.1 part of the catalyst, 0.2 to 1.5 parts of the alkali solution (with a concentration of 5 to 15%) and 0.05 to 1 part of the accessory material According to the invention, a nonacid titanate catalyst is preferably used for the esterification reaction; the prepared plasticizer is capable of resisting both high temperature and cold; production cost is saved; low volatility is obtained; the characteristics of the prepared plasticizer can be maintained for a longer time; and the plasticizer is applicable to production and manufacturing of automotive trimming products.

Owner:JIANGSU SENHE CHEM TECH CO LTD

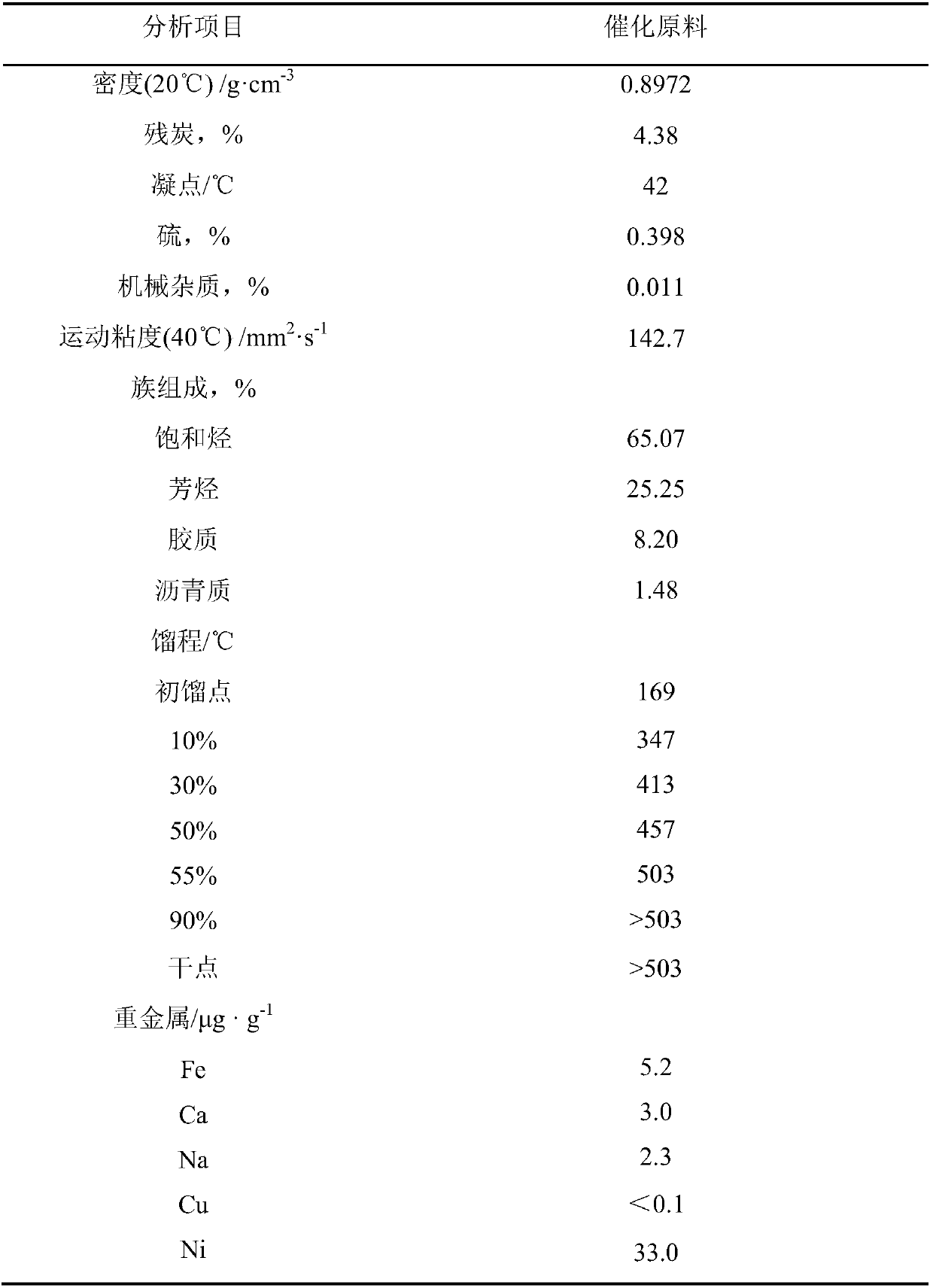

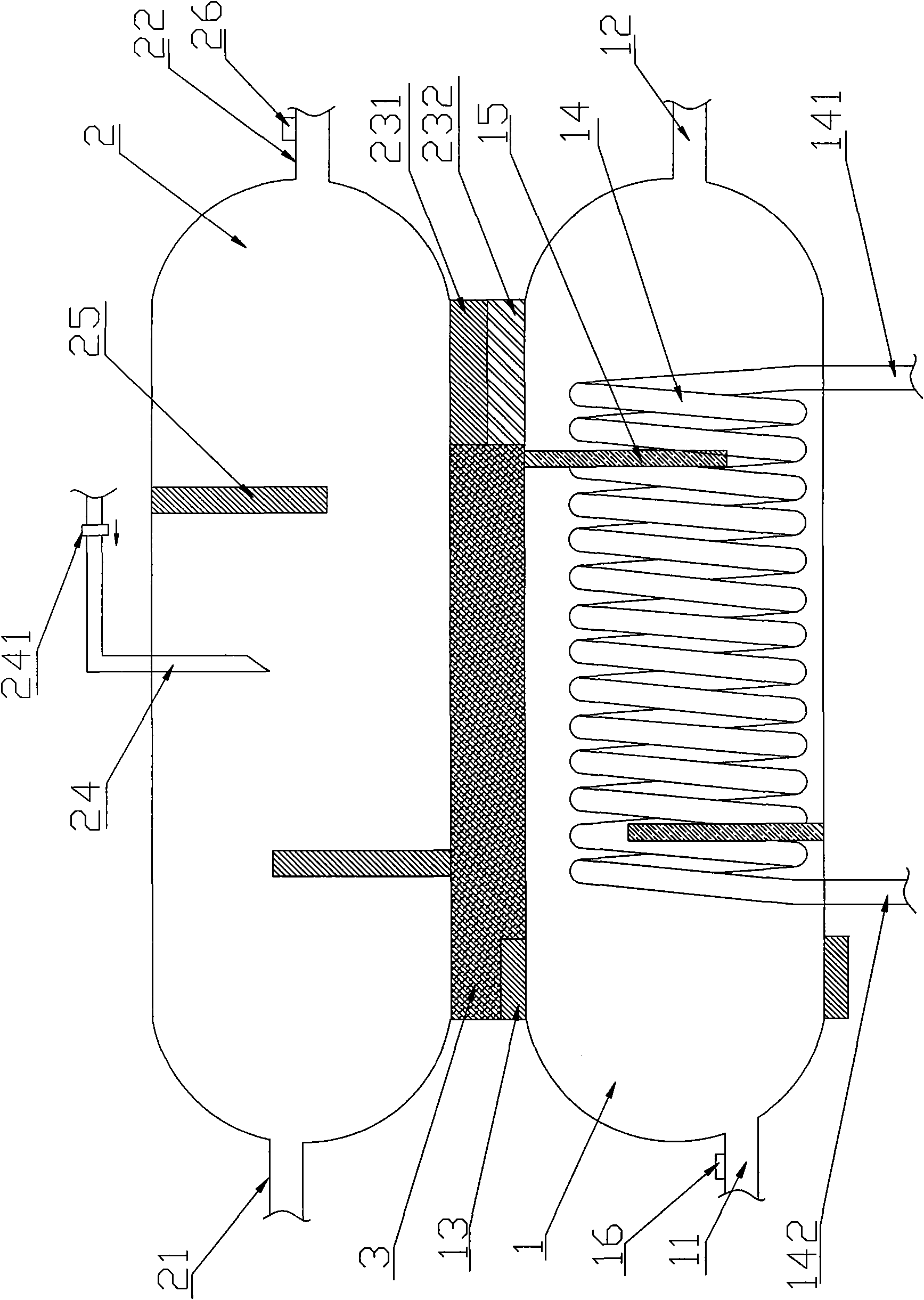

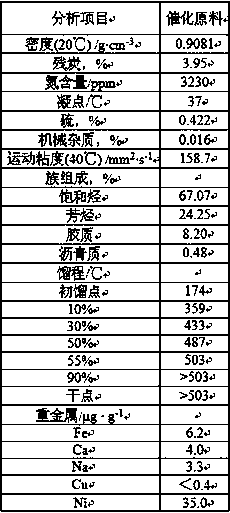

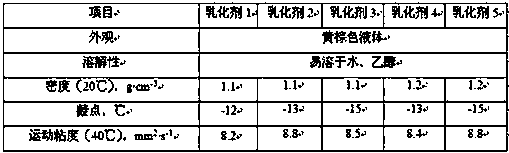

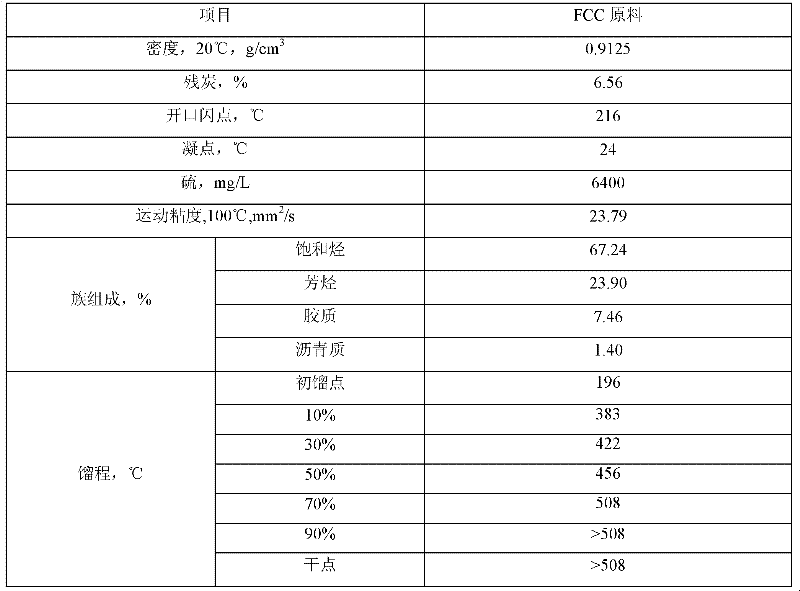

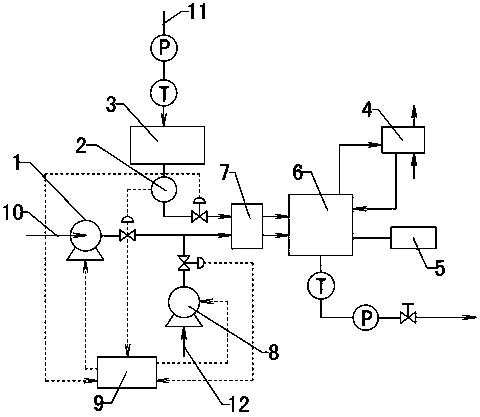

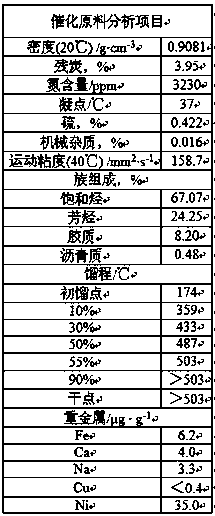

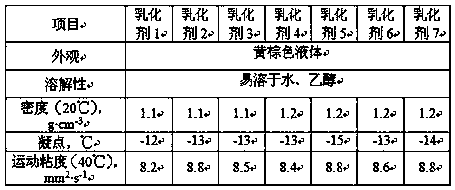

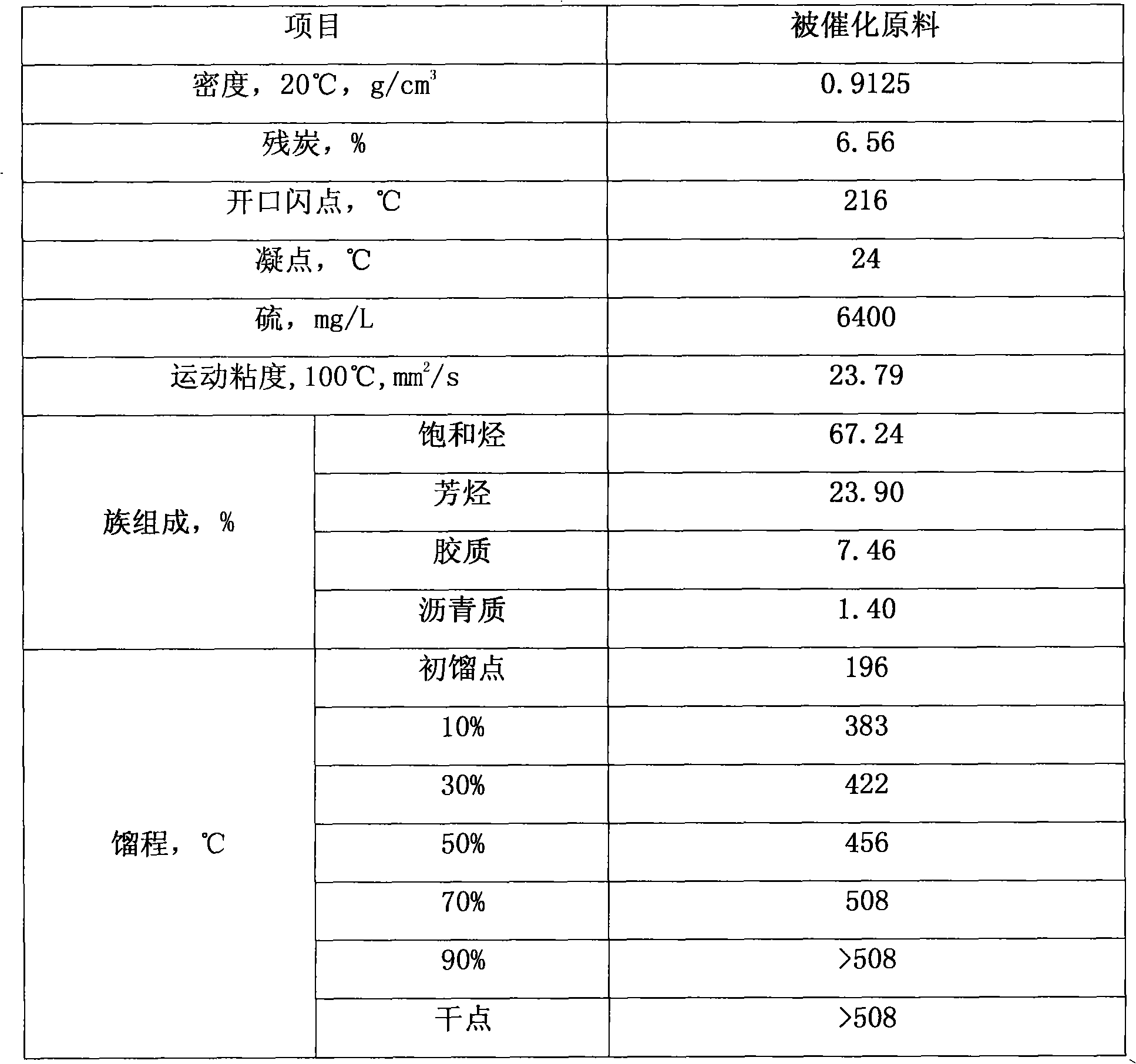

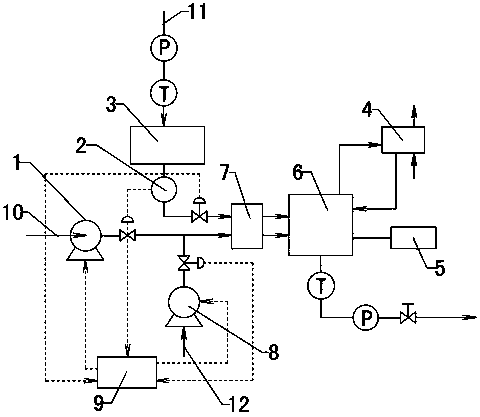

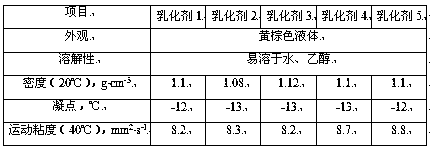

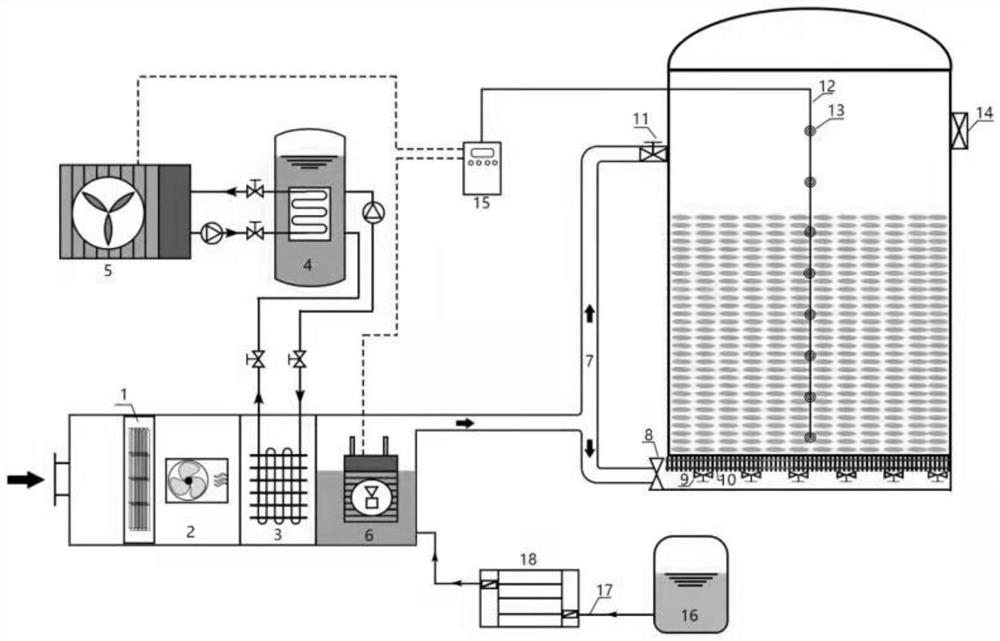

Heavy oil emulsion for catalytic cracking processing of heavy oil, preparation method and applications thereof

