Primary pulp dilution device for antibacterial fabric

A dilution device and technology for antibacterial fabrics, which is applied in the field of puree dilution devices for antibacterial fabrics, can solve problems such as substandard concentration, uneven distribution, and reduced dilution efficiency, and achieve uniform concentration, improve discharge efficiency, and increase dilution efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

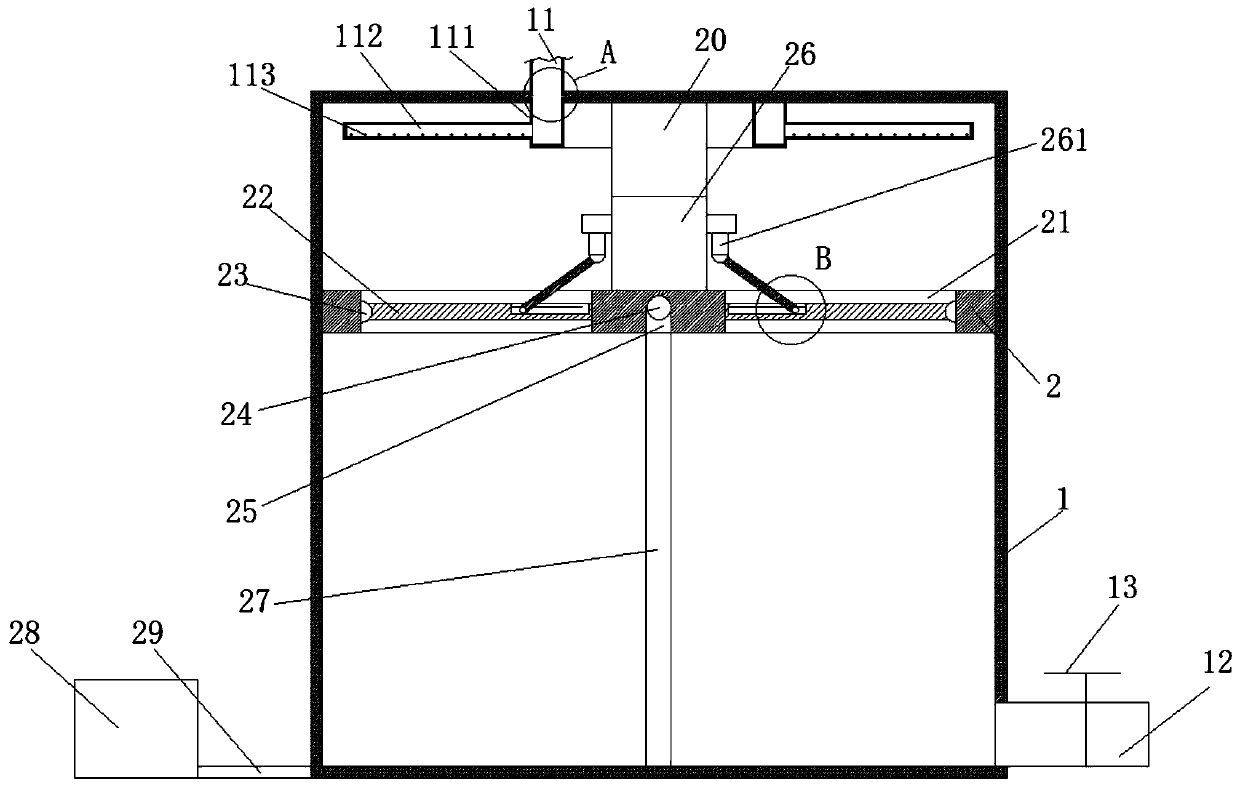

[0032] see Figure 1-3 , a puree dilution device for antibacterial fabrics, comprising a puree tank 1, the upper end of the puree tank 1 is provided with a feed pipe 11 for feeding, and one side of the bottom of the puree tank 1 is provided with a discharge port for discharging Pipe 12, and the dilution plate 2 that matches with the original slurry tank 1 and can slide up and down is provided in the original slurry tank 1, and the dilution plate 2 is provided with a plurality of through-type dilution tanks 21, and the inside of the dilution tank 21 A sealing cover 22 that can be opened and closed and used to seal the dilution tank 21 is provided. The bottom of the dilution pan 2 is provided with a communication hole 25 for the up and down communication of the dilution pan 2. The upper end of the dilution pan 2 is provided with a plurality of evenly distributed exposure holes. The air pipe 24, the aeration pipe 24 is provided with evenly distributed aeration holes 241, and the ...

