A method for hydrogenation of medium and low temperature coal tar

A low-temperature coal tar and hydrorefining technology, applied in the coal chemical industry, can solve the problems of increasing equipment size and catalyst dosage, short catalyst service life, waste of resources, etc., to protect safety and normal operation, increase cracking pressure, prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

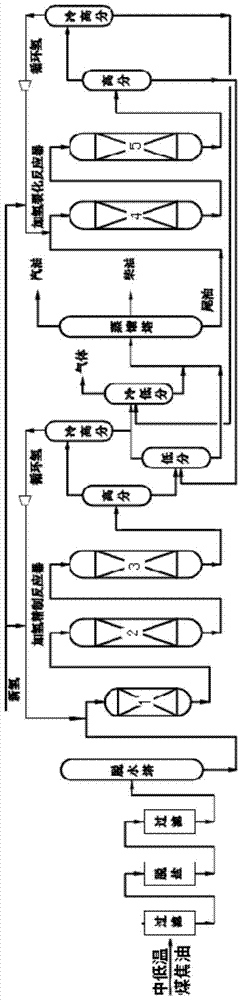

Image

Examples

Embodiment 1

[0036] A method for hydrogenation of medium and low temperature coal tar, comprising the following steps:

[0037] Step 1. Mix the medium and low temperature coal tar according to the weight ratio of 5:7, and the performance index of the raw material oil after mixing is shown in Table 1.

[0038] Table 1

[0039] index

detection value

Density (20℃), g / cm3

1.08

S, ug / g

2204

N, ug / g

2937

[0040] Step 2, the raw material oil after mixing is filtered through primary filtration (filtering out particulate impurities larger than 25um in coal tar), three-stage desalination treatment, secondary filtration (filtering particulate impurities in coal tar less than 10um), dehydration (170°C Enter the dehydration tower, the temperature at the top of the dehydration tower is controlled at 105°C, and the bottom of the tower is fed with low-pressure steam to ensure that the bottom of the tower is 210°C);

[0041] Step 3, the dehydrated raw oil ...

Embodiment 2

[0058] According to the method described in embodiment 1, the coal tar is lightened. The difference is that:

[0059] 1) Step 1 is to mix medium and low temperature coal tar according to the weight ratio of 3:4, and the performance indicators of the raw material oil after mixing are shown in Table 2.

[0060] Table 2

[0061] index

detection value

Density (20℃), g / cm3

1.07

S, ug / g

2134

N, ug / g

3052

[0062] 2), the reaction conditions in each reactor:

[0063] The reaction conditions in the No. 1 reactor are: reaction temperature 230°C; pressure 12MPa; hydrogen-oil volume ratio 22001; liquid hourly volume space velocity 0.6 / h.

[0064] The reaction conditions in the No. 2 reactor are: reaction temperature 330°C; pressure 12Mpa; hydrogen-oil volume ratio 2100:1; liquid hourly volume space velocity 0.4 / h.

[0065] The reaction conditions in the No. 3 reactor are: reaction temperature 350°C; pressure 12Mpa; hydrogen-oil volume r...

Embodiment 3

[0070] According to the method described in embodiment 1, the coal tar is lightened. The difference is that:

[0071] 1), step 1 is to mix the medium and low temperature coal tar according to the weight ratio of 5:9, and the performance index of the raw material oil after mixing is shown in Table 3.

[0072] table 3

[0073] index

detection value

Density (20℃), g / cm3

1.06

S, ug / g

2191

N, ug / g

3186

[0074] 2), the reaction conditions of each reactor:

[0075] The reaction conditions in No. 1 reactor are: reaction temperature 270°C; pressure 12MPa; hydrogen-oil volume ratio 2200:1; liquid hourly volume space velocity 0.7 / h.

[0076] The reaction conditions in the No. 2 reactor are: reaction temperature 350°C; pressure 12Mpa; hydrogen-oil volume ratio 2100:1; liquid hourly volume space velocity 0.5 / h.

[0077] The reaction conditions in No. 3 reactor are: reaction temperature 340°C; pressure 12Mpa; hydrogen-oil volume ratio 220...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com