Patents

Literature

56results about How to "Improve dilution efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of optimizing heavy crude transportation by incorporation under pressure of dimethyl ether

InactiveUS7861737B2Simple methodImprove dilution efficiencyMolecular sieve catalystsRefining by heating/coolingPolymer scienceSolvent

Heavy crude transportation optimization method wherein at least one solvent is added to said crude. According to the method, a predetermined amount of dimethyl ether (DME) is added under pressure so as to adjust the viscosity of the crude.

Owner:INST FR DU PETROLE

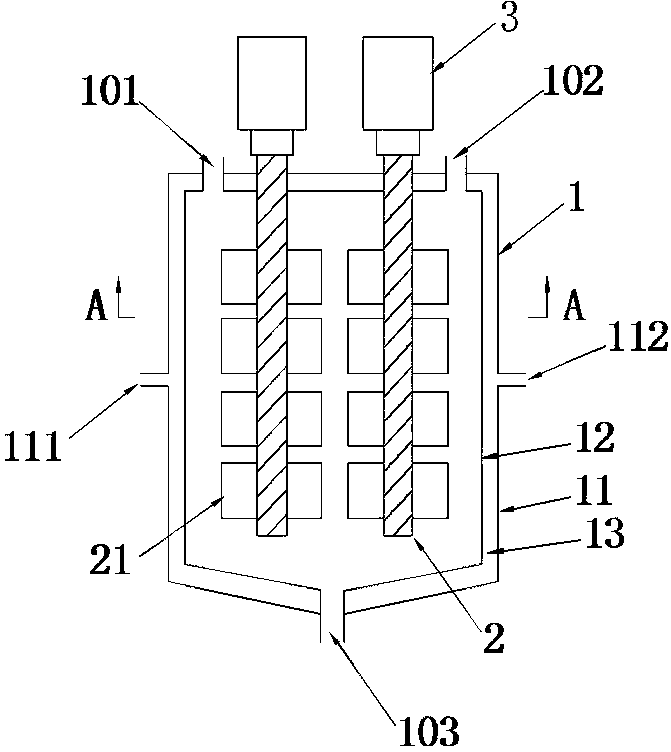

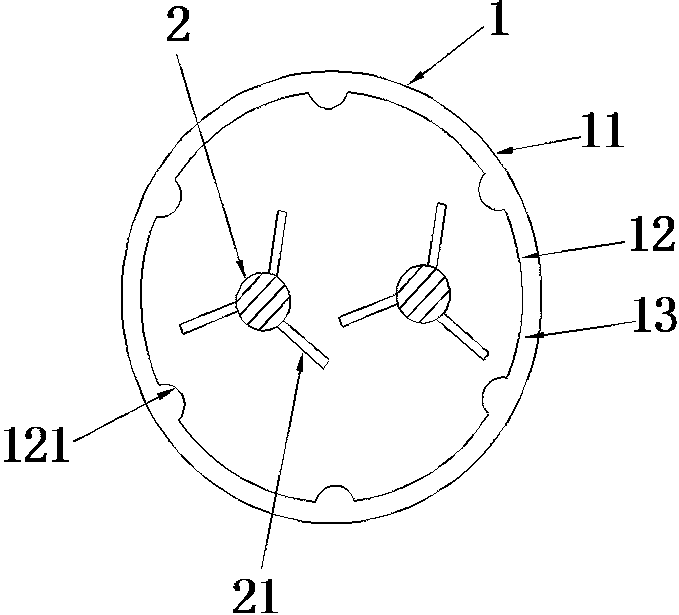

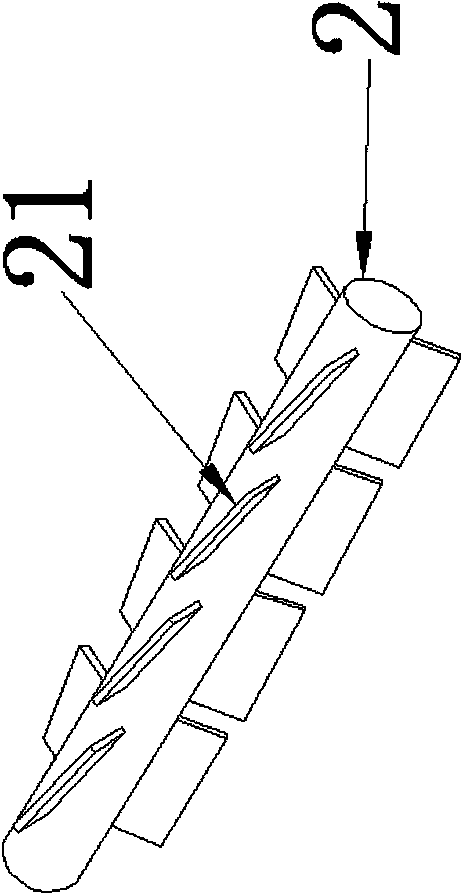

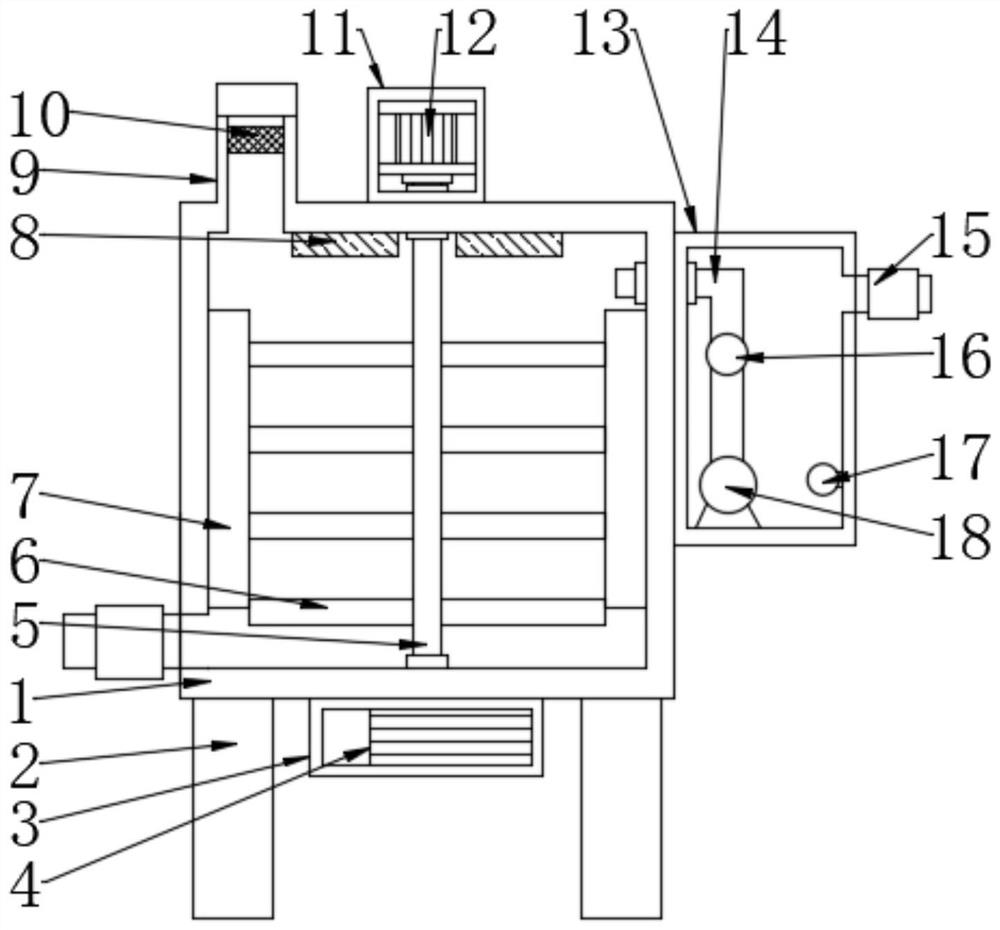

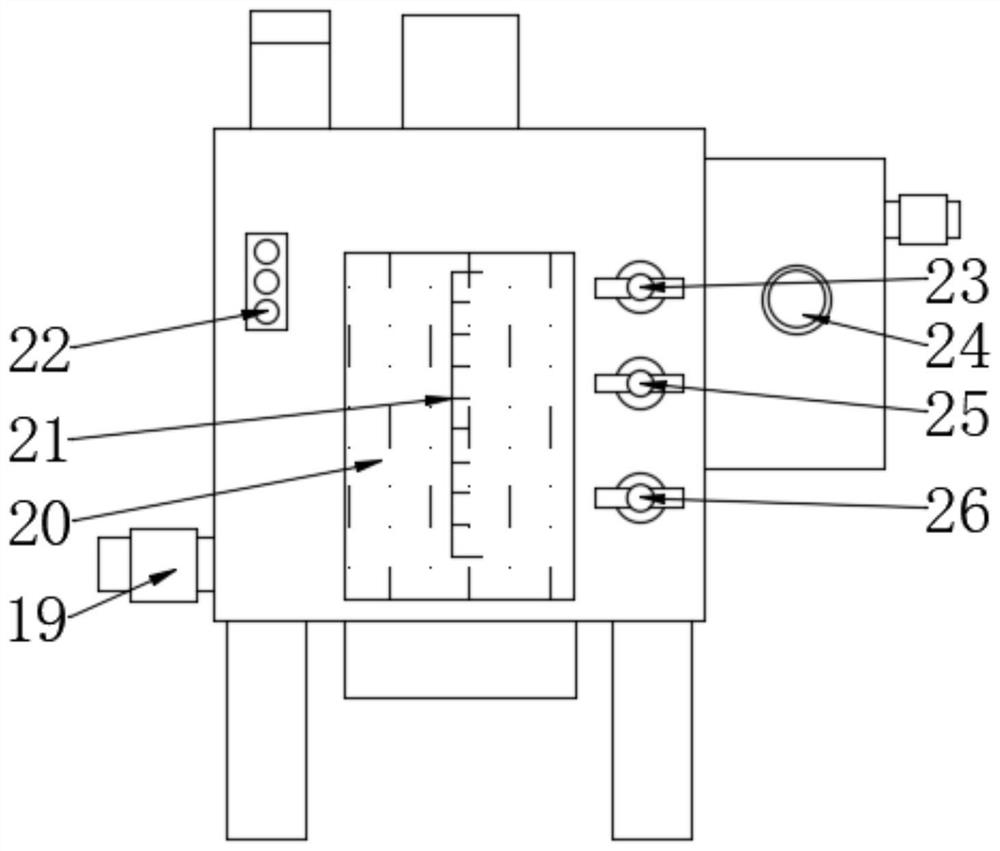

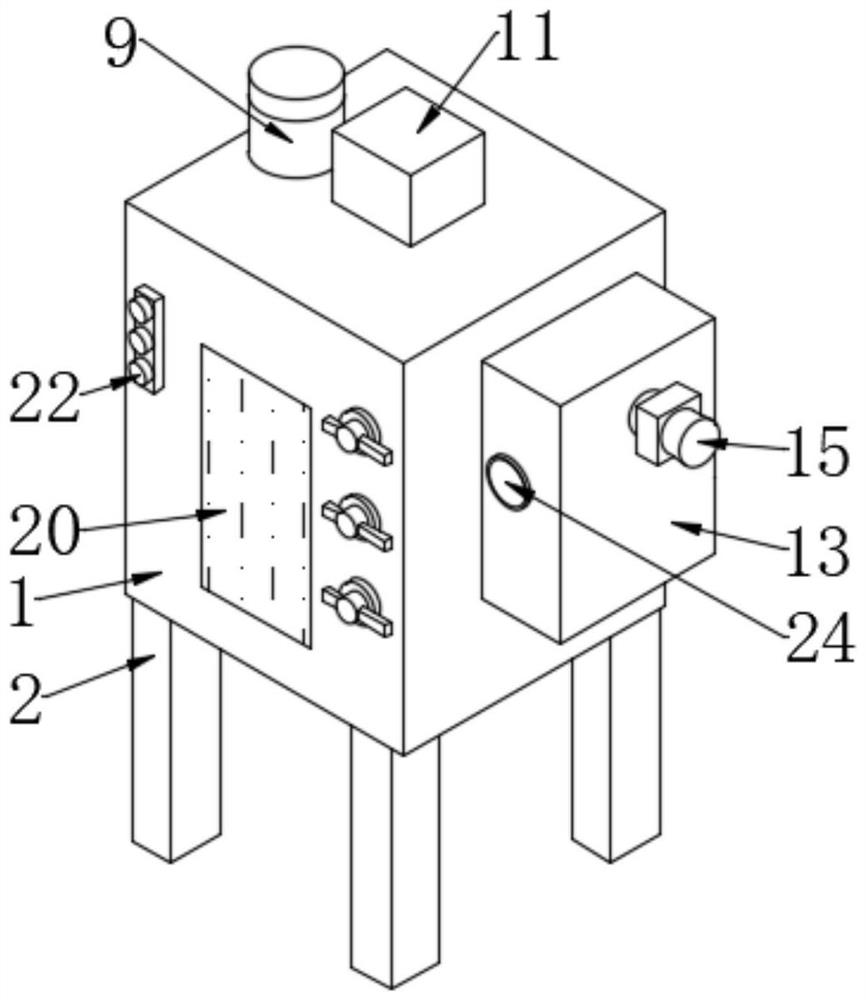

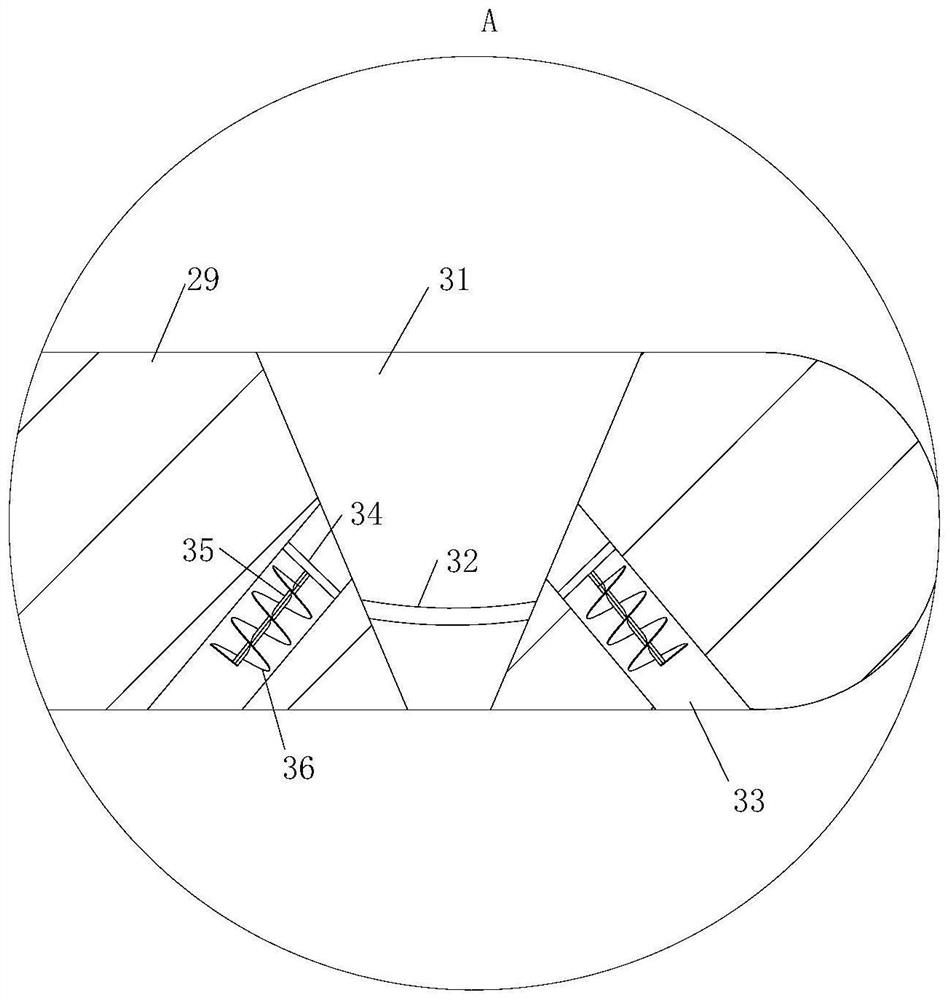

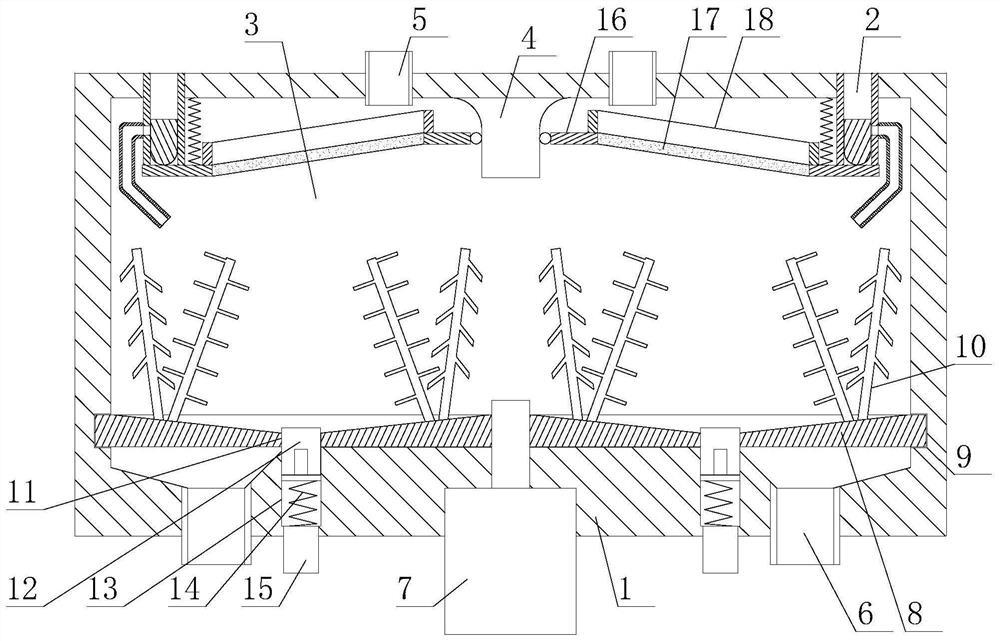

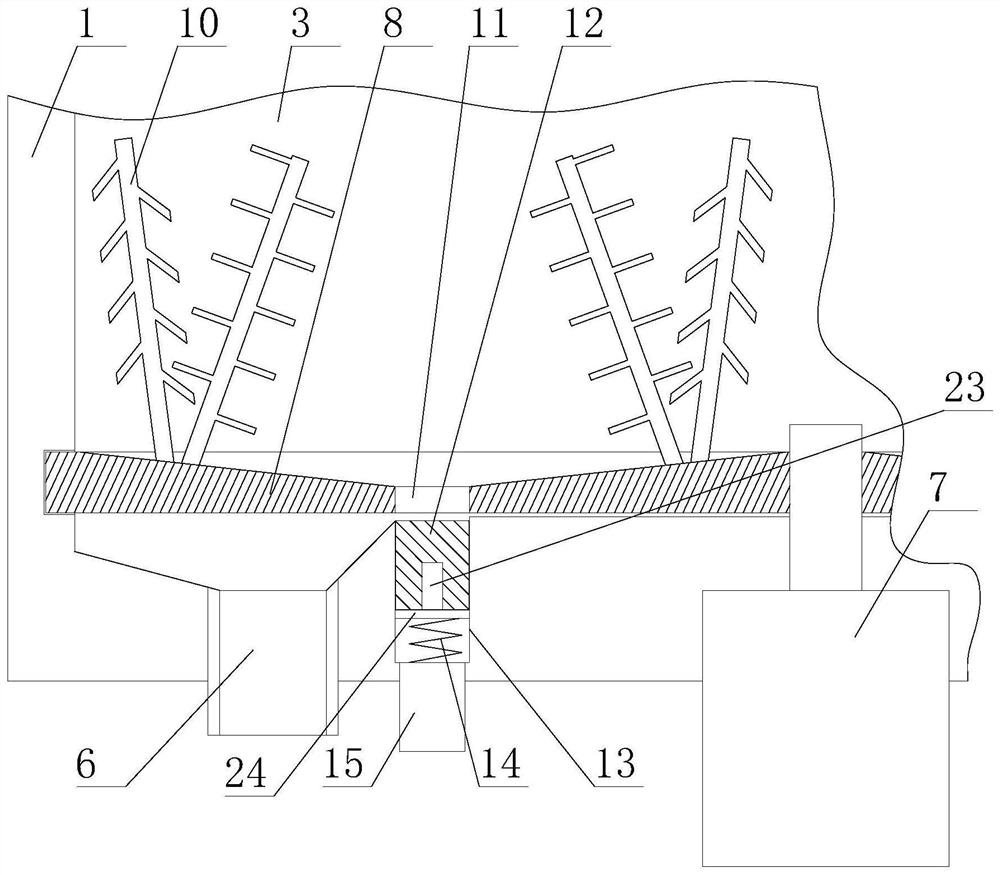

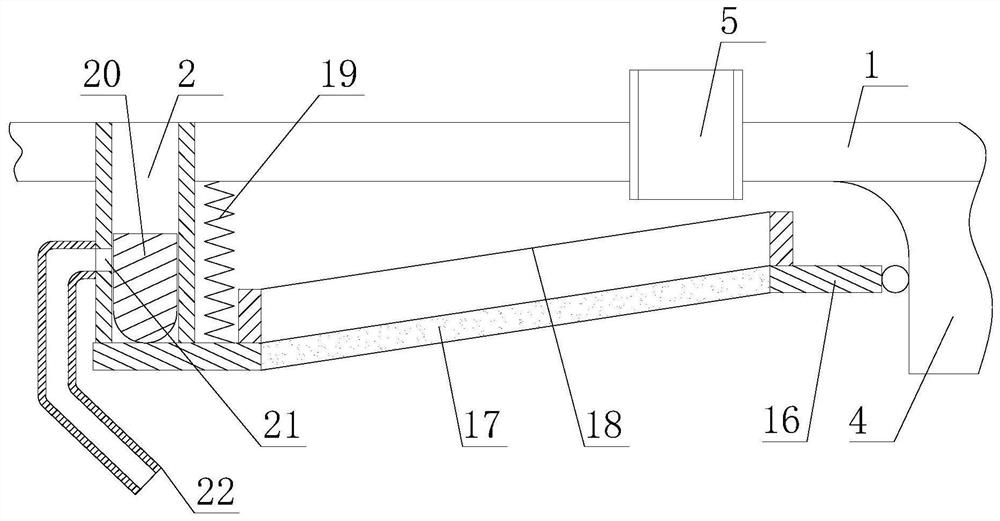

Honey dilution apparatus

The invention discloses a honey dilution apparatus which comprises a tank, rotating shafts and motors. The tank is provided with a honey inlet, a water inlet and a honey outlet. The rotating shafts are installed inside the tank. The motors and the rotating shafts are connected. There are two rotating shafts and two motors. The two motors have opposite rotating directions. The tank is two-layered and comprises an outer layer and an inner layer. There is a space between the outer layer and the inner layer. The outer layer is provided with a hot water inlet and a hot water outlet which are communicated with the space. Multiple stirring blades are fixed on the rotating shafts in their length direction. The honey dilution apparatus has advantages of simple structure, convenience in usage and high dilution efficiency.

