Honey dilution apparatus

A dilution device and honey technology, applied in applications, food preparation, food science, etc., can solve problems such as difficult cleaning, easy crystallization of honey, and reduction of honey dilution speed, so as to prevent crystallization and improve dilution efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings, so as to make the technical solutions of the present invention easier to understand and grasp.

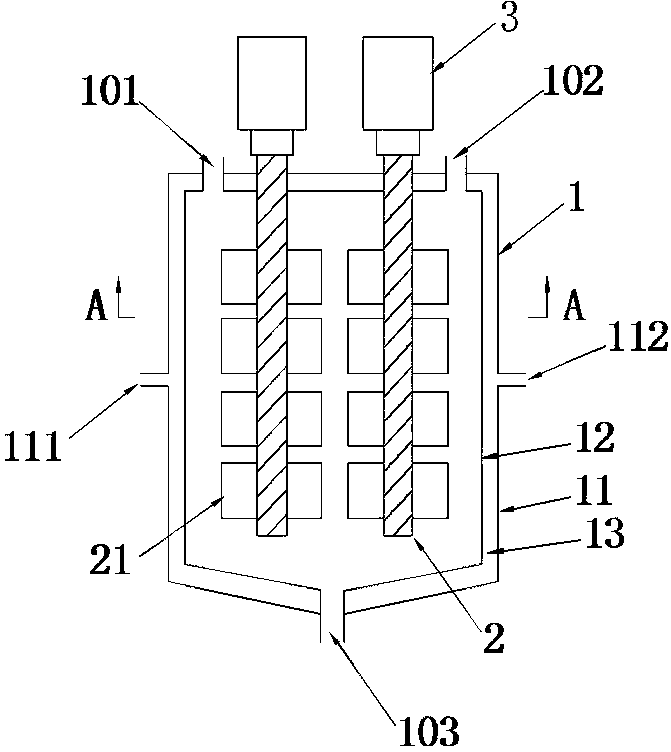

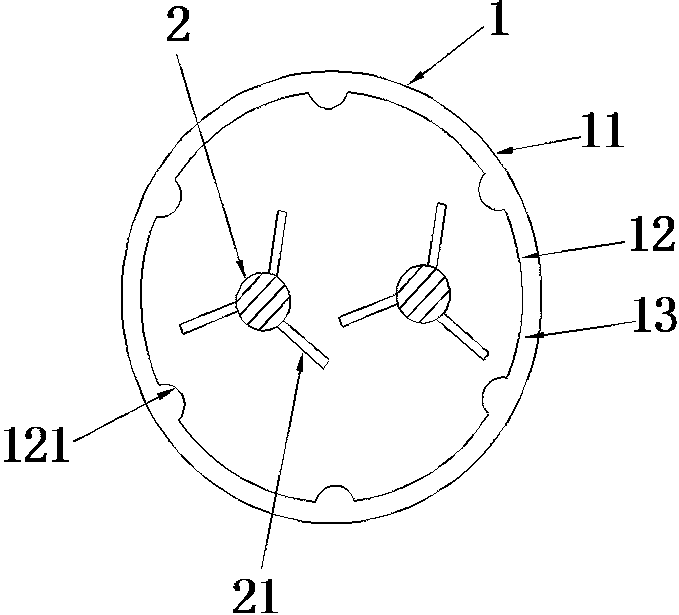

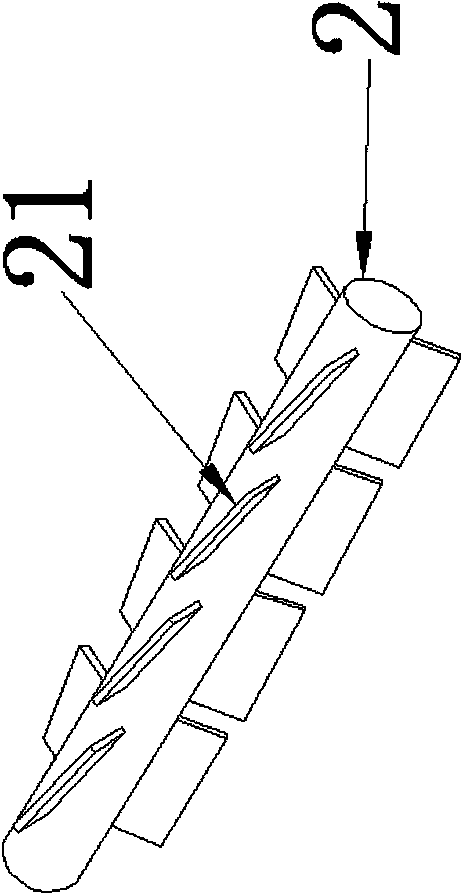

[0018] Such as figure 1 , figure 2 As shown, a honey dilution device includes a tank body 1, a rotating shaft 2 and a motor 3, the top of the tank body 1 is provided with a honey inlet 101, a water inlet 102, the bottom of the tank body 1 is provided with a honey outlet 103, and the rotating shaft 2 is installed on Inside the tank body 1, the motor 3 is connected to the upper end of the rotating shaft 2, the number of the rotating shaft 2 and the motor 3 is two, the two rotating shafts 2 are parallel to each other, and the rotation directions of the two motors 3 are opposite. Layer 11 and inner layer 12, the thickness of outer layer 11 is greater than the thickness of inner layer 12, because considering the effect of outer layer 11 hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com