InactiveCN110878217AUniform sizeImprove emulsification efficiencyCatalytic crackingOil emulsionPorous membrane

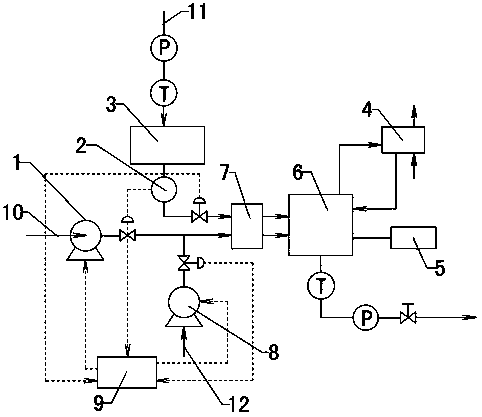

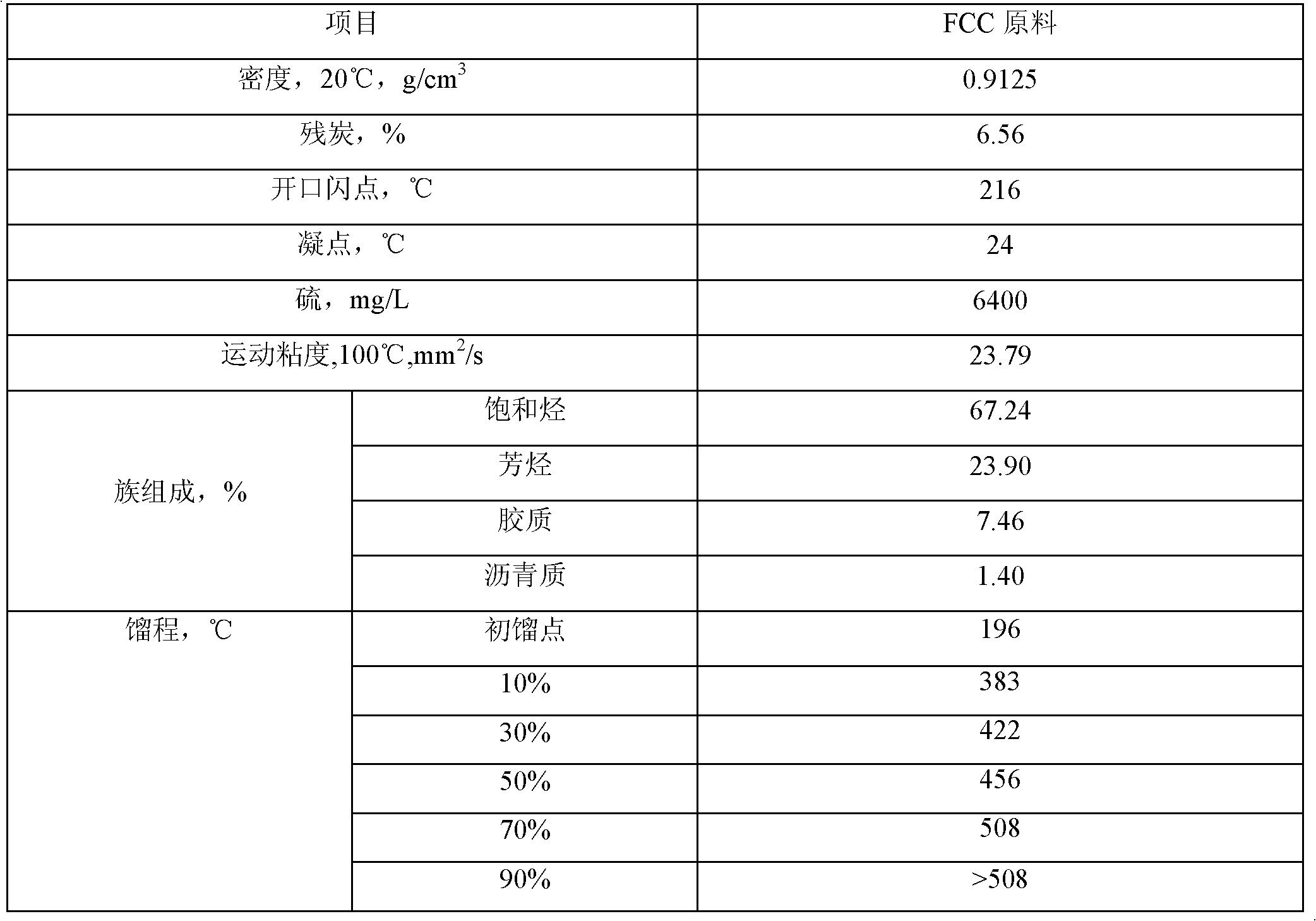

The invention belongs to the technical field of catalytic cracking of petroleum refining, and particularly relates to a heavy oil emulsion for catalytic cracking processing of heavy oil, a preparationmethod and applications thereof. According to the heavy oil emulsion, an emulsifier and water are mixed as a dispersion phase, heavy oil is used as a continuous phase, and an inorganic monodisperse porous membrane is used as an emulsifying medium; the dispersion phase and the continuous phase are respectively positioned on the two sides of the inorganic monodisperse porous membrane; the pressureof the dispersion phase is 1.0-2.8 MPa, the pressure of the heavy oil is 0.8-1.7 MPa, the pressure of the dispersion phase is 0.2-2.0 MPa higher than the pressure of the continuous phase, and under the action of the pressure difference, the dispersion phase enters the continuous phase through the membrane pores in the inorganic monodisperse porous membrane; and the dispersion phase forms a uniformwater-in-oil type emulsion under the action of the continuous shearing force of the continuous phase. The water-in-oil emulsion formed by the method is uniform in liquid droplet size, the dispersityand the atomization degree of the catalytic cracking feed are improved, the cracking depth is increased, the product distribution of the catalytic device is improved, and the yield is increased. The invention also provides a preparation method and applications of the heavy oil emulsion.

Owner:CHINA PETROLEUM & CHEM CORP +1

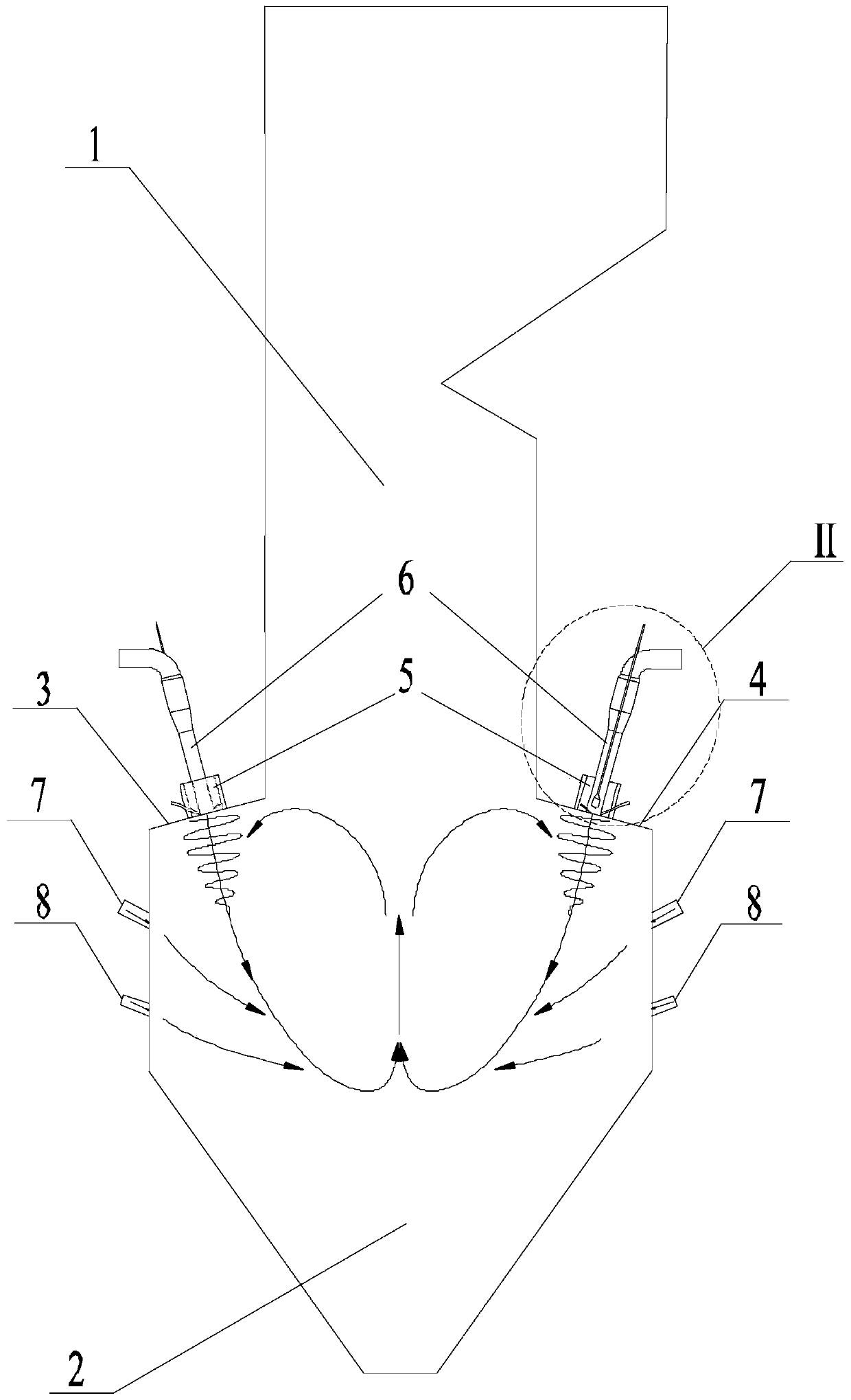

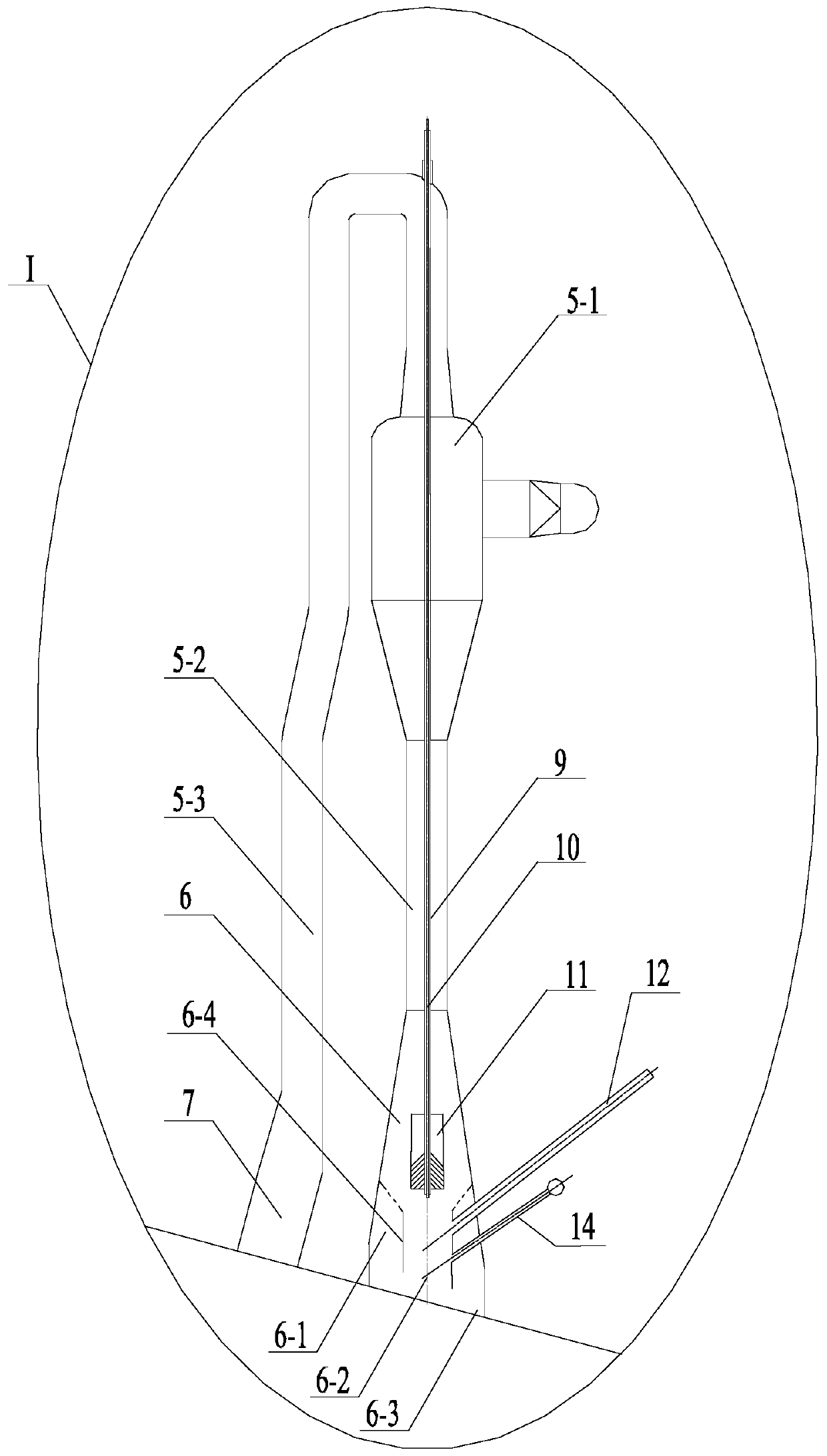

W flame boiler adopting turbulent burners

ActiveCN111023083APromote fireImprove featuresPulverulent fuel combustion burnersIndirect carbon-dioxide mitigationPower stationCombustor

The invention discloses a W flame boiler adopting turbulent burners, relates to a power station boiler adopting a flexible peak shaving technology, and belongs to the field of boilers. The invention aims to solve the problem that the W flame boiler adopts the turbulent pulverized coal burners in the prior art, the maximum peak shaving capacity of a boiler with a common micro-oil ignition mode is about 50%, the requirement of the government on the flexible peak shaving capacity of the power station boiler cannot be met; the W flame boiler adopting the turbulent burners comprises an upper hearth, a lower hearth, a front furnace arch, a rear furnace arch, a front wall, a rear wall and a plurality of turbulent pulverized coal burners, each turbulent pulverized coal burner comprises an adjustable cone pulling rod, a micro oil ignition gun and a flow guide cone, wherein the micro oil ignition guns are installed in the adjustable cone pulling rods, the bottom ends of the adjustable cone pulling rods are fixedly installed in the flow guide cones, the adjustable cone pulling rods, the micro oil ignition guns and the flow guide cones are installed in shells of the turbulent pulverized coal burners, and the turbulent pulverized coal burners are installed on a front furnace arch water wall and a rear furnace arch water wall correspondingly.