Owner:NINGBO ZHENHAI MIFENG ENERGY SAVING & ENVIRONMENT PROTECTION TECH

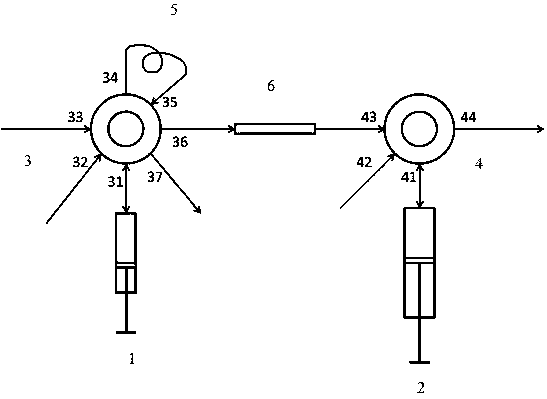

Constant-volume type automatic diluter

PendingCN108072557ANo pollution in the processReduce pollutionPreparing sample for investigationFour-way valveEngineering

The invention discloses a constant-volume type automatic diluter which comprises a trace-amount injector driven by a stepping motor, a constant-amount injector driven by a stepping motor, a seven-wayvalve with channels freely switched, and a four-way valve with channels freely switched. The seven-way valve comprises the first channel used for being connected with the trace-amount injector, the second channel used as a to-be-diluted liquid extraction inlet, the third channel used as a diluted liquid extraction inlet, the fourth channel used for quantitative allocation output, the fifth channelused for quantitative allocation input, the sixth channel used for being connected with the three-way valve, and the seventh channel used for trace-amount allocation discharge. The four-way valve comprises the channel I used for being connected with the constant-amount injector, the channel II used as a to-be-diluted liquid extraction inlet, the channel III used for being connected with the seven-way valve and the channel IV used for constant-amount liquid preparing discharge. The trace-amount injector is connected to the first channel. The constant-amount injector is connected to the channelI. The sixth channel and the channel III are connected, and a pipeline mixer is connected between the sixth channel and the channel III. Through the linkage of the double precision injectors and thetwo stepping motors, the various defects of various existing diluters and manual dilution are well overcome.

Owner:南京科创检测技术有限公司

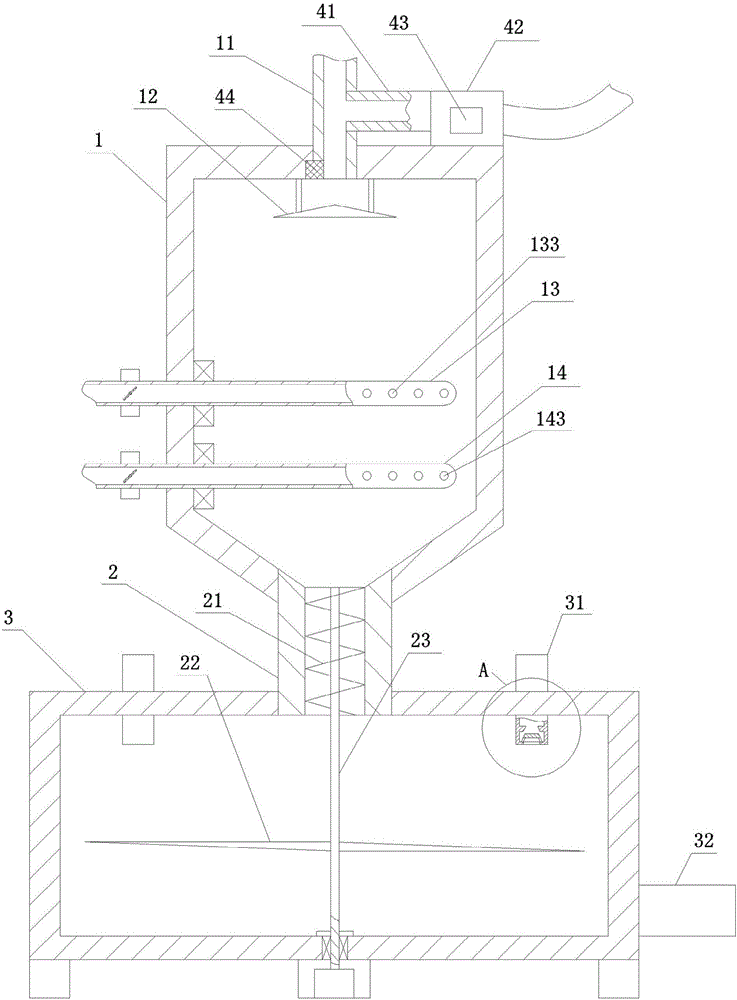

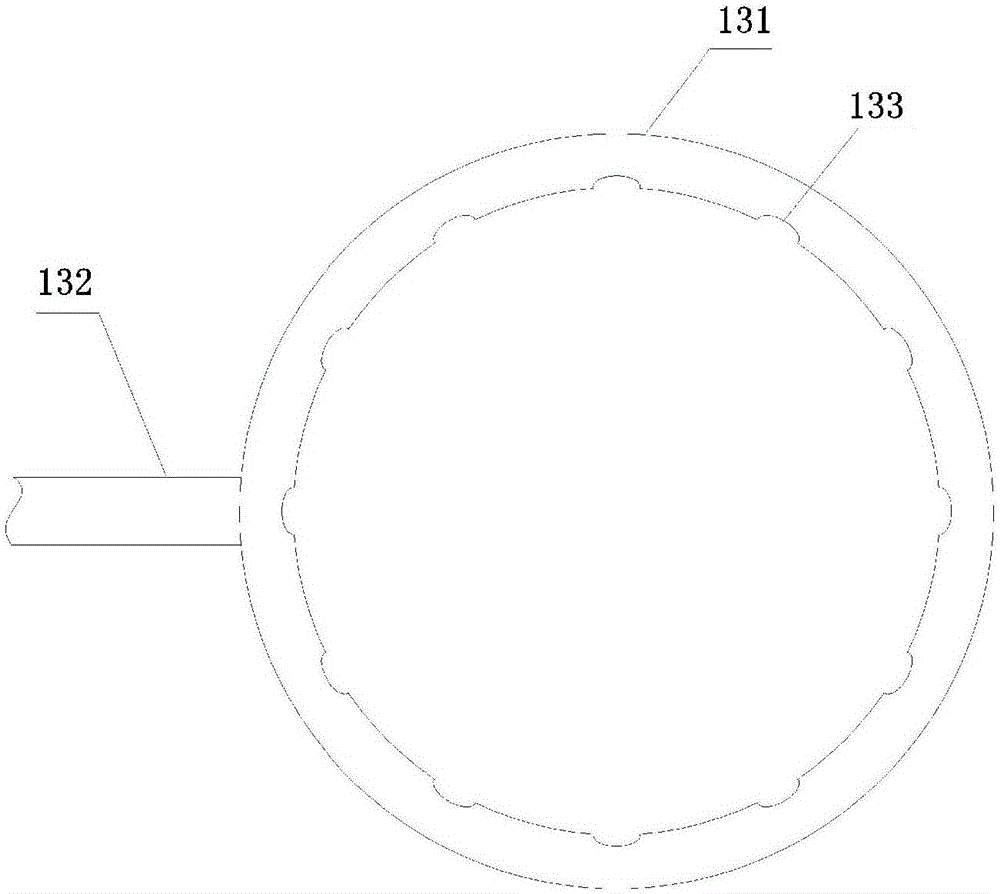

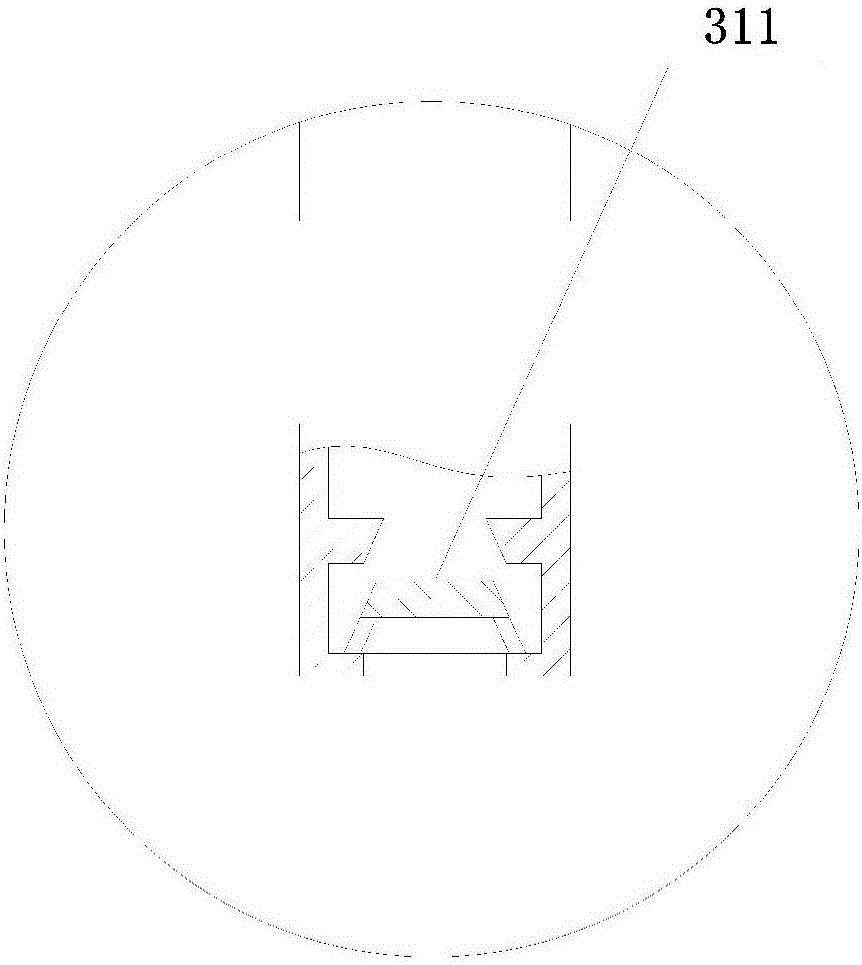

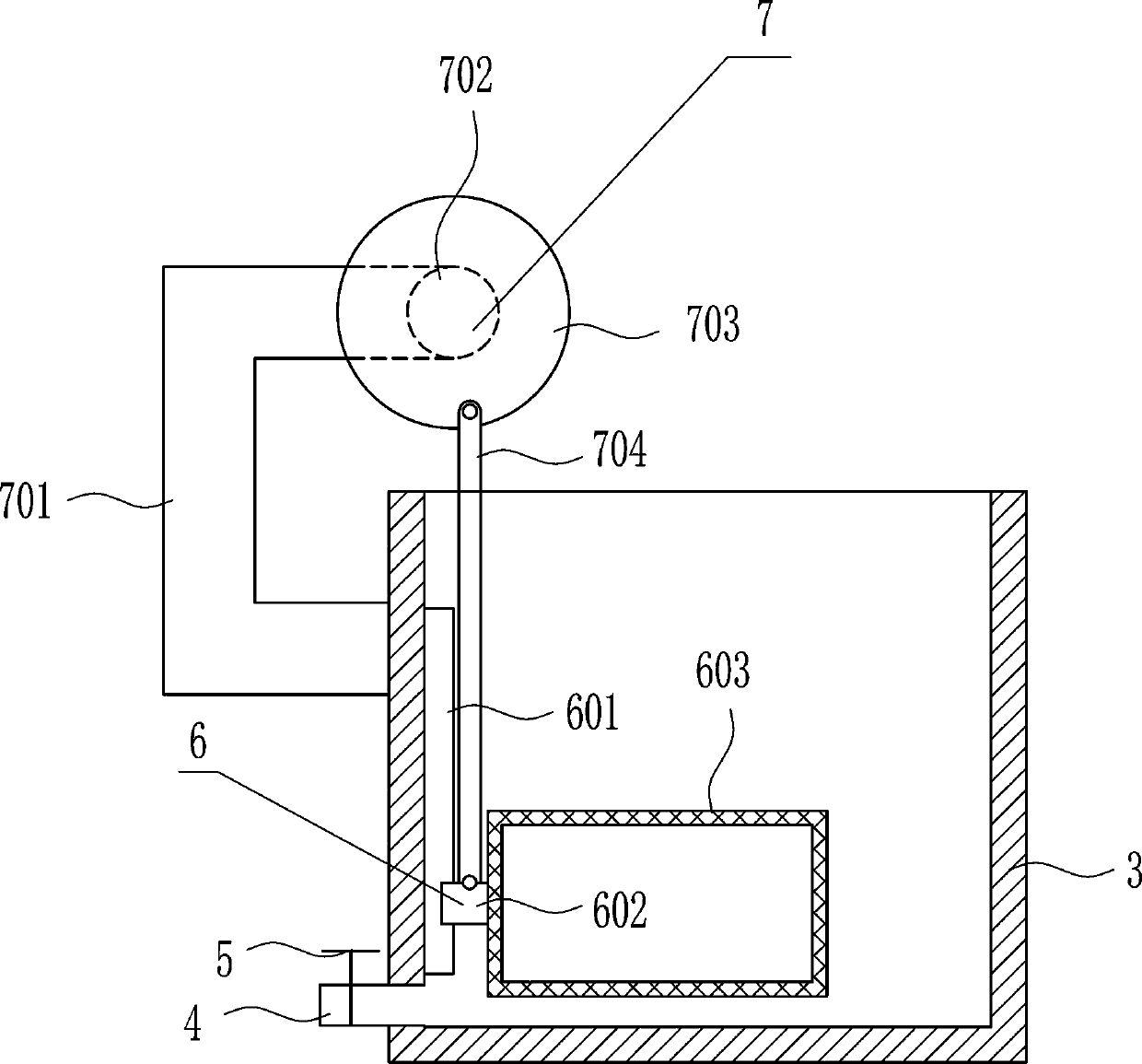

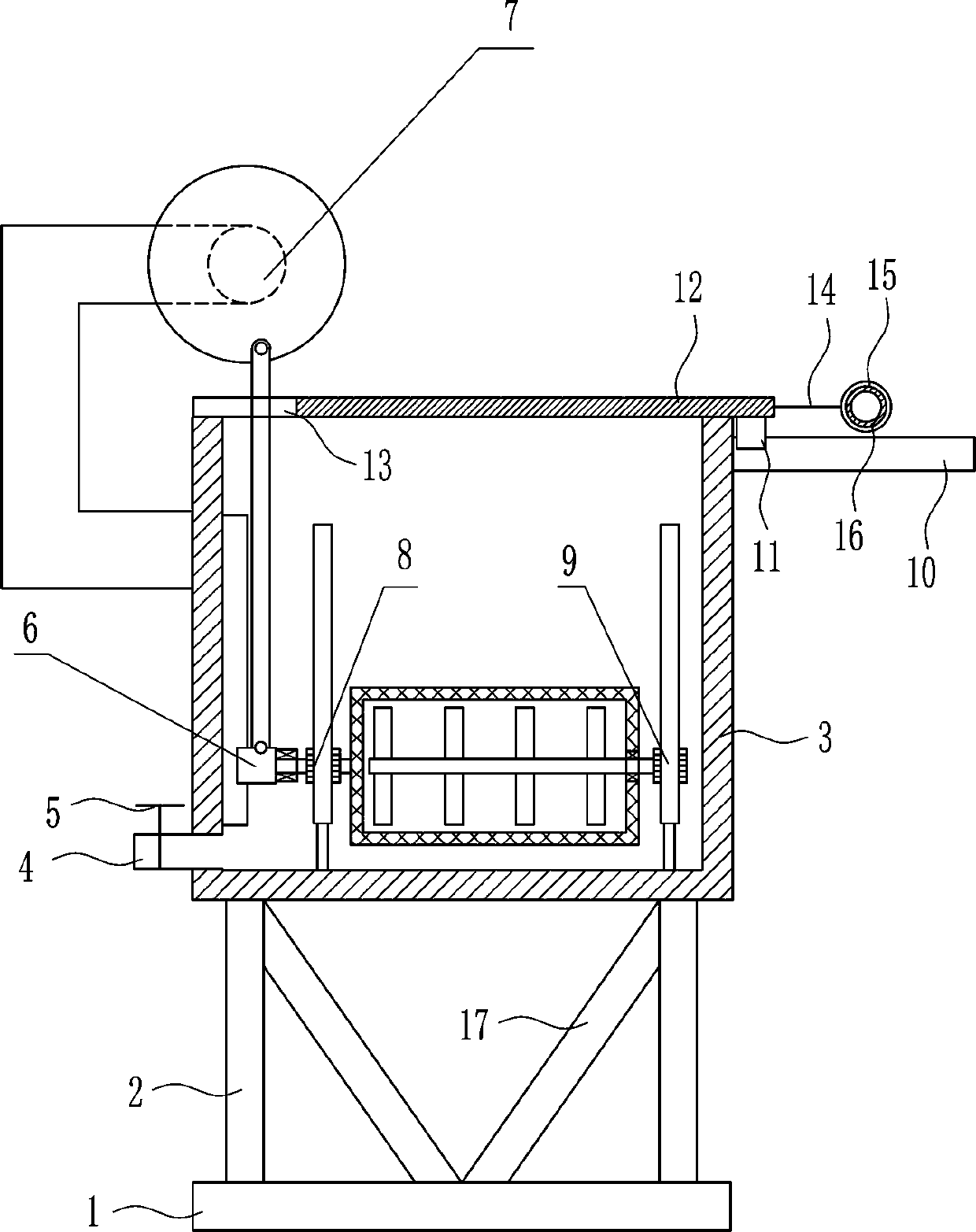

Pulp bleaching apparatus with flushing mechanism

InactiveCN106609478APrevent backflowImprove dilution efficiencyWashing/displacing pulp-treating liquorsPulp bleachingSpray nozzlePulp and paper industry

The invention especially relates to a pulp bleaching apparatus with a flushing mechanism, belonging to the field of pulp bleaching equipment. The pulp bleaching apparatus with the flushing mechanism comprises a bleaching assembly and a flushing assembly, wherein the bleaching assembly comprises a bleaching chamber and a dilution chamber arranged below and connected with the bleaching chamber via a conveying pipeline; the top of the bleaching chamber is connected with a pulp inlet pipe; the interior of the bleaching chamber is provided with a pulp distributing disc, a bleaching solution inlet pipe and a primary dilution solution inlet pipe from top to bottom; the pulp distributing disc comprises a taper top which is correspondingly arranged below the pulp inlet pipe; the bleaching solution inlet pipe comprises a solution spraying pipe and a solution conveying pipe connected with a solution outlet pipe; the solution spraying pipe is provided with a plurality of solution spraying nozzles; the primary dilution solution inlet pipe comprises a solution sprinkling pipe and a solution inlet pipe connected with the solution sprinkling pipe; and the solution sprinkling pipe is provided with a plurality of solution sprinkling nozzles.

