High-efficient and energy-saving sliding controller of vehicle

A skid control device, a high-efficiency and energy-saving technology, applied in the control device, vehicle parts, transportation and packaging, etc., can solve the problems of inaccurate coordination of parts and poor results, and achieve extended skid distance, compact and reasonable structure, and service life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

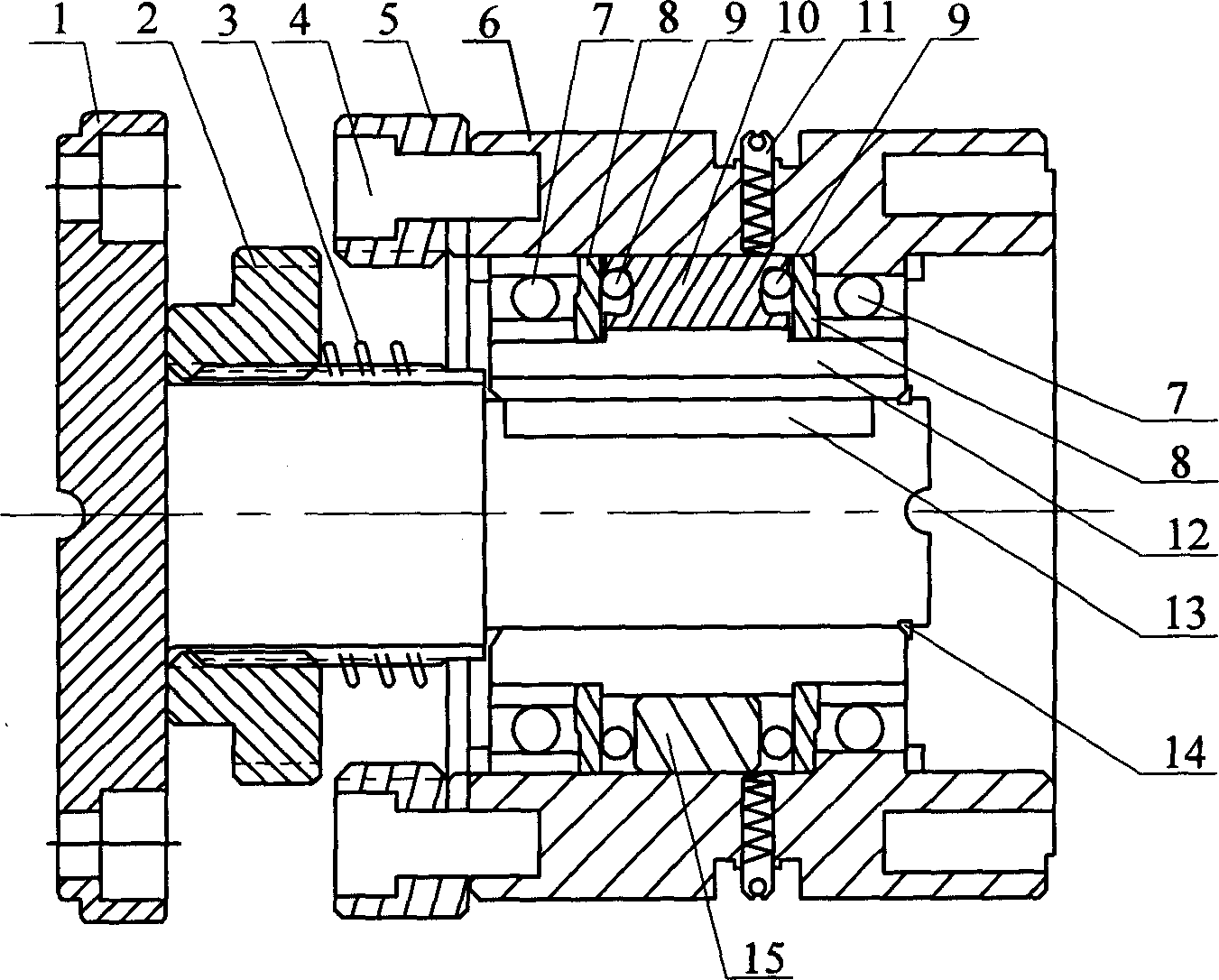

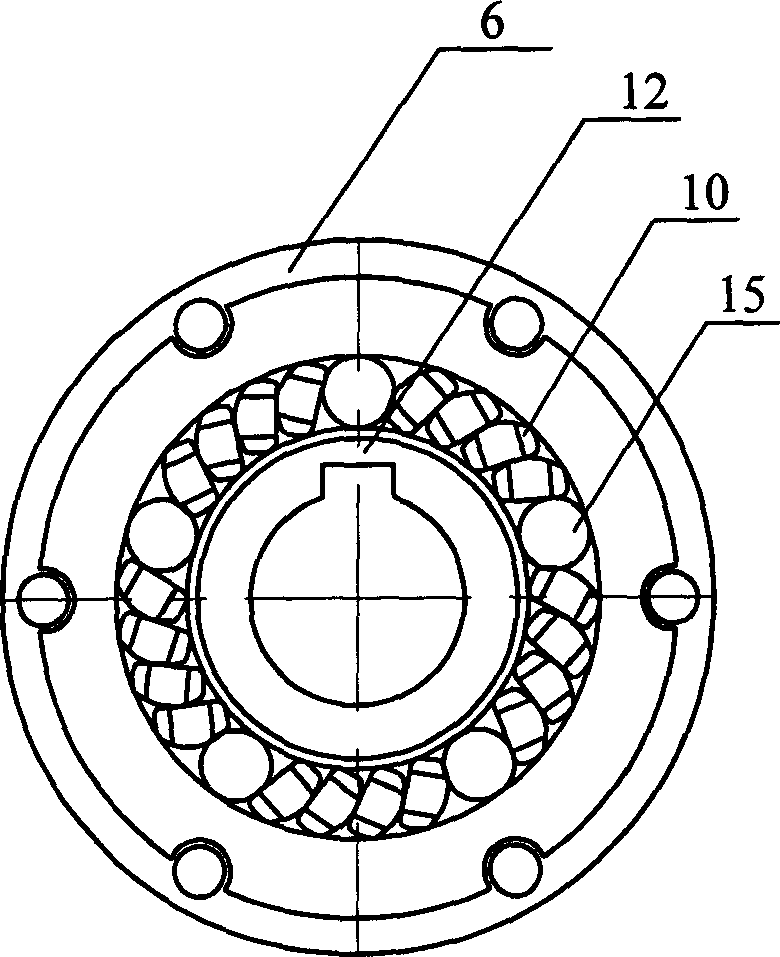

[0018] Such as figure 1 , 2 As shown, an automobile high-efficiency and energy-saving gliding control device, both ends are connected with the engine drive system and the wheel drive system, including a connecting shaft 1, a gliding jacket 6 that is connected to the connecting shaft 