Owner:HARBIN INST OF TECH

High-pressure ionization spraying rod type amphibious plant protection vehicle with water and no pesticide

The invention provides a high-pressure ionization spraying rod type amphibious plant protection vehicle with water and no pesticide. The vehicle comprises an amphibious plant protection vehicle body,an onboard oxygen production module, an onboard liquid production module and an onboard spraying module. Compared with the prior art, the amphibious plant protection vehicle has the advantages that 'self-production and self-spraying' and 'production while spraying' medicaments are adopted as an efficient preventive ozone water solution, the medicaments are made from air and water, non-pesticide operation is achieved from the source, and due to the fact that after ozone touch killing of agricultural and forest harmful microorganisms and some pest, remaining ozone in the solution under normal temperature and normal pressure can be independently dissolved into oxygen, non-pesticide-residue operation is achieved; the amphibious vehicle and spraying rod type spraying are combined, and thereforeagricultural plant protection work is achieved; the amphibious plant protection vehicle is adopted, and the requirement that a ground plant protection machine and a water plant protection machine areboth needed in some regions is met.

Owner:SHANDONG UNIV OF TECH

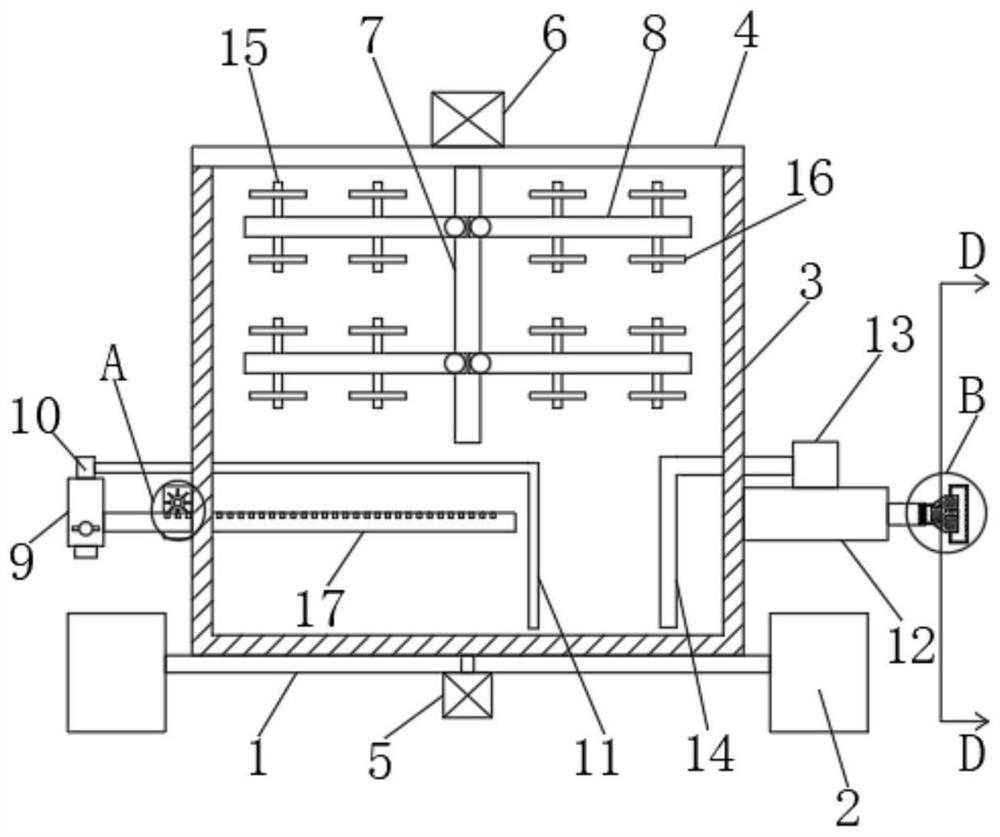

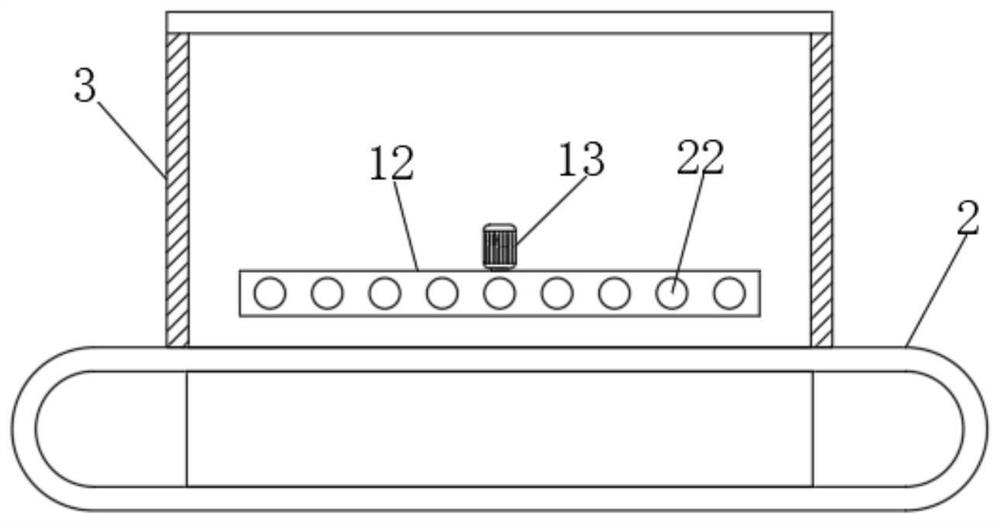

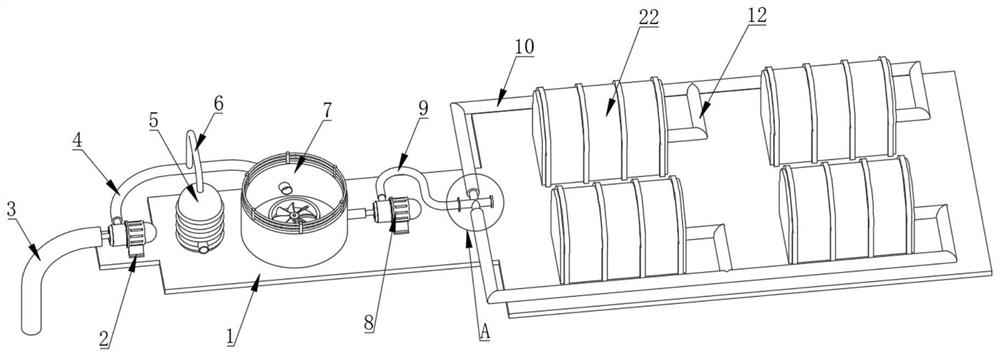

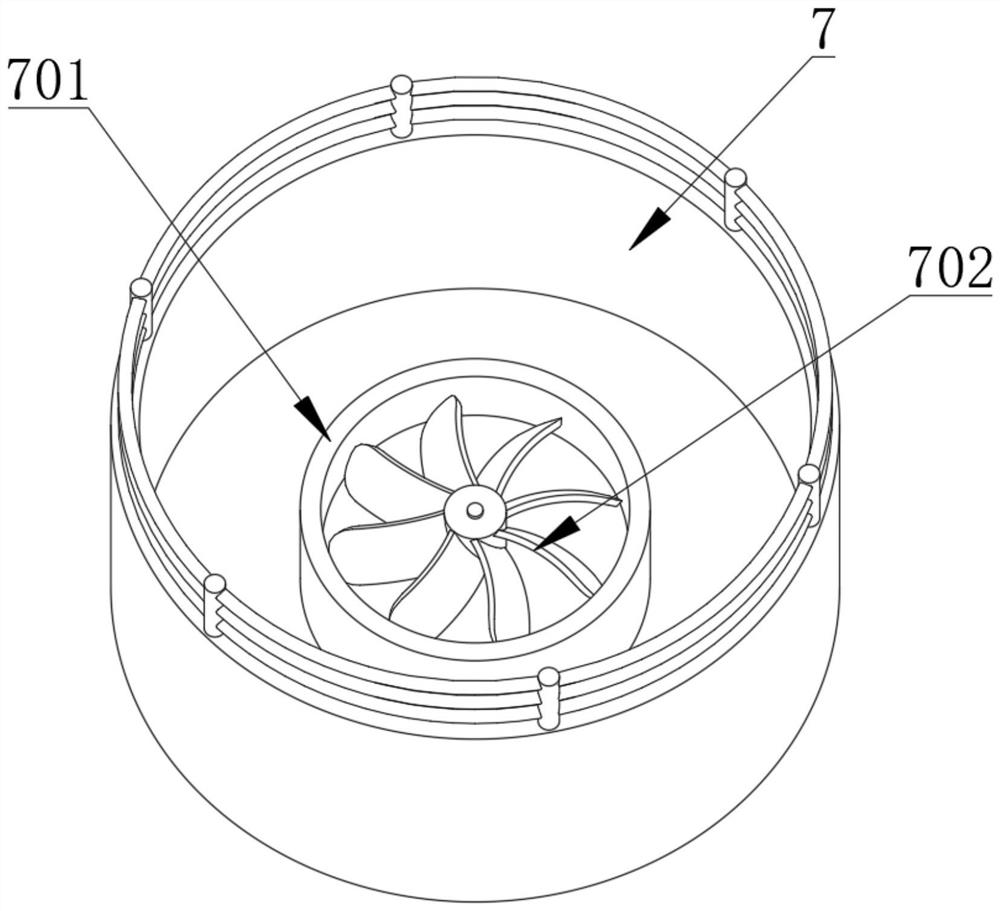

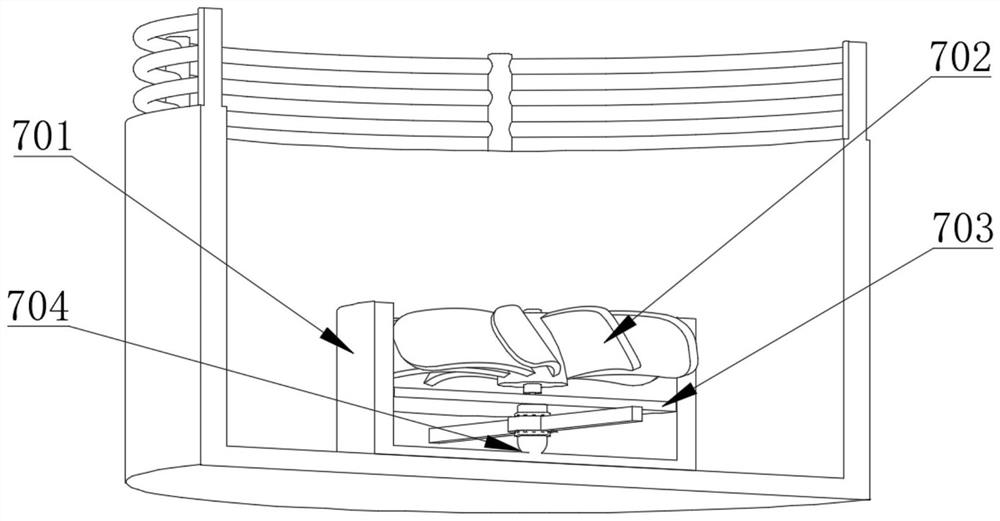

Soilless culture device and soilless culture method

InactiveCN113179933AShorten the construction periodEasy to useAgriculture gas emission reductionCultivating equipmentsAgricultural scienceCulture fluid

The invention relates to the technical field of agriculture. The invention aims to provide a modularized soilless culture device and a soilless culture method capable of effectively inhibiting pathogen transmission. The soilless culture device comprises a liquid storage tank, a supporting tank fixedly arranged above the liquid storage tank, and a field planting plate erected on the supporting tank, wherein the supporting tank comprises a tank body, end plates arranged at the two ends of the tank body and a supporting frame arranged in the center of the tank body and extending in the length direction of the tank body. According to the soilless culture device provided by the invention, a modular structure and a field assembly mode are adopted, so that the construction period is shortened, and as long as a field is available, the device can be used after being assembled so as to be very convenient to use. An ultrasonic atomization mode is adopted, so that the atomization degree of a culture solution is better, plant absorption is facilitated, and the aeroponic culture effect is improved. A culture solution disinfection filter is adopted to disinfect and kill the culture solution in real time, and meanwhile, separation strips are utilized to realize culture solution circulation, so that circulation dead angles are reduced, and plant diseases can be effectively inhibited.

Owner:XINYANG AGRI & FORESTRY UNIV

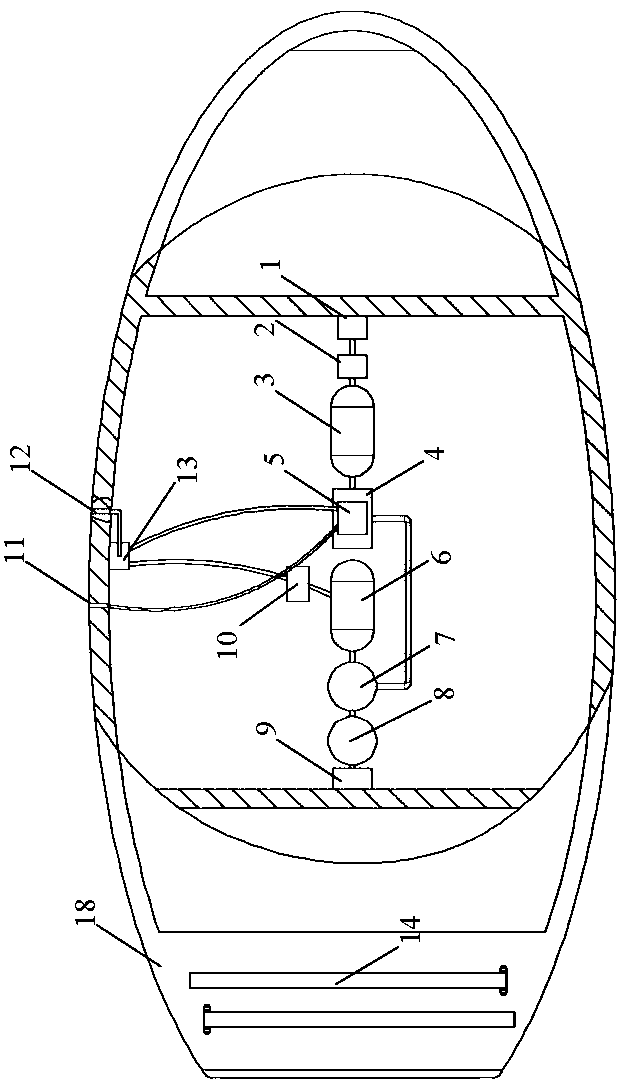

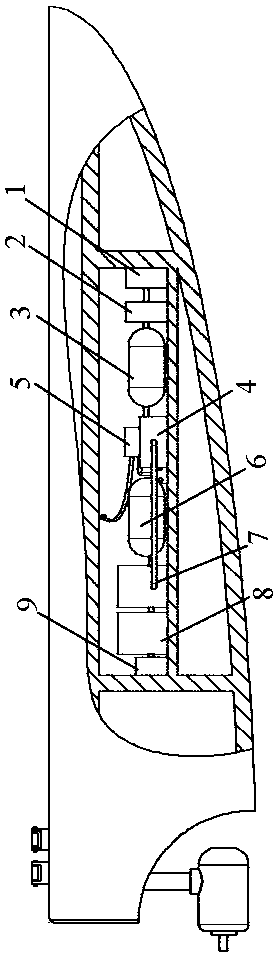

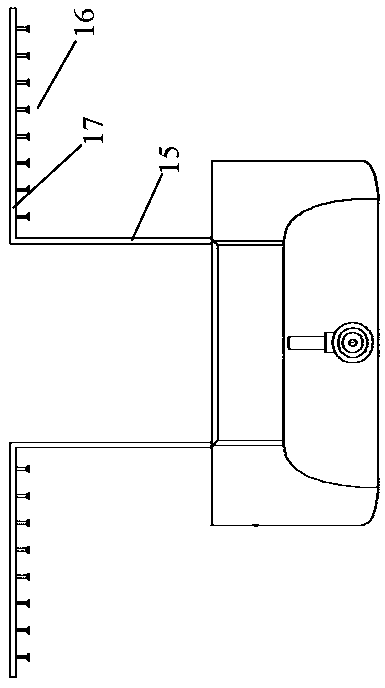

High-pressure ionization spraying rod type plant protection ship with water and no pesticide

InactiveCN109819960ARealize water plant protection operationsWorking method greenLavatory sanitoryChemicalsIonizationAgriculture

The invention provides a high-pressure ionization spraying rod type plant protection ship with water and no pesticide. The ship comprises a plant protection ship body, an onboard power module, an onboard oxygen production module, an onboard liquid production module, an onboard spraying module and a circulating water cooler module. Compared with the prior art, the plant protection ship has the advantages that 'self-production and self-spraying' and 'production while spraying' medicaments are adopted as an efficient preventive ozone water solution, the medicaments are made from air and water, non-pesticide operation is achieved from the source, and due to the fact that after ozone touch killing of agricultural and forest harmful microorganisms and some pest, remaining ozone in the solution can be independently dissolved into oxygen, non-pesticide-residue operation is achieved fundamentally; the principle of using local materials is adopted, water in working plant protection water regionsis used for performing circulating water cooling and water purifying to prepare the ozone water solution, the working time of the plant protection ship is prolonged, the working range is enlarged, and raw material and time cost is saved.