Owner:安徽鑫久亚光电科技有限公司

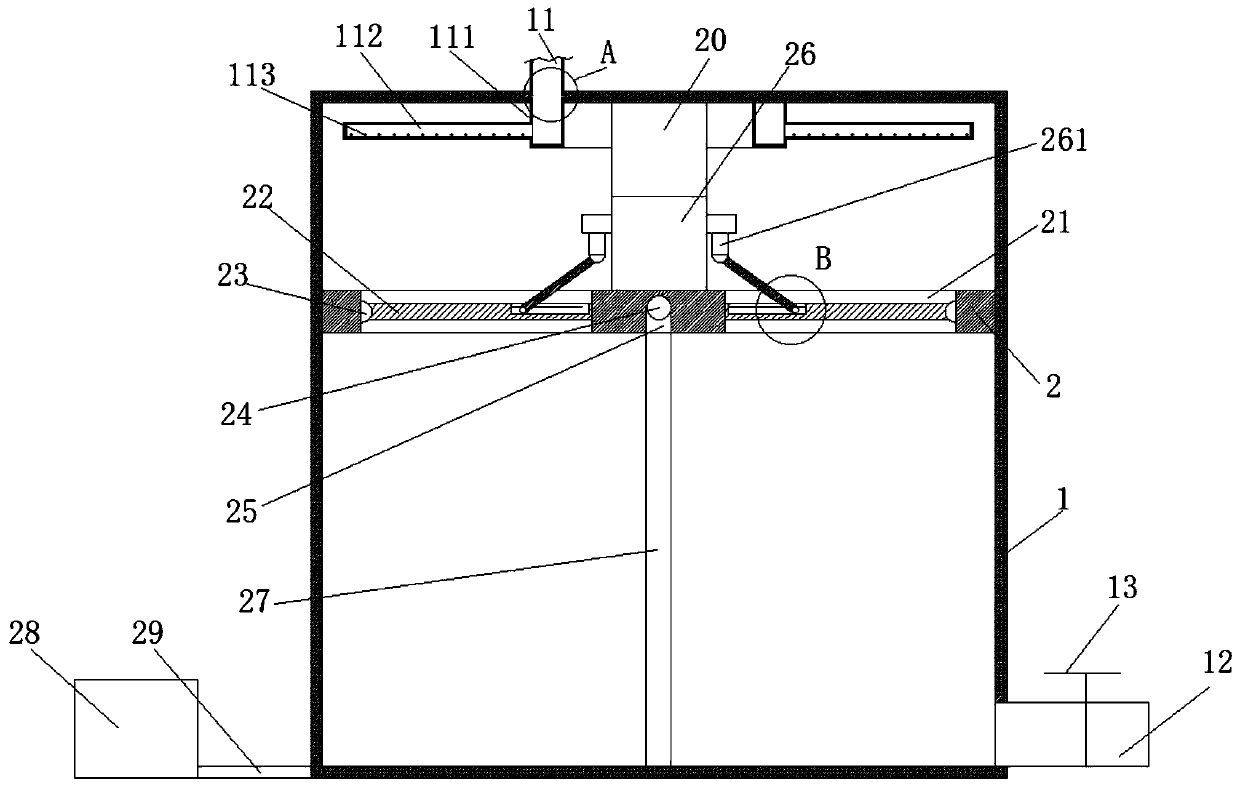

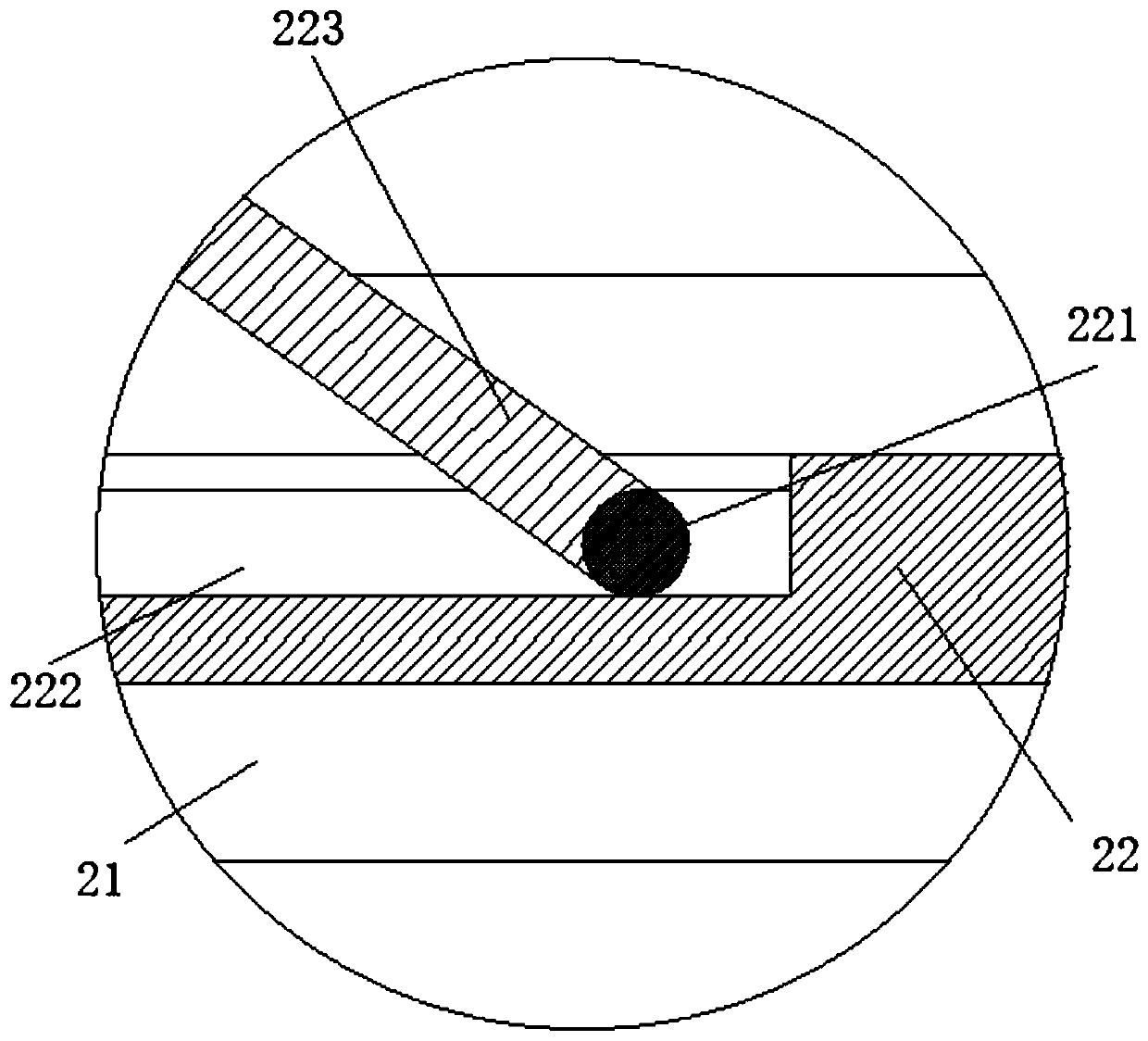

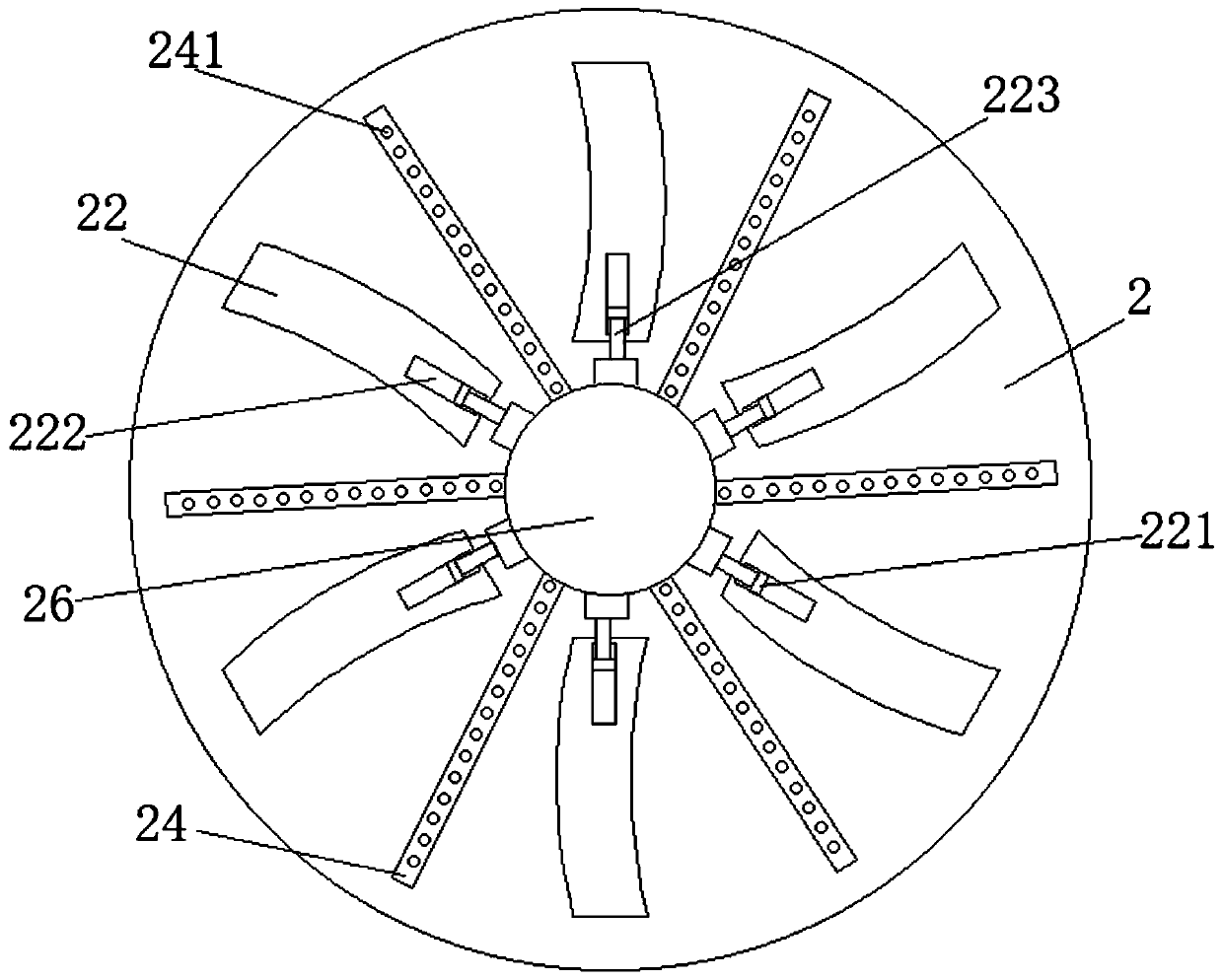

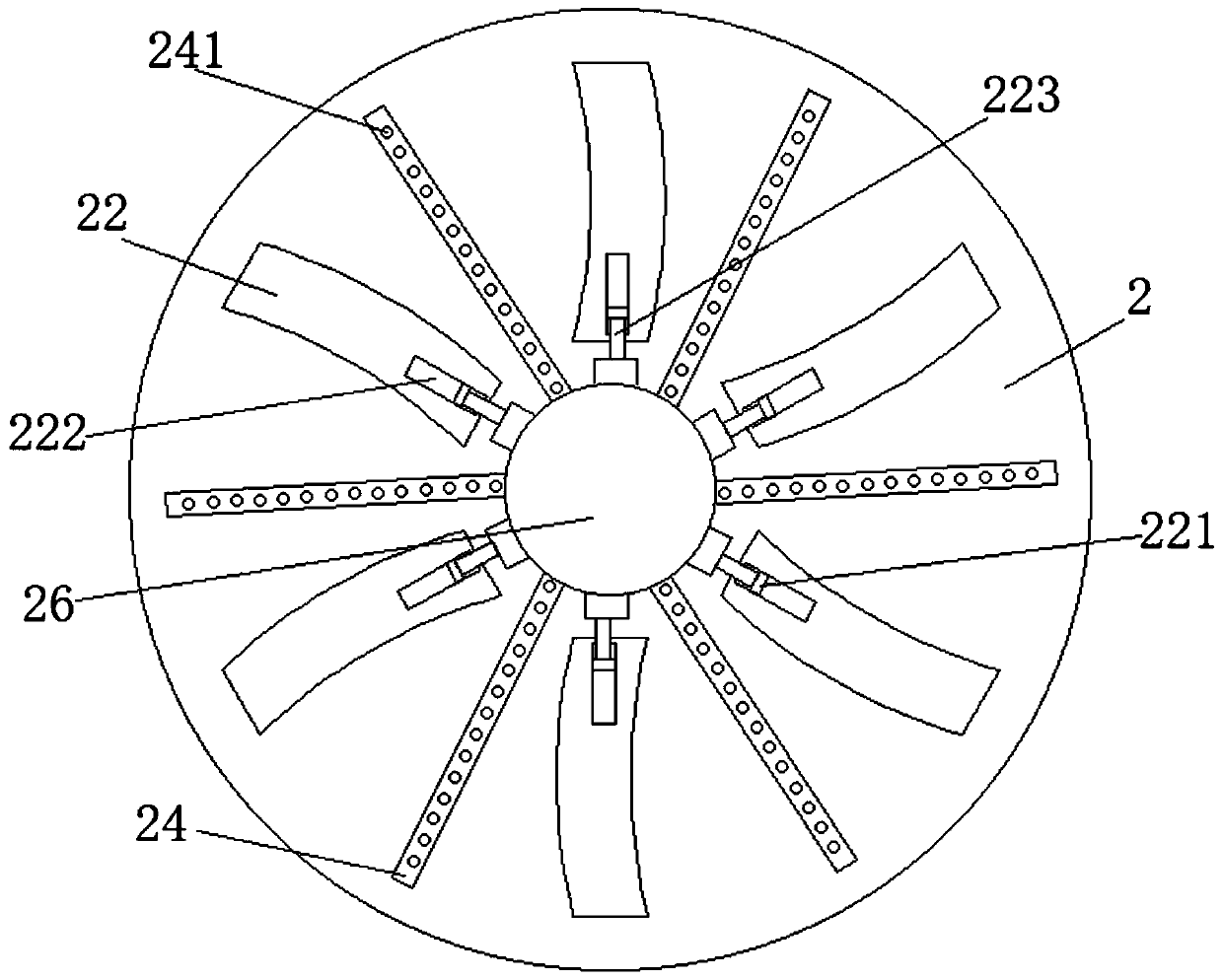

Liquid adding and diluting device for medical examination and diluting method

InactiveCN113198338AImprove efficiencyHigh precisionTransportation and packagingMixing methodsPhysicsElectric machinery

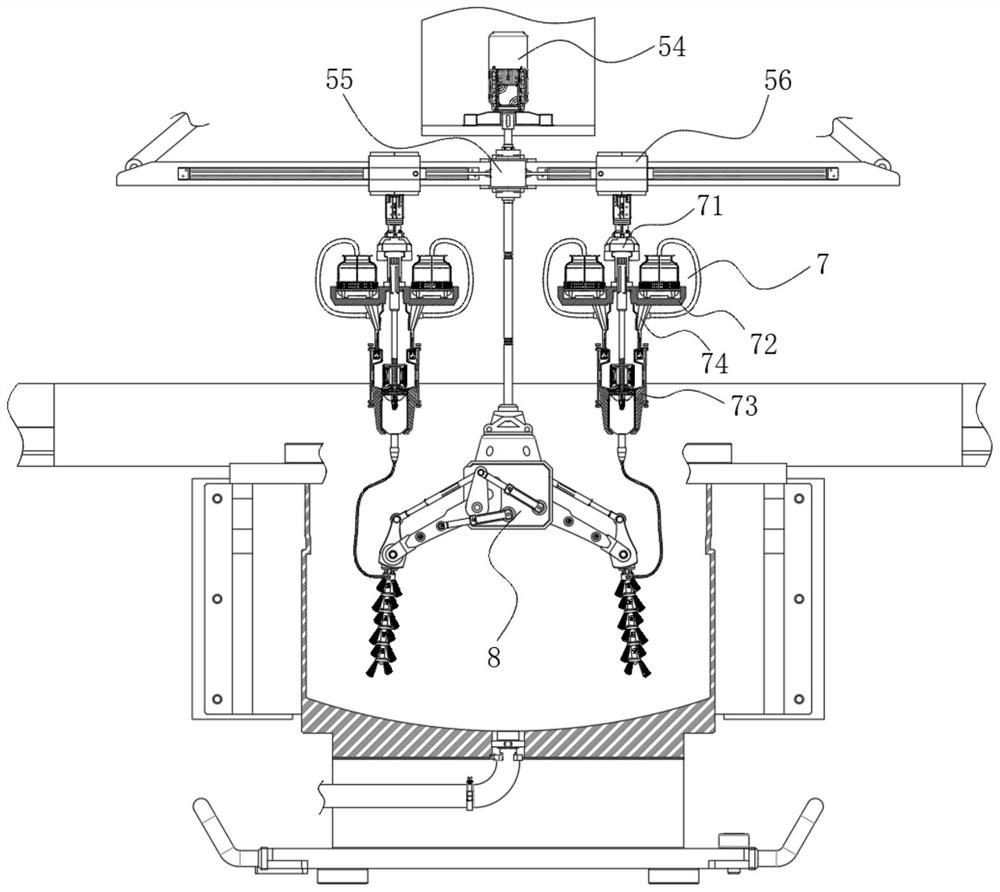

The invention discloses a liquid adding and diluting device for medical examination. The device comprises a workbench, a first motor, a first rotating shaft, transverse sliding rail plates, a mixing and diluting device and diluting boxes, multiple sets of diluting boxes are arranged in a box body at the bottom end of the workbench in a circumferential mode, and the first longitudinal motor is arranged in the center of the shell at the top end of the workbench; a first rotating shaft is fixed to the output end of the first motor, the side face of the first rotating shaft is sleeved with multiple sets of transverse sliding rail plates, there are multiple transverse sliding rail plates which are circularly arranged, and the mixing and diluting device is installed on the transverse sliding rail plates and correspondingly arranged on the diluting boxes.

Owner:YICHANG NO 1 PEOPLES HOSPITAL PEOPLES HOSPITAL OF CHINA THREE GORGES UNIV

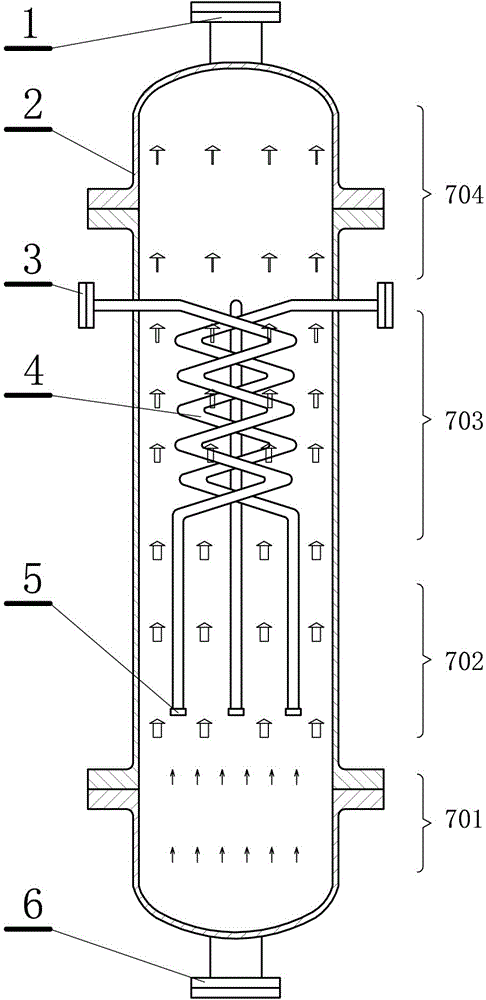

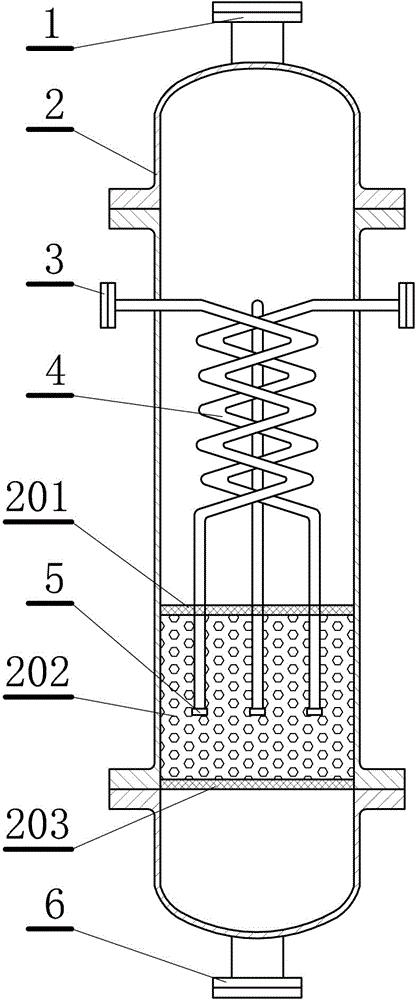

No-heat-exchange energy saving preparation device and method for preparing ammonia water from liquid ammonia directly

The invention relates to a no-heat-exchange energy saving preparation device and method for preparing ammonia water from liquid ammonia directly. The preparation device comprises a cylindrical reaction tank, a water inlet is arranged at the bottom of the reaction tank, a diluted ammonia water outlet is arranged at the top of the reaction tank, a plurality of liquid ammonia inlets are arranged in the upper and middle part of the reaction tank, each liquid ammonia inlet is connected with a respective coil pipe. The coil pipes are installed in a staggered manner, and extend towards the middle and lower part of the reaction tank. Each coil pipe is connected with a respective distributor. The coil pipes are heated by heat energy generated by diluted ammonia water during the dilution reaction process, thus liquid ammonia in the coil pipe expands and absorb heat, thus heat generated during the liquid ammonia dilution reaction is reduced, liquid ammonia expands before dilution, and the liquid ammonia dilution speed is raised. The device takes full advantage of waste heat generated during liquid ammonia dilution, the liquid ammonia dilution efficiency is raised, the situation that energy is employed to lower the temperature of the diluted ammonia water is avoided, energy consumption is lowered and a lot of energy is saved.

Owner:BEIJING BOHUITONG S & T DEV

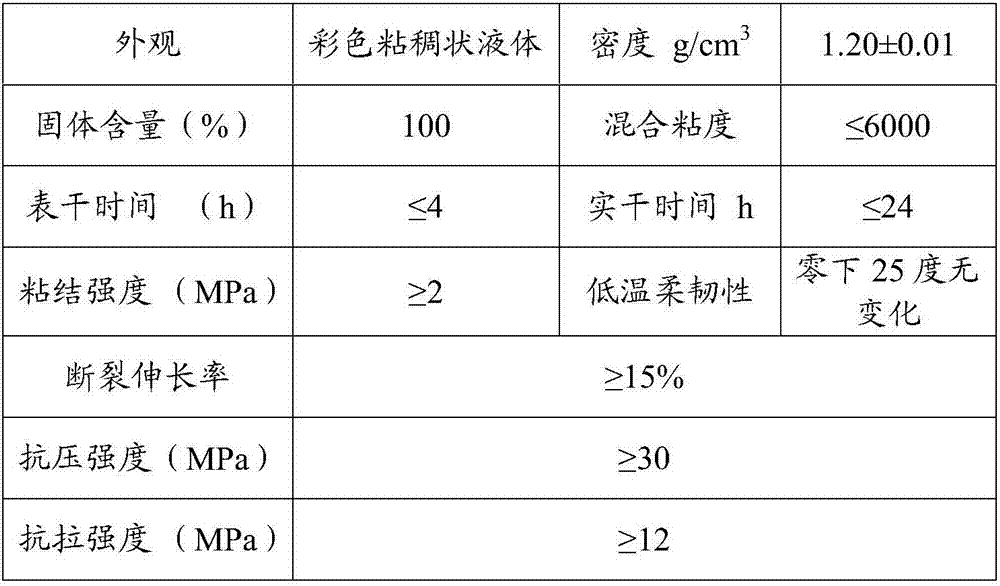

Epoxy colored pavement finish paint and preparation and construction process thereof

InactiveCN107083157AExcellent physical and chemical propertiesGood weather resistanceIn situ pavingsAnti-corrosive paintsEnvironmental resistanceWeather resistance

The invention discloses an epoxy colored pavement finish paint and a preparation and construction process thereof. The epoxy colored pavement finish paint contains components A and B, wherein the component A is a curing agent, and the component B is prepared from, by mass, 30-50% of epoxy resin, 5-10% of reactive diluent, 0.5-2% of anti-settling agent, 1-5% of pigment, 20-40% of quartz powder and 20-40% of coarse whiting. The epoxy colored pavement finish paint is green and environmentally friendly, is free of irritant smell, has reliable and permanent adhesion power with different basal planes, also has good weather resistance and chemical corrosion resistance, is not saponified on alkaline concrete, and has excellent waterproof and dampproof properties, good flexibility, impact resisting property and excellent anti-slip protection property. In addition, the preparation process of the finish paint is simple, the conditions are mild, the construction time is longer than conventional time, construction operation is easy, the requirements for the environment is not strict during construction, and the finish paint is low in cost, economical, practical and suitable for large-area popularization.

