Biodiesel-based mixed diesel and production method thereof

A technology of biodiesel and diesel oil, which is applied in the direction of biofuel, petroleum industry, liquid carbon-containing fuel, etc., can solve the problems of unfavorable popularization and application, power, cleanliness, and failure to achieve comprehensive optimization of production costs, so as to be suitable for popularization and application , high production cost, good atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

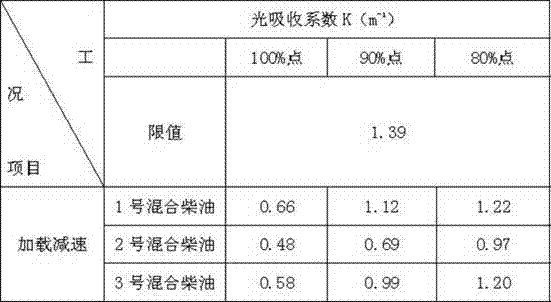

Examples

Embodiment 1

[0021] Process blended diesel as follows:

[0022] (1) Preparation of biological base fluid: Mix 60kg of palm oil, 25kg of sunflower oil and 15kg of coconut oil to prepare 100kg of biological base fluid;

[0023] (2) Preparation of biodiesel, including the following steps:

[0024] ①Mix 100kg of biological base fluid with 40kg of ethanol, then add 20kg of 1-(3-sulfonic acid)propyl-3-methylimidazolium phosphotungstate solution with a concentration of more than 85%, heat and keep under normal pressure React at a temperature of 45-55°C for 1.5h, then heat under normal pressure and keep the temperature at 60-65°C for 2h, and cool to room temperature after the reaction; among them, biological base fluid, ethanol, 1-(3-sulfonic acid)propane The mass ratio of base-3-methylimidazolium phosphotungstate solution is 5:2:1;

[0025] ②Add 3kg of sodium dodecylbenzenesulfonate, 2kg of heavy alkylbenzenesulfonate, 2kg of fatty alcohol polyoxyethylene ether ammonium sulfate, 6kg of acetamid...

Embodiment 2

[0029] Process blended diesel as follows:

[0030] (1) Preparation of biological base fluid: 50kg of palm oil, 30kg of sunflower oil and 20kg of coconut oil were mixed to prepare 100kg of biological base fluid;

[0031] (2) Preparation of biodiesel, including the following steps:

[0032] ①Mix 100kg of biological base fluid with 40kg of ethanol, then add 20kg of 1-(3-sulfonic acid)propyl-3-methylimidazolium phosphotungstate solution with a concentration of more than 85%, heat and keep under normal pressure React at a temperature of 45-55°C for 1.5h, then heat under normal pressure and keep the temperature at 60-65°C for 2h, and cool to room temperature after the reaction; among them, biological base fluid, ethanol, 1-(3-sulfonic acid)propane The mass ratio of base-3-methylimidazolium phosphotungstate solution is 5:2:1;

[0033] ② Add 2kg of sodium dodecylbenzenesulfonate, 3kg of heavy alkylbenzenesulfonate, 3kg of fatty alcohol polyoxyethylene ether ammonium sulfate, 5kg of ...

Embodiment 3

[0037] Process blended diesel as follows:

[0038] (1) Preparation of biological base fluid: Mix 80kg of palm oil, 10kg of sunflower oil and 10kg of coconut oil to prepare 100kg of biological base fluid;

[0039] (2) Preparation of biodiesel, including the following steps:

[0040] ①Mix 100kg of biological base fluid with 40kg of ethanol, then add 20kg of 1-(3-sulfonic acid)propyl-3-methylimidazolium phosphotungstate solution with a concentration of more than 85%, heat and keep under normal pressure React at a temperature of 45-55°C for 1.5h, then heat under normal pressure and keep the temperature at 60-65°C for 2h, and cool to room temperature after the reaction; among them, biological base fluid, ethanol, 1-(3-sulfonic acid)propane The mass ratio of base-3-methylimidazolium phosphotungstate solution is 5:2:1;

[0041] ② Add 5kg of sodium dodecylbenzenesulfonate, 1kg of heavy alkylbenzenesulfonate, 1kg of fatty alcohol polyoxyethylene ether ammonium sulfate, 8kg of acetami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com