Coal-mine gas injection system and jet ejector used in coal-mine gas injection system

A coal mine gas and gas sensor technology, applied in the direction of gas discharge, jet pumps, mining equipment, etc., can solve problems that easily affect the service life of equipment, affect the operation of pneumatic equipment, and waste air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

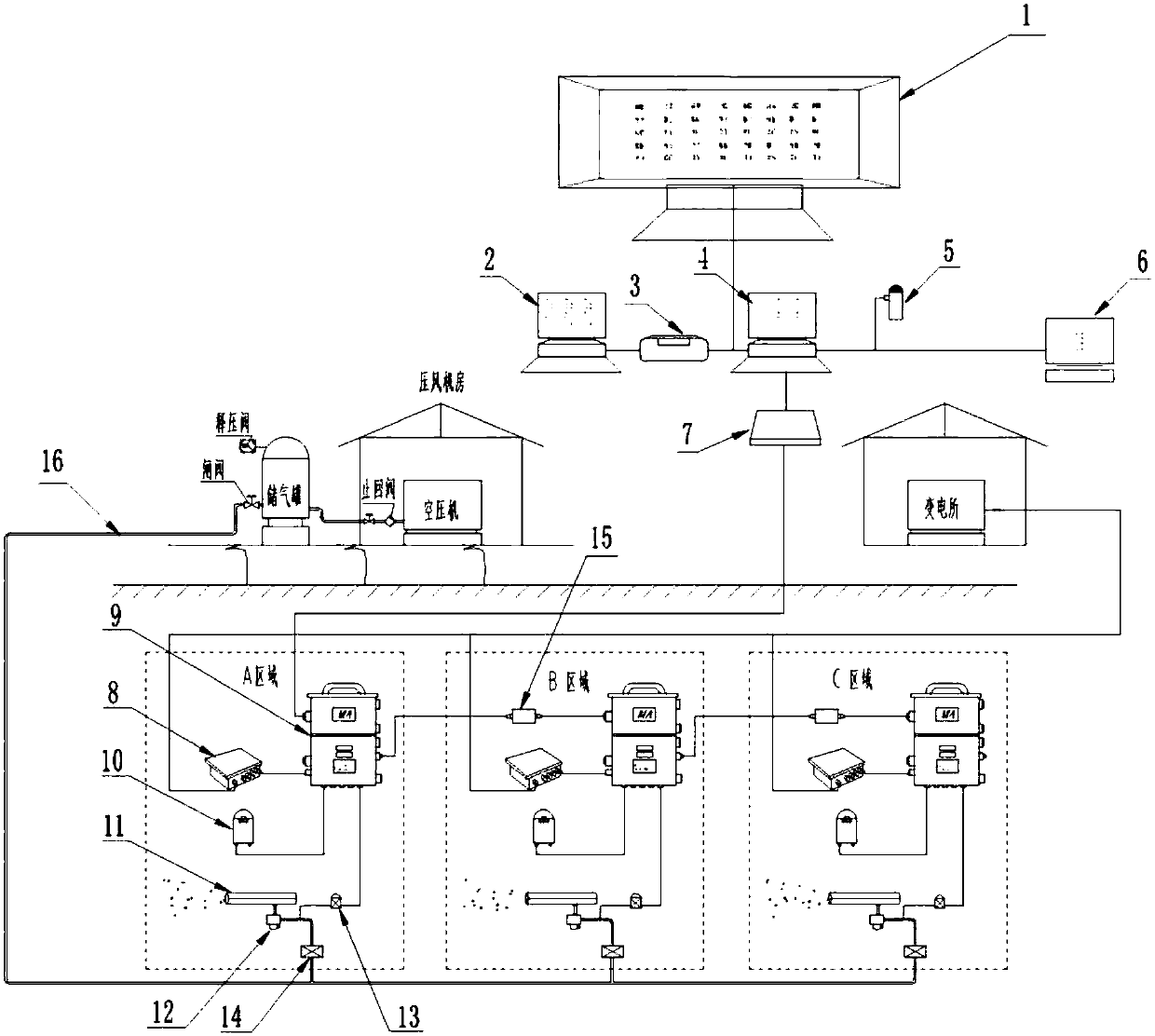

[0022] like figure 1 As shown, a coal mine gas injection system includes a monitoring host 4, a data information conversion and transmission device 7, a gas dilution unit and a signal repeater 15, the monitoring host 4 and the data information conversion and transmission device 7 are set on the ground, and the monitoring host 4. It is connected to the data information conversion and transmission device 7. The gas dilution unit and the signal repeater 15 are installed underground in the coal mine.

[0023] The gas dilution unit includes an underground monitoring substation 9, an intrinsically safe power module 8, a gas sensor 10, a flow device 11, a breaker 13, a solenoid valve 12 and a compressed air filter 14, an intrinsically safe power module 8 and an underground monitoring substation 9 The power supply input terminal of the underground monitoring substation 9 is connected with the data information conversion transmission device 7, the gas sensor 10 is connected with the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com