Owner:深圳市威尔地坪材料有限公司

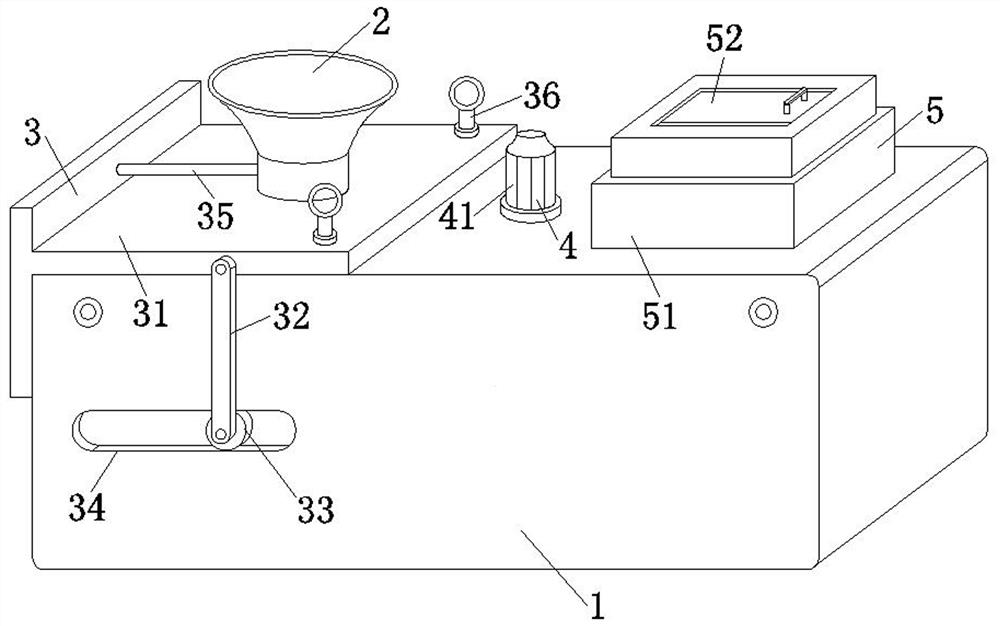

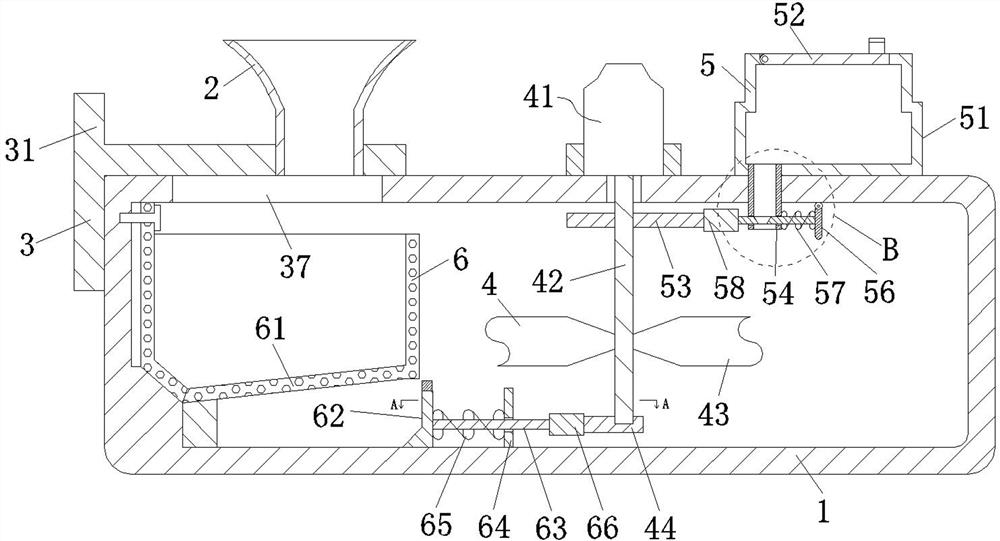

Shale gas flowback fluid recovery treatment device and method

ActiveCN112717519AGuaranteed patencyGuaranteed filtering effectTransportation and packagingRotary stirring mixersTreatment pondDiluent

The invention discloses a shale gas flowback fluid recovery treatment device and method. The device comprises a treatment pond, a feeding hopper is arranged at the top of the treatment pond, a filtering mechanism used for filtering shale gas flowback fluid is arranged on one side of the interior of the treatment pond, and a liquid conveying mechanism used for supplying diluent at intervals is arranged on the other side of the interior of the treatment pond; and a stirring mechanism used for mixing shale gas flowback fluid and diluent is arranged between the filtering mechanism and the liquid conveying mechanism, and a movable push plate is arranged at the bottom of a filter cartridge of the filtering mechanism. The invention further discloses a recovery treatment method corresponding to the device. According to the invention, the overall recovery treatment efficiency of the rock gas flowback fluid can be effectively improved, and the problems that the filter cartridge is easily blocked by filter residues and the diluent adding efficiency is low are solved.

Owner:TIANJIN UNIV

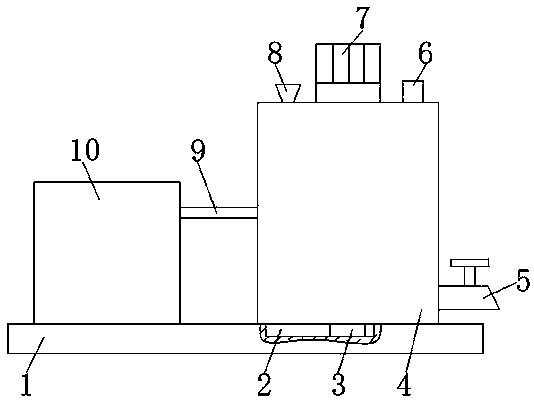

Pesticide dilution device for agriculture

InactiveCN108031373ASolve the problem of low dilution efficiencyImprove dilution efficiencyShaking/oscillating/vibrating mixersMixing methodsEngineeringThreaded rod

The invention discloses a pesticide dilution device for agriculture. The pesticide dilution device comprises a base; a shell and a box body are sequentially arranged on the top of the base from left to right; a second motor is fixedly connected with the bottom at the right side of an inner cavity of the shell; an output end of the second motor is fixedly connected with a threaded rod, and the leftend of the threaded rod is movably connected with the inner wall of the shell. The pesticide dilution device is provided with the base, the box body, a first motor, a pull rod, the shell, a connecting rod, a sliding sleeve, a vertical rod, the second motor, a threaded bush, the threaded rod, a sliding rod, a rotating shaft, a mixing frame and a stirring rod which are used cooperatively, so that the problem that the existing pesticide dilution device for agriculture is low in dilution efficiency is solved. The pesticide dilution device for agriculture has the advantage of being high in dilution efficiency, reduces the work load of a user, increases the working efficiency of the user, brings great convenience to the user, and improves the practicality of the pesticide dilution device, thusbeing worth popularizing.

Owner:衡阳博思科技有限公司

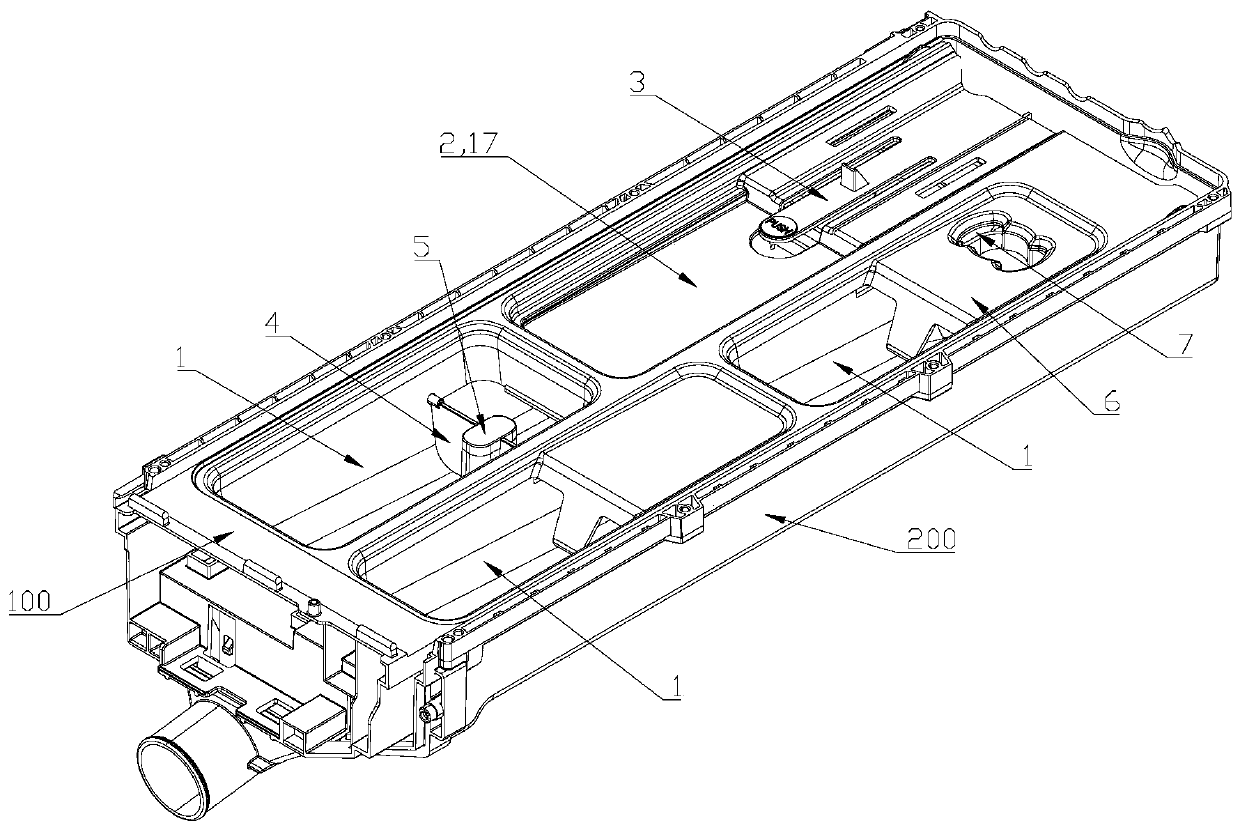

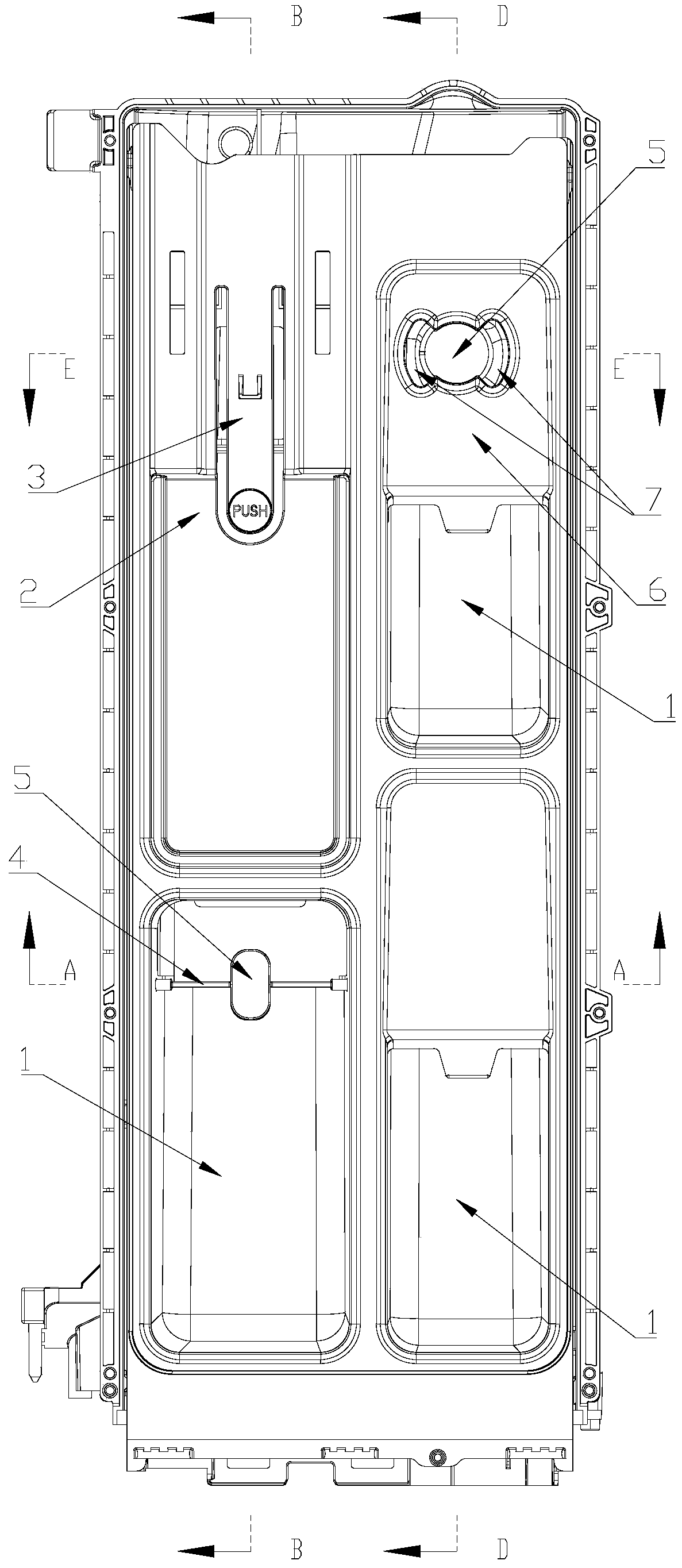

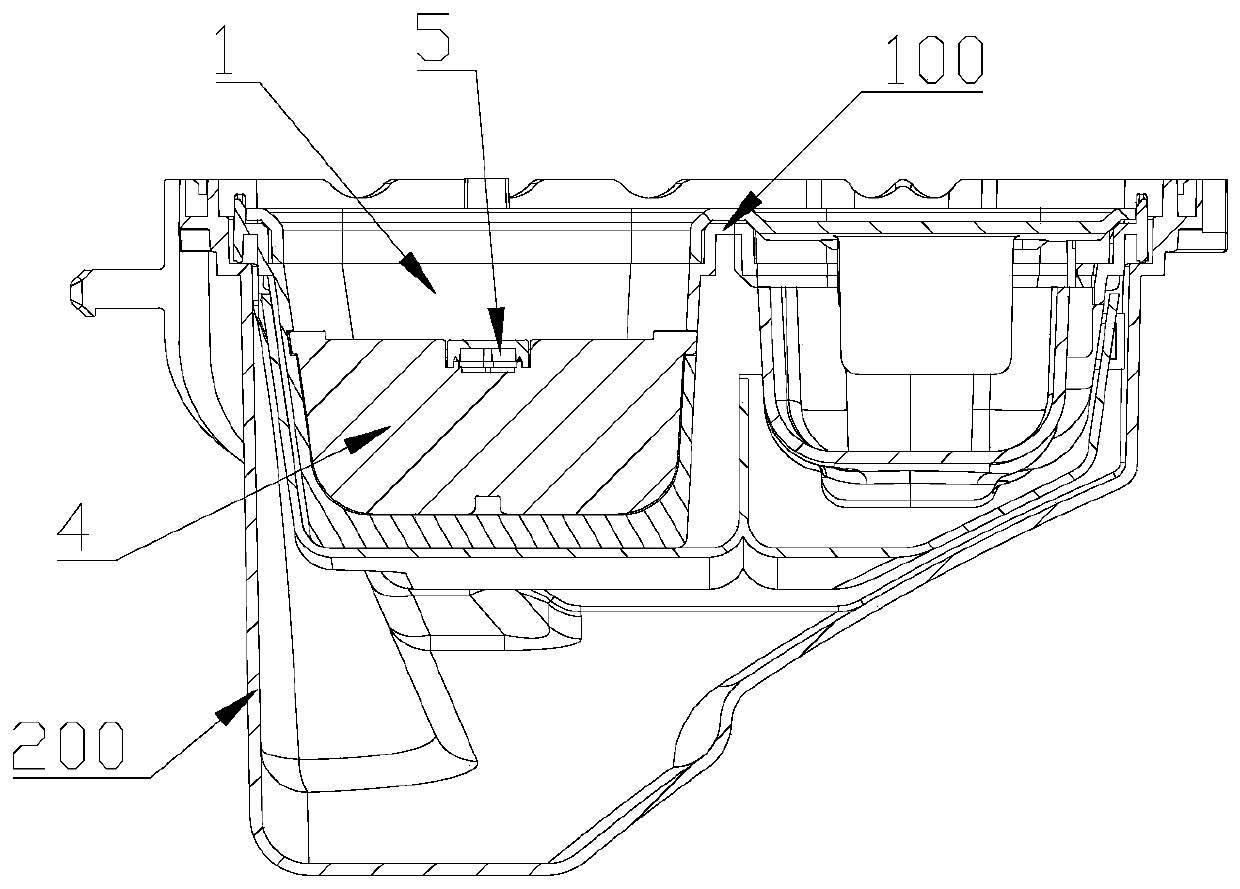

Washing additive feeding device

ActiveCN111455622AAvoid residuesRealize the purpose of preventing washing powder residueOther washing machinesTextiles and paperWater flowMechanical engineering

The invention discloses a washing additive feeding device. The washing additive feeding device comprises a water box. A feeding box is arranged in the water box. At least one feeding cavity is formedin the feeding box, siphon columns are arranged in the feeding cavities, and a central flow passage and a peripheral flow passage which are independent to each other and extend vertically are arrangedin each siphon column. The top ends of the central flow passages and the peripheral flow passages are sealed by siphon covers and communicate with each other, and the bottom ends of the central flowpassages and the peripheral flow passages communicate with the water box and the feeding cavities correspondingly. A blocking rib sleeving the periphery of each siphon column is arranged in the corresponding feeding cavity, so that detergents in the feeding cavities and inflowing water flow through the blocking ribs and then flow to locations between the blocking ribs and the siphon columns. By arranging the circle of blocking ribs on the peripheries of the siphon columns, the siphon columns are isolated from the feeding cavities, the situation that liquid in the feeding cavities surges when the feeding cavities are pulled, the liquid level at the siphon columns rises and thus the siphon columns are triggered by mistake to perform siphoning is solved, and the purpose of preventing the siphon columns from being triggered by mistake to perform siphoning due to liquid surging is achieved.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

