A Reverse Carnot Cycle Vehicle Emission Reduction Device

A reverse Carnot cycle and automobile technology, which is applied to fuel heat treatment devices, charging systems, engine components, etc., can solve problems such as difficult promotion and cumbersome steps, and achieve reduced operating steps, easy operation, and high reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

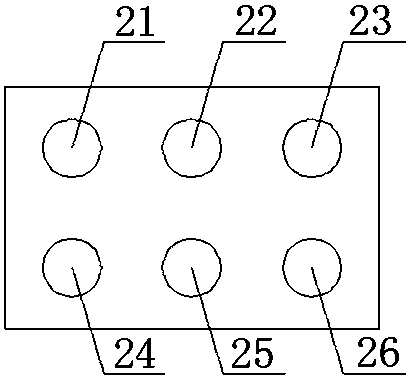

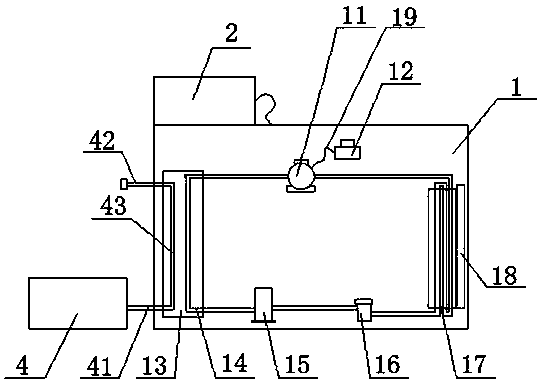

[0021] see figure 1 , figure 2 and image 3 , the present invention provides a technical solution: a reverse Carnot cycle automobile emission reduction device, including a heater 1, a processing box 2, a detector 3 and a liquid storage tank 4, the detector 3 is installed under the driver's seat of the car, and the processing box 2 Installed above the heater 1, the inside of the processing box 2 is provided with a printed circuit board, and the printed circuit board is welded with an analog-to-digital converter 21, a micro-processing chip 22, a storage chip 23, a digital-to-analog converter 24, and a relay 25 and a battery 26, the processing box 2 is electrically connected to the heater 1 through an electrical connecting wire 19, and the interio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com