Owner:SHANDONG UNIV OF TECH

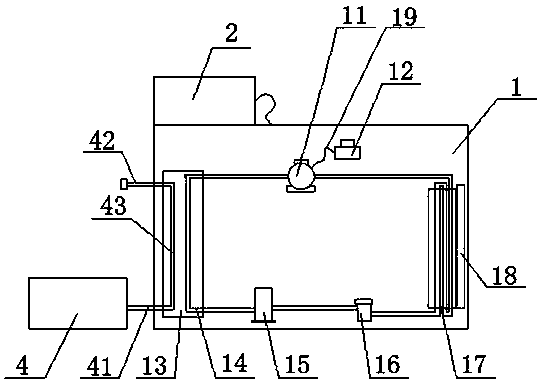

Energy-saving emission reduction device for automobile

InactiveCN102107605AGood atomizationBurn completelyInternal combustion piston enginesThermal treatment of fuelProcess engineeringFuel oil

The invention discloses an energy-saving emission reduction device for an automobile. The device comprises a buffer heating liquid storage tank, wherein the head end of the buffer heating liquid storage tank is provided with a fuel oil inlet which is communicated with an oil outlet pipeline of an oil tank, and the tail end of the buffer heating liquid storage tank is provided with a fuel oil outlet which is communicated with an oil inlet pipeline of an engine; the buffer heating liquid storage tank is provided with a heating unit for heating the interior of the buffer heating liquid storage tank; and preferably, the emission reduction device also comprises a buffer refrigerating liquid storage tank. The energy-saving emission reduction device for the automobile can greatly reduce the carbon emission of the automobile and has superior energy conservation and environmental protection functions.

Owner:廖森林

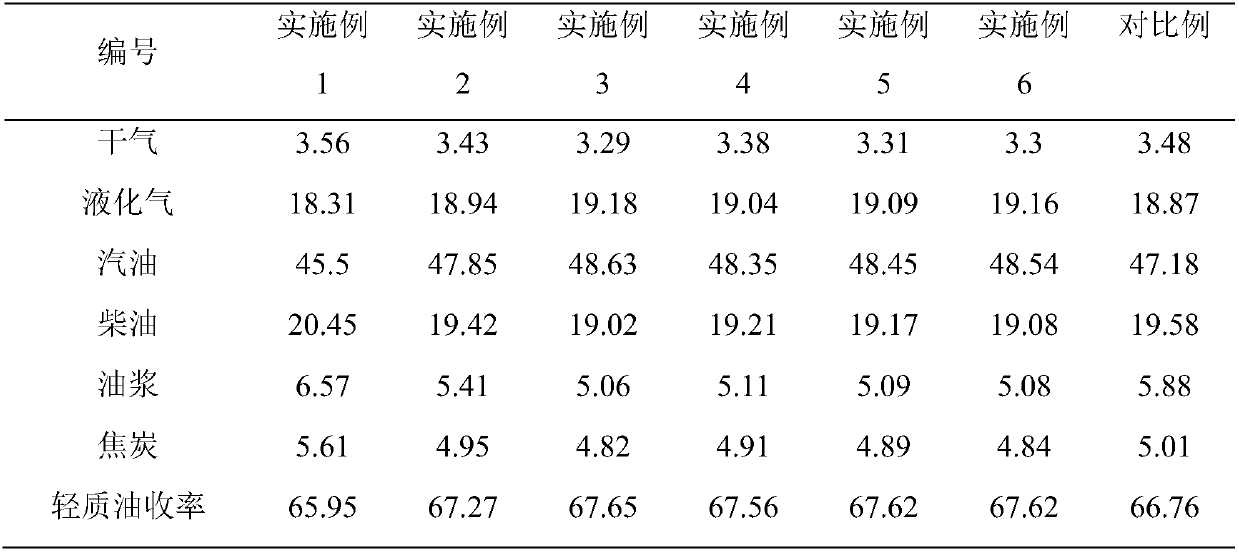

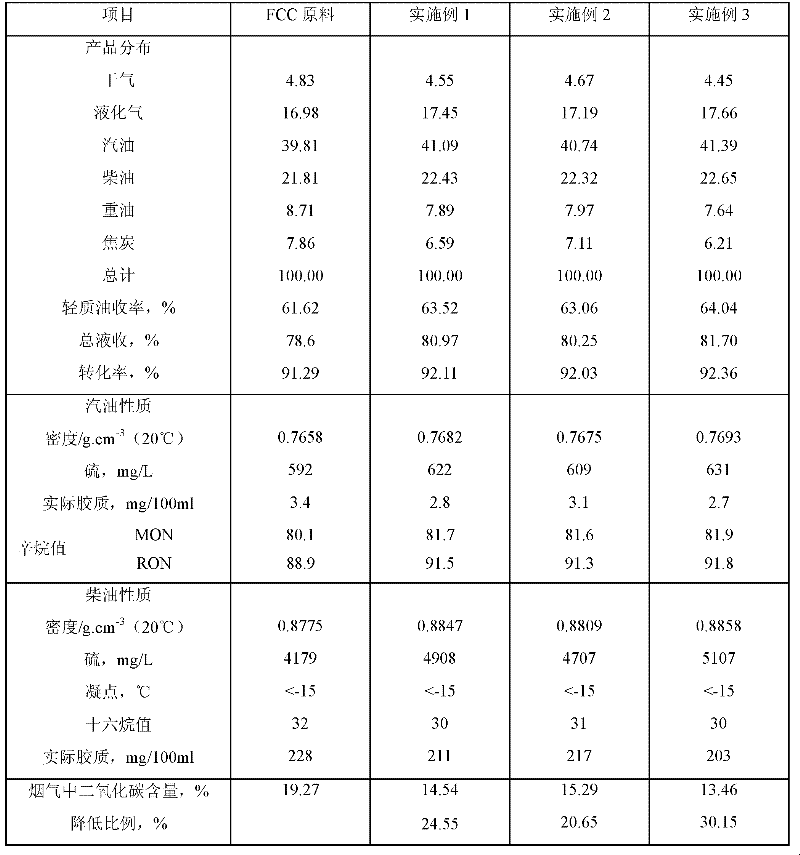

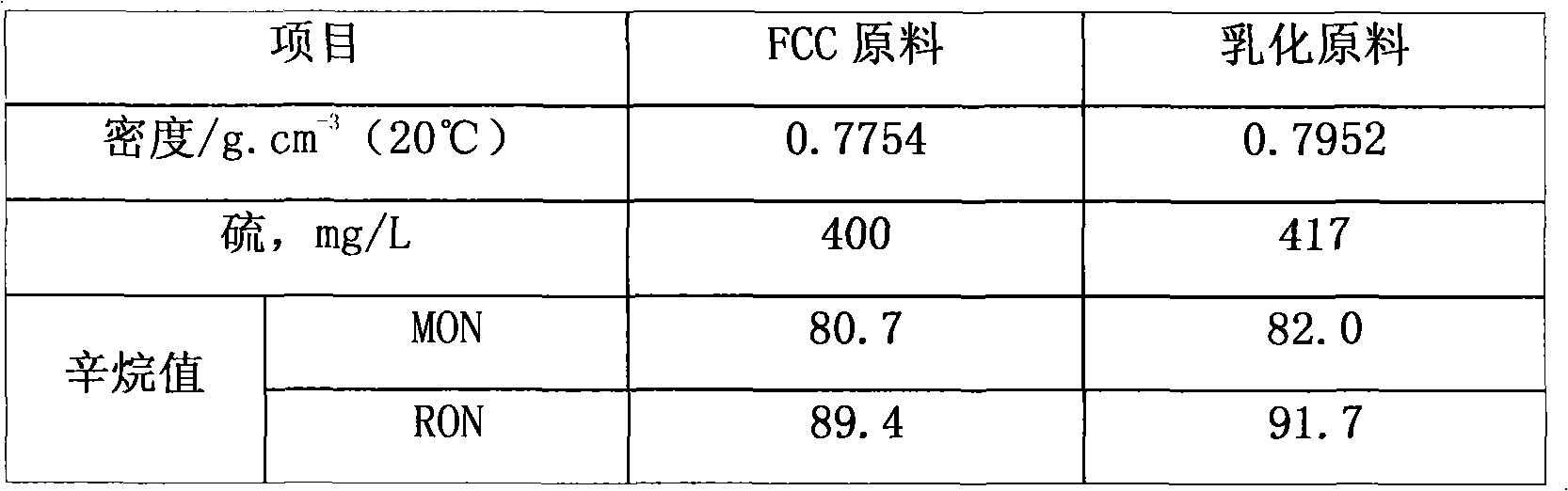

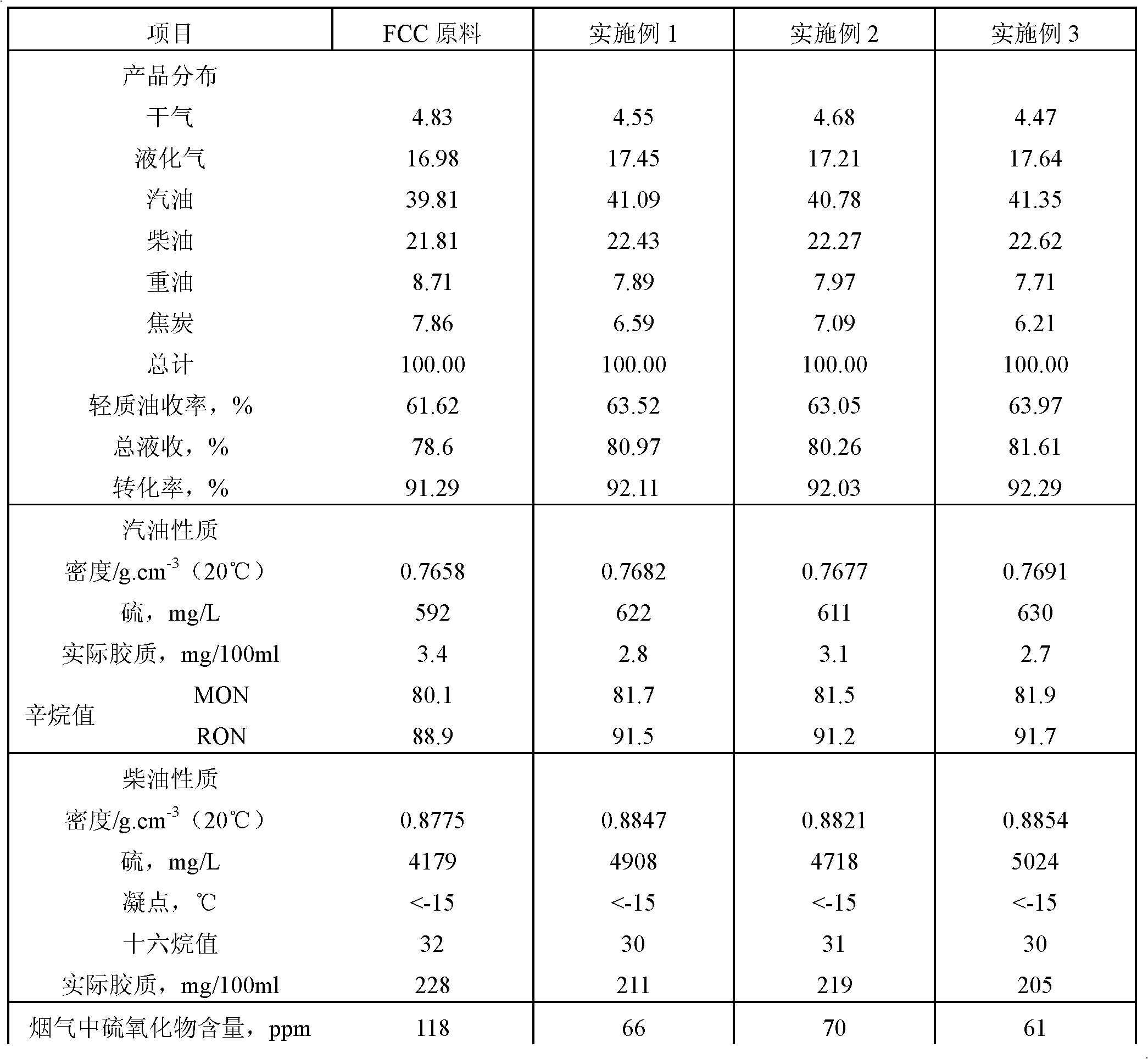

Method capable of improving gasoline yield of catalytic cracking device

InactiveCN107557062AHigh yieldPromote atomizationTreatment with plural serial stages onlyDispersityMass ratio

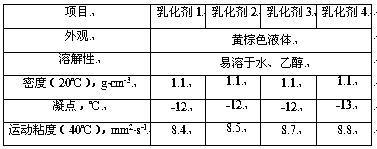

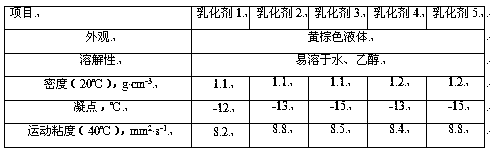

The invention provides a method capable of improving the gasoline yield of a catalytic cracking device, belonging to the technical field of catalytic cracking of petroleum refining. The method is characterized in that a to-be-catalytically-cracked raw material, water and an emulsifier are mixed through a premixer, and then enter an emulsifying device for emulsifying; the mass ratio of the to-be-catalytically-cracked raw material to the water to the emulsifier is (88-89.7): (8.5-10): (1.8-2); emulsified oil obtained by emulsifying directly enters a catalytic device for a catalytic reaction; andthe conditions of emulsifying in the emulsifying device are as follows: shearing and stirring are performed at a rotating speed of 6000 r / min to 8000 r / min, and a pressure of 1.3 MPa to 1.4 MPa and atemperature of 180 DEG C to 195 DEG C are maintained in the emulsifying device at the same time. The method provided by the invention improves the dispersity and the fogging degree of a catalytic cracking feeding material, improves the depth of cracking, and enhances the motor octane number and the research octane number of catalytically cracked gasoline at the same time. Meanwhile, a calibrationtest is performed on an industrial device, so the distribution of a cracked product is improved, and the yield of gasoline is enhanced.