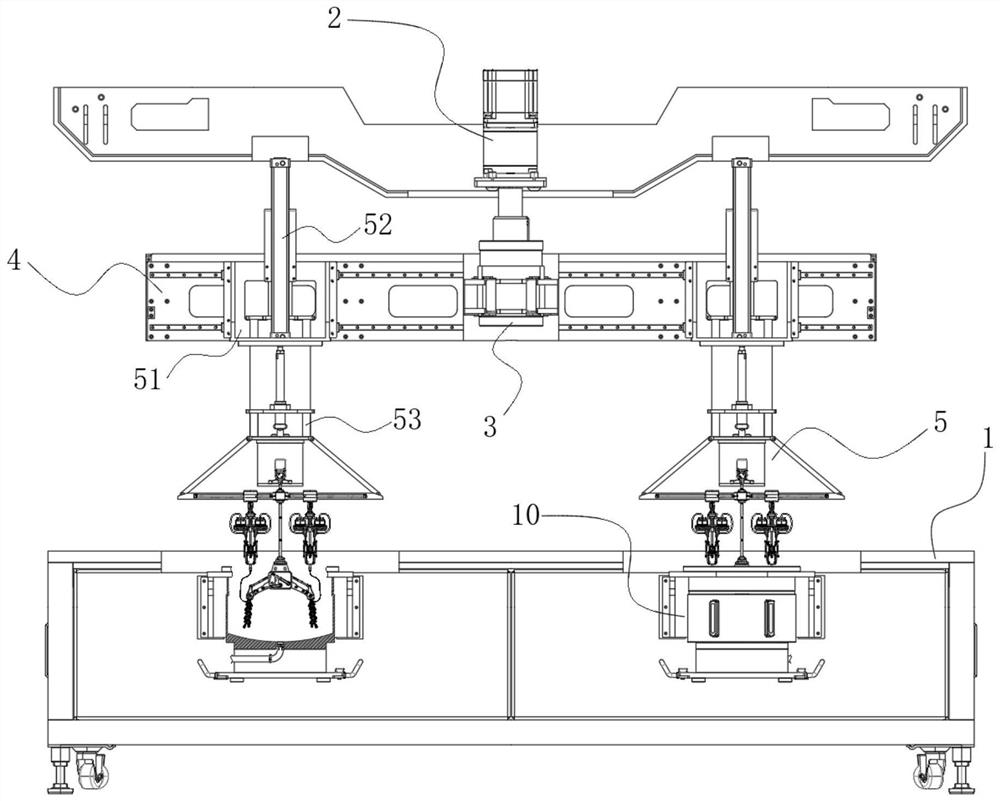

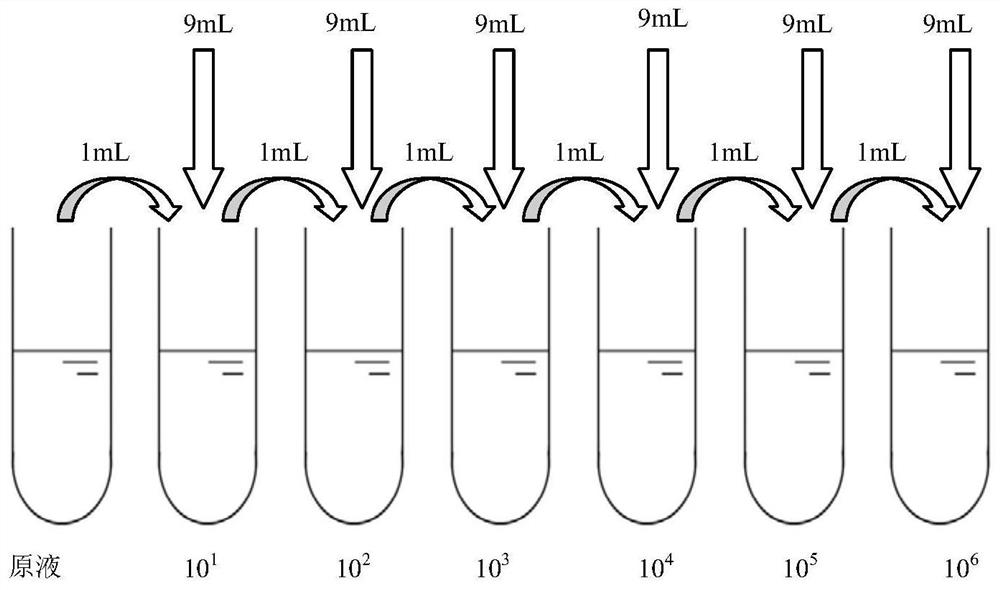

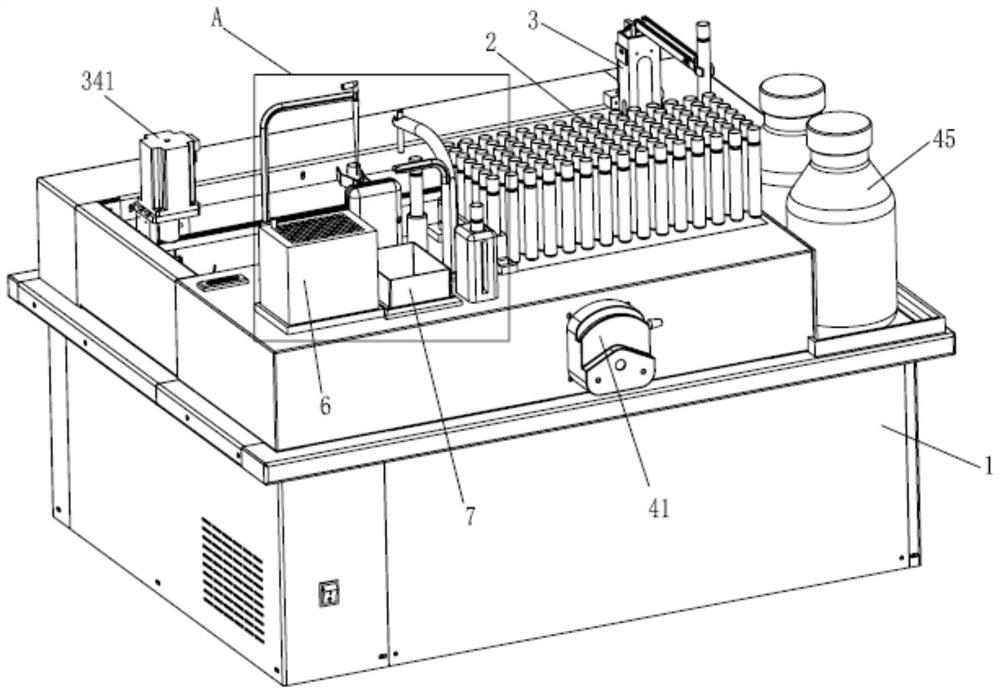

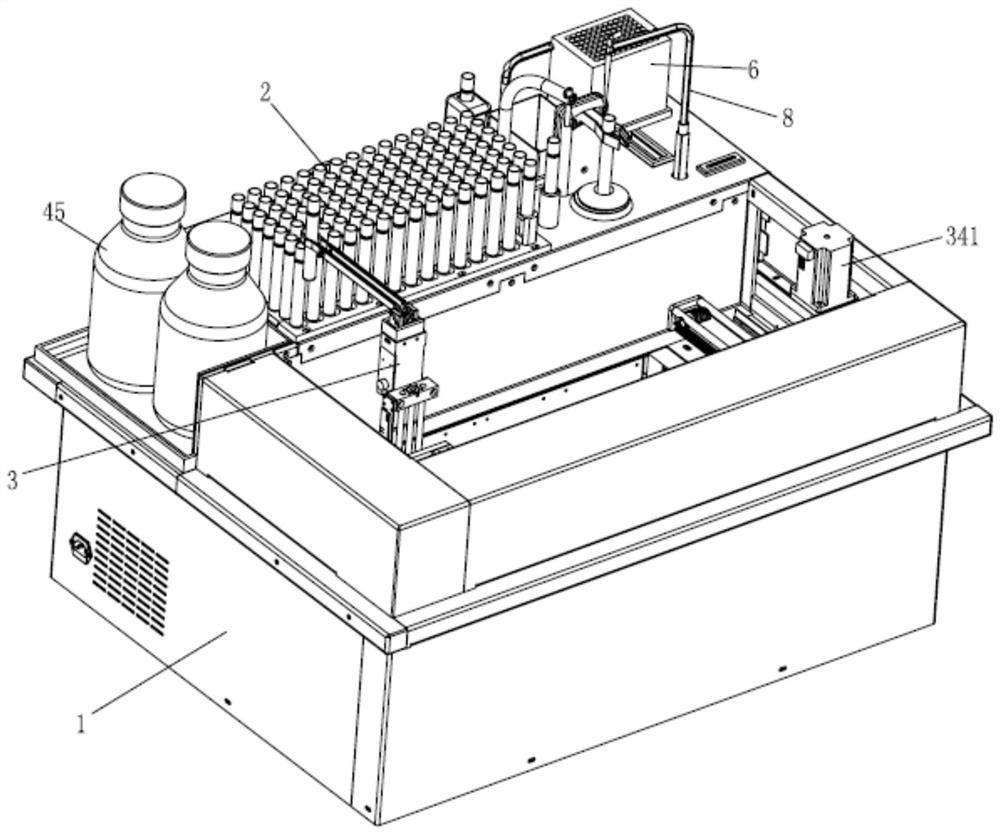

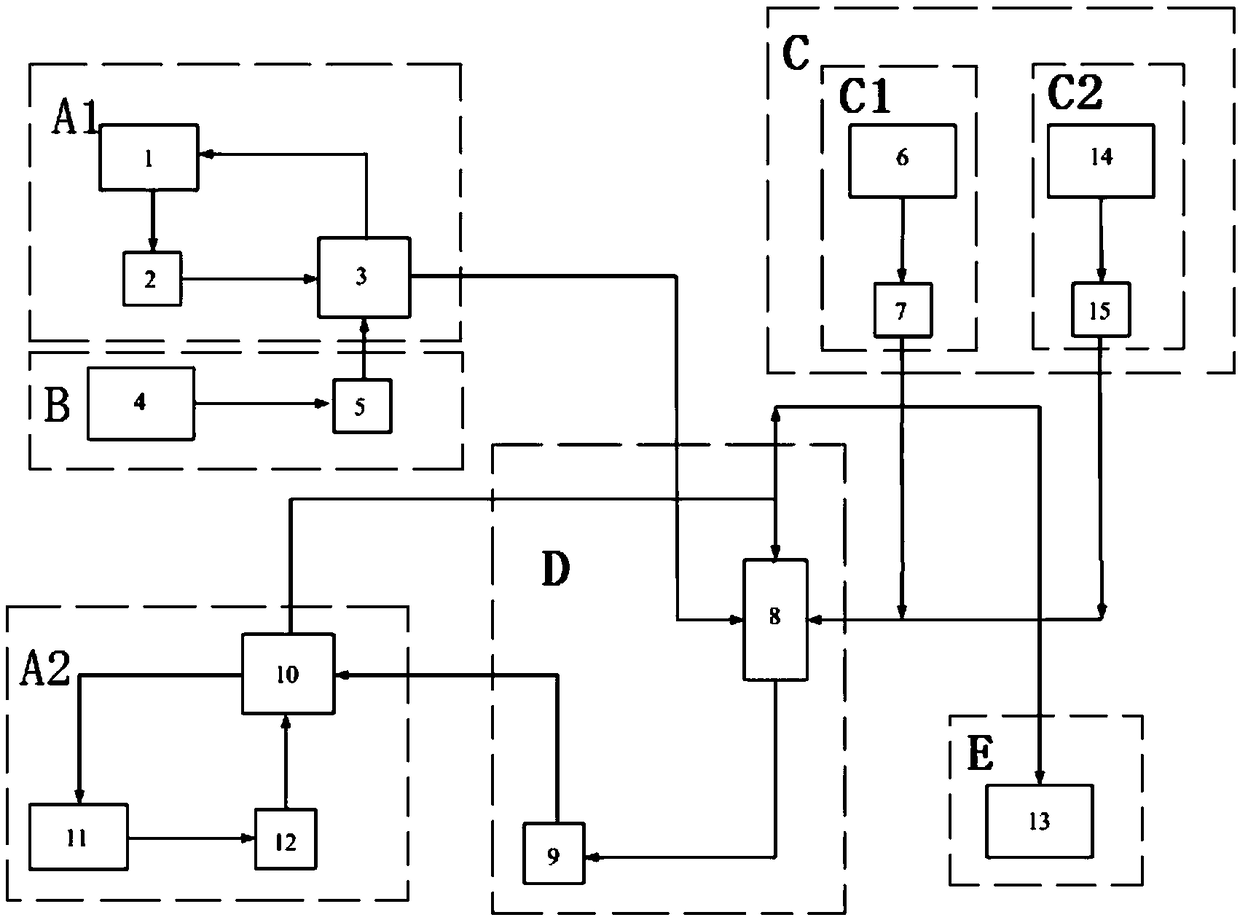

Full-automatic dilution instrument and liquid dilution method

PendingCN112697569AReduce work intensityGuaranteed accuracyPreparing sample for investigationRobot handPipette

The invention discloses a full-automatic dilution instrument and a liquid dilution method. The full-automatic dilution instrument comprises a workbench and a container placing area arranged on the workbench, and the container placing area is provided with a plurality of container positions for placing containers; the full-automatic dilution instrument further comprises a container transferring mechanical arm, a liquid injection device, a uniform mixing device, a containing device, a pipette device, a waste pipette head containing device and a control device which are connected to the workbench, wherein the uniform mixing device is used for uniformly mixing liquid in the containers, the containing device is used for containing a pipette head to be used, and the waste pipette head containing device is used for receiving a replaced pipette head. On the basis of the full-automatic dilution instrument, when the dilution method is adopted for liquid dilution, the working intensity of operators can be greatly reduced, uncertainty and errors caused by manual operation are effectively avoided, then the accuracy and repeatability of continuous dilution results are guaranteed, the reliability of subsequent test results is improved, and the traceability of a dilution process is improved.

Owner:TIANJIN HENGAO TECH DEV

Continuous dilution device and continuous dilution method for cooling devitrification of 4-acetamidobenzenesulfonyl chloride

PendingCN108863857AImprove qualityIncrease the heat exchange areaOrganic chemistryOrganic compound preparationDevitrificationHydrolysate

The invention discloses a continuous dilution device and a continuous dilution method for cooling devitrification of 4-acetamidobenzenesulfonyl chloride. The continuous dilution device comprises two heat exchange units, a diluted water unit, a feed liquid adding unit, a continuous diluting and mixing circulation unit and a diluted liquid collection unit; the first heat exchange unit is used for heat exchange of diluted water; the second heat exchange unit is used for cooling a diluting material to separate out the 4-acetamidobenzenesulfonyl chloride through crystallization; the diluted water unit comprises a diluted water tank and a diluted water discharge pump; the feed liquid adding unit comprises a 4-acetamidobenzenesulfonyl chloride hydrolysate adding unit and a washing unit. The continuous dilution method includes the steps of online continuous feeding, circular dilution, cooling crystallization and discharge of 4-acetamidobenzenesulfonyl chloride hydrolysis materials. The continuous dilution device and the continuous dilution method have the advantage that online continuous feeding, circular dilution and cooling crystallization can be realized to obtain high-quality products.

Owner:ZHEJIANG LONGSHENG CHEM RES

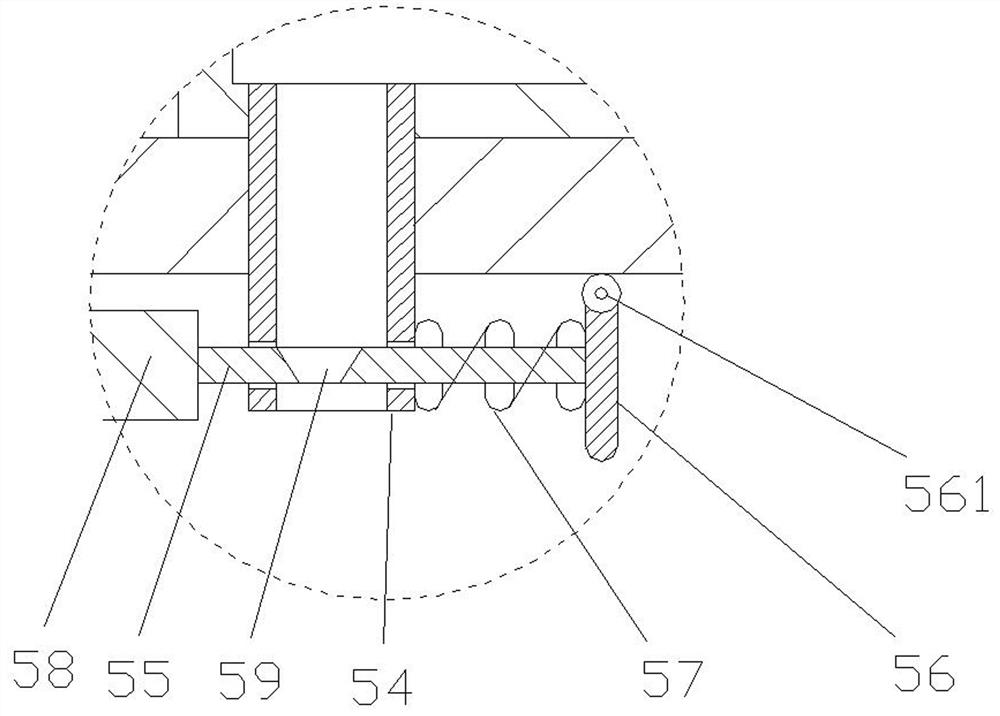

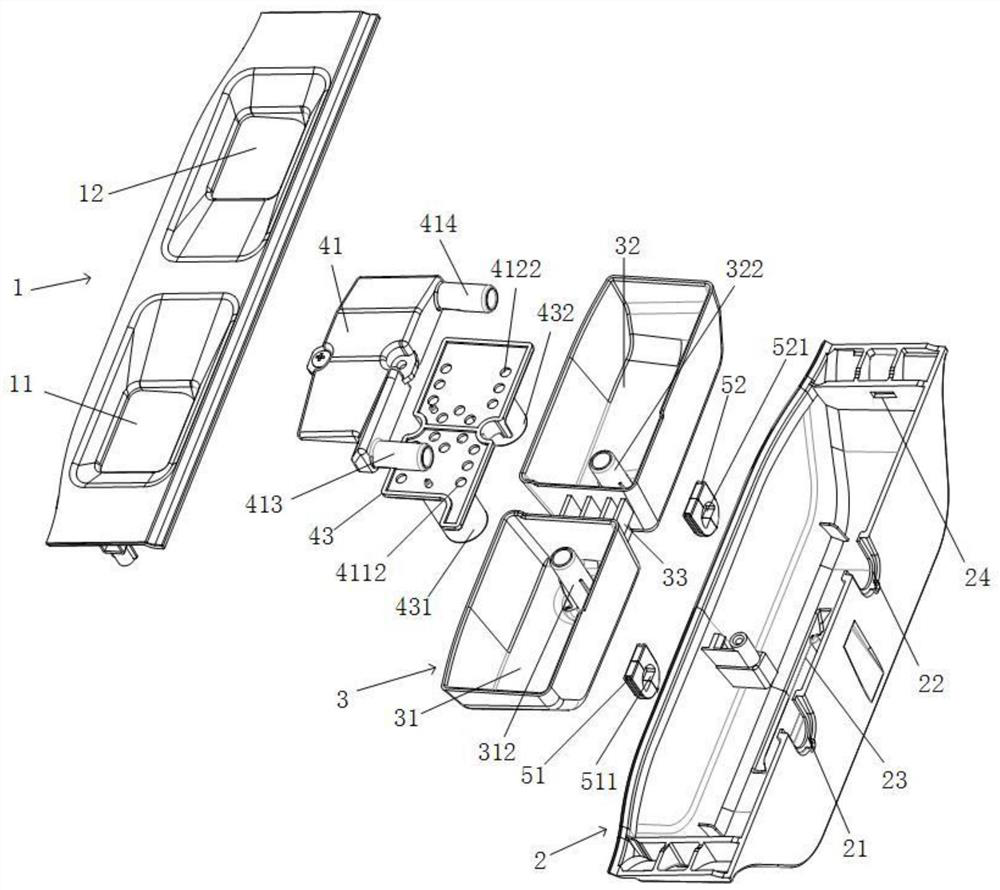

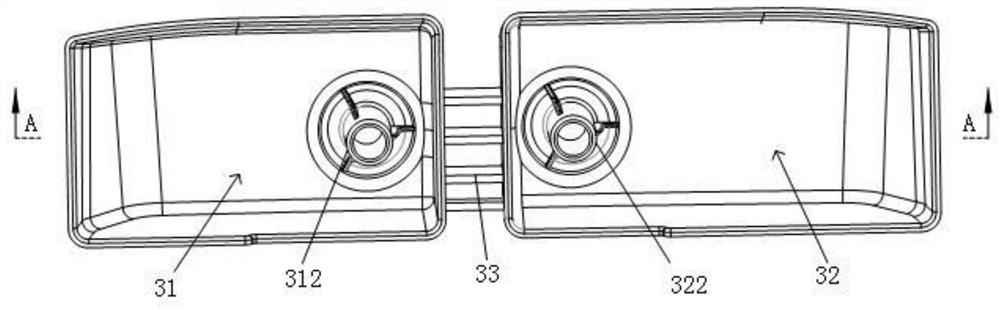

Detergent putting device of washing equipment and washing equipment

PendingCN113622159AImprove dilution efficiencyEasy to operateOther washing machinesTextiles and paperProcess engineeringLaundry

The invention relates to the technical field of washing equipment, in particular to a detergent putting device of washing equipment and the washing equipment. The invention aims to solve the problems of complex structure and high installation cost of the existing detergent putting device. In order to achieve the purpose, the detergent putting device comprises a cover body, a shell, a liquid storage box and a water distribution box, wherein the cover body is buckled on the shell; the water distribution box and the liquid storage box are sequentially arranged in the shell from top to bottom; a liquid injection opening is formed in the bottom wall of the shell and communicated with a washing drum; two independent water inlet cavities communicated with the water inlet and the water outlet are formed in the water distribution box; the water inlet is communicated with an external water source; and the liquid storage box is provided with two independent liquid storage cavities, and liquid in the different liquid storage cavities is guided into the washing drum through different siphon assemblies. Through the arrangement, the structure is simple, the operation is convenient, the installation cost is low, meanwhile, the interference effect between different putting units is avoided, and the user experience is improved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

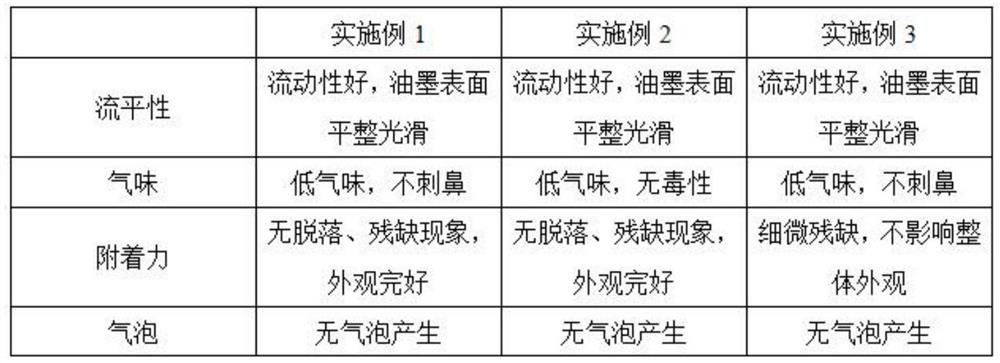

Solvent type toughened glass ink diluent and preparation method thereof

The invention discloses a solvent type tempered glass ink diluent, which belongs to the field of fine chemical engineering, the product comprises the raw material components in percentage by weight: 30-50% of a high-boiling-point medium-low polar solvent, 20-40% of a medium-boiling-point medium-low polar solvent and 20-40% of terpilenol system varnish. The invention further discloses a preparationmethod of the solvent type toughened glass ink diluent. The diluent prepared by the method is relatively small in smell and has good compatibility with high-temperature sintered glass ink of variousflux systems; the solvent-type high-temperature sintered glass ink diluent has the advantages of simple preparation process, proper volatilization speed, good leveling performance, extremely high dilution efficiency, improvement of the drying adhesion of ink, defoaming and foam inhibition effects on the ink, and general applicability to the market.

