Diluting equipment for novel coronavirus detection kit

A virus detection and kit technology, applied in the field of dilution equipment, can solve the problems of low liquid dilution efficiency, single stirring method, affecting the detection speed and efficiency of the kit, and achieve the effect of improving mixing efficiency, improving dilution efficiency and good mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

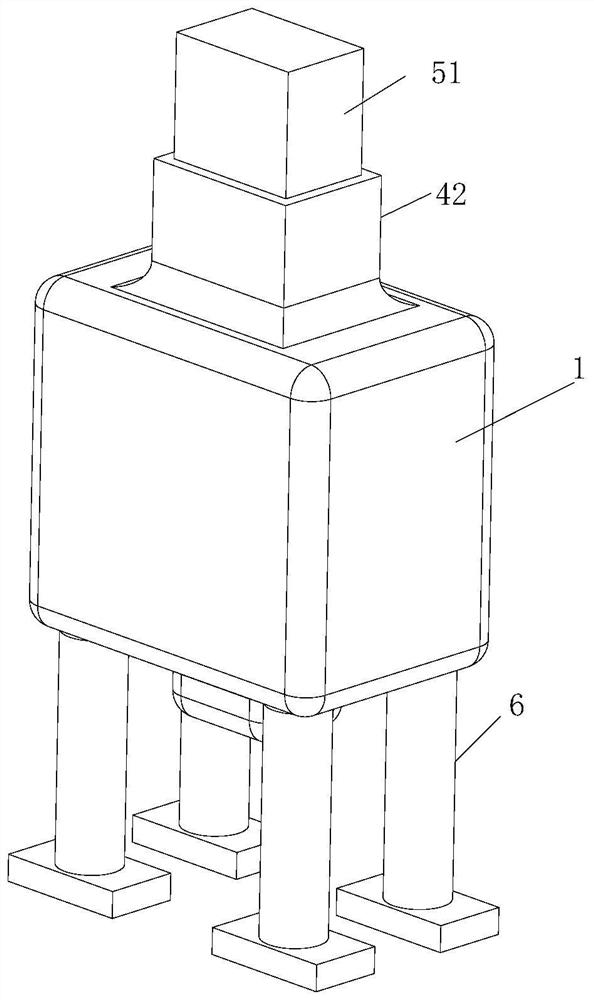

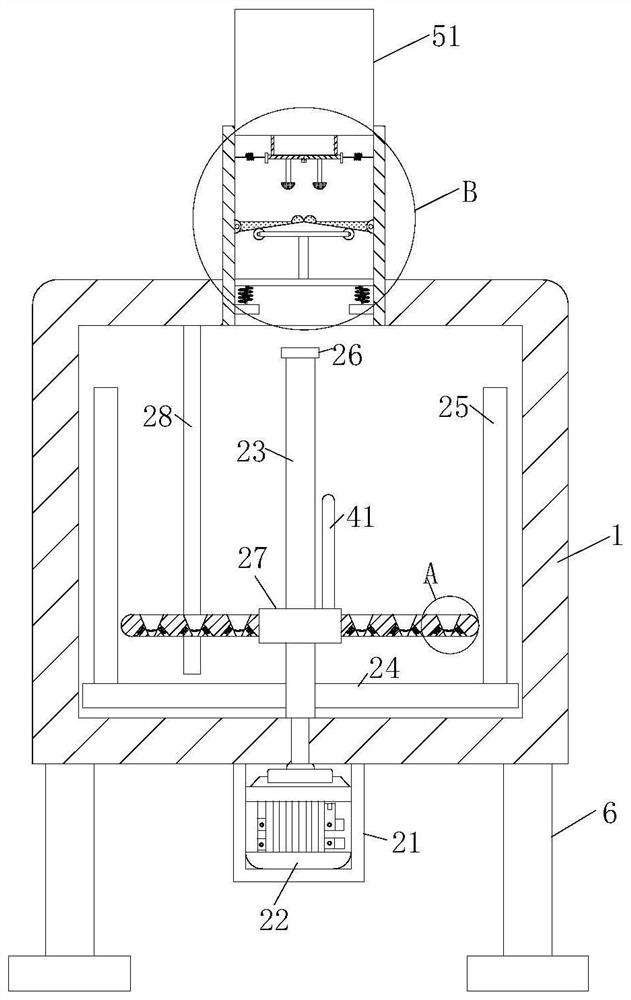

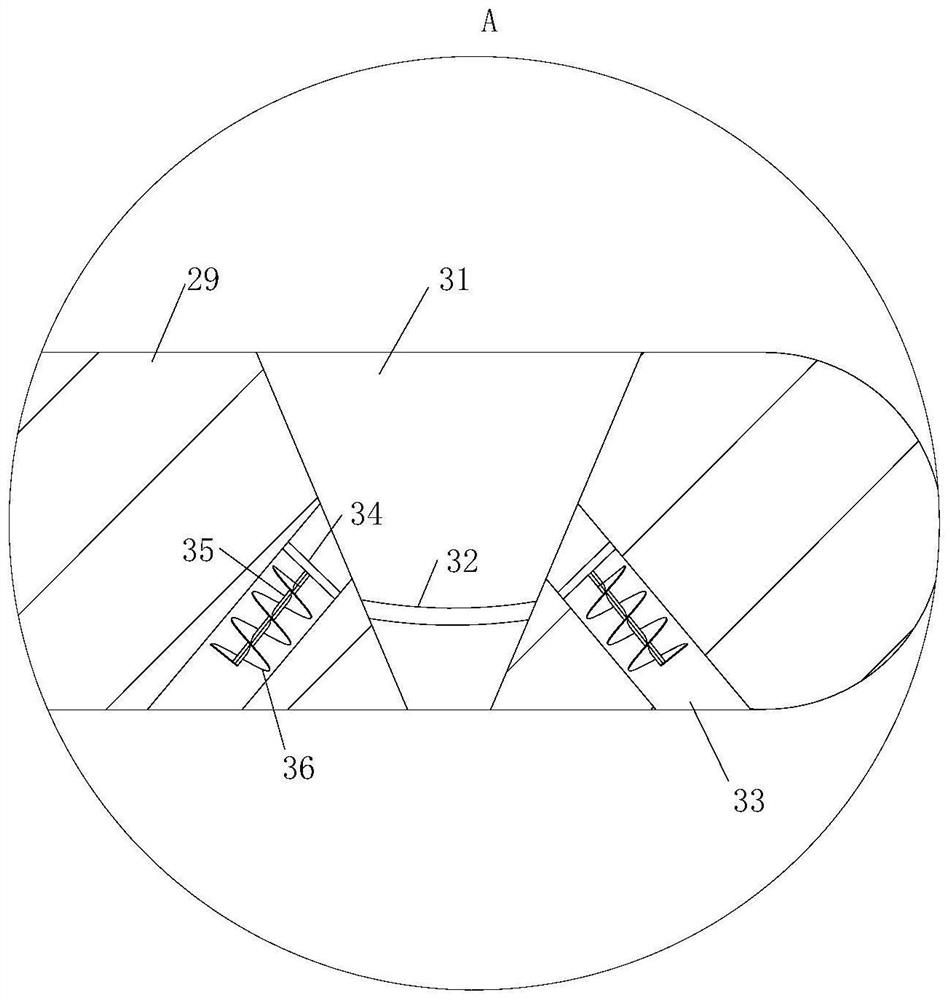

[0026] see Figure 1-4 As shown, a dilution device for a new coronavirus detection kit includes a dilution box 1; the top of the dilution box 1 is provided with a liquid inlet hole 42; the bottom of the dilution box 1 is fixed with a fixed box 21; The inside of the fixing box 21 is fixed with a motor 22; the output end of the motor 22 is fixed with a lead screw 23; the lead screw 23 and the slider 27 are connected by a screw nut pair; the inner wall of the dilution box 1 is fixed The limit rod 28 is connected to the end of the slider 27; the two ends of the slider 27 are fixed with a guide plate 29; the inside of the guide plate 29 is provided with a guide hole 31, and there are several The inner side wall of the guide hole 31 is fixed with a drain net 32; the top of the screw rod 23 is fixed with a limit plate 26; during operation, in the prior art, when the liquid is diluted, due to mixing The method is relatively simple, resulting in low liquid dilution efficiency, which a...

Embodiment 2

[0035] see Figure 5 As shown in the comparison example 1, as another embodiment of the present invention, the bottom of the guide plate 46 is fixed with a protective pad 7; during operation, the protective pad 7 is installed to prevent the push rod 41 from moving upward and squeezing When the guide plate 46 is installed, the problem of wear and tear is caused, thereby improving the protective effect of the guide plate 46 .

[0036] Working principle, in the prior art, when diluting the liquid, due to the relatively simple mixing method, the liquid dilution efficiency is low, which affects the detection speed and efficiency of the kit; The liquid flows to the inside of the dilution box 1 through the liquid inlet hole 42, and then the motor 22 is turned on, so that the output end of the motor 22 drives the screw rod 23 to rotate, and the screw rod 23 drives the slider 27 to move up and down. When the slider 27 moves up and down At the time, the guide plate 29 is driven to move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com