Black soybean milk powder and production method with spray-drying technology thereof

A technology of spray dryer and black beans, which is applied in the field of nutritious food, can solve the problems that beans cannot reach a new level, and achieve the effects of strong controllability of output, uniform particle size, and good atomization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

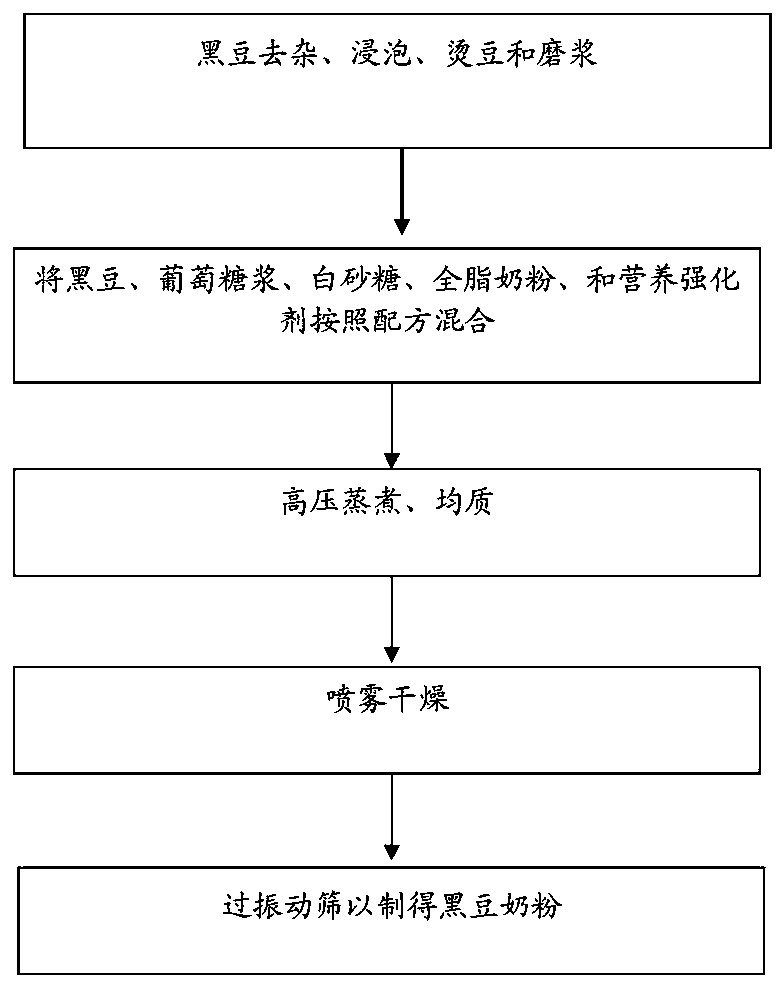

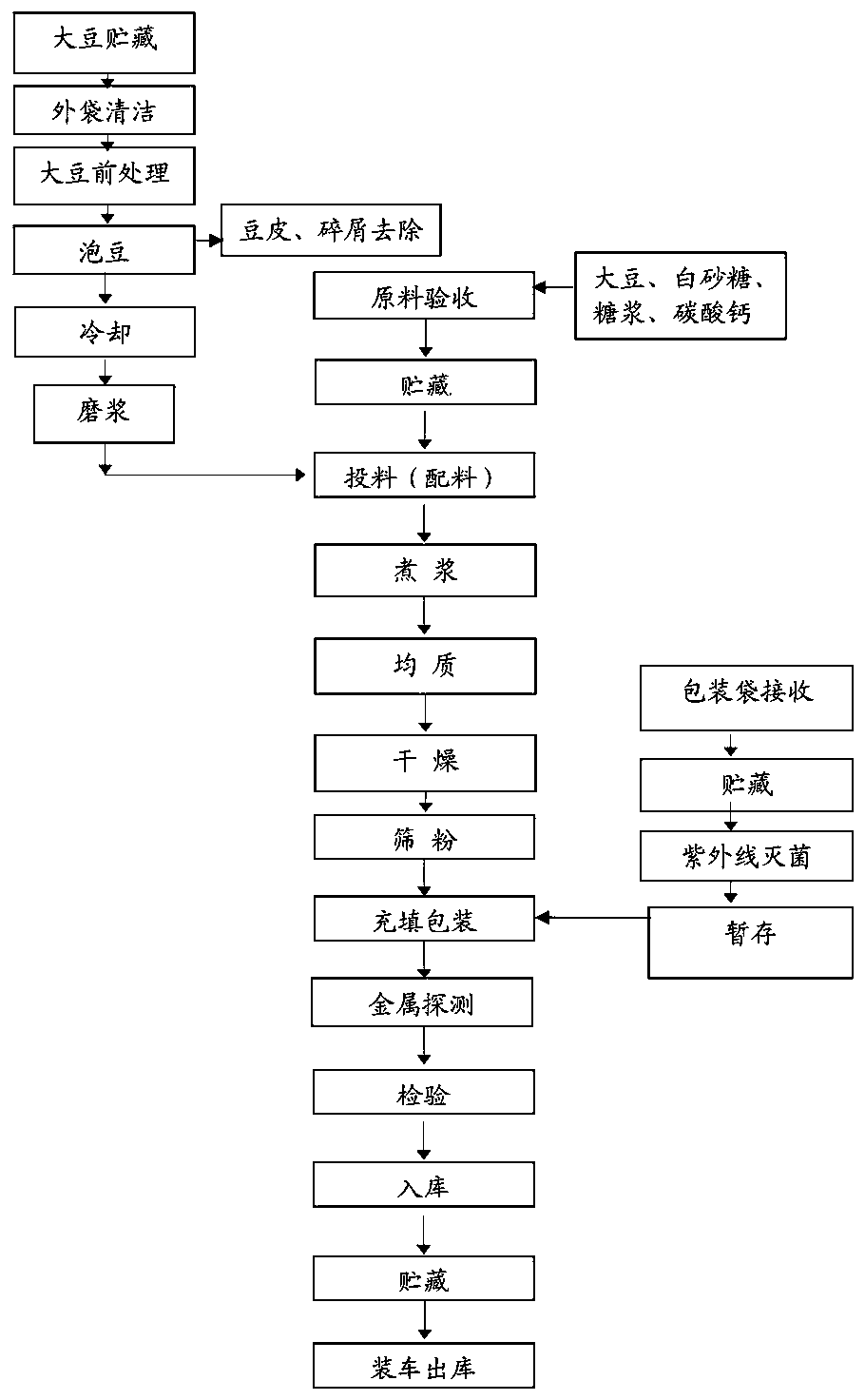

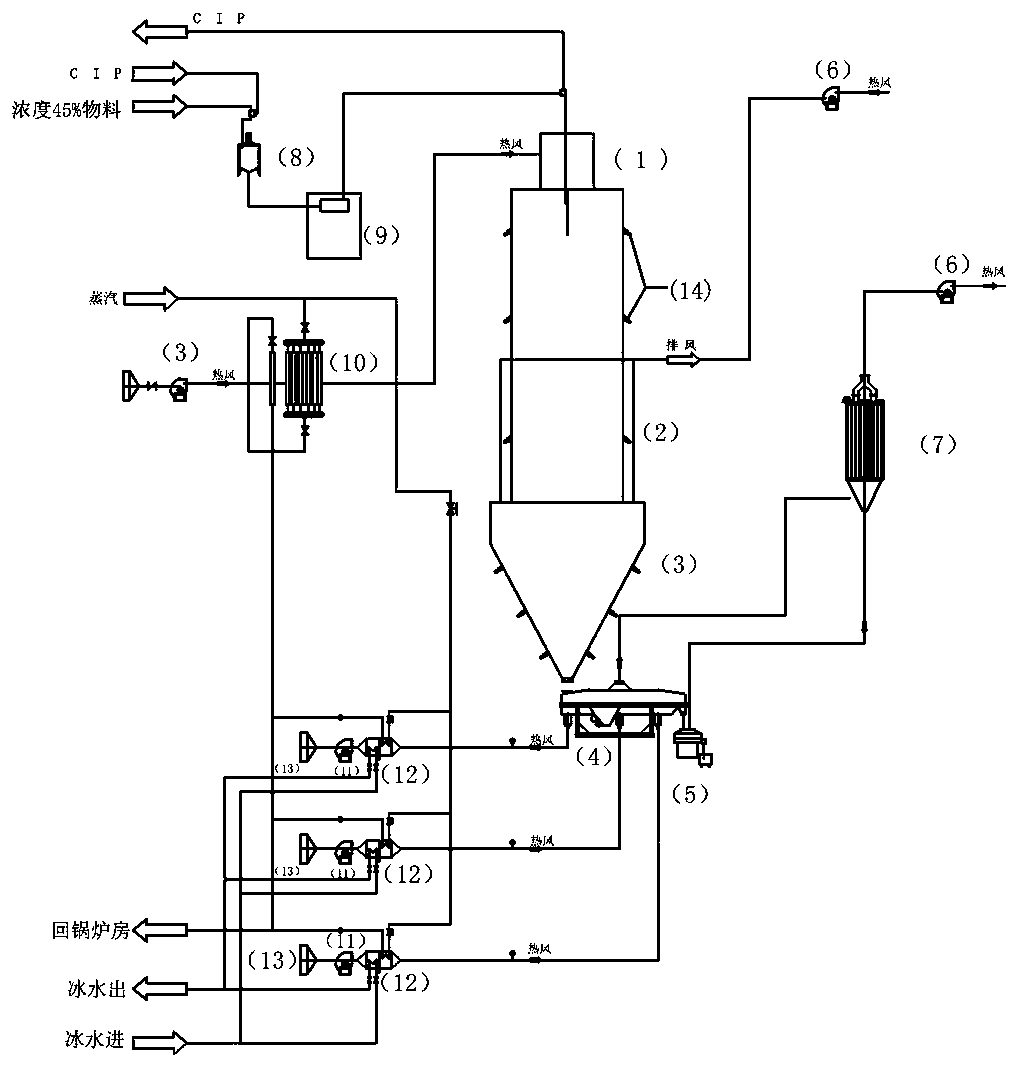

[0039] Such as Figure 1-Figure 3 As shown, another aspect of the present disclosure provides a method for preparing black soybean milk powder, which is characterized in that, comprising: mixing black soybeans, glucose syrup, white granulated sugar, whole milk powder, and nutritional fortifiers according to the following formula: The parts by weight of black beans are 40-70 parts, the parts by weight of the glucose syrup are 10-20 parts, the parts by weight of the white granulated sugar are 2-15 parts, the parts by weight of the whole milk powder are 2-15 parts, The weight portion of the nutritional fortifier is 2 to 15 parts; after the black beans are removed