High-air-tightness gas diluting and discharging device

A discharge device and high-sealing technology, applied in gas discharge, safety devices, mining equipment, etc., can solve the problems of low dilution efficiency, no reflux device, gas can not be fully diluted, etc., to achieve high dilution efficiency and good safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

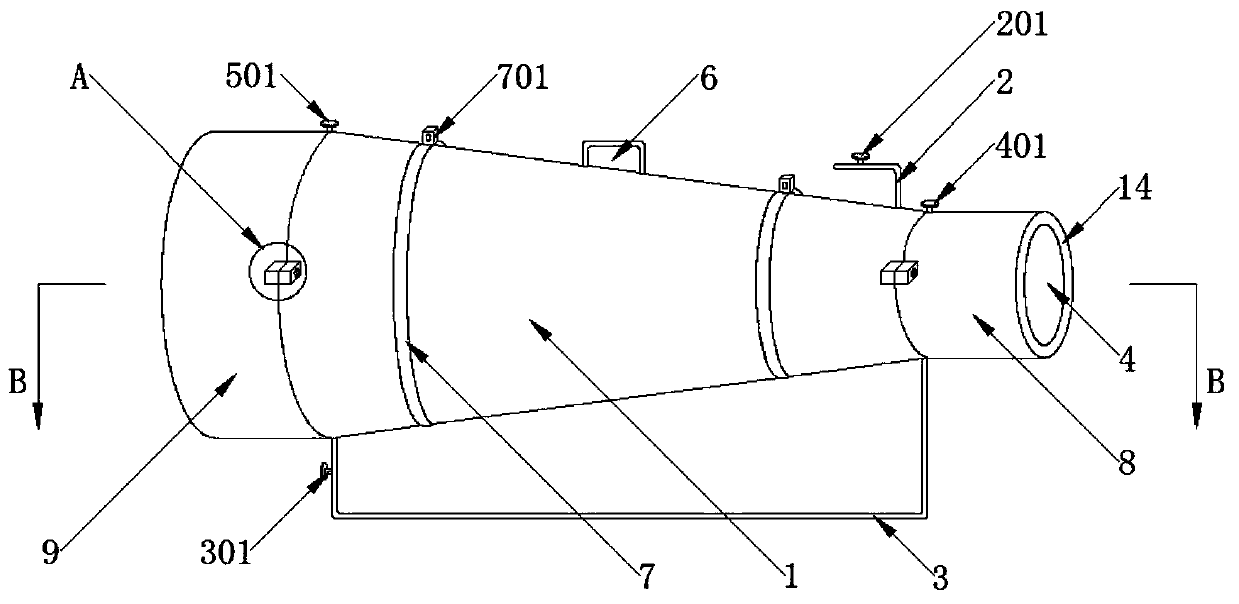

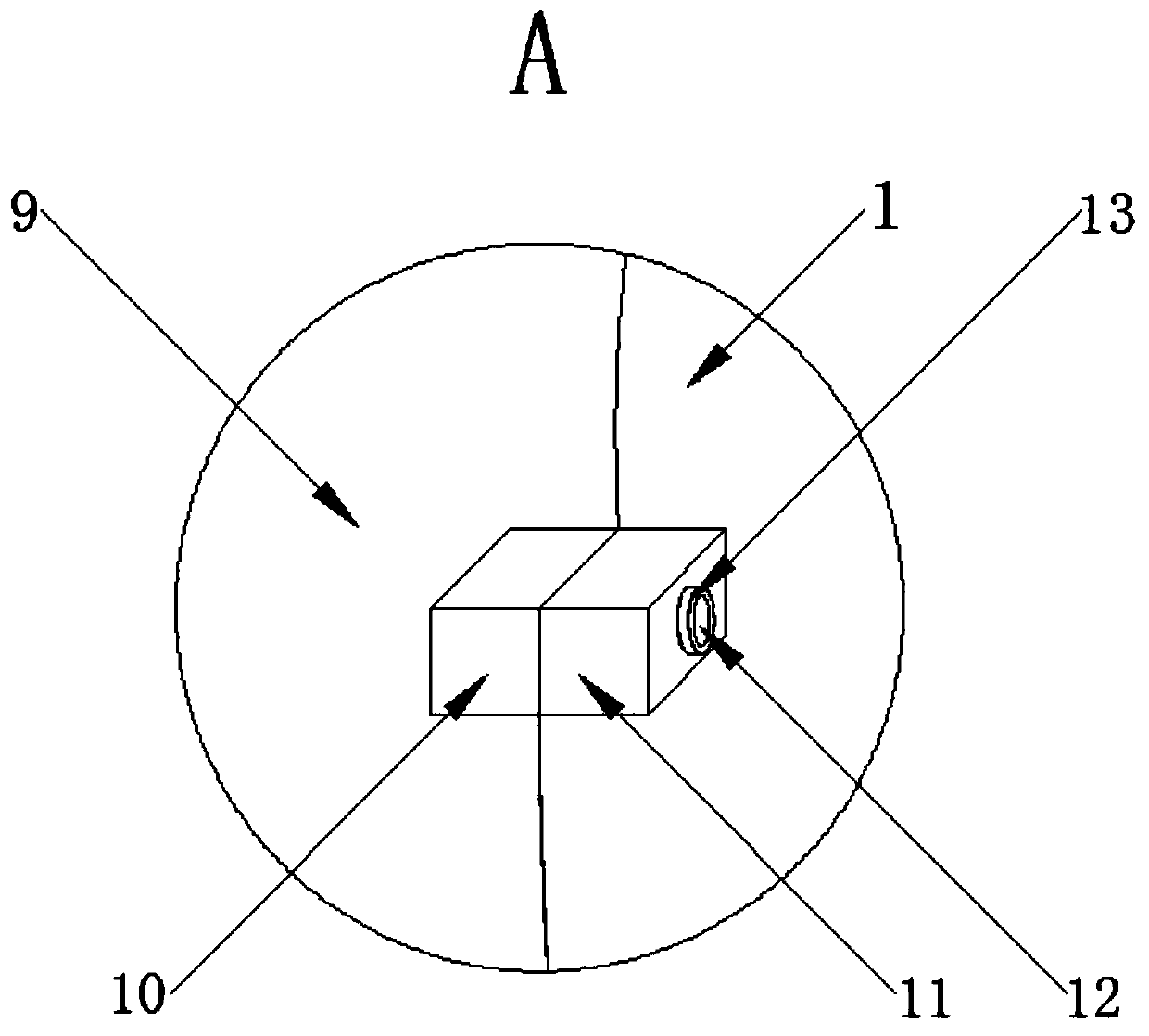

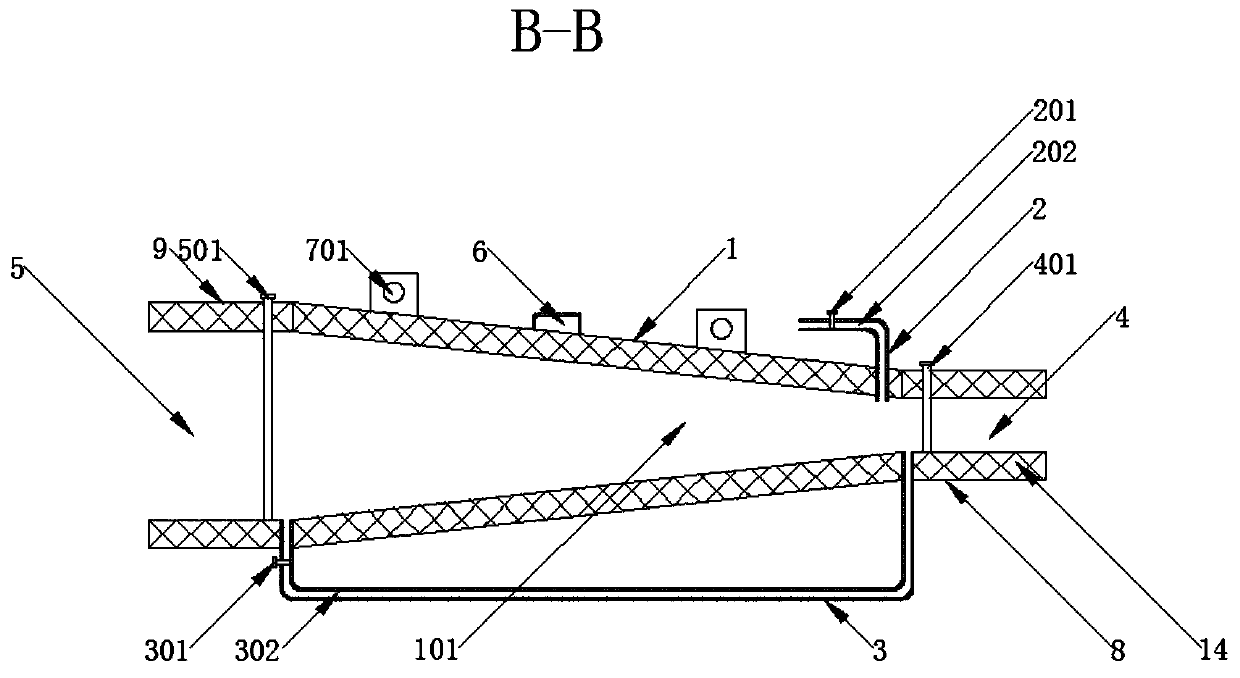

[0017] See Figure 1~3 In the embodiment of the present invention, a high-sealing gas dilution and discharge device includes a stainless steel pipe 1, a low-pressure gas delivery pipe 2 and a return pipe 3. The stainless steel pipe 1 is provided with a dilution pipe 101 inside. The intake pipe 4 is fixedly connected to the left side, and the reducing pipe 402 is fixedly connected to the right side of the intake pipe 4. The entire dilution exhaust device can be installed in a safe location far away from the gas area to improve the safety of the staff. The right side of the dilution tube 101 is fixedly connected with the air outlet tube 5, and the aperture size of the dilution tube 101 is gradually changed, showing a small left side and a large right side, so that the low-pressure compressed air and gas can be fully mixed, improving the entire dilution discharge device The pore size of the inlet pipe 4 matches the pore size of the left side of the dilution pipe 101, the pore size...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com