Method capable of improving gasoline yield of catalytic cracking device

A catalytic cracking unit and a technology for catalytic cracking raw materials, which are applied in the multi-stage series-connected refining and cracking process treatment, etc., can solve the problems of difficult to form an emulsified state, unfavorable production, and fluctuations in nozzle pressure, so as to improve the degree of vaporization and increase the Alkane number, the effect of increasing the cracking depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

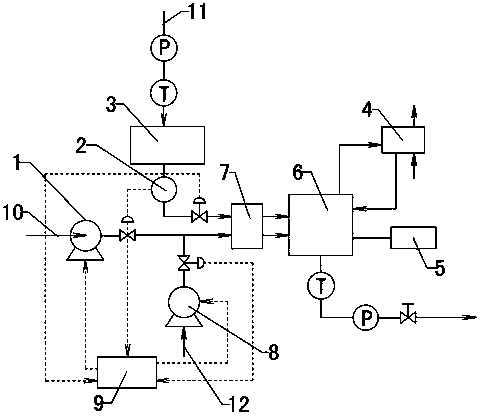

Method used

Image

Examples

Embodiment

[0030] 88~89.7: 8.5~10: 1.8~2, 1.3MPa~1.4MPa, temperature 180℃~195℃

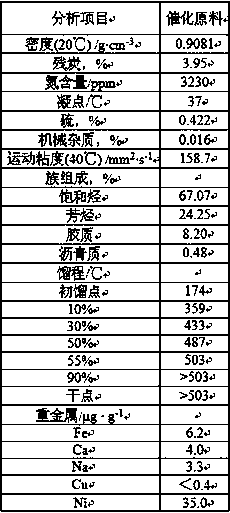

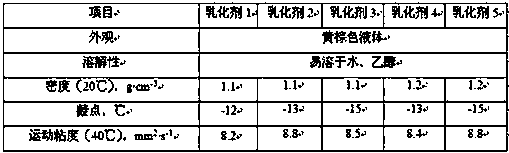

[0031]Among them, Examples 1 to 7 are tests after pretreatment of raw materials, and calibration tests are carried out on a 600,000-ton / year catalytic device. At a reaction temperature of 515°C, the balance agent (RAG-11) is currently used in industry. Wherein in embodiment 1, 89 parts by weight of heavy oil, 9.1 parts by weight of water, 1.9 parts by weight of emulsifier, the emulsification condition in the emulsification equipment is: while three groups of 6000r / min shearing and stirring, keep the internal pressure of the emulsification equipment at 1.3MPa, Temperature 185°C; in Example 2, 89 parts by weight of heavy oil, 9.1 parts by weight of water, and 1.9 parts by weight of emulsifier. The emulsification conditions in the emulsification equipment are: while three groups of 6500r / min shearing and stirring, keep the internal pressure of the emulsification equipment 1.3MPa, temperature 188°C; in Example ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com