Solvent type toughened glass ink diluent and preparation method thereof

A technology of glass ink and diluent, which is applied in inks, household utensils, applications, etc., can solve the problems of unfavorable sales of self-owned inks, and achieve the effects of improving drying adhesion, good leveling performance, and low odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A solvent-type tempered glass ink diluent, the raw material components of which are calculated by weight percentage: 30% of high boiling point kerosene, 30% of dipropylene glycol methyl ether, 38% of terpineol system varnish, and 2% of dispersant.

[0023] A preparation method of a solvent-based tempered glass ink diluent, specifically comprising the following steps:

[0024] Step 1: According to the above weight percentage, the high boiling point kerosene, dipropylene glycol methyl ether and terpineol system varnish are mixed and stirred in proportion, and a dispersant is added during stirring until a uniform transparent liquid is formed;

[0025] Step 2: ultrasonically vibrate the transparent liquid obtained in step 1 for 40 minutes, and finally let it stand for 70 minutes to obtain a diluent.

Embodiment 2

[0027] A solvent type tempered glass ink diluent, its raw material components by weight percentage: 35% of 200# solvent, 40% of propylene glycol methyl ether acetate, 20% of terpineol system varnish, and 5% of adhesion promoter.

[0028] A preparation method of a solvent-based tempered glass ink diluent, specifically comprising the following steps:

[0029] Step 1: Mix and stir 200# solvent, propylene glycol methyl ether acetate and terpineol system varnish in proportion according to the above weight percentage, and add an adhesion promoter during stirring until a uniform transparent liquid is formed;

[0030] Step 2: ultrasonically vibrate the transparent liquid obtained in step 1 for 60 minutes, and finally let it stand for 55 minutes to obtain a diluent.

Embodiment 3

[0032] A solvent-based tempered glass ink thinner, its raw material components are calculated by weight percentage: 50% of diethylene glycol butyl ether, 20% of propylene glycol methyl ether acetate, 25% of terpineol system varnish, and 5% of leveling agent %.

[0033] A preparation method of a solvent-based tempered glass ink diluent, specifically comprising the following steps:

[0034] Step 1: Mix and stir diethylene glycol butyl ether, propylene glycol methyl ether acetate, and terpineol system varnish in proportion according to the above weight percentage, and add a leveling agent during stirring until a uniform transparent liquid is formed;

[0035] Step 2: ultrasonically vibrate the transparent liquid obtained in step 1 for 50 minutes, and finally let it stand for 65 minutes to obtain a diluent.

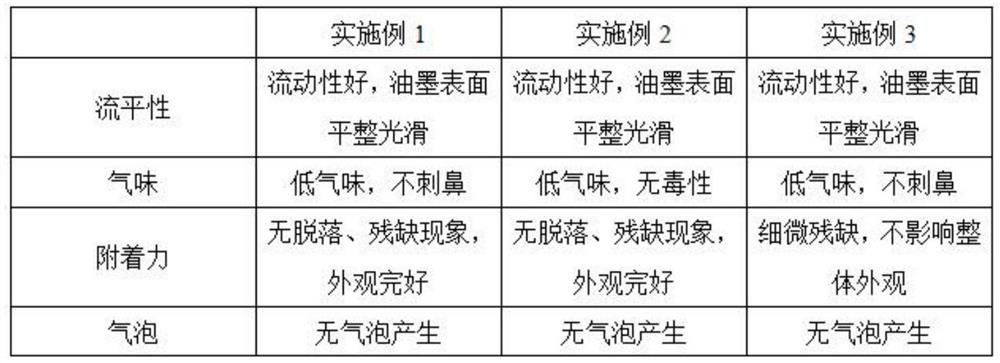

[0036] The diluent prepared in the above examples was applied to the solvent-based tempered glass ink, and the technical index of the obtained ink was tested, and the test re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com