High and low temperature-resistant low-fogging degree functional environment-friendly plasticizer

An environmentally friendly plasticizer, high and low temperature resistant technology, used in organic chemistry, chemical instruments and methods, preparation of organic compounds, etc. , High plasticizing efficiency, good environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

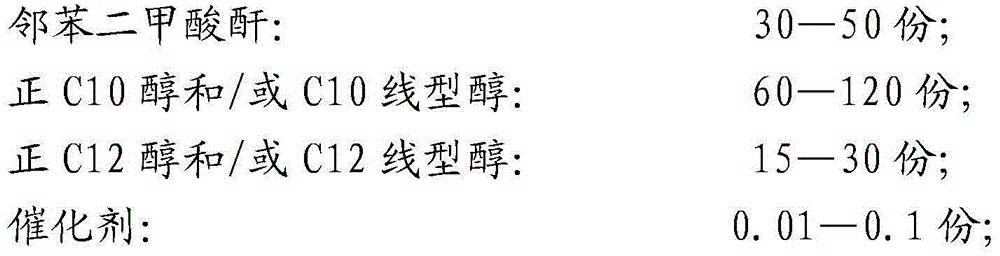

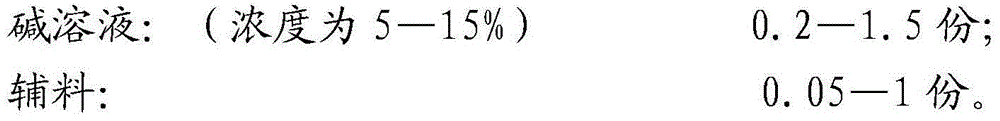

Method used

Image

Examples

specific Embodiment 1

[0022]

[0023]

specific Embodiment 2

[0024]

specific Embodiment 3

[0025]

[0026] Comparison of atomization performance of plasticizer SH1012 of the present invention:

[0027] DOP: bis(2-ethylhexyl) phthalate;

[0028] DPHP: bis(2-propylheptyl) phthalate;

[0029] DTDP: Di-n-decyl phthalate;

[0030] TOTM: Trioctyl trimellitate;

[0031] 911P: 911 phthalate (foreign product);

[0032] SH1012: The plasticizer of the present invention, 1012 phthalate.

[0033] Atomization performance comparison table

[0034] (Adopt DIN75201 / B)

[0035]

[0036] Low temperature performance comparison of plasticizer SH1012 of the present invention:

[0037] Comparative test conditions: low temperature performance of unfilled general purpose PVC; Tf is low temperature toughness; Tb is embrittlement temperature; ①ASTMD1043;②ASTMD746; PVC formula (calculated by mass): 100 parts of pvc, 50 parts of plasticizer, liquid Ba / Cd / Zn stabilizer 2.0 parts, stearic acid 0.25 parts.

[0038] Low temperature performance comparison table

[0039] Plasticizer

[0040] Through the above-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com