from impurities, soaked, scalded and refined, they are mixed with the glucose syrup, white sugar, whole milk powder and nutritional fortifier according to the Formula is carried out batching, then after high-pressure cooking, homogenization, and spray-drying, pass through a vibrating sieve to obtain the described black s...

example 1

[0044] The black soybean milk powder in this example is, for example, a nutritious soybean powder that is reasonably matched with black foods (including black soybeans, glucose syrup, whole milk powder, etc.). The black soybean milk powder is prepared from the following raw materials in parts by weight: 40-70 parts of black soybeans, 10-20 parts of glucose syrup, 2-15 parts of white sugar; 2-15 parts of whole milk powder, calcium carbonate or vitamin A or vitamin D. 2~15 servings.

[0045] The preparation method of the black soybean milk powder in this example is: remove impurities from the black soybeans in the above parts by weight, add glucose syrup, white sugar, and whole milk powder, and selectively mix the obtained components with calcium carbonate or vitamin A or vitamin D The ingredients are evenly distributed, and the finished product can be obtained through the spray drying process.

[0046] The black soybean milk powder in this example can be made into nutritional ...

example 2

[0048] The black soybean milk powder in this example, for example, uses black soybeans as the main ingredient, glucose syrup and whole milk powder as the main auxiliary materials, and according to the growth and development characteristics and nutritional deficiencies of various groups of people in my country, appropriate nutrient fortifiers (including calcium, iron, zinc, Vitamin A, vitamin D, etc.), so as to design a scientific formula of black soybean milk powder suitable for all kinds of people to ensure that its nutrition is comprehensive and reasonable, and can achieve the effect of strong bones.

[0049] The black soybean milk powder in this example is made of black soybeans and other raw materials according to the following formula ingredients: 50 parts of black soybeans, 20 parts of glucose syrup, 10 parts of white sugar, 10 parts of whole milk powder and 10 parts of nutrient fortifier; black beans, glucose syrup, white sugar , Whole milk powder ingredients; pre-mixed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com