Constant-volume type automatic diluter

A diluter and constant-volume technology, which is applied in the field of constant-volume automatic diluters, can solve the problems of diluting toxic, harmful and volatile liquids, the inability to precisely dilute and constant volume at the same time, and the liquid volume is not accurate enough to achieve a wide range of dilution multiples , Dilution is simple and fast, and the effect of shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

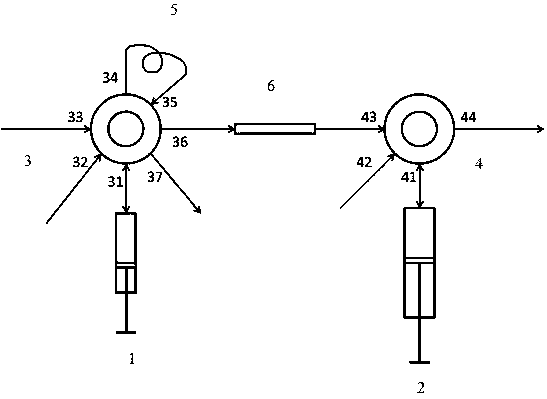

[0023] like figure 1 As shown, a constant-volume automatic diluter of the present invention includes a micro-injector 1 driven by a stepping motor, a constant syringe 2 driven by a stepping motor, a seven-way valve 3 with a freely switchable flow path, a freely switchable The four-way valve 4 of the flow path, a quantitative loop 5 and a pipeline mixer 6 are composed. In this example, a 1000 μL glass syringe was used as the microsyringe. A 1000 μL glass syringe is connected to the first channel 31 position of the seven-way valve. The constant syringe uses a 25mL glass syringe. The 25mL glass syringe is connected to the channel one 41 position of the four-way valve, and the seven-way valve 3 and the four-way valve 4 are connected in series through the sixth channel 36 and the third channel 43, and there is a small section between the sixth channel 36 and the third channel 43 In the line mixer 6, the liquid to be diluted and the diluted liquid pass through the seven-way valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com