Owner:CHINA PETROLEUM & CHEM CORP

Method for reducing emission of carbon dioxide in catalytic cracking flue gas

ActiveCN102453514AIncrease contactEmission reductionTreatment with plural serial stages onlyRefining by water treatmentFlue gasFuel oil

Belonging to the technical field of catalytic cracking for petroleum refining, the invention relates to a method for reducing emission of carbon dioxide in catalytic cracking flue gas. The method comprises the steps of: conducting emulsification to a catalytic cracking raw material under the conditions of normal pressure, an emulsification of 45-90DEG C, a water adding amount of 1%-10%, a multifunctional composite emulsifier adding amount of 0.01%-2%, and a stirring speed of 15000-20000r / min, and subjecting the emulsified raw oil to direct catalytic reaction as a catalytic material. After emulsification of a heavy oil catalytic cracking raw material, the atomization degree and dispersibility of catalytic charged material are improved, and particle sizes of charged droplets are greatly reduced, thus reaching the purposes of enhancing light oil yield and total liquid yield, lowering coke yield so as to reduce the content of carbon dioxide in flue gas.

Owner:CHINA PETROLEUM & CHEM CORP

Municipal garden nutrient solution proportioning dilution stirring device

The invention provides a municipal garden nutrient solution proportioning dilution stirring device, and discloses a device for mixing and dilution through injecting a nutrition solution and a dilutionsolution at the same time, performing spraying after the mixing, and forming atomization. The municipal garden nutrient solution proportioning dilution stirring device is characterized in that a driving shaft is arranged on a driving motor; a fixed ring is arranged on a driving shaft in a sleeving way; a ceramic gasket is arranged between the inner side of the fixing ring and the outer side of the driving shaft; one end of the transmission shaft is arranged in the fixed ring and is connected with one end of the driving shaft through a plurality of rotation stop pins; the ceramic gasket is arranged between the outer side of the transmission shaft and the inner side of the fixed ring; the transmission shaft is of a hollow structure; a plurality of through holes are formed in the fixed ring;one end of an injection pipe is arranged in the through hole and communicates with the inside of the fixed ring; a sealing ring is arranged between the injection pipe and the hole wall of the corresponding through hole; a plurality of spoilers are arranged on the inner wall of the transmission shaft and extends in a direction along the longitudinal depth of the axial direction; the number of thespoilers is an even number, and is at least two; the height of the spoilers is gradually increased from one end to the other end.

Owner:江苏华淼电子科技有限公司

Method capable of improving gasoline-diesel ratio of catalytic cracking device

InactiveCN107557052AImproved dispersion and atomizationIncrease cracking depthCatalytic crackingChemistryPetroleum

Owner:CHINA PETROLEUM & CHEM CORP

Multi-nozzle fire extinguishing device

InactiveCN114225282AGood atomizationFacilitated DiffusionFire rescueEngineeringStructural engineering

The invention discloses a multi-nozzle fire extinguishing device, and belongs to the technical field of fire fighting equipment. The device comprises a bottle body, a shield, a valve seat, a rupture disk, a valve and a nozzle, the upper half part of the spray head is provided with an upper nozzle and four side nozzles, the upper nozzle is positioned right above the spray head, the side nozzles are uniformly distributed in the circumferential direction of the spray head, the front end surfaces of the upper nozzle and the side nozzles are spherical surfaces, and spray holes are distributed in the spherical surfaces; the lower half part of the spray head is of a cylindrical cavity structure, and a threaded section is machined on the outer circumferential surface of the cylindrical cavity structure; the valve seat is fixedly connected to a bottle opening of the bottle body, the spray head is connected with an internal thread on the valve in a matched mode through a threaded section of the lower half portion of the spray head, the spray head and the protective cover are fixed together through the upper nozzle and the side nozzle, after the protective cover and the bottle body are fixed, the rupture disk is pressed on the upper end face of the valve seat through the valve, and an opening of the bottle body is closed through the rupture disk. The liquid fire extinguishing agent can be gasified or the solid fire extinguishing agent can be quickly atomized and dispersed all around, so that the purposes of extinguishing fire and suppressing explosion are achieved.

Owner:北京北机机电工业有限责任公司

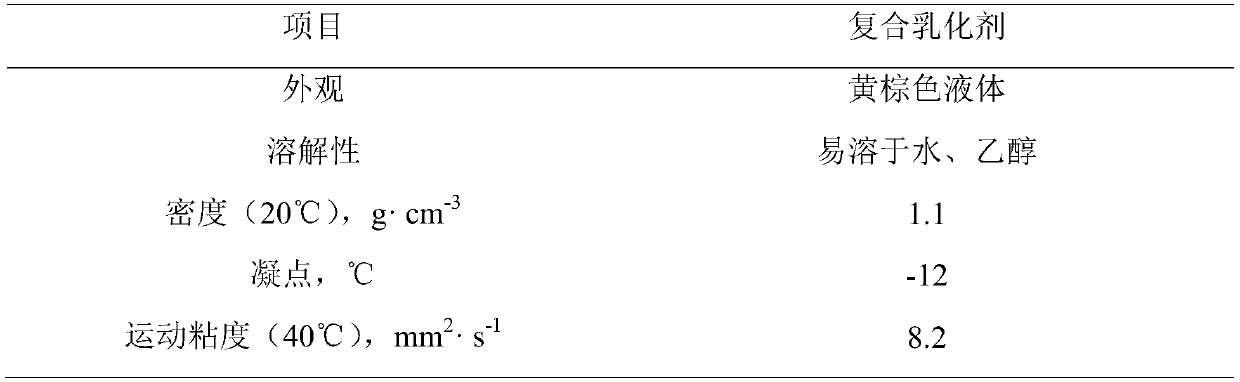

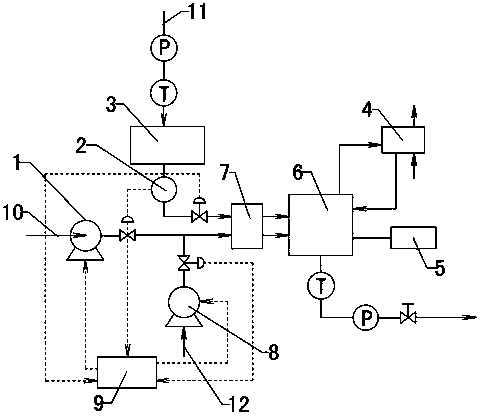

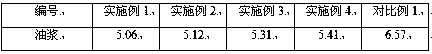

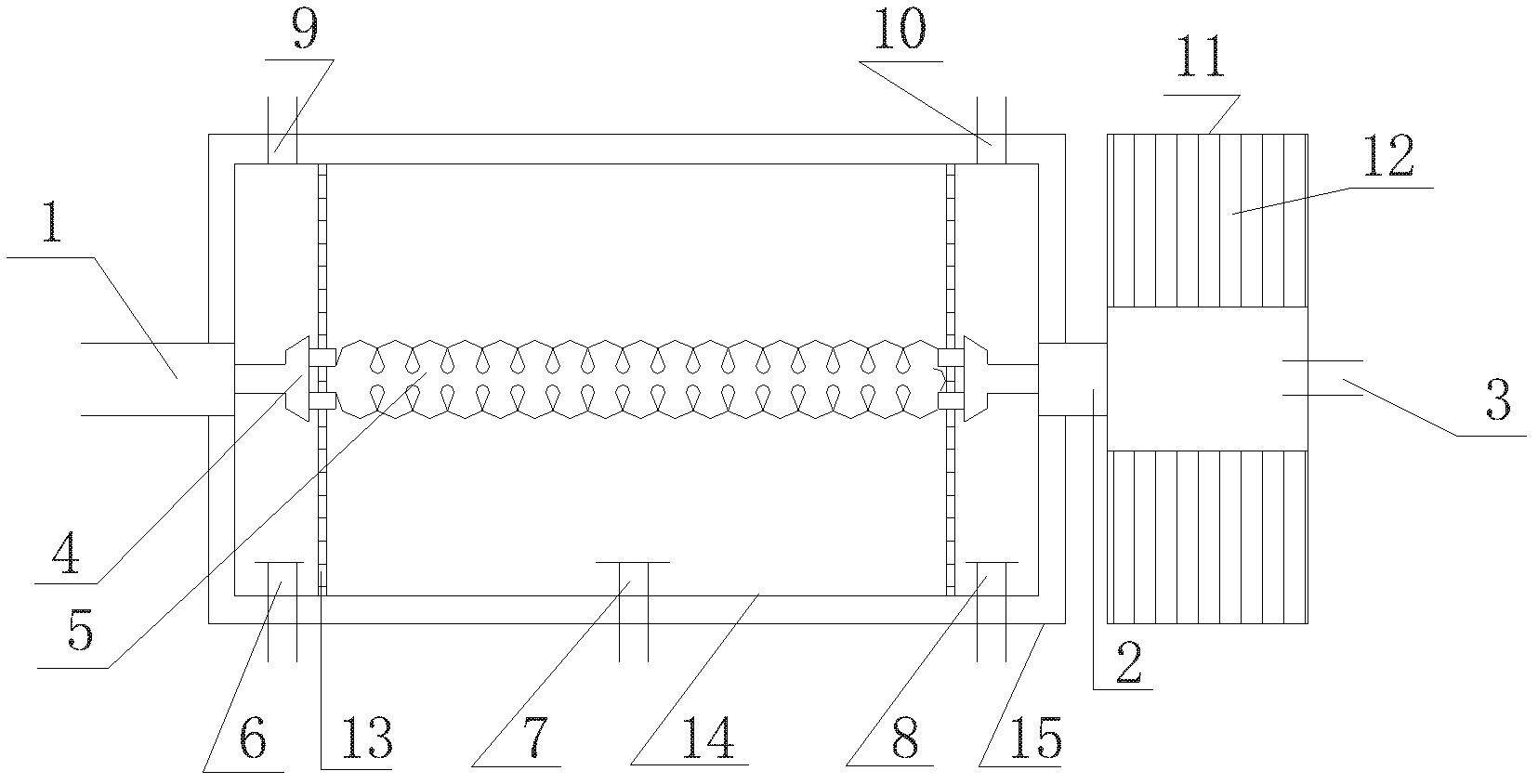

Method for emulsification continuous feeding of heavy oil weight catalytic cracking raw material

The invention relates to a method for emulsification continuous feeding of a heavy oil weight catalytic cracking raw material, comprising the following steps of: mixing and emulsifying the catalytic cracking raw material, a compound emulsifier and water; and directly introducing emulsified emulsifying oil into a catalytic device for catalytic reaction, wherein the emulsifying is carried out at normal pressure and the temperature of 50-95 DEG C, the water adding quantity accounts for 1-15% of the mass of the emulsifying oil, the adding quantity of the compound emulsifier accounts for 0.01-2% of the mass of the emulsifying oil, and the stirring speed is more than 15,000r / min. In the invention, the emulsified emulsifying oil as the catalytic raw material is directly introduced into the catalytic device for catalytic reaction without utilizing a buffer oil tank in the middle process, the dwell time after emulsification is short and the emulsion breaking problem is unavailable. After the heavy oil catalytic cracking raw material is emulsified, the dispersity and the atomization degree of the catalytic cracking feeding are improved, the atomization efficiency is enhanced, the particle diameter of feeding oil drop is greatly reduced, an oiling agent is ensured to be effectively contacted, the cracking depth is increased, and the purposes of enhancing the yield of light weight oil and the total liquid yield and reducing the yield of coke can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP

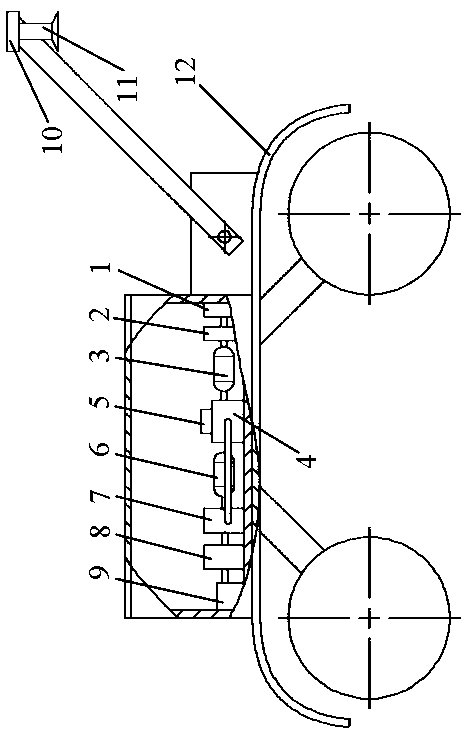

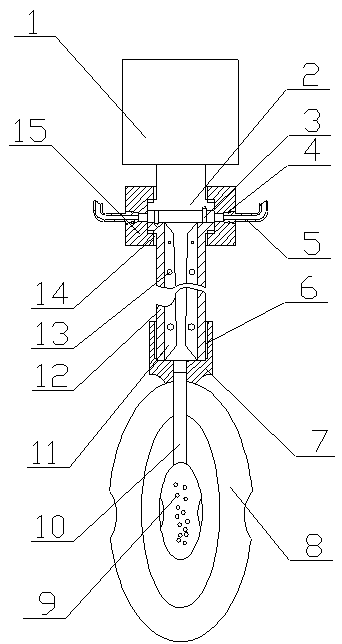

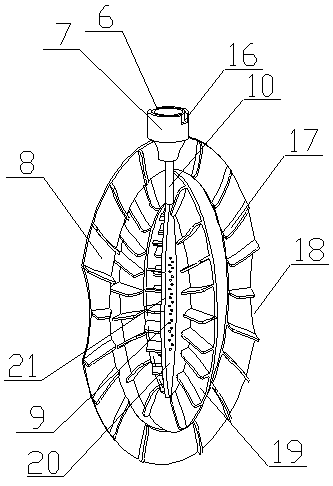

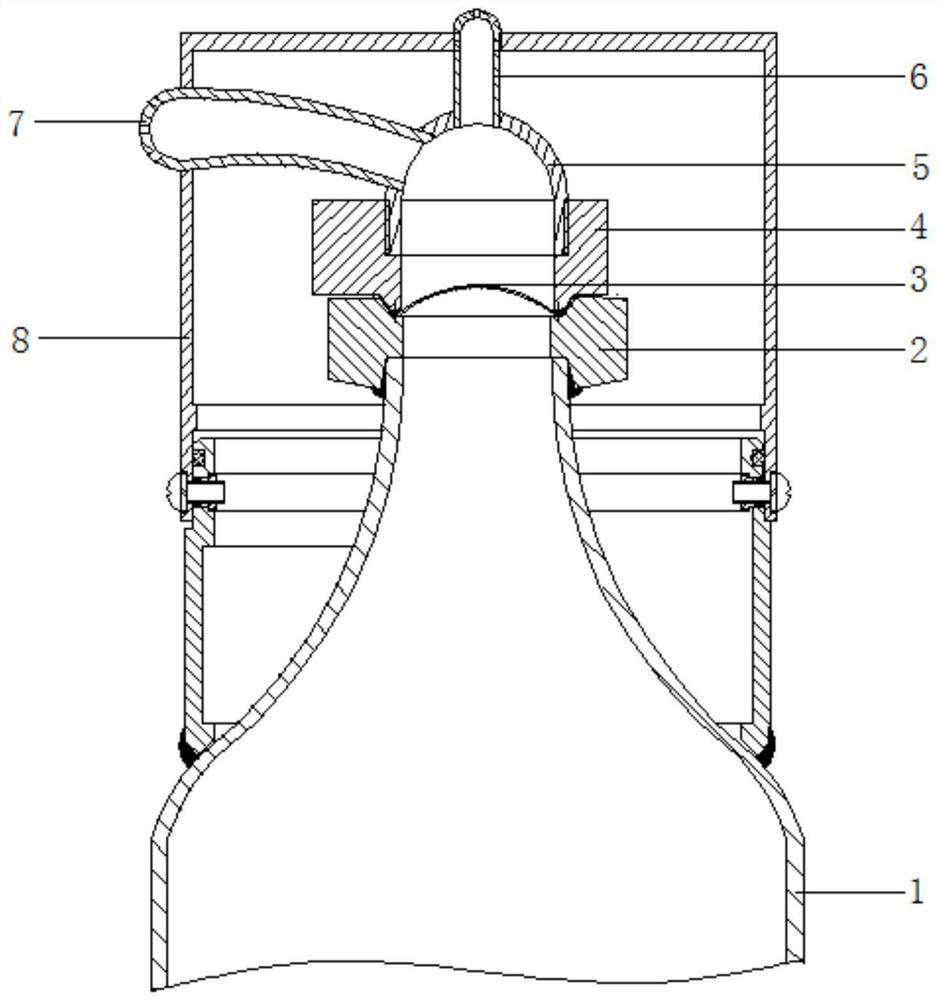

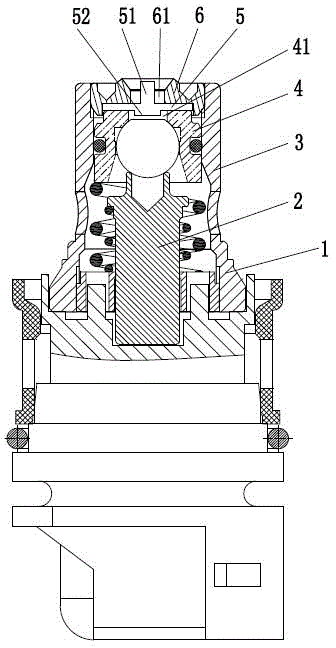

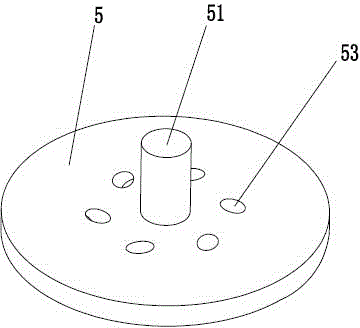

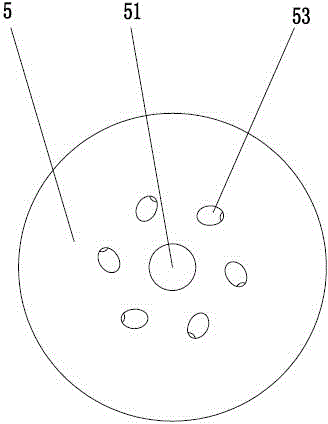

Electronic injection type automotive umbrella-shaped spiral ethanol oil injector assembly