Embodiment 2

[0038] The same as embodiment 1 is not repeated, and the difference with embodiment 1 is:

[0039] see Figure 4-5, the material distribution box 111 is an annular groove with an open upper end, and the inner wall of the puree tank 1 located at the upper end of the material distribution box 111 is provided with a material matching with the material distribution box 111 and sliding with the material distribution box 111 Connected distribution trough 116, the inner side walls of the distribution chute 116 are provided with an annular clamping groove 115, the clamping groove 115 is provided with a clamping plate 114 that matches the clamping groove 115 and is slidingly connected. The inner wall of the clamping plate 114 is fixedly connected with the corresponding outer wall of the distribution box 111 .

[0040] Further, the distributing pipe 112 is symmetrically distributed on the outside of the distributing box 111 with the distributing box 111 as the center, and the distribut...

Embodiment 3

[0043] The same as embodiment 1 is not repeated, and the difference with embodiment 1 is:

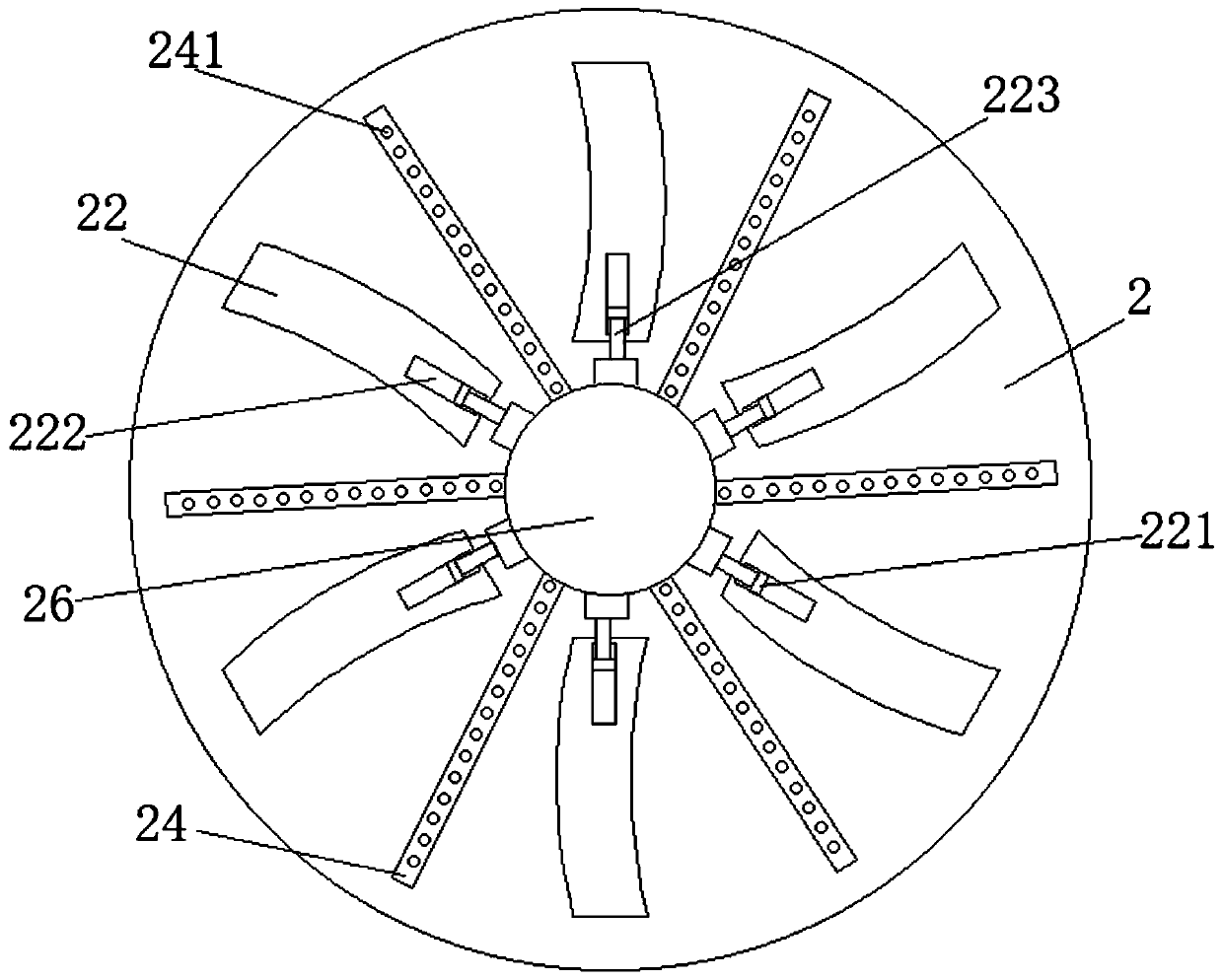

[0044] see Figure 6-7 , the dilution tanks 21 are distributed centrally symmetrically with the center of the dilution plate 2 as the center, and the two sides of the dilution tanks 21 are arc-shaped, and the dilution tanks 21 are distributed on the dilution plate 2 in the shape of fan blades.

