Method for reducing content of sulfur oxides in catalytic cracking smoke

A technology of sulfur oxides and catalytic cracking, which is applied in the refining and cracking process treatment of multi-stage series connection, petroleum industry, water treatment and refining, etc. Sulfur oxide content, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Composition of the multifunctional composite emulsifier: Span 6060%, triethanolamine surfactant 32% and mixed aromatics 8%, wherein the mixed aromatics are mixed with C8 aromatics and C9 aromatics in a mass ratio of 1:1.

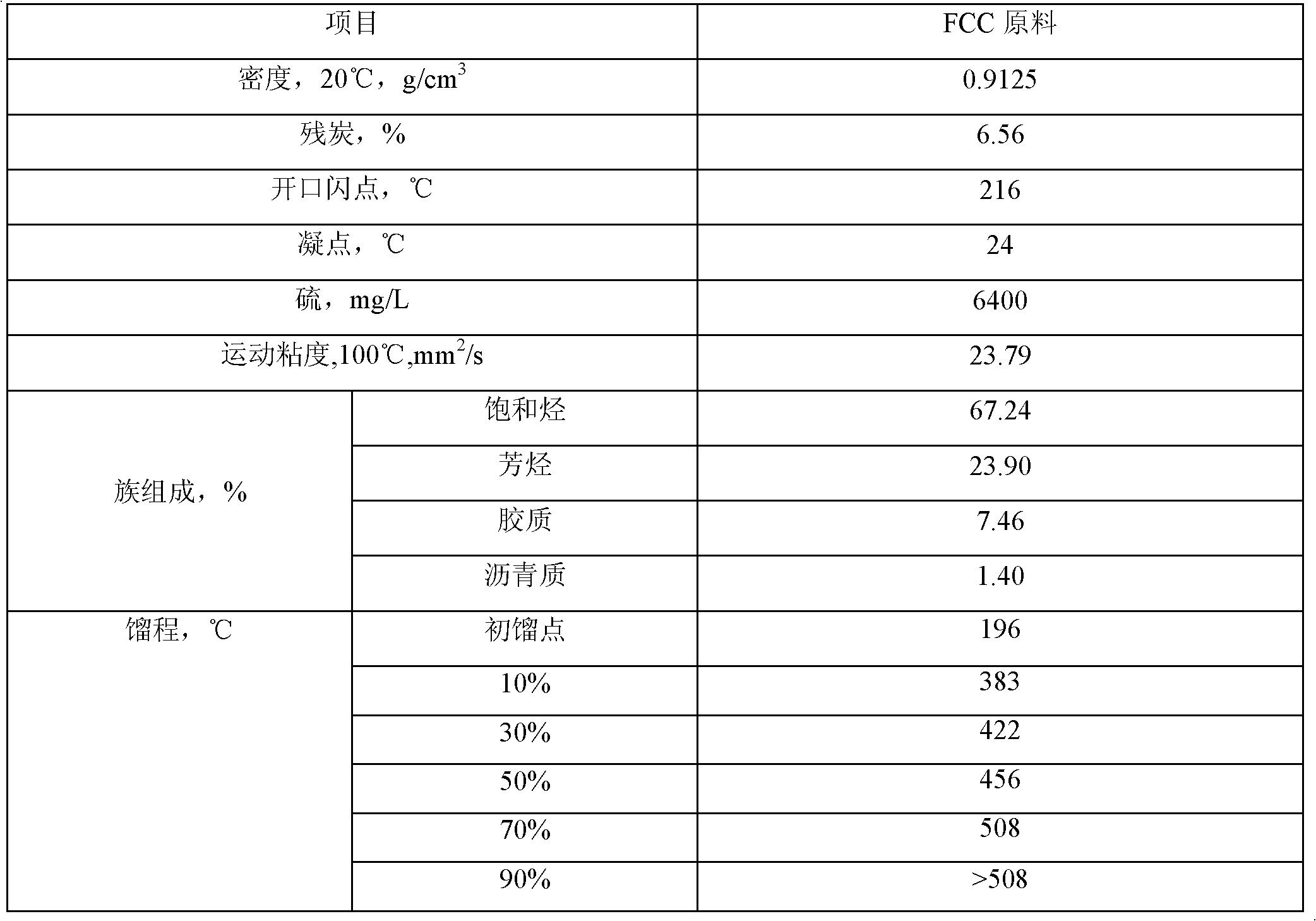

[0025] FCC raw emulsified oil was prepared under the conditions of 6% water addition, 0.05% emulsifier addition, 70°C emulsification temperature, and 22000r / min stirring speed, and its properties are listed in Table 2.

