Precise efficient mixing diluter for pesticides

A diluter, precise technology, applied in mixers, mixer accessories, chemical instruments and methods, etc., to achieve the effect of high dilution efficiency, easy portability, and improved dilution efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In this example, ultraviolet-visible spectrophotometry is used to measure the dilution efficiency of the pesticide precision and high-efficiency mixing diluter:

[0021] First, accurately measure a certain amount of pesticide preparation samples (according to the recommended dose for field use of pesticides). The pesticide formulations can be emulsifiable concentrate, microemulsion, or water emulsion. When the pesticide preparation is diluted in the field, the water consumption per mu of land is 50L. The processing method is as follows:

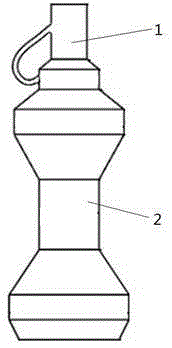

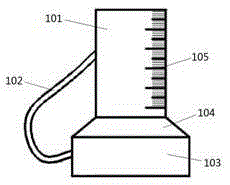

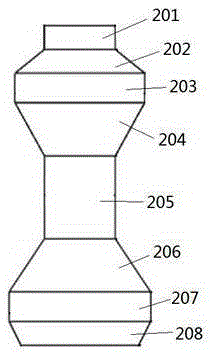

[0022] A. Use the measuring cup cover 1 to measure a certain amount of pesticide preparation in the mixing tank 2, add water to the 800mL mark, tighten the measuring cup cover 1, turn it upside down 30 times at a speed of one back and forth every two seconds, and then pour it into the agricultural sprayer. Fill up with water, stir 30 times, use a 100mL syringe (with a 50cm plastic tube at the head of the injector) to randomly draw 5 po...

Embodiment 2

[0030] In this example, the gravimetric method is used to determine the dilution efficiency of the pesticide precision and high-efficiency mixing diluter:

[0031] First, accurately weigh a certain amount of pesticide preparation (accurate to 0.0002g; the pesticide formulation can be wettable powder or water suspension). When the pesticide preparation is diluted in the field, the water consumption per mu is 50L. The processing method is as follows:

[0032] Standard treatment: Accurately weigh a certain amount of pesticide preparation and pour it into a 250mL stoppered measuring cylinder, add 10mL of water, shake it well, then set the volume to 250mL, turn it upside down at a speed of one back and forth every two seconds, so that the pesticide is fully and evenly dispersed in the In water, immediately remove 25mL with a pipette, transfer to a weighed centrifuge tube, and wait for centrifugation;

[0033]a. Use the measuring cup cover 1 to measure a certain amount of pesticid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com