Owner:湖南衡义材料科技有限公司

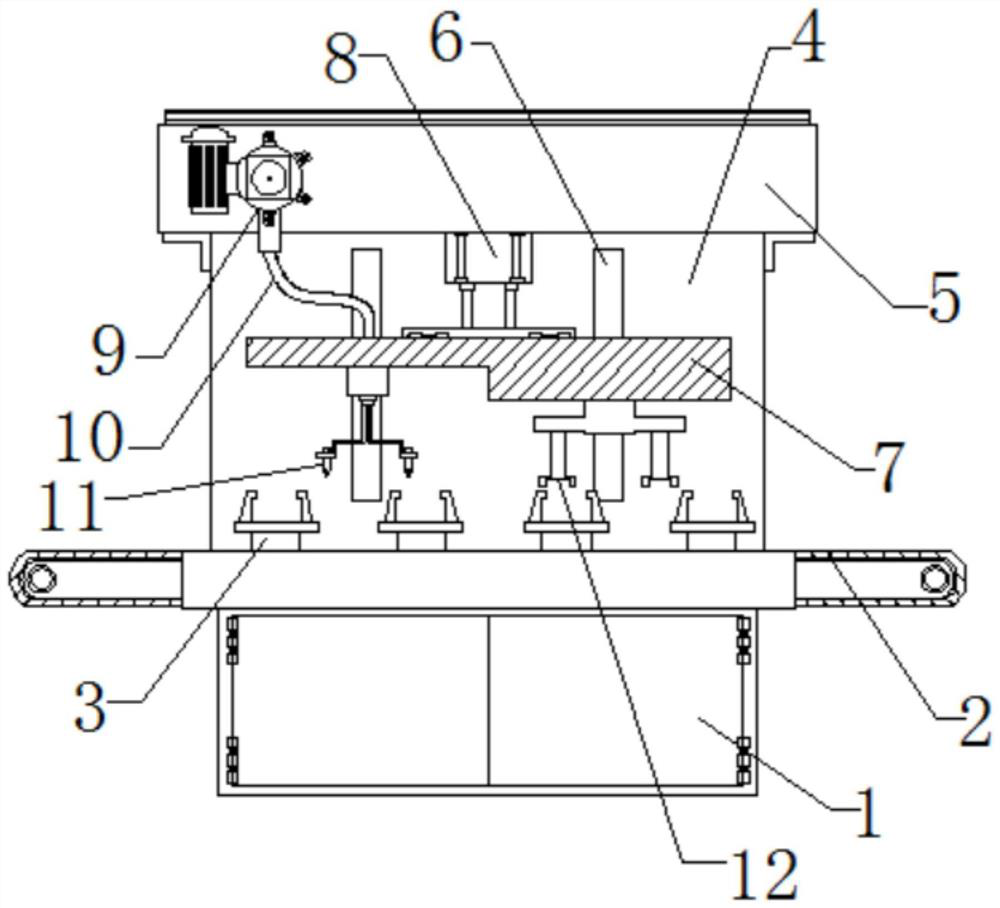

Electrolyte supplementing device and method applied to production of soft package lithium battery core

ActiveCN113611989AGuaranteed stabilityAvoid Offset SituationsConveyorsCell component detailsElectrolytic agentEngineering

The invention discloses an electrolyte supplementing device applied to soft package lithium cell production. A conveying belt is arranged right above a device base, a battery bracket is connected right above the conveying belt in a clamping manner, the outer side of the conveying belt is in shaft connection with a guide back plate, and a rectangular clamping groove is formed right above the conveying belt. The device comprises a liquid storage box body, wherein a driving water pump is connected to the upper surface of the base in a penetrating mode, a liquid injection pipeline is connected to the output end of the driving water pump, a liquid injection needle is fixedly nested to the outer side of the liquid injection pipeline, and a sealing force arm is arranged on one side of the liquid injection needle; and the sealing force arm. The invention discloses an electrolyte supplementing device and method applied to production of a soft package lithium battery cell. The battery bracket and the clamping force arm b are arranged, the clamping force arm a at the bottom of the battery bracket is used for clamping and limiting the upper surface of the conveying belt, the clamping force arm a is clamped and fixed according to the width of a clamping groove of the conveying belt, and the stability of the battery bracket in the assembling and locking process is ensured.

Owner:广东嘉尚新能源科技有限公司

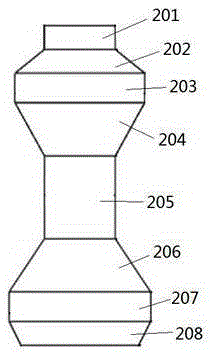

A precise and efficient mixing diluter for pesticides

ActiveCN105251401BImprove dilution efficiencyHigh precisionShaking/oscillating/vibrating mixersMixer accessoriesEnvironmental engineeringOrganic chemistry

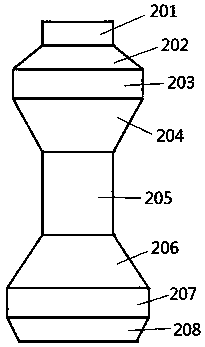

The invention discloses a precise and high-efficiency pesticide mixing diluter, which is composed of a measuring cup cover provided with scales and a dumbbell-shaped medicine mixing barrel, and the measuring cup cover and the medicine mixing barrel are screwed together. The measuring cup cover of the present invention is provided with a scale, which can accurately measure the pesticide and improve the accuracy of the dosage of the pesticide preparation in the field. Simultaneously, the drug mixing barrel of the present invention is dumbbell-shaped, and the diameter of the middle part is smaller. One, it is convenient to hold and mix the drugs upside down during the drug mixing process; The area is smaller than that at both ends, and a vortex is formed when the liquid medicine flows through the middle, which is convenient for the full mixing of the liquid medicine and improves the dilution efficiency of the pesticide.

Owner:GUIZHOU UNIV

Fertilizer diluting device for citrus planting

InactiveCN114177803AAvoid enteringImprove purityRotary stirring mixersTransportation and packagingElectric machineAgricultural engineering

The invention belongs to the technical field of citrus planting, and particularly relates to a fertilizer diluting device for citrus planting, which comprises a box body, supporting legs are fixedly connected to the bottom of the box body, a drain valve is fixedly connected to the left side of the box body, an injection port and a motor box are fixedly connected to the top of the box body, and a filter screen is fixedly connected in the injection port. A rotating motor is fixedly connected into the motor box, a stirring shaft is arranged in the box body in a penetrating manner through a bearing, and stirring blades are fixedly connected to the surface of the stirring shaft; according to the fertilizer diluting device for citrus planting, an injected liquid fertilizer can be filtered through a filter screen, undissolved fertilizer particles are prevented from entering the box body, so that the purity of a mixed solution is improved, and a rotating motor works to drive a stirring shaft, stirring blades and a scraper to rotate, so that the stirring effect of the mixed solution is improved. And the whole device is reasonable in structure, convenient to use and high in practicability.

Owner:石门县黄牯山柑桔专业合作社

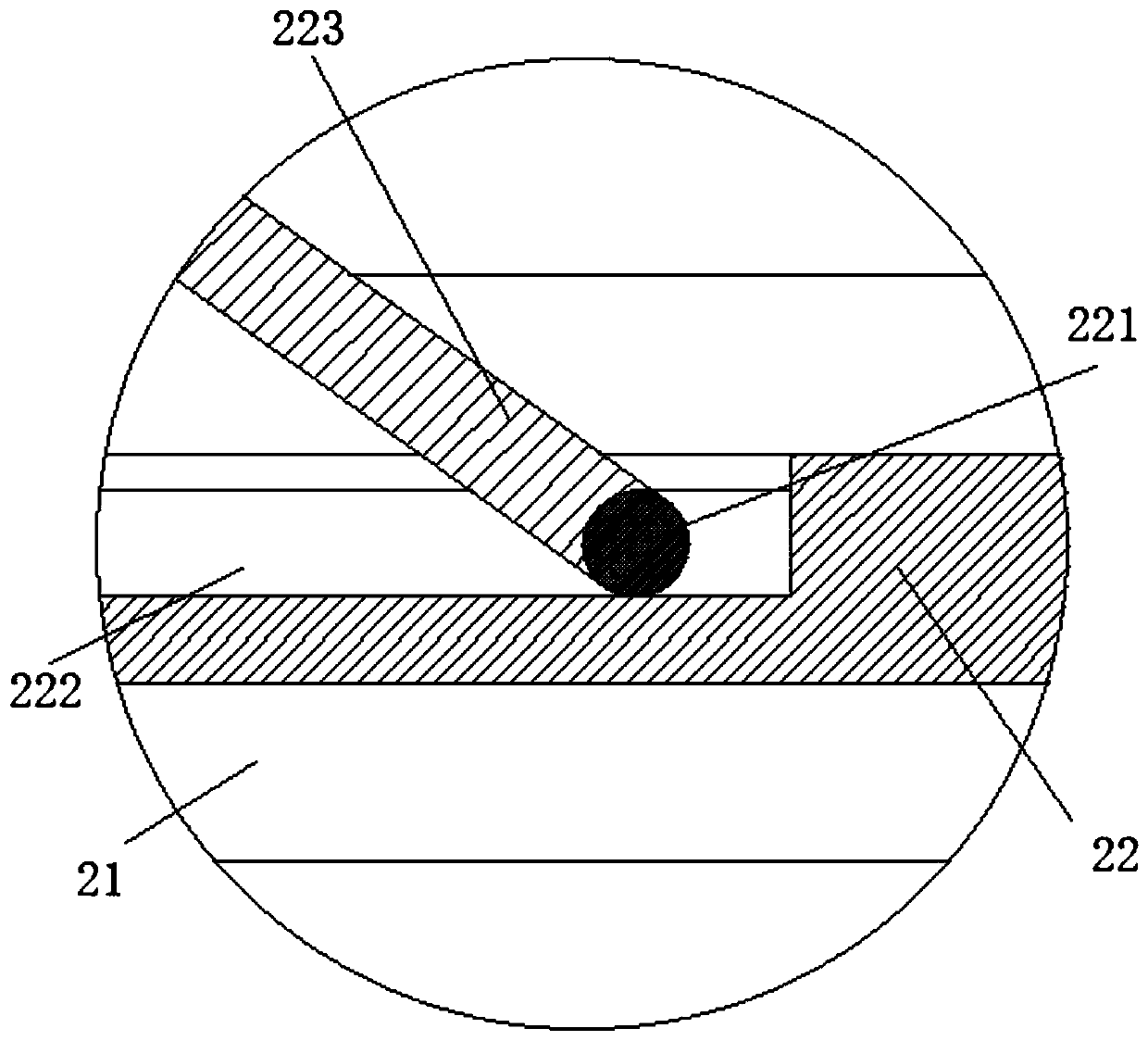

Primary pulp dilution device for antibacterial fabric

InactiveCN111545105AImprove dilution efficiencyUniform concentrationRotary stirring mixersTransportation and packagingAnti bacteriaMaterial distribution

The invention belongs to the technical field of fabric raw stock dilution, in particular to a primary pulp dilution device for antibacterial fabric. A primary pulp tank is included, wherein a feedingpipe is arranged at the upper end of the primary pulp tank; a discharge pipe is arranged on one side of the bottom of the primary pulp tank; a diluting disc which is matched with the primary pulp tankand can slide up and down is arranged in the primary pulp tank; a plurality of through dilution grooves are formed in the dilution disc; a sealing cover which can be opened and closed and is used forsealing the dilution tank is arranged in the dilution tank; a communicating hole for communicating the diluting disc up and down is formed in the bottom of the diluting disc; a plurality of aerationpipes which are uniformly distributed are arranged at the upper end of the dilution disc; aeration holes which are uniformly distributed are formed in the aeration pipe; a movably connected material distribution box is arranged in the primary pulp tank, a plurality of communicated material distribution pipes are arranged on the outer side of the material distribution box, a plurality of material distribution holes are formed in the material distribution pipes, and the material distribution holes are uniformly distributed on the same side of the material distribution pipes in a line shape, so that diluent can be uniformly distributed in the primary pulp tank, and the overall dilution efficiency is improved.

Owner:合肥克拉伦斯科技有限公司

High-air-tightness gas diluting and discharging device

InactiveCN110374669AImprove dilution efficiencyImprove securityGas removalHigh concentrationEngineering

The invention relates to the technical field of gas treatment equipment and particularly discloses a high-air-tightness gas diluting and discharging device. A diluting pipe is arranged in a stainlesssteel pipe, the two ends of the diluting pipe are separately fixedly connected with a gas inlet pipe and a gas outlet pipe, the hole diameter of the diluting pipe gradually varies, the left side of the hole is small, and the right side of the hole is large. The hole diameter of the air inlet pipe is matched with the left hole diameter of the diluting pipe, and the hole diameter of the air outlet pipe is matched with the right hole diameter of the diluting pipe. A low-pressure gas delivery pipe is arranged at the upper end of the left side of the stainless steel pipe, the low-pressure gas delivery pipe communicates with the diluting pipe, and the air inlet pipe is connected with the air outlet pipe through a backflow pipe. By arranging the backflow pipe between the air inlet pipe and the air outlet pipe, multiple circulating treatment can be carried out according to the concentration of to-be-diluted gas, high-concentration gas is discharged through the air outlet pipe after being fullydiluted, the diluting efficiency is high, and the safety is great.

Owner:GUIZHOU UNIV

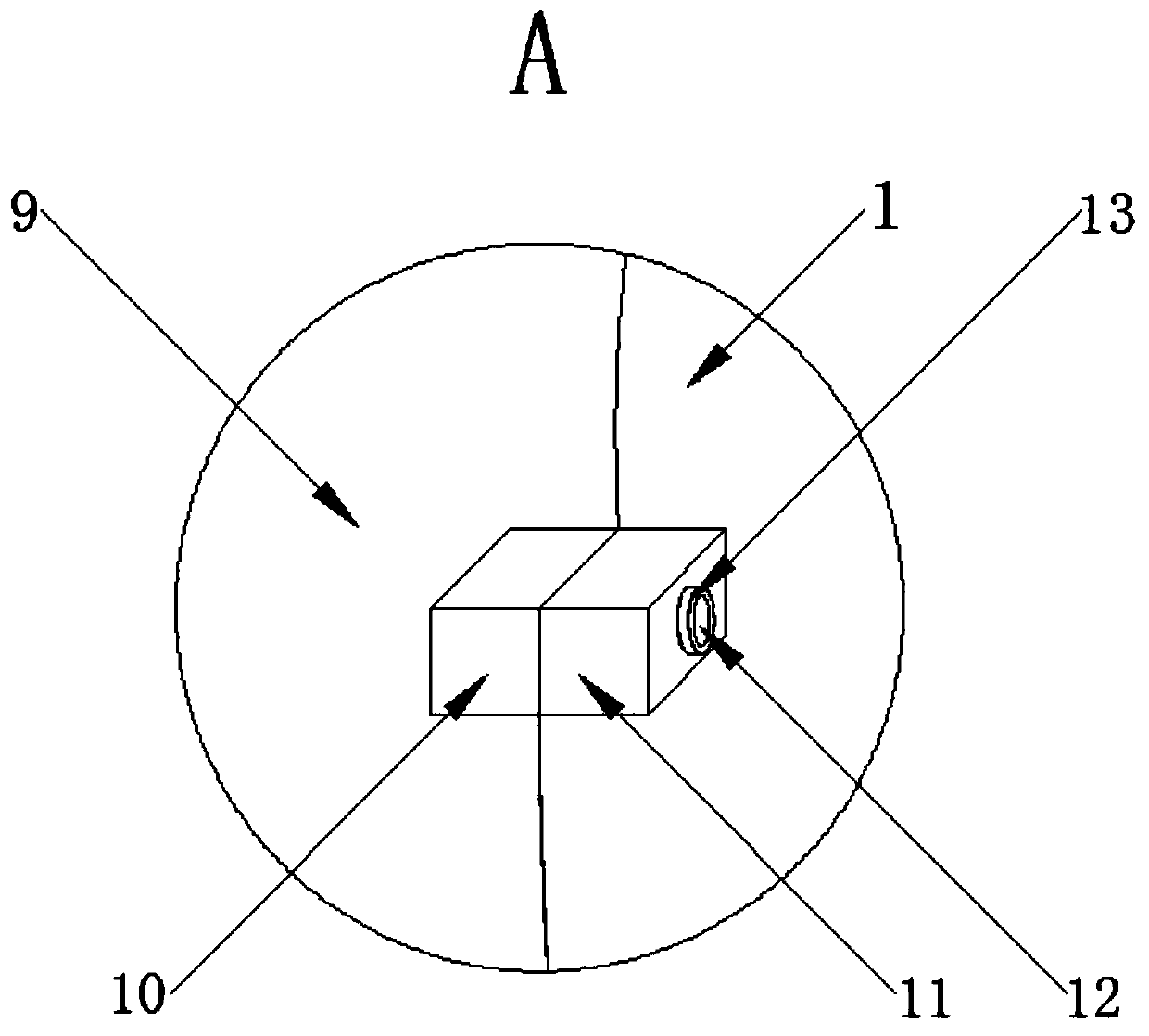

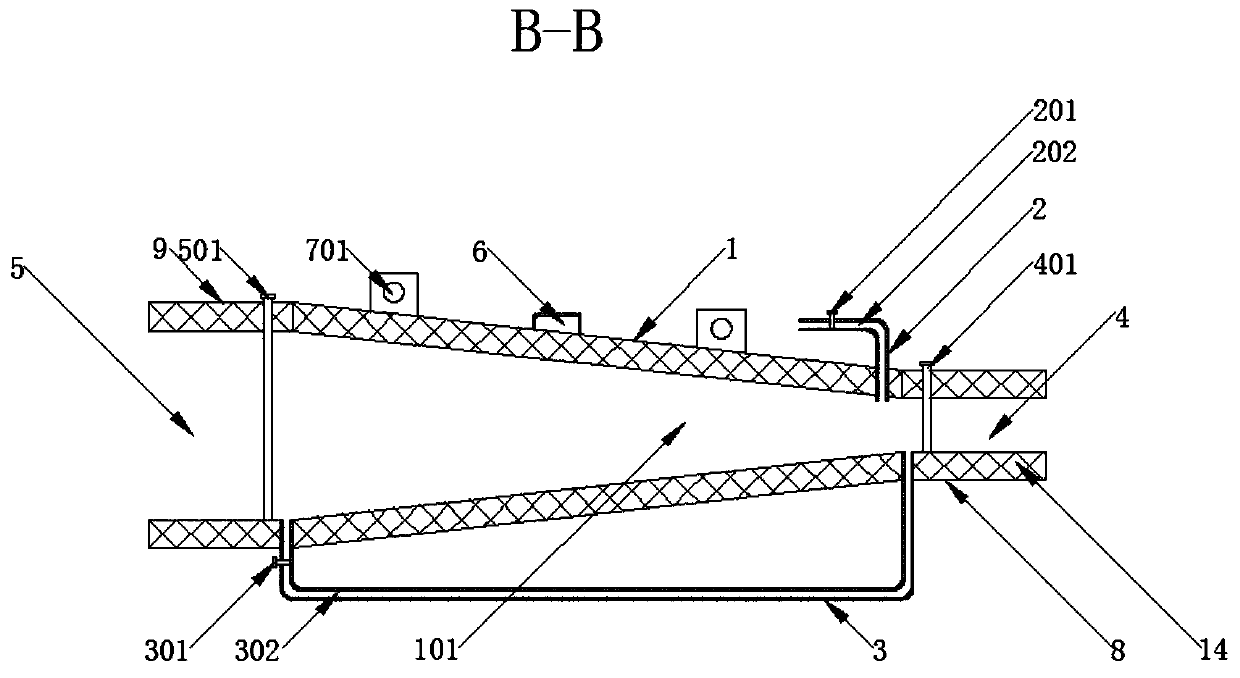

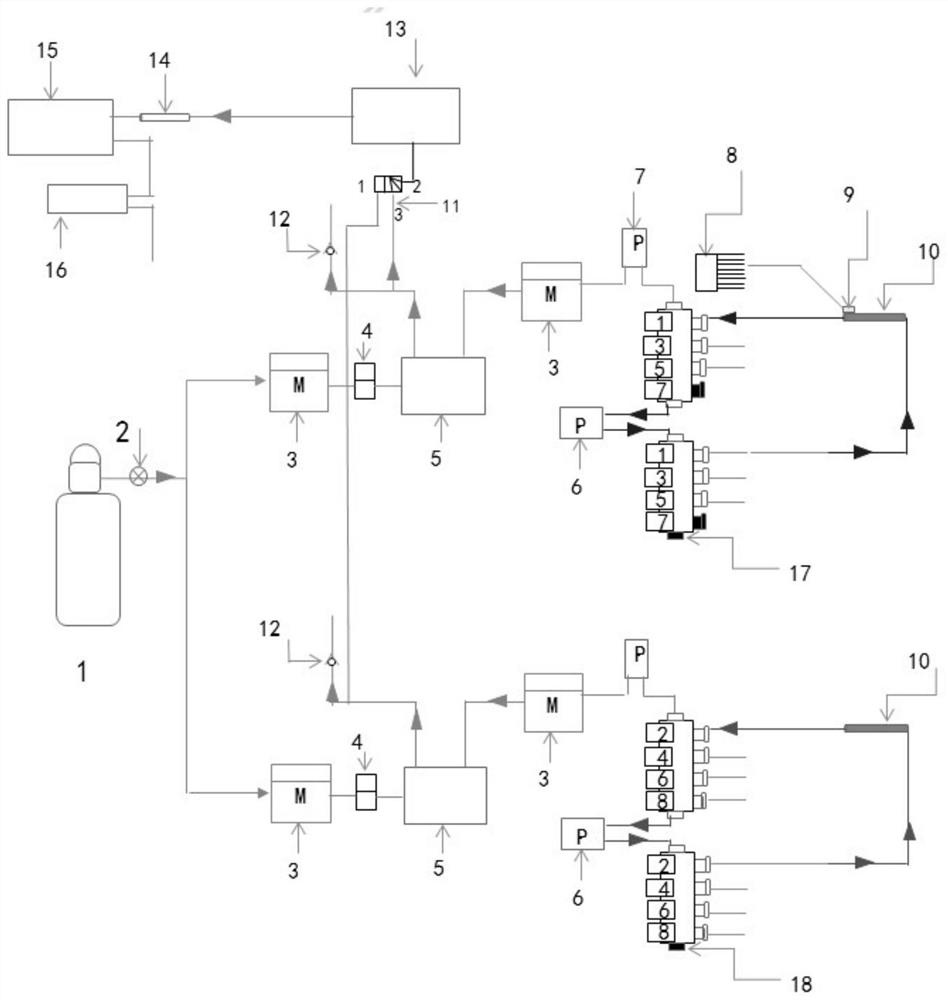

CO2 high-concentration online dilution system and dilution method thereof

PendingCN113820196AExtend the mixing timeWell mixedPreparing sample for investigationGas cylinderSemipermeable membrane

The invention discloses a CO2 high-concentration online dilution system and a dilution method thereof. The online dilution system mainly comprises a zero gas cylinder, a pressure reducing valve, a mass flow meter, gas mixing modules, a low-flow-rate pump, a semi-permeable membrane adopting pipe, a profile system, a filter and an analyzer, the pressure reducing valve is connected with a three-way electromagnetic valve and divided into an upper pipeline and a lower pipeline, each pipeline is connected with a mass flow meter, each mass flow meter is sequentially connected with a two-way electromagnetic valve and the gas mixing module, a mass flow meter and a low-flow-rate pump are sequentially connected behind each gas mixing module, each low-flow-rate pump is connected with the first four interfaces of an eight-channel electromagnetic valve, the two gas mixing modules are connected with a two-position three-way electromagnetic valve, the two-position three-way electromagnetic valve is connected with the profile system, and the profile system is sequentially connected with the filter and a PICARRO analyzer through a pipeline. According to the invention, two groups of dilution systems are used in parallel, and when one group is used for measurement, the other group can be used for gas extraction and complementary measurement, so that the gas mixing time is prolonged, and the dilution speed is increased.