InactiveCN103061933AIncrease the diffusion spaceGood atomizationFuel injection apparatusMachines/enginesPetroleum engineeringInjector

The invention relates to an electronic injection type automotive umbrella-shaped spiral ethanol oil injector assembly and mainly solves the problem of the existing electronic injection type automotive umbrella-shaped spiral ethanol oil injector assembly of being low in atomization degree and fuel burning ratio in use. The electronic injection type automotive umbrella-shaped spiral ethanol oil injector assembly comprises an oil inlet pipe, a valve rod, a valve base, a cap and an oil outlet pipe. An oil inlet is arranged on the lateral surface of the oil inlet pipe, the valve rod is arranged in the oil inlet pipe, and an oil outlet pipe is arranged on the valve base and corresponds to the valve rod. The cap is arranged on the other side of the valve base corresponding to the valve rod, a first through hole is arranged at the central position of the cap of the valve base, a second through hole corresponding to the first through hole is arranged at the central position of the valve base, a guide plate is arranged between the valve base and the cap, and a plurality of spiral holes which are circumferentially distributed along the center of the guide plate are arranged on the guide plate. The electronic injection type automotive umbrella-shaped spiral ethanol oil injector assembly has the advantages of being good in atomization degree and sufficient in fuel burning.

Owner:WENZHOU BATON ELECTRONICS TECH

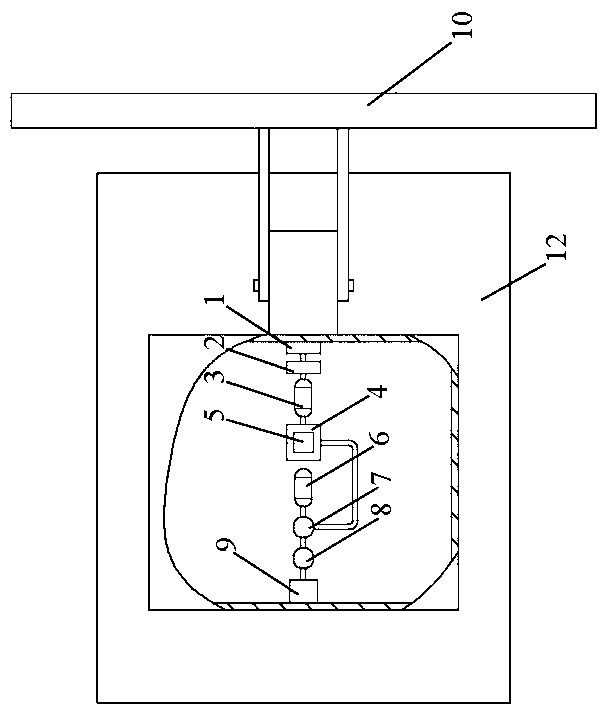

W-flame boiler adopting slit type combustor

ActiveCN111023081AImprove ignition characteristicsImprove low-load combustion stabilityCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelThermodynamicsCombustor

The invention discloses a W-flame boiler adopting a slit type combustor, and relates to a W-flame boiler adopting a flexible peak regulation technology. The W-flame boiler adopting the slit type combustor aims to solve the problems that when the load of the conventional W-flame boiler is lower than 50 percent by adopting an oil gun ignition mode, the combustion is unstable and even the fire is extinguished; and the flexible peak regulation capacity of the boiler needs to reach 20% of full load, but a boiler meeting the condition does not exist in the prior art. The W-flame boiler comprises anupper hearth, a lower hearth, a front boiler arch, a rear boiler arch, a front wall, a rear wall, a plurality of straight flow gap type combustors and a plurality of grading air nozzles; and each straight flow gap type combustor comprises a hollow rotational flow adjusting pull rod, a tiny-oil burning torch and a pulverized coal flow guiding body, wherein the tiny-oil burning torch is installed inthe hollow rotational flow adjusting pull rod, the bottom end of the hollow rotational flow adjusting pull rod is fixedly connected with the pulverized coal flow guiding body, and the hollow rotational flow adjusting pull rod, the tiny-oil burning torch and the pulverized coal flow guiding body are installed in the straight flow gap type combustor shell. The invention belongs to the field of boilers.

Owner:HARBIN INST OF TECH

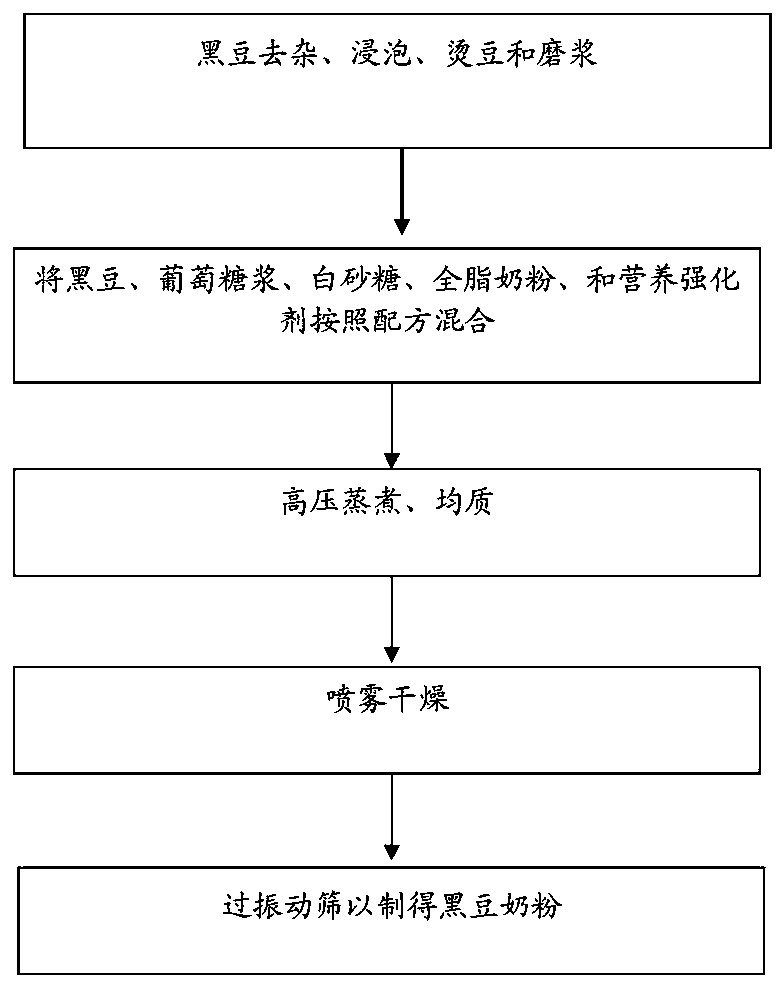

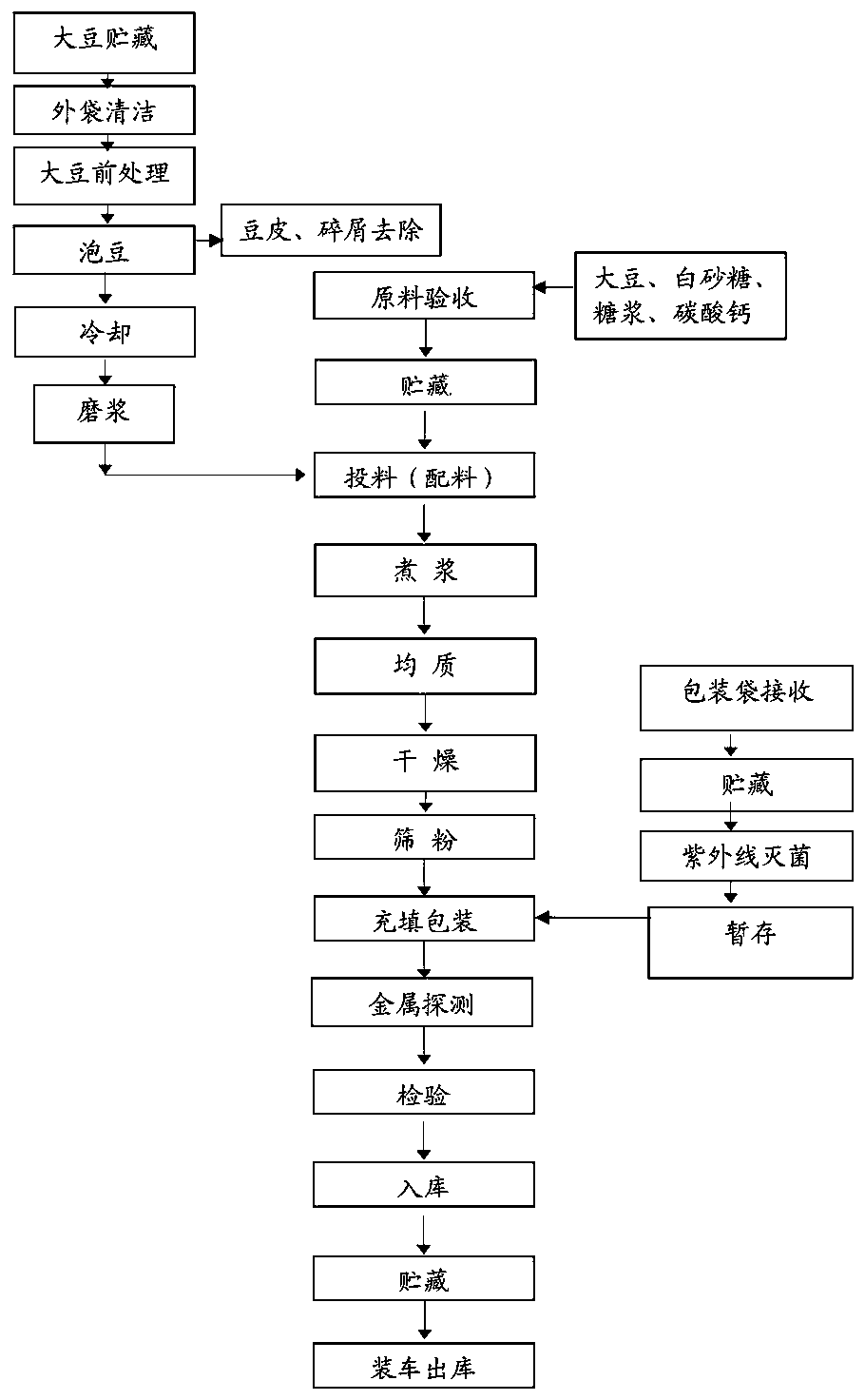

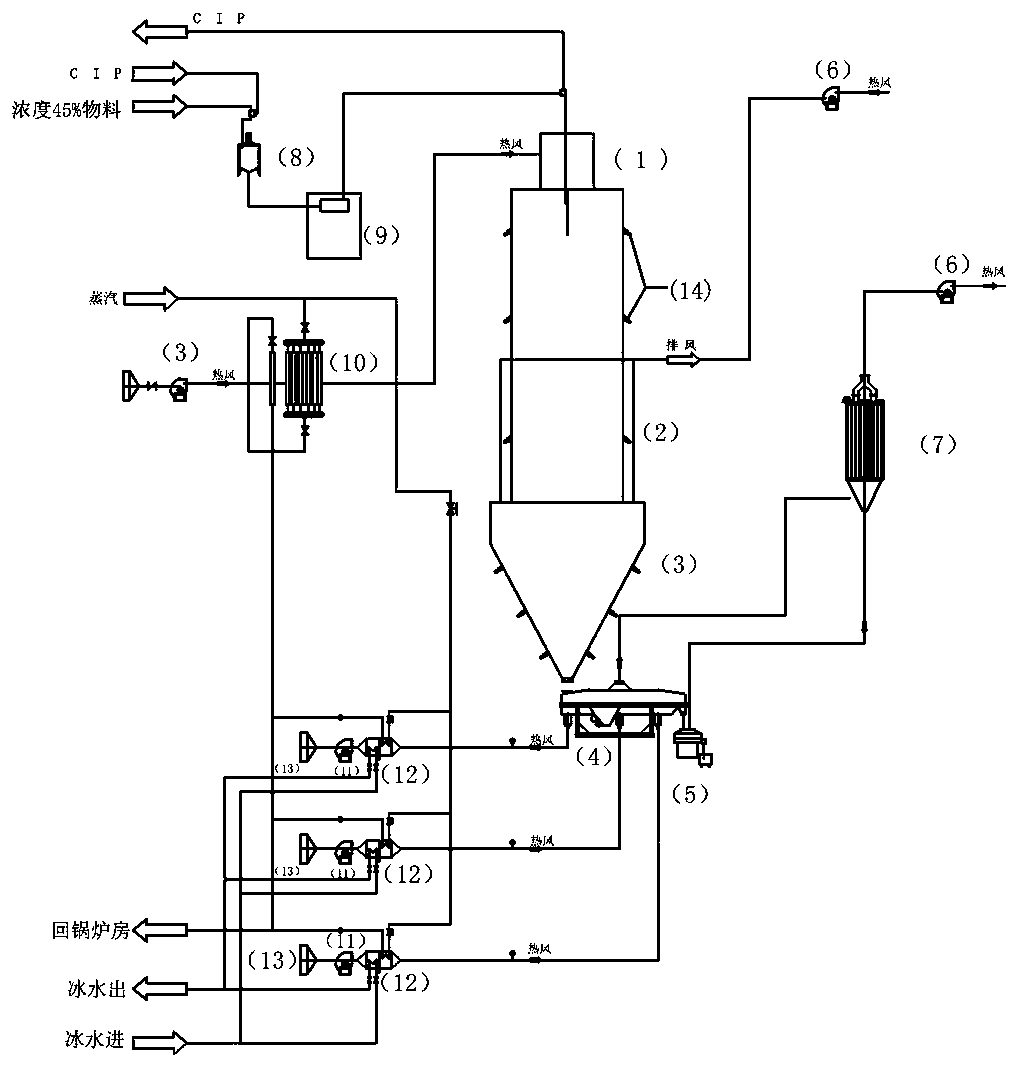

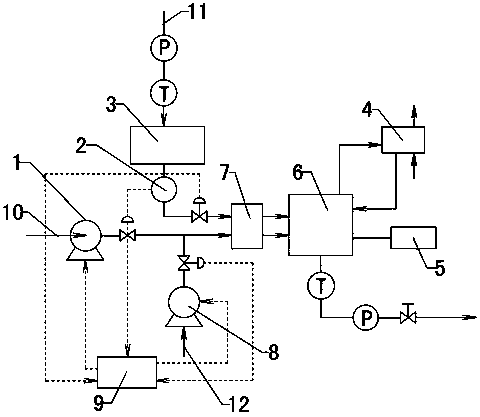

Black soybean milk powder and production method with spray-drying technology thereof

The invention provides black soybean milk powder and a production method with a spray-drying technology thereof. The black soybean milk powder is prepared from the following raw materials in parts byweight according to the following formula: 40 to 70 parts of black soybeans, 10 to 20 parts of glucose syrup, 2 to 15 parts of white granulated sugar, 2 to 15 parts of whole milk powder and 2 to 15 parts of a nutrition enhancer. The production method comprises the following steps: removing impurities from the black soybeans, soaking the black soybeans, scalding the black soybeans and grinding theblack soybeans into thick liquid, preparing the black soybean thick liquid with the glucose syrup, the white granulated sugar, the whole milk powder and the nutrition enhancer according to formula, steaming and boiling at high pressure, homogenizing, performing spray-drying, and sieving by a vibration sieve to obtain the black soybean milk powder.

