Pulp bleaching apparatus with flushing mechanism

A pulp bleaching and pulp technology, which is applied in pulp bleaching, washing/replacement of pulp treatment liquid, etc., can solve the problems of poor pulp quality, reducing bleaching time, and reducing the probability of pulp input pipe clogging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

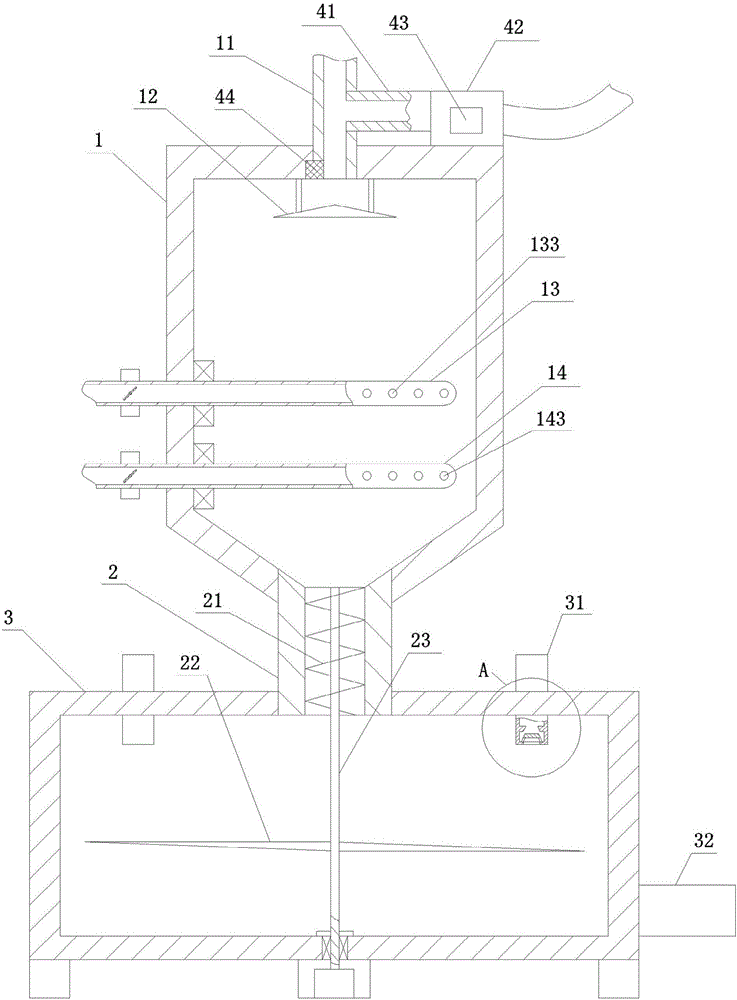

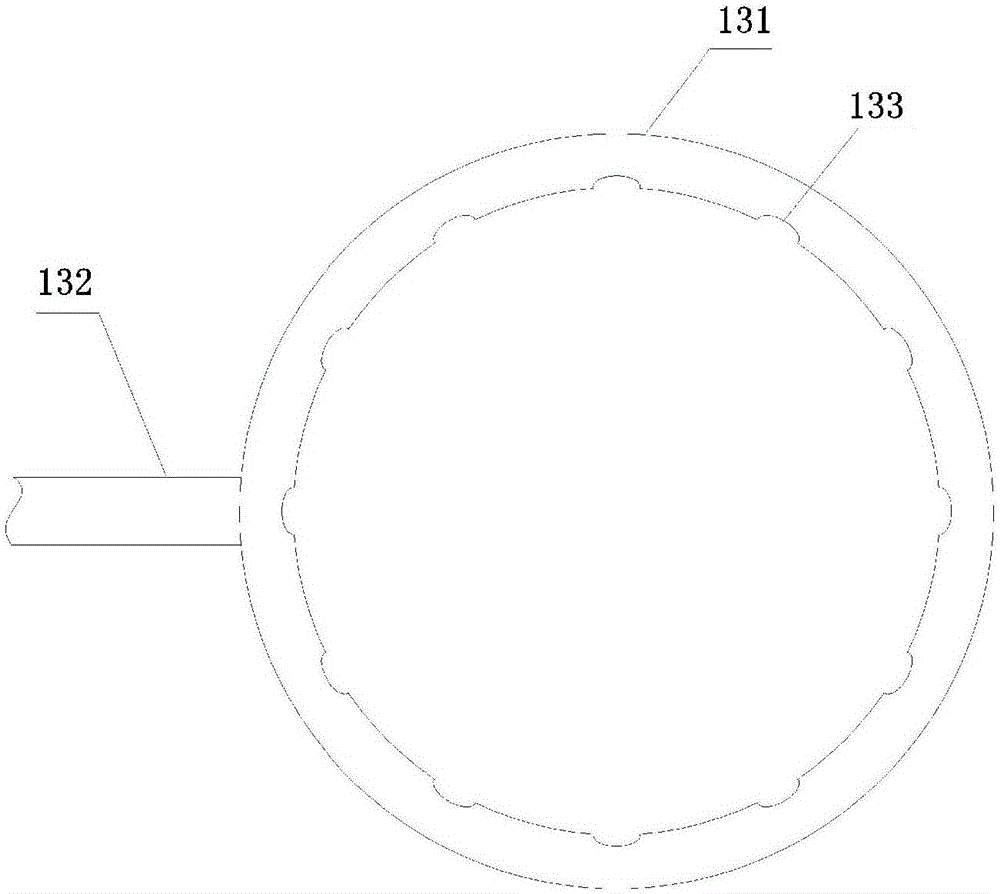

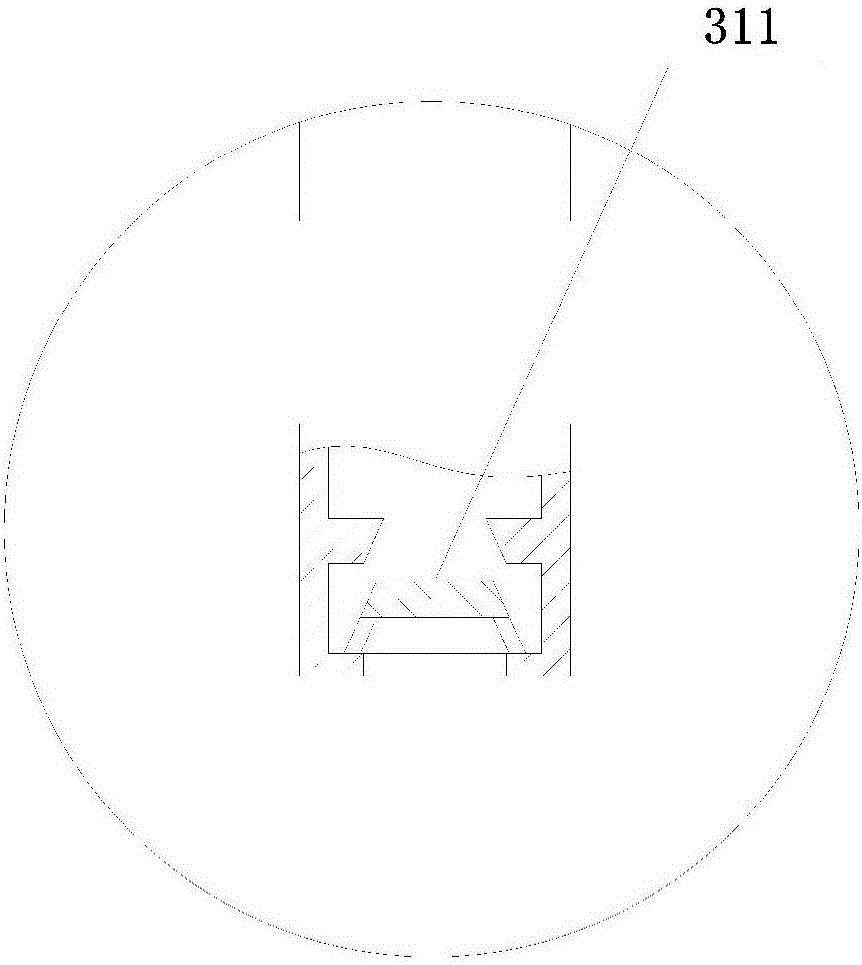

[0018] to combine figure 1 , an embodiment of the present invention. A pulp bleaching device with a flushing mechanism, comprising a bleaching assembly and a flushing assembly, the bleaching assembly includes a bleaching chamber 1, which is connected to a dilution chamber 3 below the bleaching chamber through a delivery pipeline 2, and a pulp is connected to the top of the bleaching chamber Input pipe 11, the bleaching chamber is sequentially provided with a pulp separation plate 12, a bleaching liquid input pipe 13 and a primary dilution liquid input pipe 14 from top to bottom, the pulp separation plate includes a conical top, and the conical top is correspondingly arranged Below the pulp input pipe, the bleaching liquid input pipe includes a liquid injection pipe 131 and an infusion pipe 132 connected with the liquid outlet pipe. A plurality of liquid injection ports 133 are opened on the liquid injection pipe, and the primary The bleaching liquid input pipe includes a liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com