Hydraulic structure

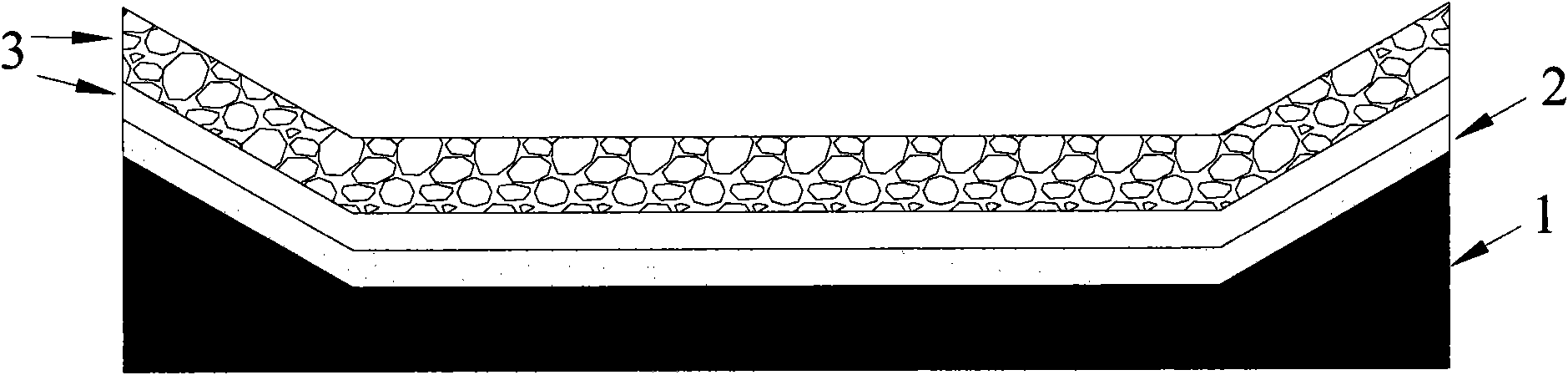

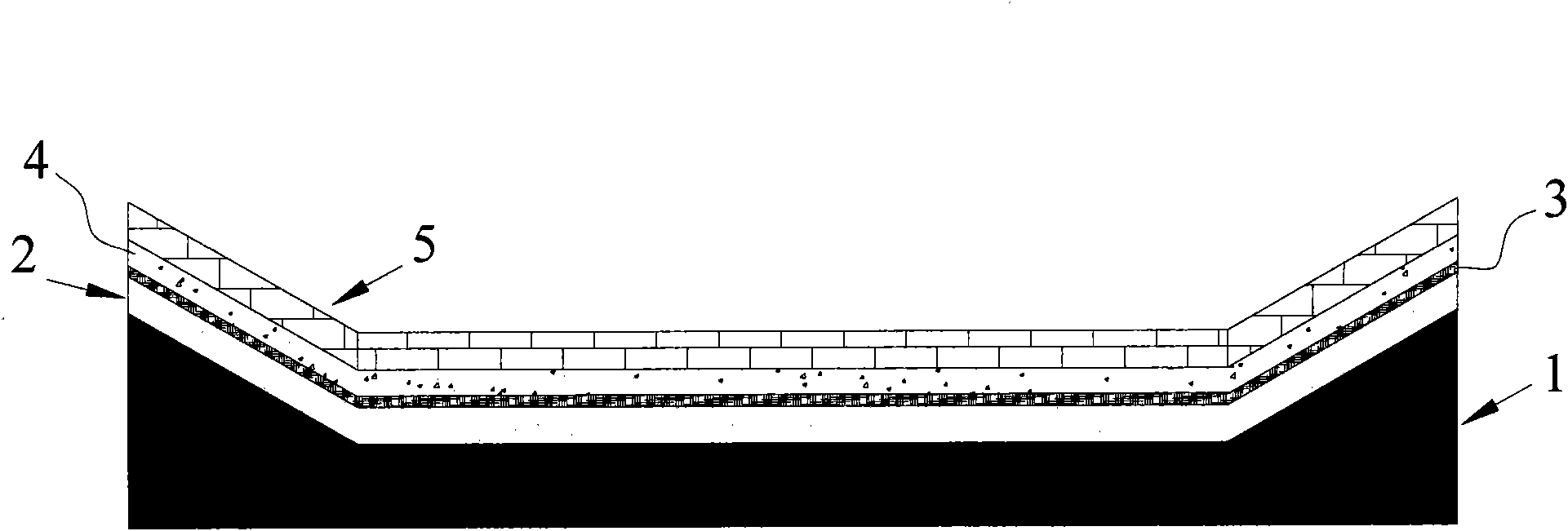

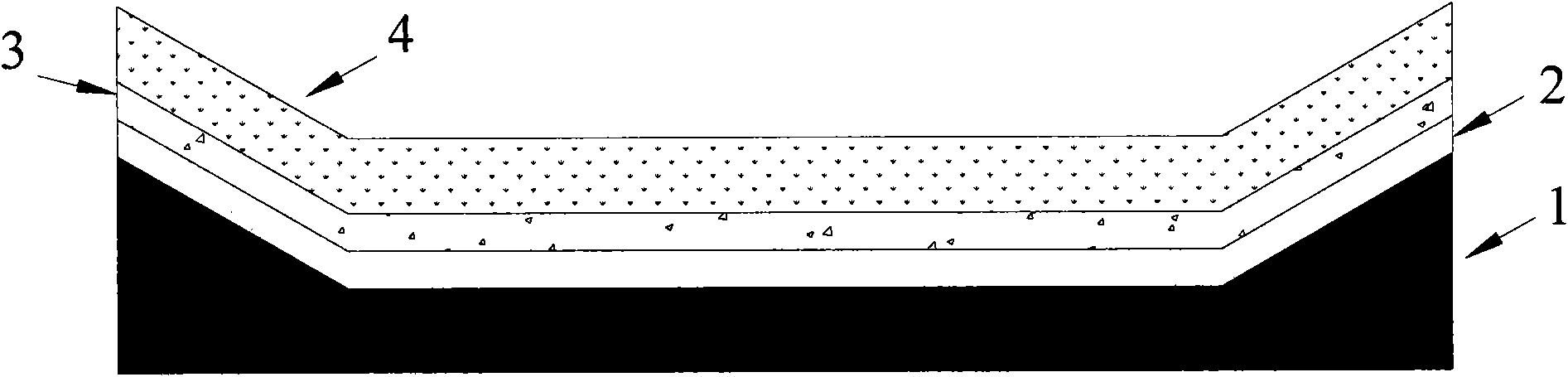

A facility and water conservancy technology, applied in the field of water conservancy facilities, can solve the problems of reducing the oxygen content of water body, poor resistance to frost heave damage, easy to produce cracks and displacement, etc. , The effect of not easy to crack and shift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] According to the present invention, the preparation method of the waterproof breathable particles comprises the following steps:

[0043] Step (1): heating the aggregate particles to 50-400°C, preferably 100-240°C;

[0044] Step (2): mixing the aggregate with a hydrophobic resin and a curing agent, and stirring evenly, so that the hydrophobic resin is cured and coated on the surface of the aggregate particles to obtain waterproof and breathable particles.

[0045] Preferably, the method further includes the steps of cooling, crushing and sieving the waterproof and air-permeable particles obtained in step (2), so as to control the particle size of the hydrophobic particles. The present invention has no special requirements on cooling conditions, preferably cooling to room temperature. In addition, crushing and sieving can be carried out using conventional crushing and sieving methods.