Owner:广东一家人食品有限公司 +1

Method capable of reducing yield of slurry oil of catalytic cracking device

InactiveCN107557049AImproved dispersion and atomizationIncrease cracking depthCatalytic crackingChemistryPetroleum

Owner:CHINA PETROLEUM & CHEM CORP

Waste heat fuel-saving device of diesel internal combustion engine

InactiveCN102352803ABurn fullyCurb emissionsInternal combustion piston enginesThermal treatment of fuelThermal energyExternal combustion engine

The invention discloses a waste heat fuel-saving device of a diesel internal combustion engine. In order to solve the technical problem that waste heat energy exhausted by an air cylinder of the internal combustion engine after operation is utilized to heat diesel before the diesel enters the air cylinder, and the diesel is magnetized after being heated. The device comprises a control circuit, a heat supply device for heating the diesel and a permanent magnetic assembly; the heat supply device is an enclosed hollow cylinder which is internally provided with a diesel delivery pipeline axially; the inlet end of the delivery pipeline is communicated with the output end of a fuel spray pump of the internal combustion engine, and the outlet end of the delivery pipeline is connected to the input end of an air cylinder spray nozzle of the internal combustion engine through the permanent magnetic assembly; and the heat supply device is also provided with a waste heat air inlet and a waste heat air outlet. According to the invention, the viscosity of the diesel entering the air cylinder of the internal combustion engine is controlled within the range of 6.5-7.5mm<2> / s; under the magnetization of greater magnetic field intensity, and the diesel molecular group becomes fine, thus the diesel entering the air cylinder of the internal combustion engine can be burned fully, fuel oil is saved, the emission of black smoke is restrained, thus being environmentally-friendly.

Owner:冯林

A method for reducing the ratio of hydrogen to methane in catalytic cracking dry gas

ActiveCN107557070BGood emulsificationGood secondary atomization effectGaseous mixture working upEngineeringMixed materials

Owner:CHINA PETROLEUM & CHEM CORP

Method for reducing content of sulfur oxides in catalytic cracking smoke

ActiveCN102453513BGood atomizationGood dispersionTreatment with plural serial stages onlyRefining by water treatmentSulfurPetroleum

The invention which relates to a method for reducing the content of sulfur oxides in a catalytic cracking smoke belongs to the technical field of petroleum refining catalytic cracking. The method comprises the following steps: 1, homogeneously emulsifying a catalytic cracking raw material under conditions that the pressure is normal, the temperature is 50-90DEG C, the water addition amount is 1-13%, the multifunctional compound emulsifier addition amount is 0.01-2% and the stirring speed is 20000-30000r / min; and 2, directly catalyzing the obtained emulsified raw oil which is used as a catalytic raw material. By adopting above heavy oil catalytic cracking raw material emulsification technology disclosed in the invention, the catalytic feeding material atomization degree is improved, the dispersibility of the catalytic feeding material is improved, and the particle size of feeding oil drops is greatly reduced, thereby purposes that the light oil yield and the total liquid yield are improved and the content of the sulfur oxides in the smoke is reduced can be reached, and the method has the advantages of small investment, low cost and convenient operation.

Owner:CHINA PETROLEUM & CHEM CORP

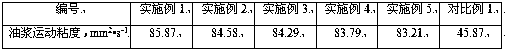

Method capable of improving viscosity of catalytic cracking slurry oil

InactiveCN107557050AImprove product launchesIncrease the kinematic viscosity of oil slurryCatalytic crackingChemistryPetroleum

The invention provides a method capable of improving the viscosity of catalytic cracking slurry oil, belonging to the technical field of catalytic cracking of petroleum refining. The method is characterized in that a to-be-catalytically-cracked raw material, water and an emulsifier are mixed through a premixer, and then enter an emulsifying device for emulsifying; the mass ratio of the to-be-catalytically-cracked raw material to the water to the emulsifier is (90.5-92.95): (6-8): (1.05-1.5); emulsified oil obtained by emulsifying directly enters a catalytic device for a catalytic reaction; andthe conditions of emulsifying in the emulsifying device are as follows: shearing and stirring are performed at a rotating speed of 6000 r / min to 8000 r / min, and a pressure of 1.6 MPa to 1.7 MPa and atemperature of 200 DEG C to 220 DEG C are maintained in the emulsifying device at the same time. The method provided by the invention enables a catalytic cracking raw material to form a stable emulsified solution through the premixer and the emulsifying device with specific pressure and temperature, greatly improves the product distribution of the catalytic device, and enhances the kinematic viscosity of the slurry oil.

Owner:CHINA PETROLEUM & CHEM CORP

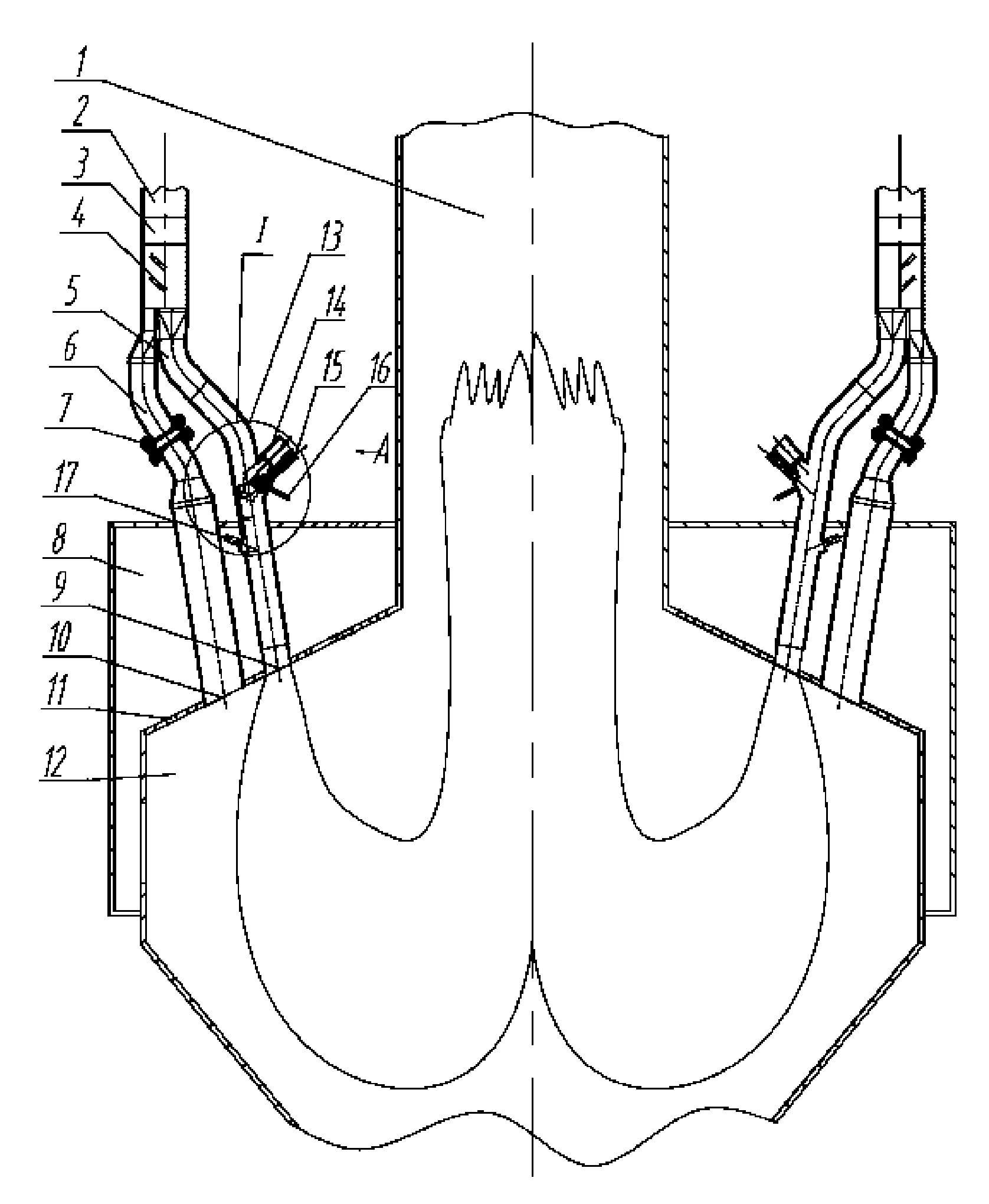

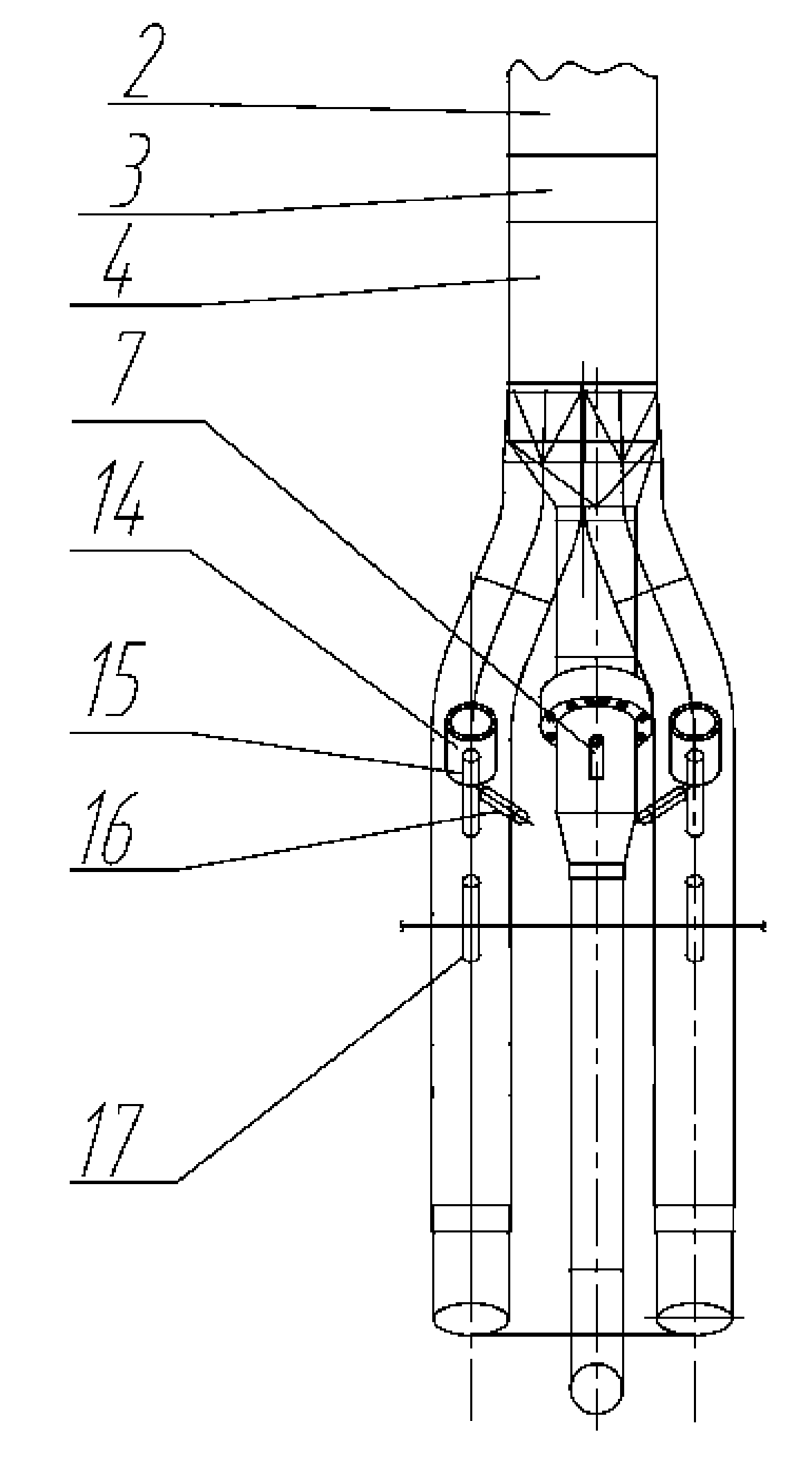

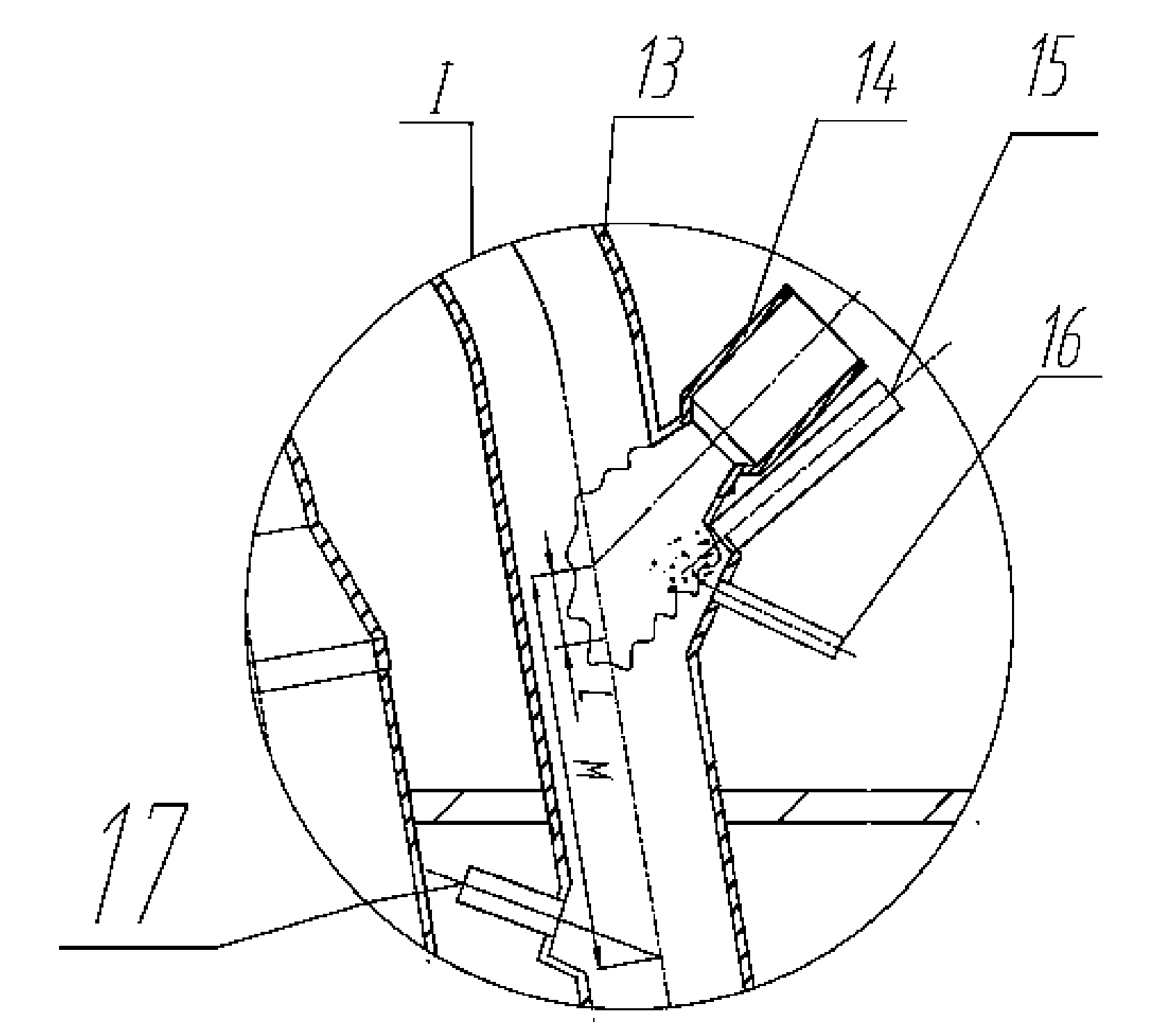

Trace oil igniting coal dust firing device for multiple oil guns

InactiveCN101603684BEasy to igniteNot easy to ignitePilot flame ignitersPulverulent fuel combustion burnersCoal dustPetroleum engineering

The invention provides a trace oil igniting coal dust firing device for multiple oil guns, relates to a firing device, and solves the problem of easily failed ignition due to the fact that distance between a main oil gun and an auxiliary oil gun on the same side is large, and the main oil gun and an auxiliary oil gun on the opposite side are not alternately arranged in the prior firing device. The main oil gun and the auxiliary oil gun on the opposite side are alternately and oppositely arranged on side walls of a concentrated coal dust pipeline; distances of crossing points among the centralline of the main oil gun, the central line of the auxiliary oil gun on the same side and the central line of the concentrated coal dust pipeline are between 80 and 100mm; and distances of the crossing points of the central line of the main oil gun, the central line of the auxiliary oil gun on the opposite side and the central line of the concentrated coal dust pipeline are between 500 and 700mm. The distance between the main oil gun and the auxiliary oil gun on the same side is close so as to ensure that fuel which is sprayed from the auxiliary oil gun and has excellent atomization can be directly sprayed into high temperature flame generated by ignition of the main oil gun for fierce firing, and the flame generated after fuel sprayed from the main oil gun and the auxiliary oil gun is fired can support each other to form whole flame which has large length and roughness and good rigidity and can ignite high concentrated coal dust.