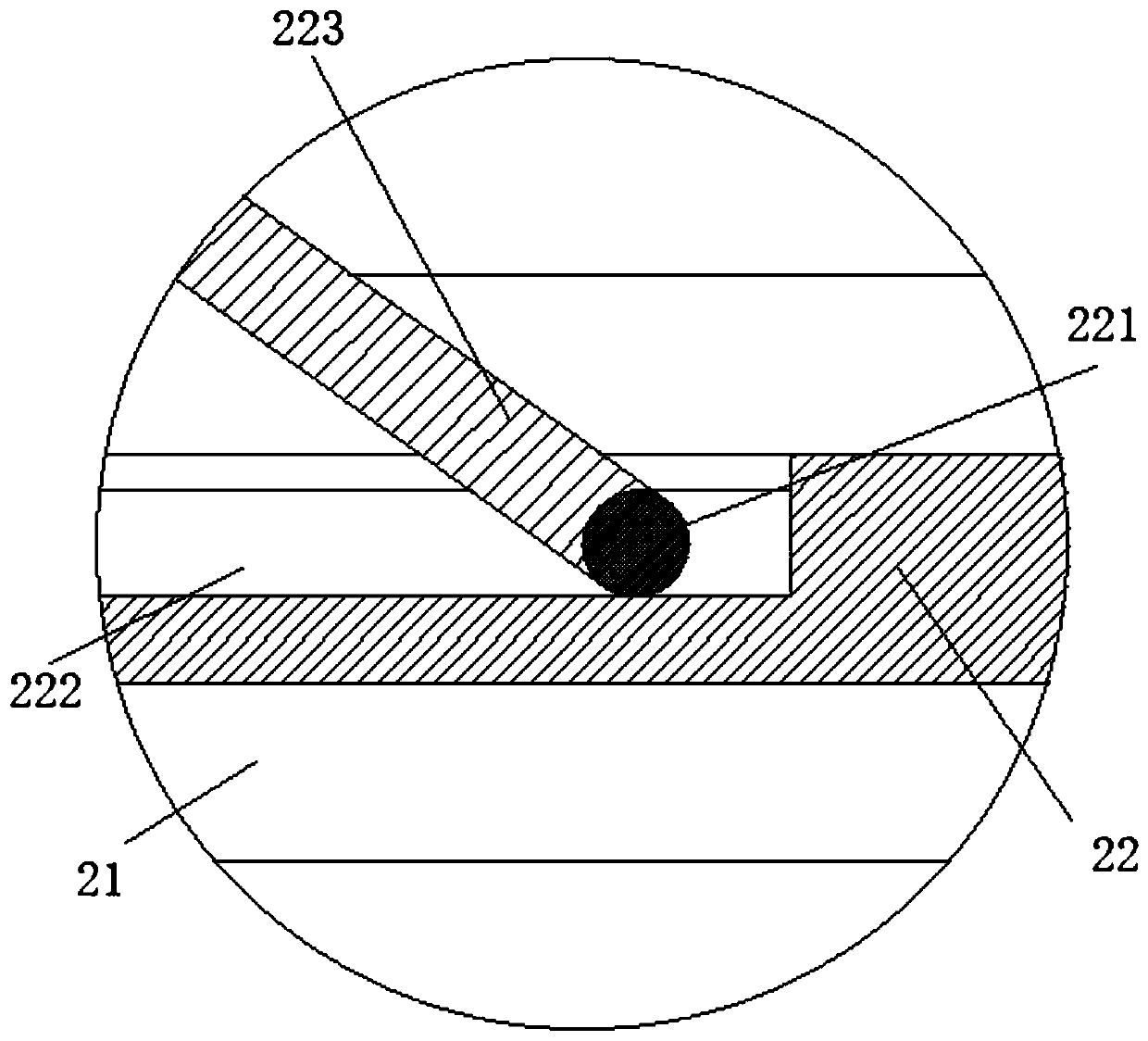

[0045] Further, the cross-sections of the two side surfaces of the dilution tank 21 are inclined, one side of the dilution tank 21 is provided with a first fixing groove 211 for fixing one side of the sealing cover 22, and the other side of the dilution tank 21 is provided with a sealing cover for sealing. 22 and the second fixing groove 212 fixed on the other side, the depth of the first fixing groove 211 is smaller than the depth of the second fixing groove 212, and the bottom of the sealing cover 22 is inclined.

[0046] The unique design of the dilution tank 21, coupled with the flexible co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com