1 through a bearing 7, and the gliding jacket 6 is provided with a refueling Hole 11, on the inner end wall of the sliding jacket 6, the reversing external gear 5 is fixed by the hexagonal screw 4, the connecting shaft 1 is equipped with the reversing internal gear 2, and the meshing part of the connecting shaft 1 and the reversing internal gear 2 is provided with a return spring 3, A one-way torque transmission clutch control device is arranged between the connecting shaft 1 and the sliding outer sleeve 6 .

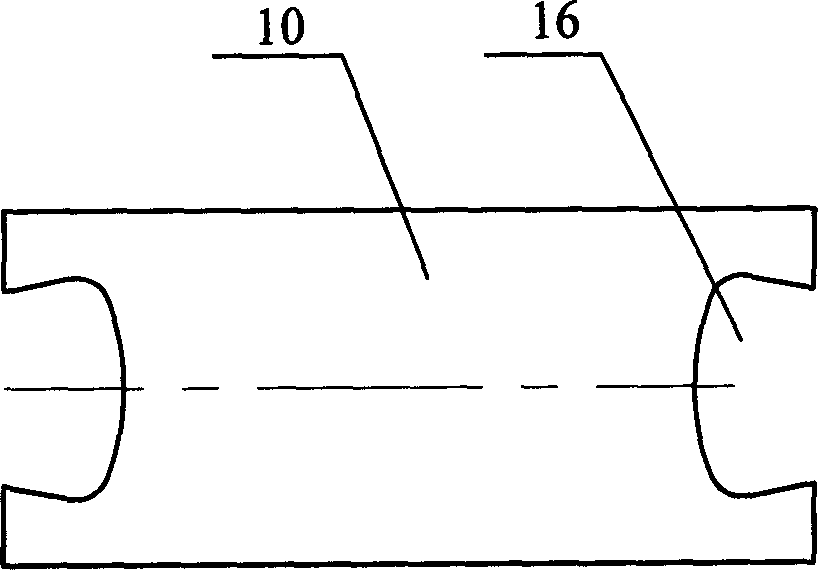

[0019] The one-way torque transmission clutch control device includes a sliding inner sleeve 12 that cooperates with the connecting shaft 1 and the sliding outer sleeve 6 and is fixed to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com