Owner:HARBIN INST OF TECH

A Reverse Carnot Cycle Vehicle Emission Reduction Device

ActiveCN105927427BTo achieve the purpose of saving fuelGood atomizationMachines/enginesThermal treatment of fuelCarnot cycleLiquid storage tank

The invention provides an automobile emission reducing device adopting reverse Carnot cycle. The automobile emission reducing device adopting reverse Carnot cycle comprises a heater, a processing box, a detector and a liquid storage tank, wherein the detector is mounted below an automobile driver's seat; the processing box is mounted above the heater; a printed circuit board is arranged inside the processing box; an analog-digital converter, a micro processing chip, a storage chip, a digital analog converter, a relay and a battery are welded on the printed circuit board; the processing box is electrically connected with the heater through an electrical connecting wire; and a compressor, a storage battery, a heat exchange water tank, a heat exchange tube, a liquid storage bottle, an evaporator and an induced draft fan are arranged inside the heater. Compared with the prior art, the automobile emission reducing device adopting reverse Carnot cycle has the following beneficial effects: the heater is arranged for buffering and heating fuels, so that emission can be reduced and oil can be saved, and generation of carbon deposit further can be reduced; and the detector is arranged, so that fuels can be automatically and intelligently heated, and therefore, the operation steps are reduced, the operation is convenient, the stability is good and the reliability is high.

Owner:JIANGSU ZHONGKE MACHINERY

Water spraying device for fine aggregate concrete protective layer pouring maintenance

InactiveCN112031442AEasy to spray maintenanceGood atomizationBuilding material handlingStructural engineeringMechanical engineering

The invention discloses a water spraying device for fine aggregate concrete protective layer pouring maintenance. The water spraying device comprises a horizontally-arranged base, wherein moving crawler belts are arranged at the two ends of the base, a water tank is arranged on the side wall of the upper side of the base, a communicating hole communicating with the outside is formed in the upper end of the water tank, a tank cover matched with the communicating hole is arranged at the upper end of the water tank, a mixing mechanism is arranged inside the water tank, a first spraying mechanismis arranged at one end of the water tank, a second spraying mechanism is arranged at the other end of the water tank, and the first spraying mechanism and the second spraying mechanism are both arranged close to the base. According to the water spraying device, through two different water spraying modes, the use requirements of users are met conveniently.

Owner:查常财

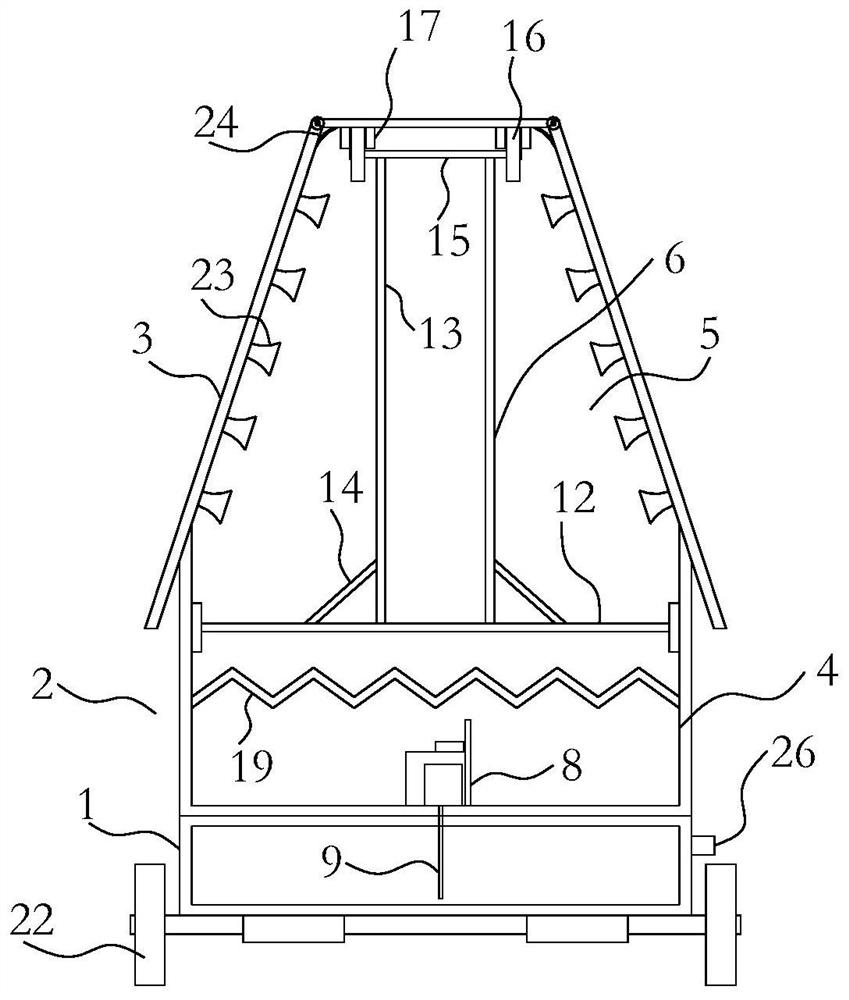

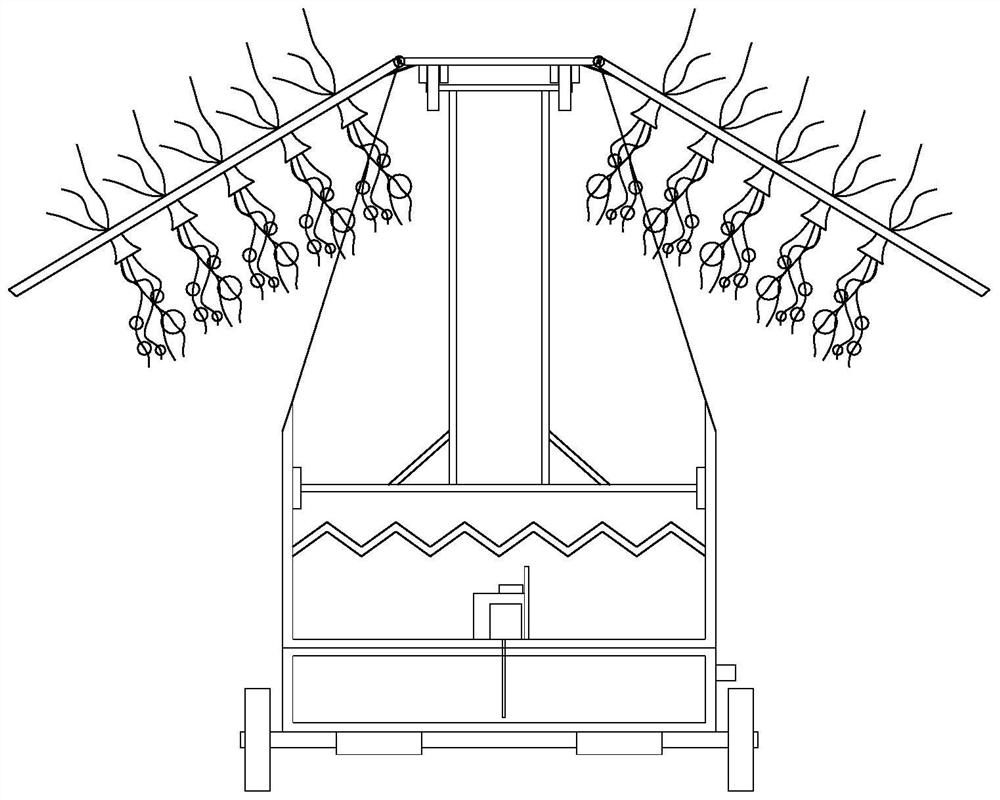

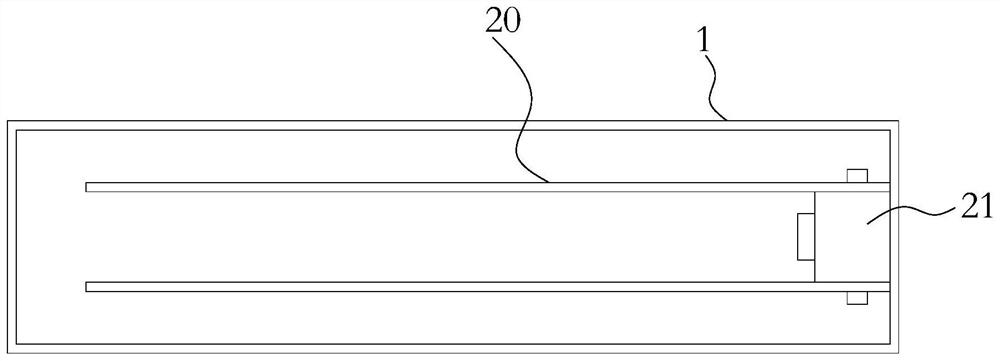

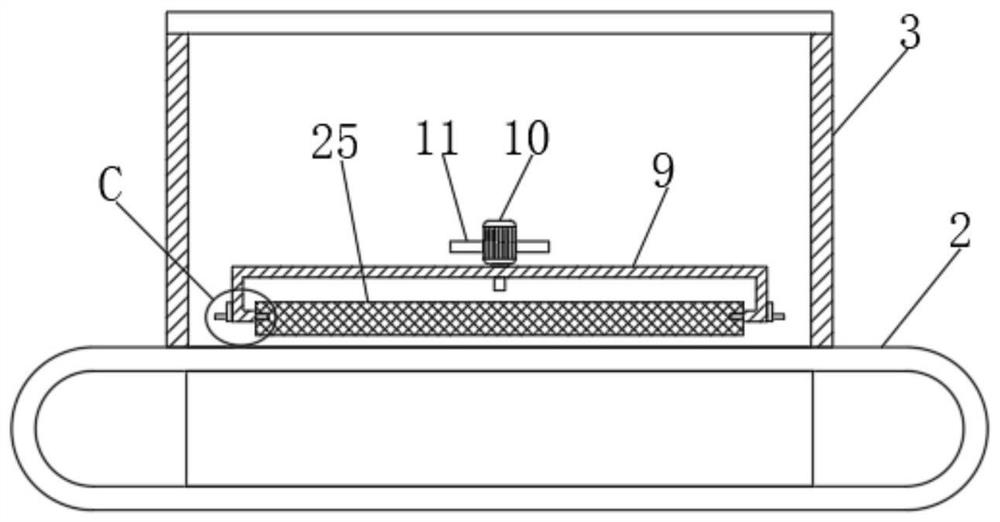

Quenching and tempering system utilizing air source heat pump and ultrasonic equipment

PendingCN114223409ASmall granularityGood atomizationAgriculture tools and machinesHarvested fruit hanging devicesWater vaporEngineering

The invention discloses a conditioning system utilizing an air source heat pump and ultrasonic equipment. The invention discloses a humidifying and conditioning system for improving grain quality before grain delivery, and the system utilizes a water purifier and a grid air port to improve the quality of humidifying and conditioning water vapor; the air source heat pump system and the ultrasonic nebulizer are combined, the air inlet temperature is slightly higher than the initial temperature of a grain pile according to data of the grain condition monitoring system, influences of seasons and weather conditions are avoided, and grains are effectively humidified and conditioned; a ventilation mode is improved, a ventilation mode of'up-down combination ', 'dynamic-static combination', 'selective humidification 'and'partition treatment' is adopted, the precision is high, the control over the moisture increase of grains is facilitated, the moisture gradient of grain piles is reduced, and the problems that moisture distribution is not uniform and the moisture gradient in the grains is large are solved; while the shelf life of the grains is not shortened, the grain storage process quality and the processing performance are improved, crushing in the circulation process is reduced, and the economic benefits of storage enterprises are improved.

Owner:XI AN JIAOTONG UNIV +1

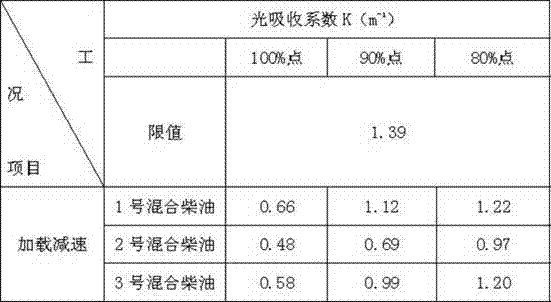

Biodiesel-based mixed diesel and production method thereof

InactiveCN105441141ALiquidityGood atomizationBiofuelsEfficient propulsion technologiesAmmonium sulfateChemistry

The invention discloses a biodiesel-based mixed diesel which is composed of biodiesel, petroleum light diesel, petroleum heavy diesel and aviation kerosene. The biodiesel comprises a biological base liquid, sodium dodecyl benzene sulfonate, heavy alkylbenzene sulfonate, fatty alcohol polyethenoxy ether ammonium sulfate, acetamide and propanediol. The biological base liquid is composed of palm oil, sunflower seed oil and coconut oil. The invention also discloses a production method of the biodiesel-based mixed diesel, which comprises the following steps: preparing the biological base liquid; preparing the biodiesel; and preparing the mixed diesel. The mixed diesel has the advantages of high flowability, favorable sprayability and high safety, can not easily precipitate, has high comprehensive cost performance in the aspects of power, cleanliness and production cost, and has obvious properties especially in the aspect of cleanliness. Compared with the traditional mixed diesel, the biodiesel-based mixed diesel has the advantages of fewer exhaust emissions and higher environment friendliness, and is suitable for popularization and application.

Owner:CHENGDU HENGRUN HIGH NEW SCI & TECH

Micro-irrigation device for panax notoginseng plantation

PendingCN114451193AAvoid lostWon't impactClimate change adaptationWater/sewage treatmentPANAX NOTOGINSENG ROOTWater storage

The invention relates to the technical field of irrigation, in particular to a pseudo-ginseng plantation micro-irrigation device which comprises a bottom plate, a first water pump, a potassium permanganate storage tower, a reservoir, a second water pump and a plurality of planting greenhouses are sequentially and fixedly connected to the end of the upper surface of the bottom plate, and an input port of the first water pump is fixedly connected with a pumping pipeline; an output port of the first water pump is fixedly connected with an inflow pipeline, the end, away from the first water pump, of the inflow pipeline fixedly penetrates through the side edge of the water storage pool, the potassium permanganate storage tower is fixedly connected with a flowing pipeline, and a plurality of planting areas are further arranged at the lower end of the planting greenhouse. Meanwhile, due to the fact that the spray irrigation technology has the advantages that water and labor are saved, the soil structure is not damaged, the ground climate is adjusted, and the spray irrigation technology is not limited by terrains, the operation cost of the pseudo-ginseng planting park is further saved.

Owner:重庆川渝七农业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com