Arsenic containing wastewater treatment method

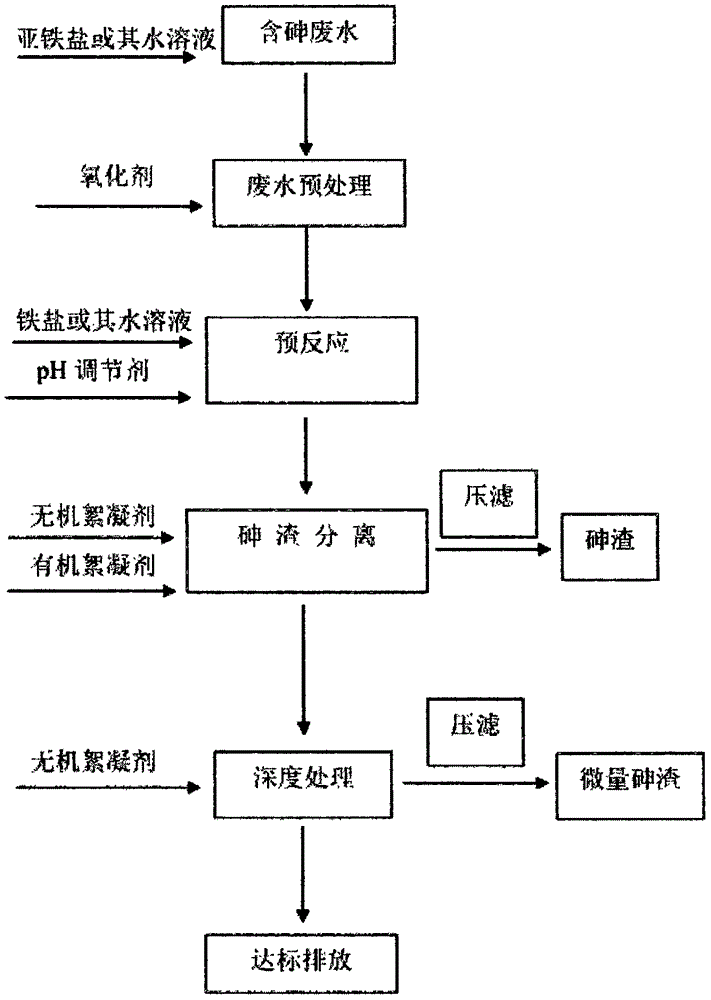

A treatment method and wastewater technology, applied in water/sewage treatment, neutralized water/sewage treatment, oxidized water/sewage treatment, etc., can solve hydrogen sulfide gas escape, arsenic removal effect is not ideal, increase cost and effluent calcium Hardness and other problems, to achieve the effect of reducing the use of pH regulators, helping to purify water, and strengthening the cleaning and decontamination function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

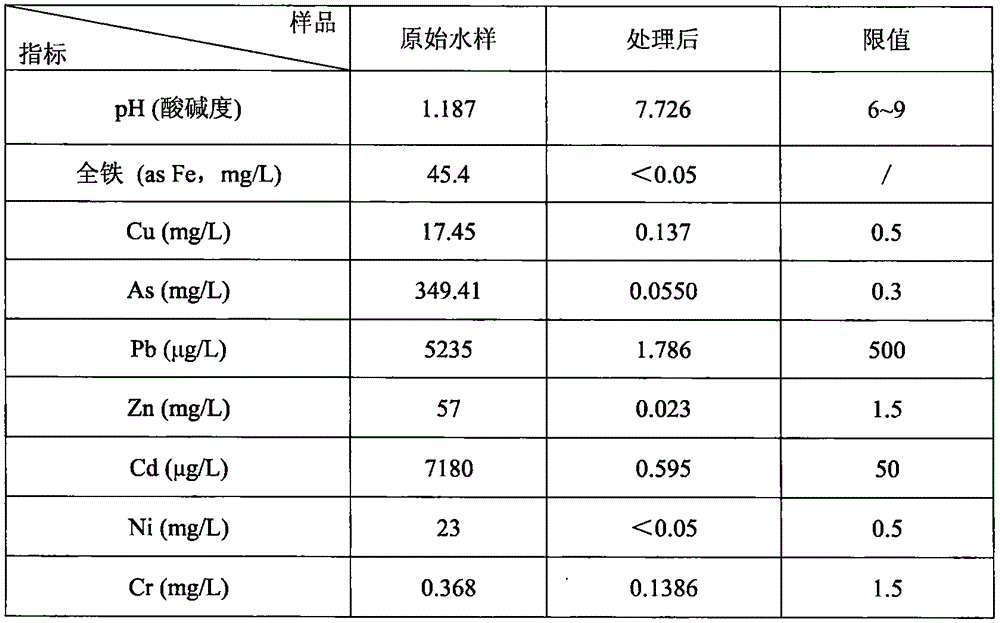

[0030] In this embodiment, the arsenic-containing wastewater of a smelter with an arsenic concentration of about 350 mg / L is treated.