Owner:INST OF GEOGRAPHICAL SCI & NATURAL RESOURCE RES CAS

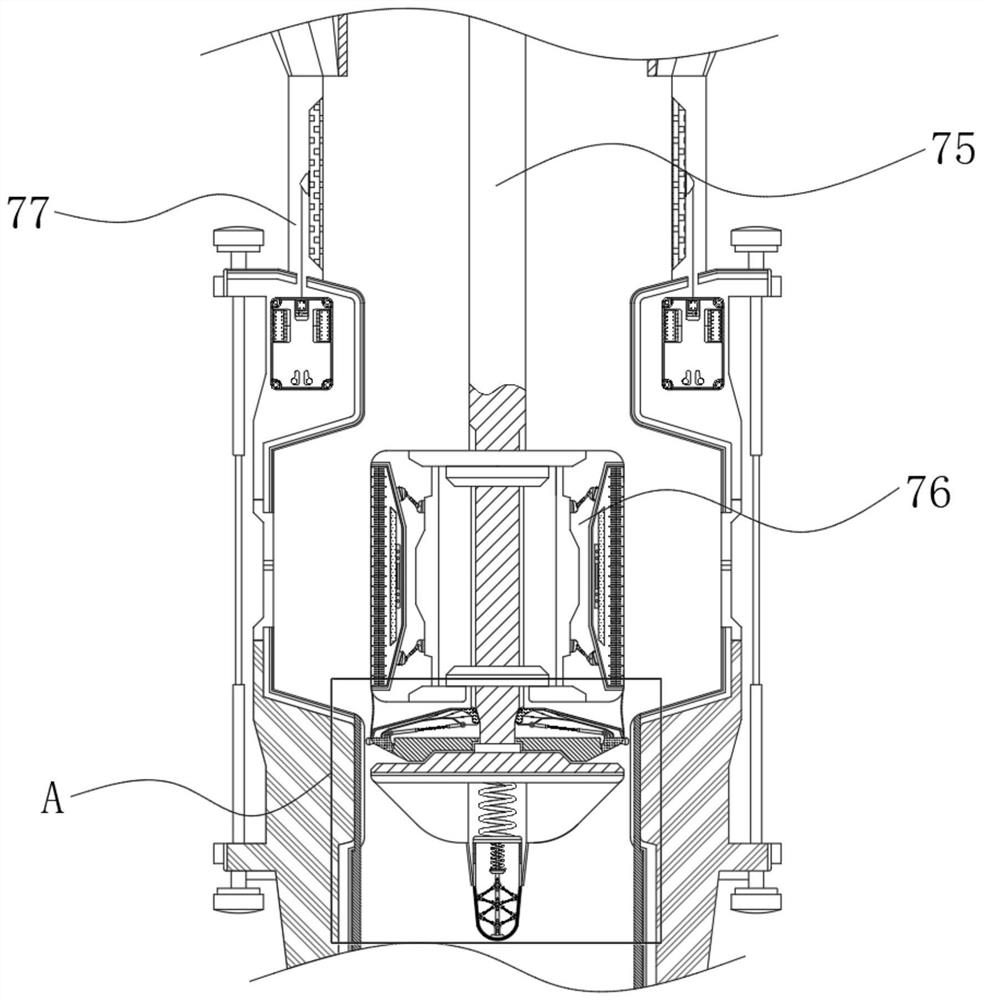

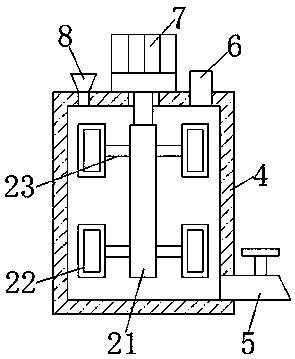

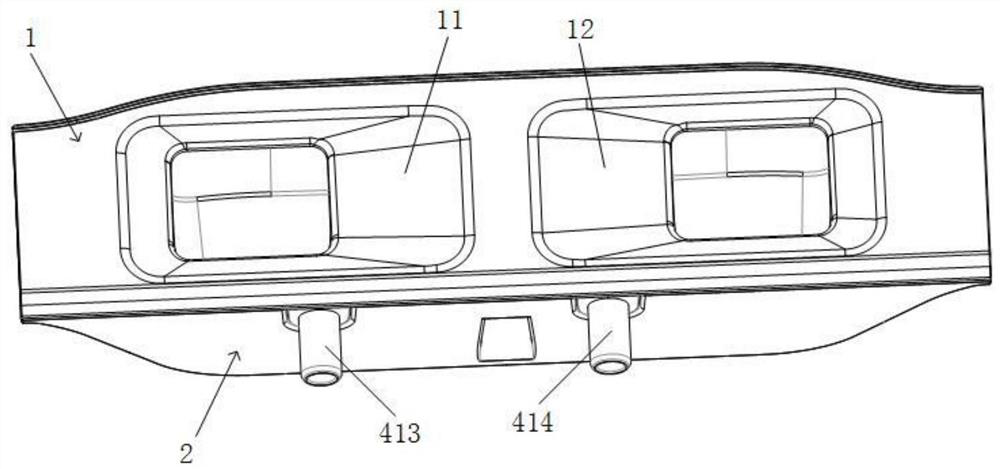

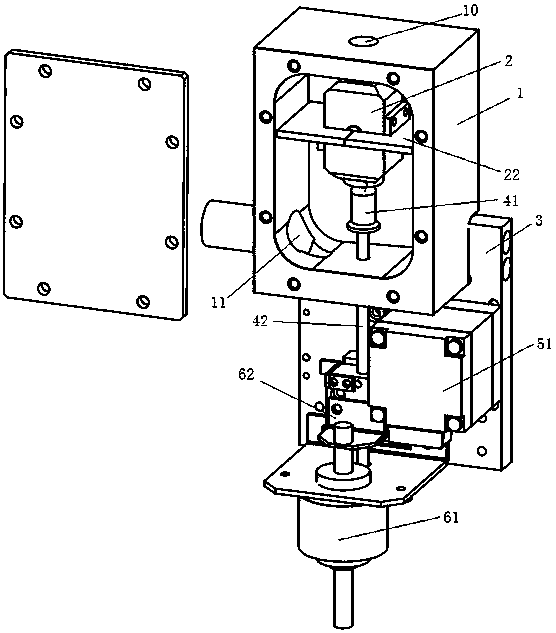

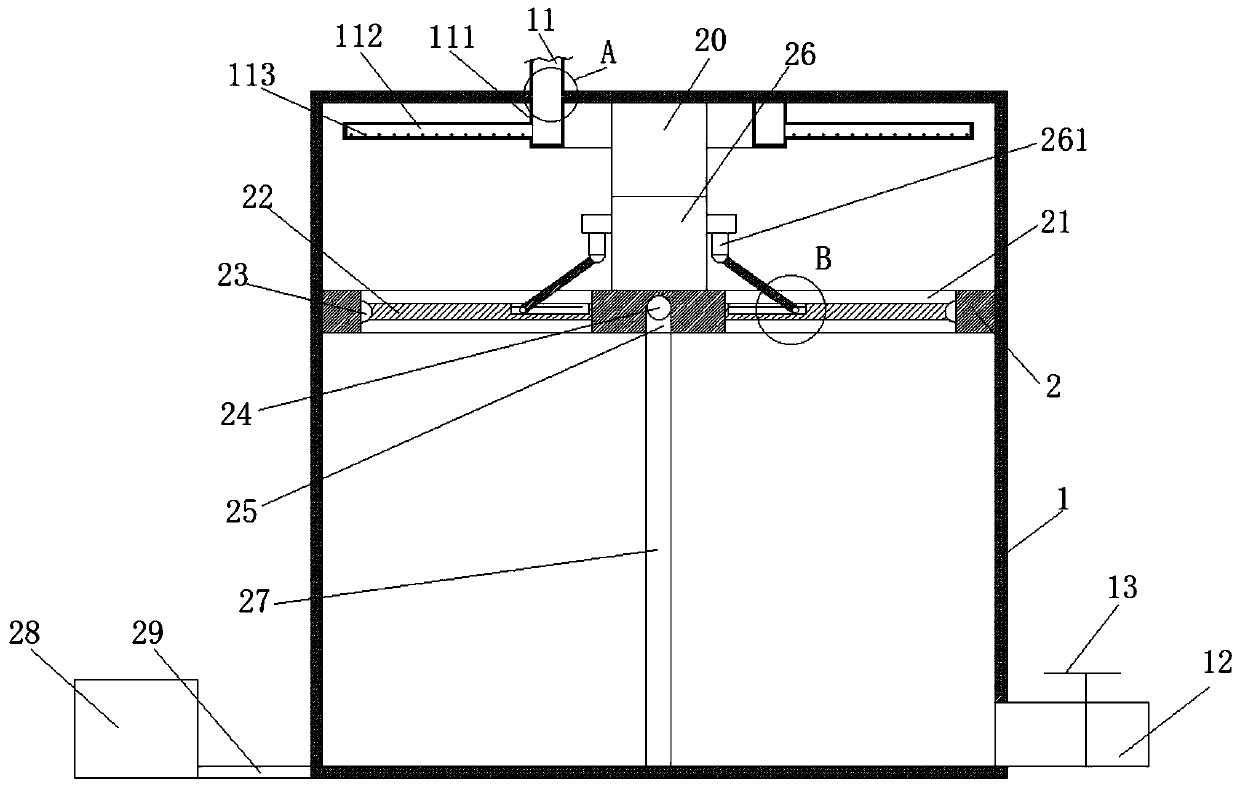

A sample dilution device with reusable dilution positions

ActiveCN105445084BImprove dilution efficiencyImprove cleaning qualityPreparing sample for investigationEngineeringSample dilution

The invention discloses a sample dilution device with reusable dilution stations. The sample dilution device comprises a purge chamber, a dilution chamber, a dilution chamber rotation driving part, a cleaning head part and a cleaning head driving part. The purge chamber comprises a purge cavity, the top of which is provided with a liquid feed inlet and the bottom of which is provided with a liquid outlet. The dilution chamber comprises two symmetrically-arranged dilution cavities which have openings facing towards two ends of the dilution chamber. The dilution chamber is rotatably installed inside the purge chamber and can be driven by the dilution chamber rotation driving part to rotate with the two dilution cavities' openings alternately facing upwards. The cleaning head part comprises a liquid inlet tube and a cleaning head. The cleaning head is provided with a liquid outlet hole communicated with the liquid inlet tube. The cleaning head is mounted below the dilution chamber. The cleaning head driving part is connected to the cleaning head part, and the cleaning head can be driven by the cleaning head driving part to move up and down so as to enter or exit from the dilution cavity. According to the invention, dilution stations can be cleaned after dilution. Thus, the same dilution station can be repeatedly used for dilution work.

Owner:SUZHOU HYBIOME BIOMEDICAL ENG CO LTD

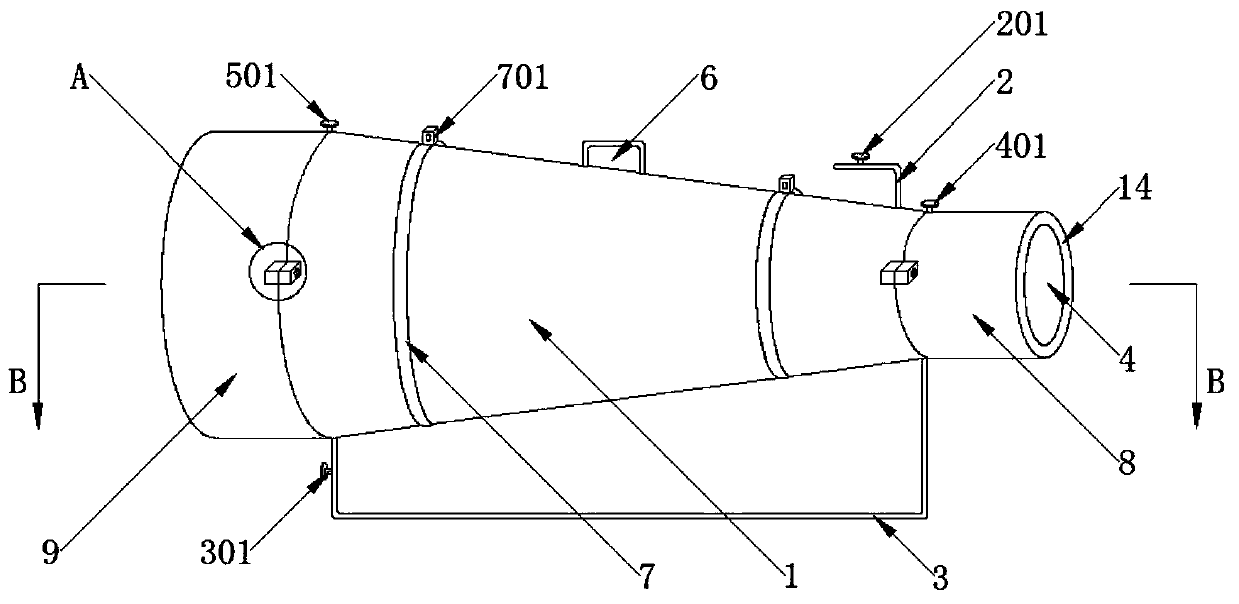

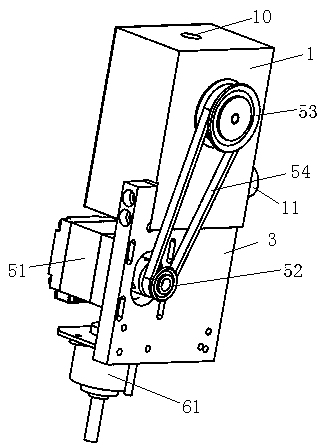

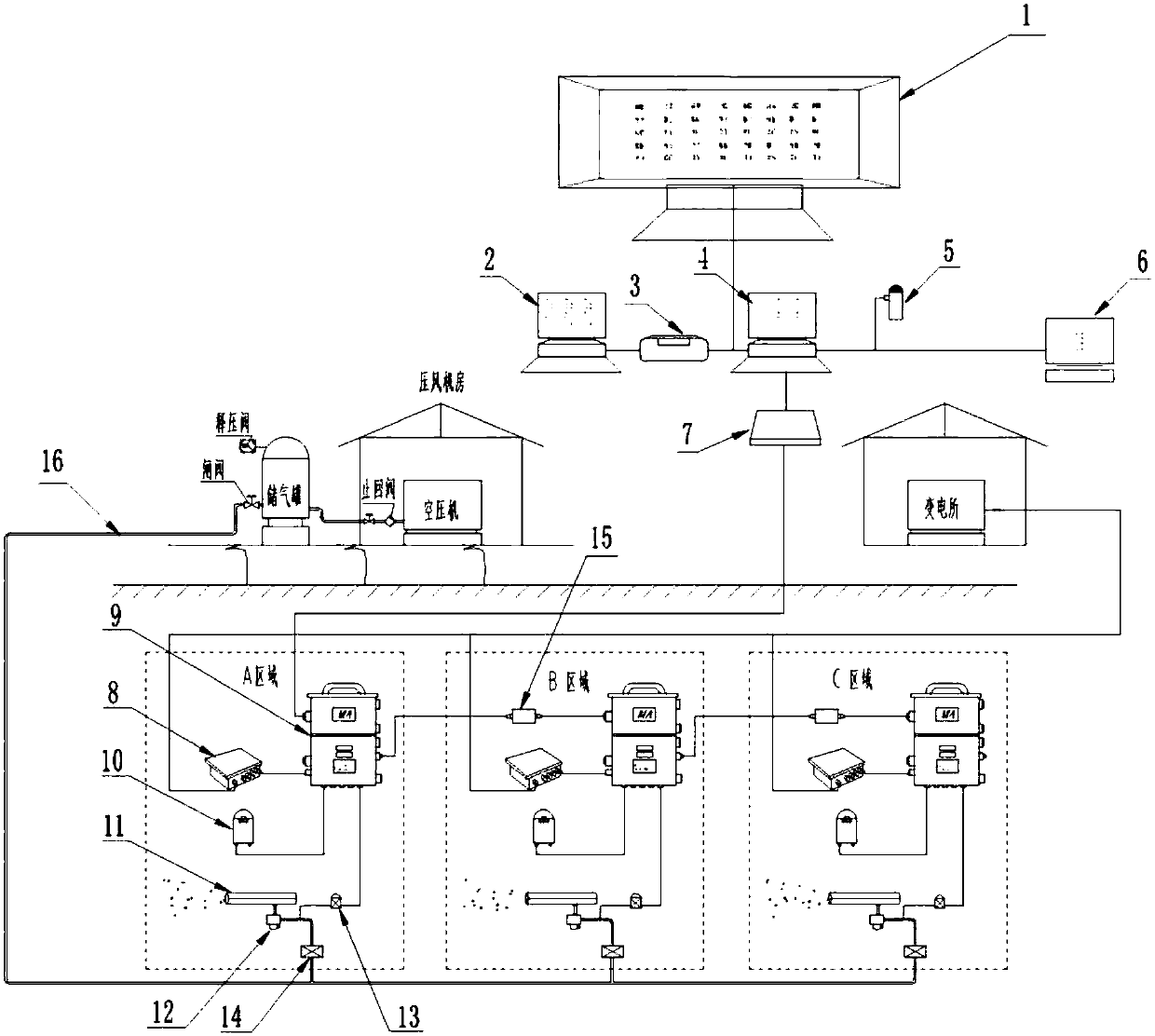

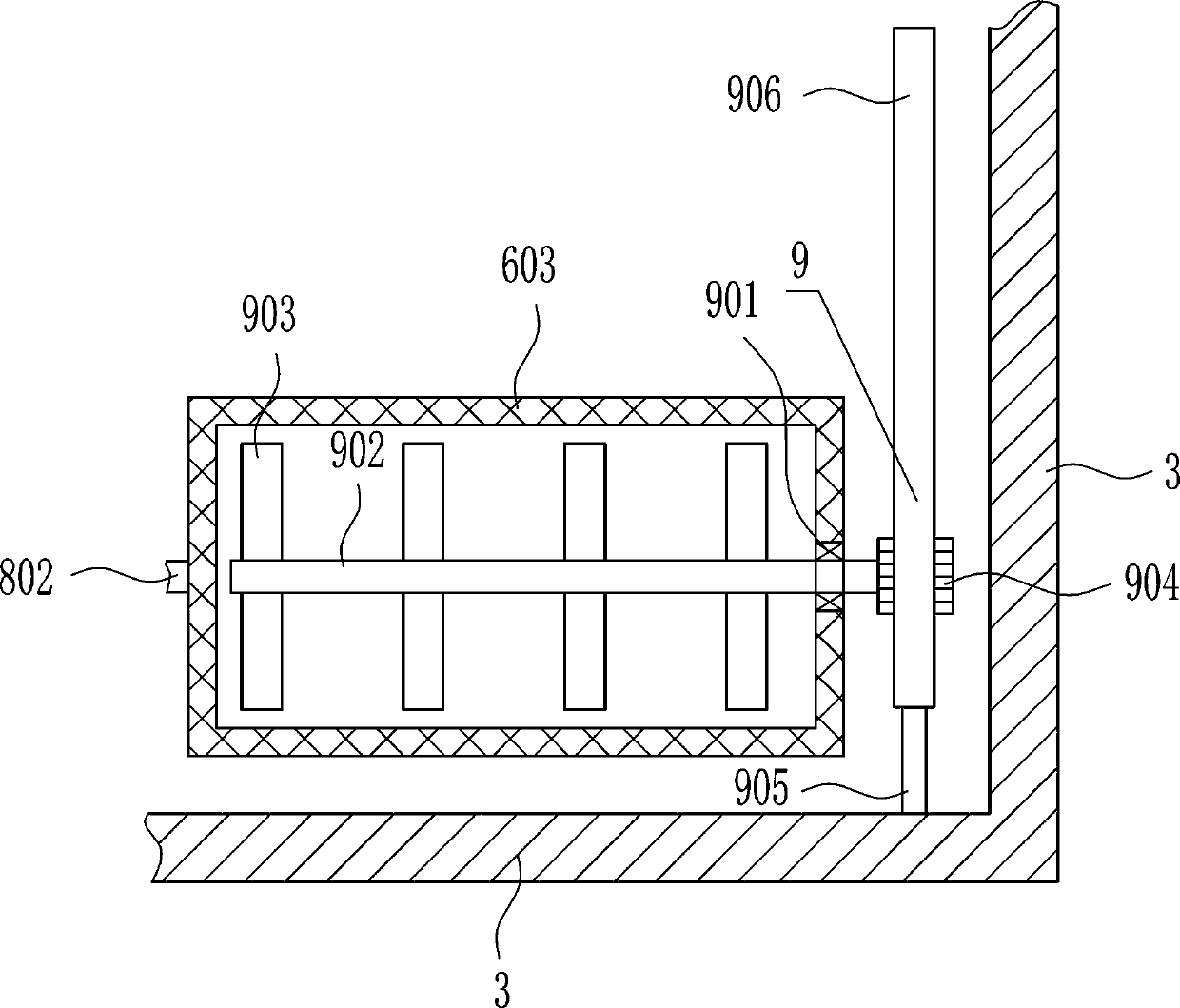

Coal-mine gas injection system and jet ejector used in coal-mine gas injection system

PendingCN108035767AImprove dilution efficiencyImprove abilitiesMining devicesJet pumpsData informationCoal mine methane

The invention provides a coal-mine gas injection system and a jet ejector used in the coal-mine gas injection system, and belongs to the technical field of mine safety. The technical problem to be solved is to provide the coal-mine gas injection system and the jet ejector used in the coal-mine gas injection system; the injection system includes a monitoring host, a data information conversion andtransmission device, gas dilution units and signal repeaters; the monitoring host and the data information conversion and transmission device are arranged on the ground, the monitoring host is connected with the data information conversion and transmission device, the gas dilution units and the signal repeaters are arranged in a coal-mine well, the plurality of gas dilution units are arranged in different operation regions in the coal-mine well, and the gas dilution units are connected through the signal repeaters.

