Shale gas flowback fluid recovery treatment device and method

A technology for recovery, treatment and flowback liquid, which is applied in the direction of mixing method, separation method, mixed material pretreatment, etc. It can solve the problems that the filter cartridge is easily blocked by filter residue and the efficiency of adding diluent is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

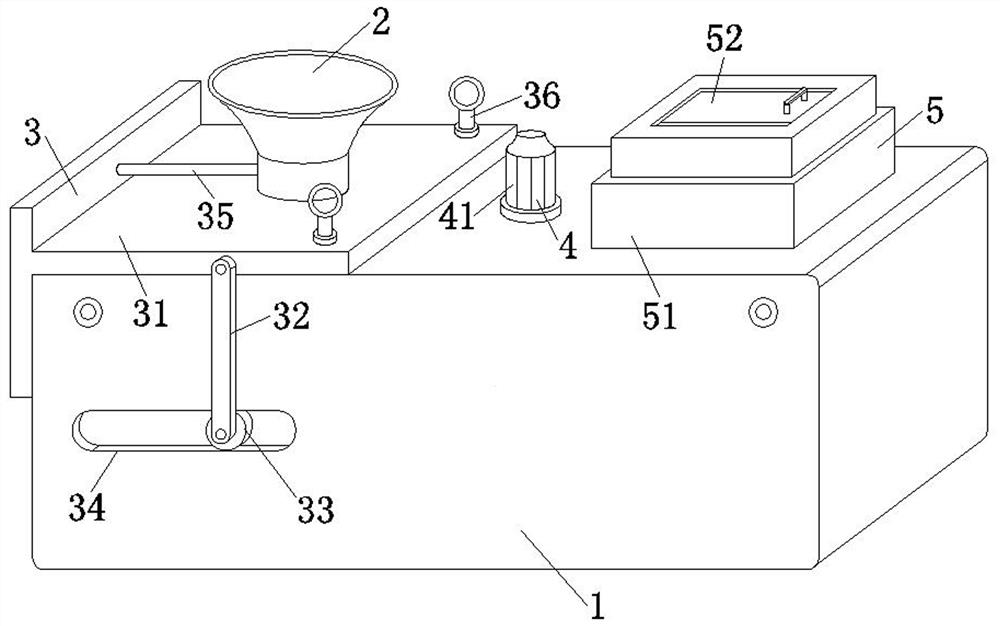

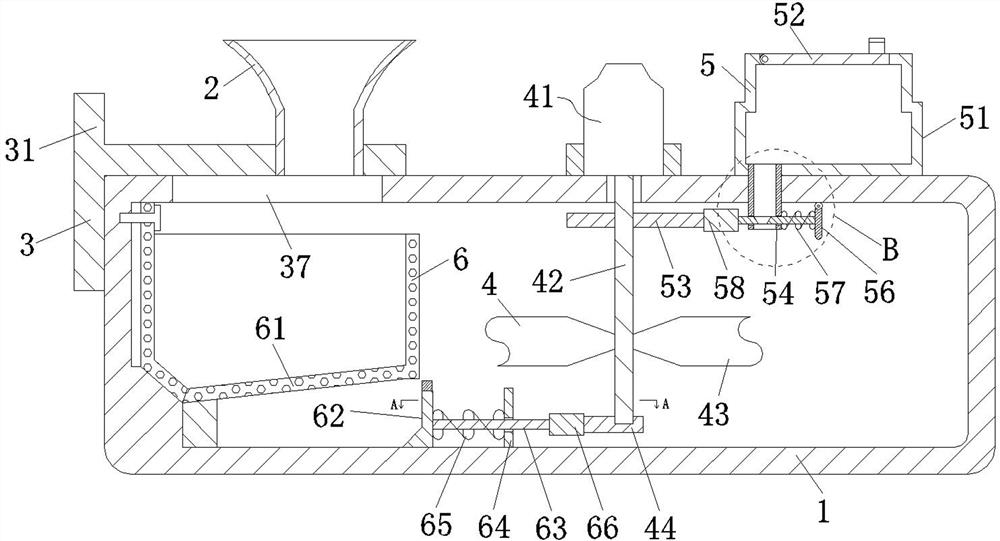

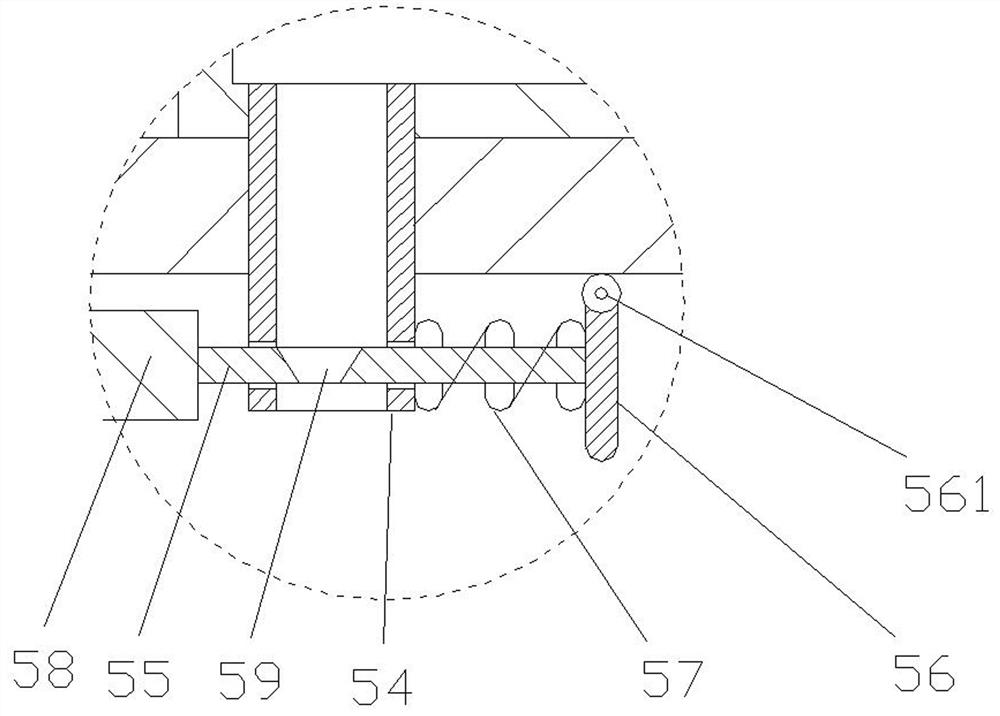

[0031] Such as Figure 1-5 Shown: a shale gas flowback liquid recovery treatment device, including a treatment pool 1, the top of the treatment pool 1 is provided with a feed hopper 2, and one side of the treatment pool 1 is provided for the shale gas flowback liquid Filtration mechanism 6, the other side of the treatment pool 1 is provided with an infusion mechanism 5 for interstitial supply of diluent, between the filter mechanism 6 and infusion mechanism 5 there is a flowback fluid and diluent for shale gas The stirring mechanism 4 for mixing, the bottom of the filter cartridge 61 of the filter mechanism 6 is provided with a movable push plate 62 .

[0032] Preferably, an adjustment mechanism 3 for adjusting the position of the feed hopper 2 is provided on the top of the processing tank 1 , and a switch door 7 is installed on one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com