[0031] Take 200ml of arsenic-containing wastewater from a smelter, add 0.72g of FeSO 4 ·7H 2 O, after stirring to make it completely dissolve, add 0.22g of industrial hydrogen peroxide aqueous solution with a mass fraction of 27.5%, after stirring at room temperature for 50min, add 0.12g of a 50% ferric chloride solution, stir rapidly for 1min, and add The pH of the water sample is adjusted to 8.67 with 20% sodium hydroxide by mass fraction. After stirring slowly for 5 minutes, continue to add 0.30 g of 40% polyferric sulfate solution and 1.80 g of 0.18% PAM aqueous solution, and stir at a constant speed for 5 min. Finally, stop stirring, after standing still for 30min, solid-liquid separation, add 0.24g of polyferric sulfate solution with a mass fraction of 40% to the filtrate, continue stirring for 5min, stop stirring, after standing for 30...

Embodiment 2

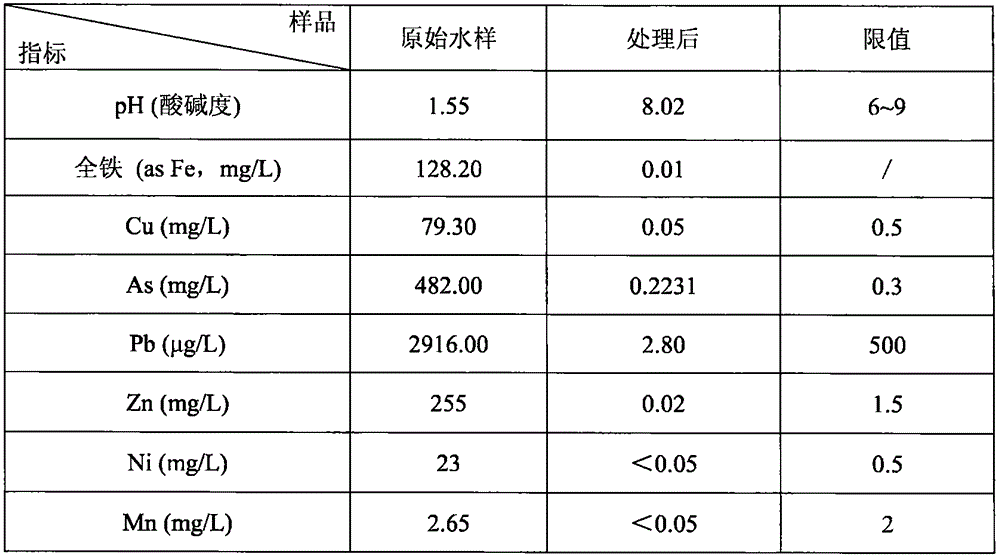

[0036] In this embodiment, the acidic arsenic-containing wastewater of a mine with an arsenic concentration of about 500 mg / L is treated.

[0037] Take 600ml of acidic wastewater from a certain mine, add 8.76g of FeBr with a mass fraction of 25% 2 Solution, after stirring to make it dissolve completely, add 6.85g of sodium hypochlorite solution with an available chlorine content of 5.5%. After stirring at room temperature for 30 minutes, add 0.63g of ferric nitrate solution with a mass fraction of 50%, and adjust it with sodium carbonate after stirring rapidly for 1 minute. The pH is 9.23, after stirring slowly for 5 minutes, continue to add 1.15g of 40% polyferric chloride sulfate solution and 1.35g of 0.12% CPAM aqueous solution, stir rapidly for 1 minute, stir slowly for 10 minutes, stop After stirring and standing for 30 minutes, filter paper, separate solid and liquid, and take the filtrate to determine the content of residual arsenic and other heavy metal ions.

[0038]...

Embodiment 3

[0042] The invention aims at treating the arsenic-containing wastewater of a smelter with arsenic concentration of about 1000mg / L.

[0043] Take 500ml of a lead mine sewage acid water, add 6.60g of FeSO with a mass fraction of 25% 4 ·7H 2 O solution (preparation now), after stirring and mixing evenly, add 1.76g mass fraction and be 27.5% industrial hydrogen peroxide aqueous solution, after stirring at room temperature for 30 minutes, add 0.75g mass fraction and be 40% polyferric sulfate solution, stir rapidly for 1 Minutes later, adjust the pH with 30% milk of lime to be about 10.26 with a mass fraction of 30%, continue to add 1.22g of 40% polyphosphorus ferric chloride solution and 2.25g of a 0.25% mass fraction of PAA aqueous solution after stirring slowly for 5 minutes, and quickly After stirring for 1 minute, stir at a slow speed for 10 minutes, stop stirring, filter paper after standing for 30 minutes, separate solid and liquid, and the filtrate enters the second process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com