Method capable of improving gasoline-diesel ratio of catalytic cracking device

A catalytic cracking unit and a technology for catalytic cracking raw materials, which are applied in catalytic cracking, cracking, petroleum industry and other directions, can solve the problems of improving the product gas-fuel ratio, nozzle pressure fluctuation, difficult emulsification state, etc. The effect of increasing the diesel ratio and improving the degree of vaporization

Inactive Publication Date: 2018-01-09

CHINA PETROLEUM & CHEM CORP

View PDF3 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] However, none of the existing technologies proposes to improve the gas-to-diesel ratio of the product by emulsifying catalytic cracking raw materials.

At the same time, the existing technology is to emulsify the catalytic cracking raw material at normal pressure and lower temperature (below 100°C). In the industrial production process, the preheating temperature of the catalyt

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

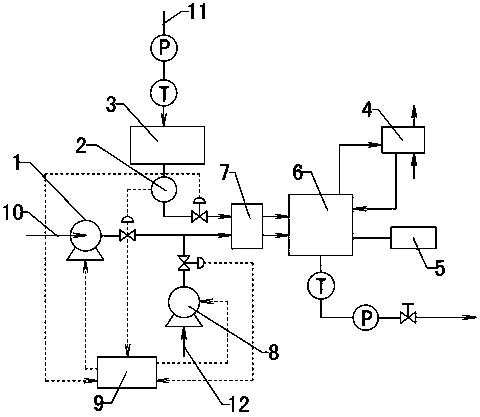

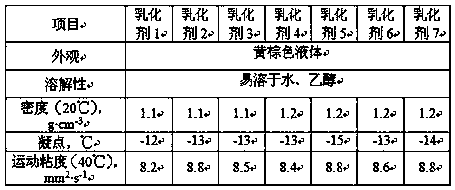

The invention provides a method capable of improving the gasoline-diesel ratio of a catalytic cracking device, belonging to the technical field of catalytic cracking of petroleum refining. The methodis characterized in that a to-be-catalytically-cracked raw material, water and an emulsifier are mixed through a premixer, and then enter an emulsifying device for emulsifying; the mass ratio of the to-be-catalytically-cracked raw material to the water to the emulsifier is (89.7-91.79): (8.2-10): (0.01-0.3); emulsified oil obtained by emulsifying directly enters a catalytic device for a catalyticreaction; and the conditions of emulsifying in the emulsifying device are as follows: shearing and stirring are performed at a rotating speed of 6000 r/min to 8000 r/min, and a pressure of 1.2 MPa to1.3 MPa and a temperature of 140 DEG C to 150 DEG C are maintained in the emulsifying device at the same time. The method of pretreating a catalytic cracking raw material with high pressure and temperature provided by the invention improves the dispersity and the fogging degree of a catalytic cracking feeding material, improves the depth of cracking, and enhances the gasoline-diesel ratio of the catalytic cracking device.

Description

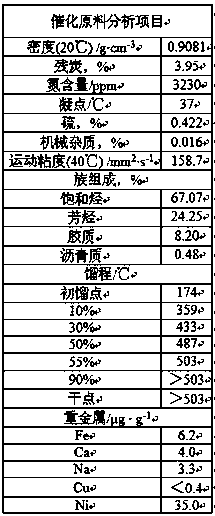

technical field [0001] The invention discloses a method for increasing the gas-to-diesel ratio of a catalytic cracking unit, which belongs to the technical field of catalytic cracking in petroleum refining. Background technique [0002] Generally, when the catalytic cracking unit implements the production situation of high-yield gasoline, the gasoline yield is mainly increased from the aspects of raw materials, catalysts, reaction depth, and product extraction. The method to improve the gasoline yield by improving the raw material composition is mainly to increase the content of light oil products (such as wax oil) in the raw material, and to reduce the residual oil rich in polycyclic aromatic hydrocarbons, colloids, asphaltenes and other components that are not easily cracked. The blending ratio of coker wax oil. At present, crude oil is becoming more and more inferior, and the oil to be processed by catalytic cracking units is also more difficult to process. This method c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10G11/00

Inventor 许金山李海燕周忠国许晓斌达建文韩新竹刘爱华

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com