Owner:SHANXI ZHENGDAHENGTONG TECH CO LTD

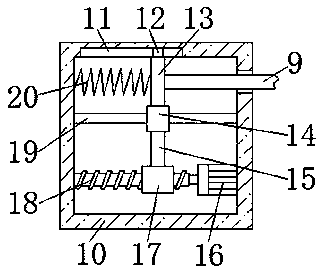

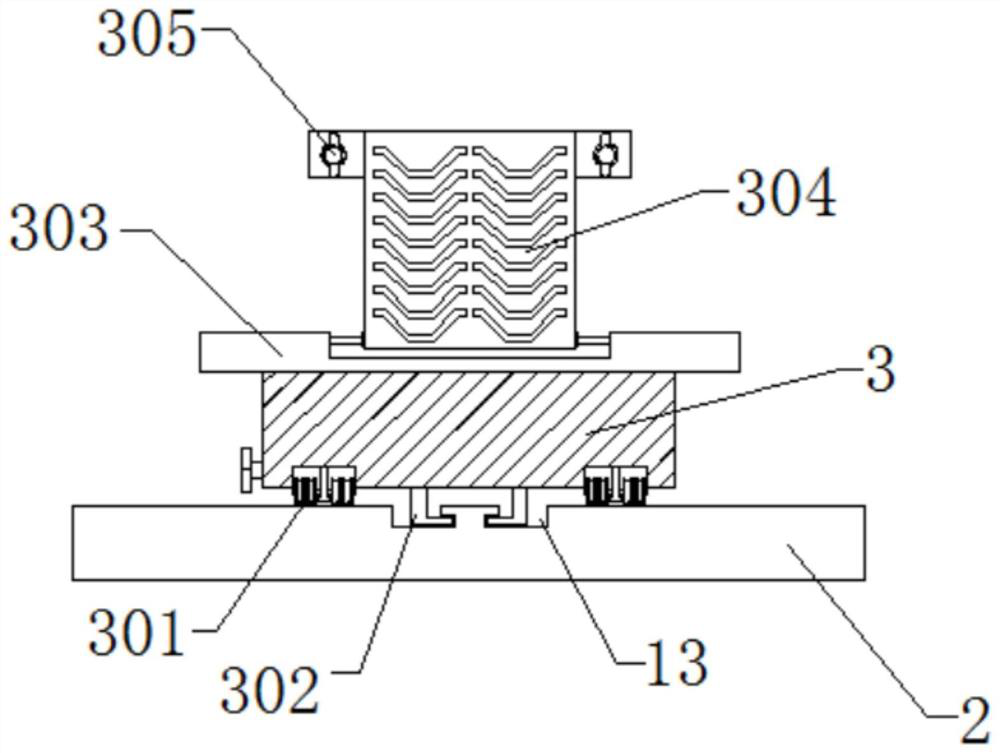

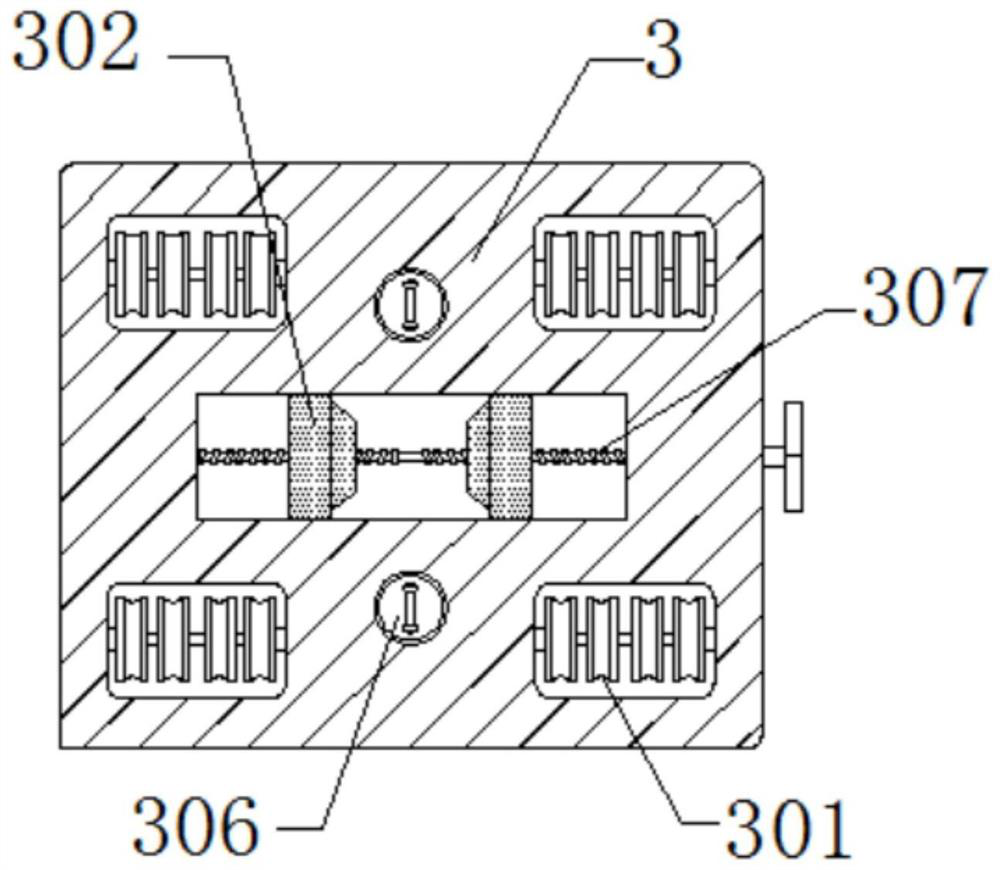

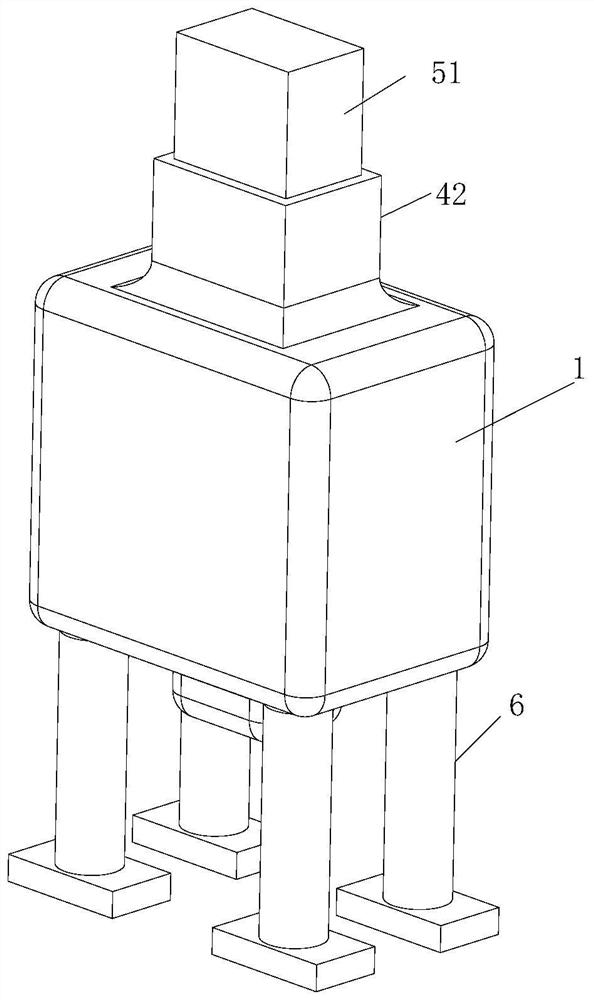

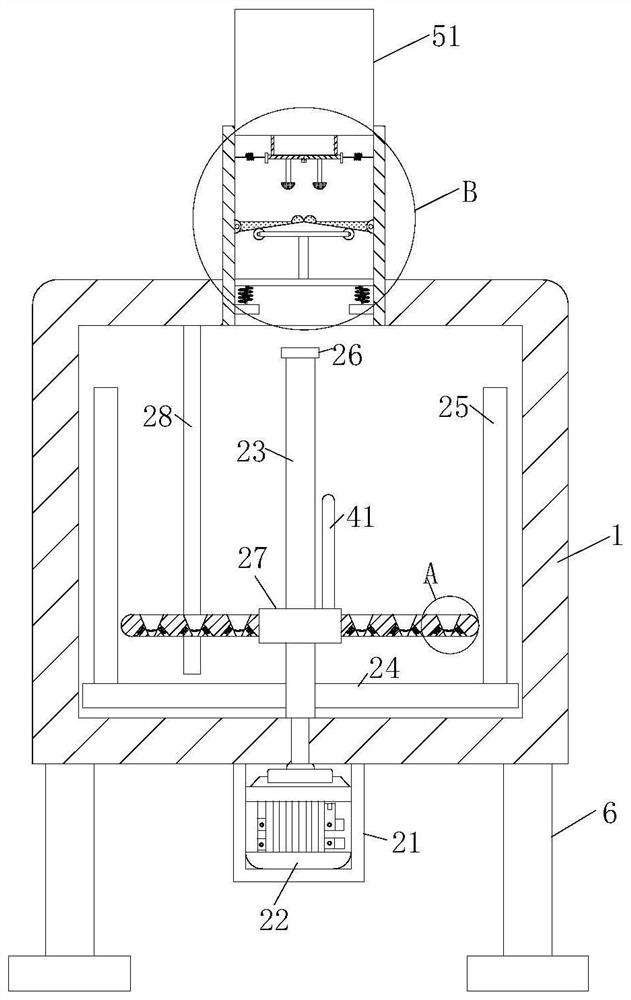

An extractant dilution device for rare earth extraction

ActiveCN107699716BRapid dilutionImprove dilution efficiencyProcess efficiency improvementKeroseneRare earth

The invention relates to a dilution device for rare earth extraction, in particular to an extractant dilution device for rare earth extraction. The technical problem to be solved by the present invention is to provide an extraction agent dilution device for rare earth extraction that can save time and effort, improve the dilution efficiency of the extraction agent, and improve the extraction efficiency of rare earths. In order to solve the above-mentioned technical problems, the present invention provides such an extraction agent dilution device for rare earth extraction, which includes a base, etc.; the left and right sides of the top of the base are vertically connected with support rods through bolts, and the top ends of the two support rods A stirring box is connected by bolts, a liquid outlet pipe is connected to the lower left side of the stirring box, a valve is arranged on the liquid outlet pipe, and a first stirring device is arranged in the stirring box. The present invention can drive the first stirring device to stir the extractant and kerosene through the driving device, and can quickly dilute the extractant, thereby achieving the effects of saving time and labor, improving the dilution efficiency of the extractant, and improving the extraction efficiency of rare earths.

Owner:业达检测有限公司

Diluting equipment for novel coronavirus detection kit

PendingCN114797567AImprove dilution efficiencyImprove mixing efficiencyMixing methodsTransportation and packagingElectric machineryEngineering

The invention belongs to the technical field of new coronavirus detection, and particularly relates to dilution equipment for a new coronavirus detection kit. Guide plates are fixedly connected to the two ends of a sliding block; a plurality of flow guide holes are formed in the flow guide plate; the inner side wall of the flow guide hole is fixedly connected with a drainage net; the top of the screw rod is fixedly connected with a limiting plate; when a stock solution needs to be diluted, a diluent flows into a dilution box through a liquid inlet hole, then a motor is started, the output end of the motor drives a lead screw to rotate, the lead screw drives a sliding block to move up and down, when the sliding block moves up and down, a flow guide plate is driven to move, and a plurality of flow guide holes are formed in the flow guide plate; and liquid in the dilution box circulates through the flow guide holes and then is drained through the drainage net, so that the liquid in the dilution box is mixed with the diluent, and the dilution efficiency of the dilution box is improved.

Owner:深圳核子华曦医学检验实验室

Bacillus subtilis viable count medium, diluent and viable count method

ActiveCN114107432BSolve the problem of counting large coloniesCurb spreadMicrobiological testing/measurementBiological material analysisBiotechnologyMonopotassium phosphate

The invention belongs to the technical field of microbial strains, and in particular relates to a culture medium for counting live bacteria of Bacillus subtilis, a sterilizing diluent and a method for counting live bacteria. Among them, the solid medium formula: peeled soybean meal powder (crushed to 100 mesh) 4‑6g, corn flour (ground to 100 mesh) 3‑5g, sodium chloride 5‑10g, xanthan gum 3‑5g, agar 11‑ 13g, distilled water 1000mL, pH value 7.3±0.2; sterile diluent: sodium chloride 8‑9g, potassium dihydrogen phosphate 1‑2g, anhydrous glucose 0.3‑0.5g, peptone 0.3‑0.5g, defoamer 0.1 ‑0.2g, 1000mL of distilled water; and the culture method of first adapting to temperature and then cooling down reduces the secretion of antibacterial substances of bacterial cells, reduces the speed of colony expansion, and reduces the competitive inhibition of bacterial cell growth. The method for counting viable Bacillus subtilis of the present invention improves the accuracy of dilution, reduces the death rate of bacterial cells in the oscillation dilution process, reduces the aggregation of bacterial cells, controls the spread of bacterial colonies, reduces the size of bacterial colonies, and improves the efficiency of Bacillus subtilis. Accuracy and repeatability of counting viable bacilli.

Owner:GUANGZHOU AONONG BIOTECH +2

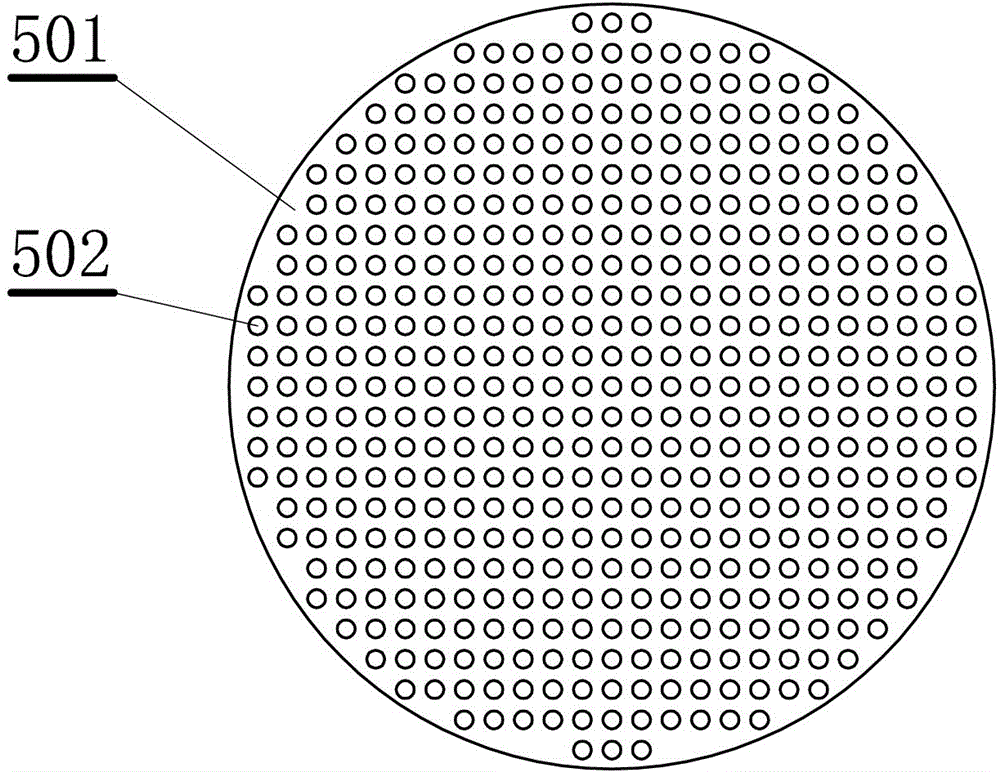

Raw material impurity removal device for polyaluminum chloride production

InactiveCN113976030AGuaranteed water purification effectImprove dilution efficiencySievingScreeningAluminium chlorideAluminium chlorohydrate

The invention provides a raw material impurity removal device for polyaluminum chloride production, and relates to the field of polyaluminum chloride, the raw material impurity removal device comprises a mixing cylinder internally provided with a mixing cavity, a motor fixed at the bottom of the mixing cavity and a chassis mounted on an output shaft of the motor, wherein the upper end face of the mixing cylinder is provided with a plurality of inlets, and the lower end face of the mixing cylinder is provided with a plurality of outlets, a plurality of through holes penetrating through the upper and lower surfaces of the chassis are formed in the chassis; the outer side of the chassis is rotationally connected with a side ring groove formed in the side wall of the mixing cavity; a plurality of stirring rods, wherein the bottom ends of the stirring rods are fixed on the upper surface of the chassis; screens corresponding to the inlets, wherein the screens are mounted under the corresponding inlets; a diluting pipe which is mounted on the upper surface of the mixing cylinder; plug columns corresponding to the through holes, and a driving part which is connected with the plug columns, wherein the diameter of the plug columns is equal to that of the corresponding through holes, and the driving part is used for driving the plug columns to move, so that the plug columns enter the through holes or are far away from the through holes. Through the device, the water purification effect of the produced polyaluminum chloride is ensured.

Owner:芜湖艾妮日化有限责任公司

Primary pulp diluting device for anti-radiation fabric

InactiveCN111545104AImprove dilution efficiencyImprove discharge efficiencyRotary stirring mixersTransportation and packagingEngineeringFan blade

The invention belongs to the technical field of fabric primary pulp dilution, in particular to a primary pulp dilution device for radiation-proof fabric. A primary pulp tank is included, wherein a feeding pipe is arranged at the upper end of the primary pulp tank; a discharge pipe is arranged on one side of the bottom of the primary pulp tank; a diluting disc which is matched with the primary pulptank and can slide up and down and rotate is arranged in the primary pulp tank; a plurality of through dilution tanks are arranged on the dilution disc, sealing covers which can be opened and closedand are used for sealing the dilution tanks are arranged in the dilution tanks, a communicating hole for communicating the dilution disc up and down is formed in the bottom of the dilution disc, and aplurality of aeration pipes which are uniformly distributed are arranged at the upper end of the dilution disc; the dilution tanks are distributed in a central symmetry manner by taking the center ofthe dilution disc as the center; the dilution grooves are formed in the dilution disc, the two sides of each dilution groove are arc-shaped, and the dilution grooves are distributed in the dilution disc in a fan blade shape, so that when primary pulp passes through the dilution grooves, a counter-acting force for pushing the dilution disc to rotate can be generated, the dilution disc is driven torotate, and the dilution efficiency of the primary pulp in a dilution area can be effectively improved.

Owner:合肥克拉伦斯科技有限公司

Method of Optimizing Heavy Crude Transportation by Incorporation Under Pressure of Dimethyl Ether

InactiveUS20070295642A1Simple methodImprove dilution efficiencyMolecular sieve catalystsRefining by heating/coolingPolymer scienceSolvent

Heavy crude transportation optimization method wherein at least one solvent is added to said crude. According to the method, a predetermined amount of dimethyl ether (DME) is added under pressure so as to adjust the viscosity of the crude.

Owner:INST FR DU PETROLE

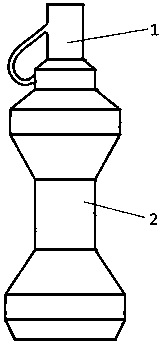

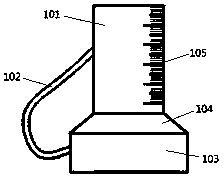

Precise efficient mixing diluter for pesticides

ActiveCN105251401AImprove dilution efficiencyHigh precisionShaking/oscillating/vibrating mixersMixer accessoriesMeasuring cupPesticide

The invention discloses a precise efficient mixing diluter for pesticides. The precise efficient mixing diluter comprises a measuring cup cover with scales and a dumbbell-shaped pesticide mixing barrel, wherein the measuring cup cover is in threaded connection with the pesticide mixing barrel. The scales are arranged on the measuring cup cover of the precise efficient mixing diluter for pesticides, so that the pesticides can be accurately measured and taken and the accuracy of dosage of the pesticides in field application can be increased. The pesticide mixing barrel of the precise efficient mixing diluter for pesticides is dumbbell-shaped and the diameter of the middle part is smaller, so that a user is convenient to hold for reversely mixing pesticides during a pesticide mixing process, and meanwhile, the liquid pesticides flow up and down during the reversing process, the cross section area of the middle part of the pesticide mixing barrel is less than the area of the two ends, and the liquid pesticides can be fully mixed when the liquid pesticides flow by the middle part and form the vortex, so that the diluting efficiency of the pesticides is increased.

Owner:GUIZHOU UNIV

Organic matter diluent

The invention discloses an organic mater diluent. The organic mater diluent comprises the following components: 30-50% of alkane residual oil, 10-15% of ethyl acetate, 10-25% of ketone, 4-6% of dichloromethane and the balance of inevitable impurities. The organic mater diluent provided by the invention has few impurities, good using effect and good functionality.

Owner:余夕蓉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com