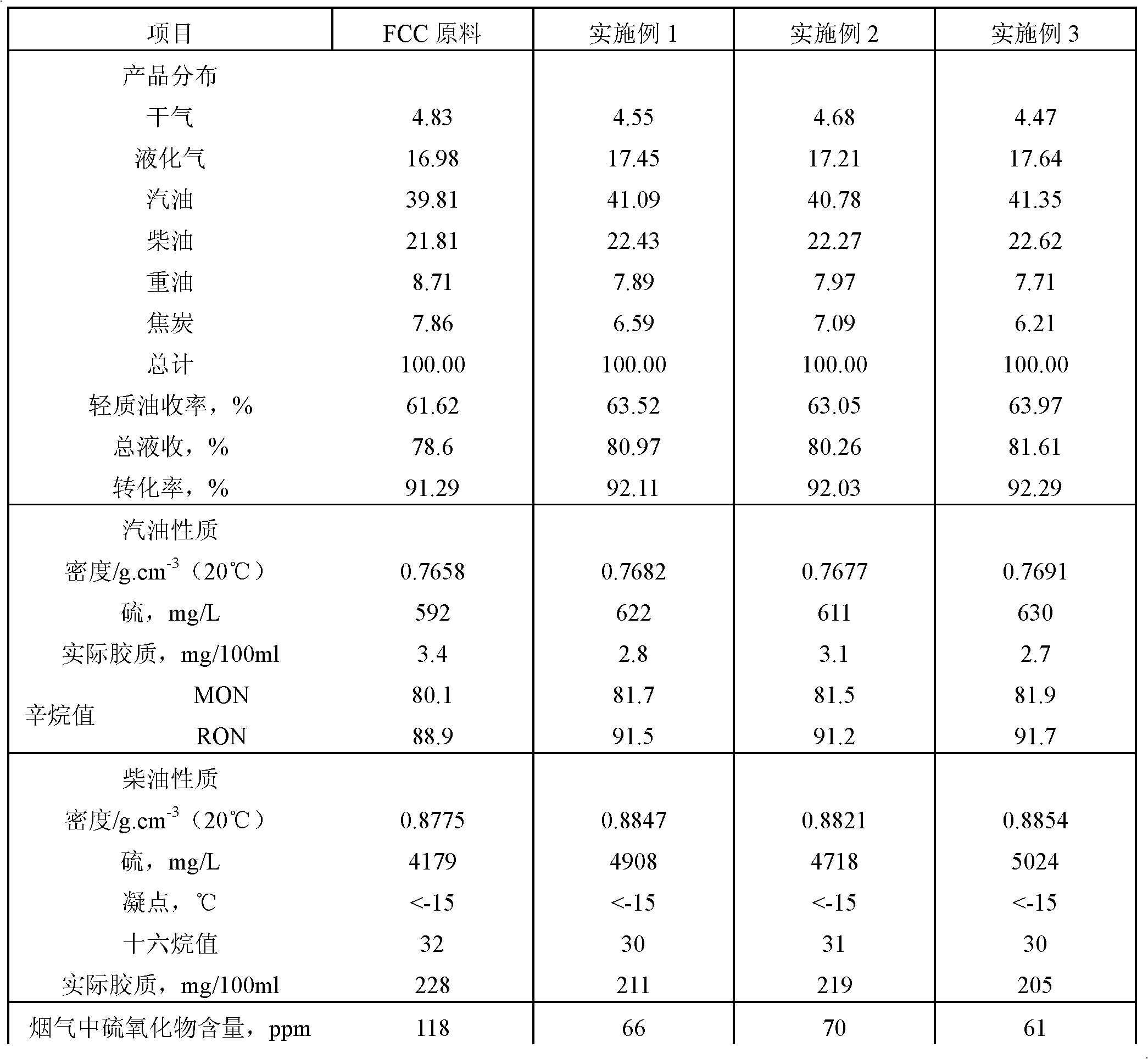

[0026] The catalytic cracking test was carried out on the riser unit with FCC feedstock and emulsified feedstock respectively. The process conditions are: reaction temperature 505°C, regeneration temperature 700°C, agent-oil ratio 5.0. The test is continuous oil feeding for 10 hours, and the oil feeding amount is 8kg; the feeding method of the emulsified raw material is continuous feeding, a homogeneous emulsifying equipment is installed in front of the riser nozzle, the stirring speed is adjustable, and the emulsified oil processing ...

Embodiment 2

[0030] Composition of multi-functional composite emulsifier: Span 6050%, triethanolamine surfactant 40% and mixed aromatics 10%, wherein mixed aromatics are mixed with C8 aromatics and C9 aromatics in a mass ratio of 1:1.

[0031] FCC raw emulsified oil was prepared under the conditions of 2% water addition, 0.01% emulsifier addition, emulsification temperature 50°C, and stirring speed 22000r / min, and its properties are listed in Table 2.

[0032] The catalytic cracking test was carried out on the riser unit with FCC feedstock and emulsified feedstock respectively. The process conditions are: reaction temperature 505°C, regeneration temperature 700°C, agent-oil ratio 5.0. The test is continuous oil feeding for 10 hours, and the oil feeding amount is 8kg; the feeding method of the emulsified raw material is continuous feeding, a homogeneous emulsifying equipment is installed in front of the riser nozzle, the stirring speed is adjustable, and the emulsified oil processing capaci...

Embodiment 3

[0036] Composition of the multifunctional composite emulsifier: Span 6052%, triethanolamine surfactant 42% and mixed aromatics 6%, wherein the mixed aromatics are mixed with C8 aromatics and C9 aromatics in a mass ratio of 1:1.

[0037] FCC raw emulsified oil was prepared under the conditions of 12% water addition, 2% emulsifier addition, 90°C emulsification temperature, and 23000r / min stirring speed, and its properties are listed in Table 2.

[0038] The catalytic cracking test was carried out on the riser unit with FCC feedstock and emulsified feedstock respectively. The process conditions are: reaction temperature 505°C, regeneration temperature 700°C, agent-oil ratio 5.0. The test is continuous oil feeding for 10 hours, and the oil feeding amount is 8kg; the feeding method of the emulsified raw material is continuous feeding, a homogeneous emulsifying equipment is installed in front of the riser nozzle, the stirring speed is adjustable, and the emulsified oil processing ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com