[0046] Preferably, before step (1), the method may also include the step of soaking...

preparation Embodiment 1

[0077] This example is used to illustrate the preparation of waterproof and breathable particles.

[0078] Heat 100 grams of quartz sand particles with a particle diameter of 3327 microns (6 mesh) to 50°C, then add 6 grams of liquid polyvinyl alcohol tert-butyraldehyde modified epoxy resin, stir thoroughly (stirring for 5 minutes), and then add polyvinyl alcohol tert-butyraldehyde modified epoxy resin. 1 gram of amide curing agent, and stir evenly, make the epoxy resin film on the surface of quartz sand particles; However, cool to room temperature, crush and sieve to obtain waterproof and air-permeable particles (particle diameter is 3350 microns).

preparation Embodiment 2

[0080] This example is used to illustrate the preparation of waterproof and breathable particles.

[0081] Heat 200 grams of quartz sand particles with a particle diameter of 74 microns (200 mesh) to 240 ° C, then add 10 grams of silicone resin, stir thoroughly (stirring for 5 minutes), and then add dibutyltin dilaurate curing agent 1.8 gram, stirred evenly, so that the silicone resin is coated on the surface of the quartz sand particles; yet, cooled to room temperature, crushed and sieved to obtain waterproof and air-permeable particles (particle diameter is 80 microns).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com