Patents

Literature

77results about How to "Easy to atomize" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aerosol and injectable formulations of nanoparticulate benzodiazepine

InactiveUS20060198896A1Easy doseReduce injection volumeBiocidePowder deliveryBenzodiazepinePolyethylene glycol

Described are nanoparticulate formulations of a benzodiazepine, such as lorazepam, that does not require the presence of polyethylene glycol and propylene glycol as stabilizers, and methods of making and using such formulations. The formulations are particularly useful in aerosol and injectable dosage forms, and comprise nanoparticulate benzodiazepine, such as lorazepam, and at least one surface stabilizer. The formulations are useful in the treatment of status epilepticus, treatment of irritable bowel syndrome, sleep induction, acute psychosis, and as a pre-anesthesia medication.

Owner:ELAN PHRMA INT LTD

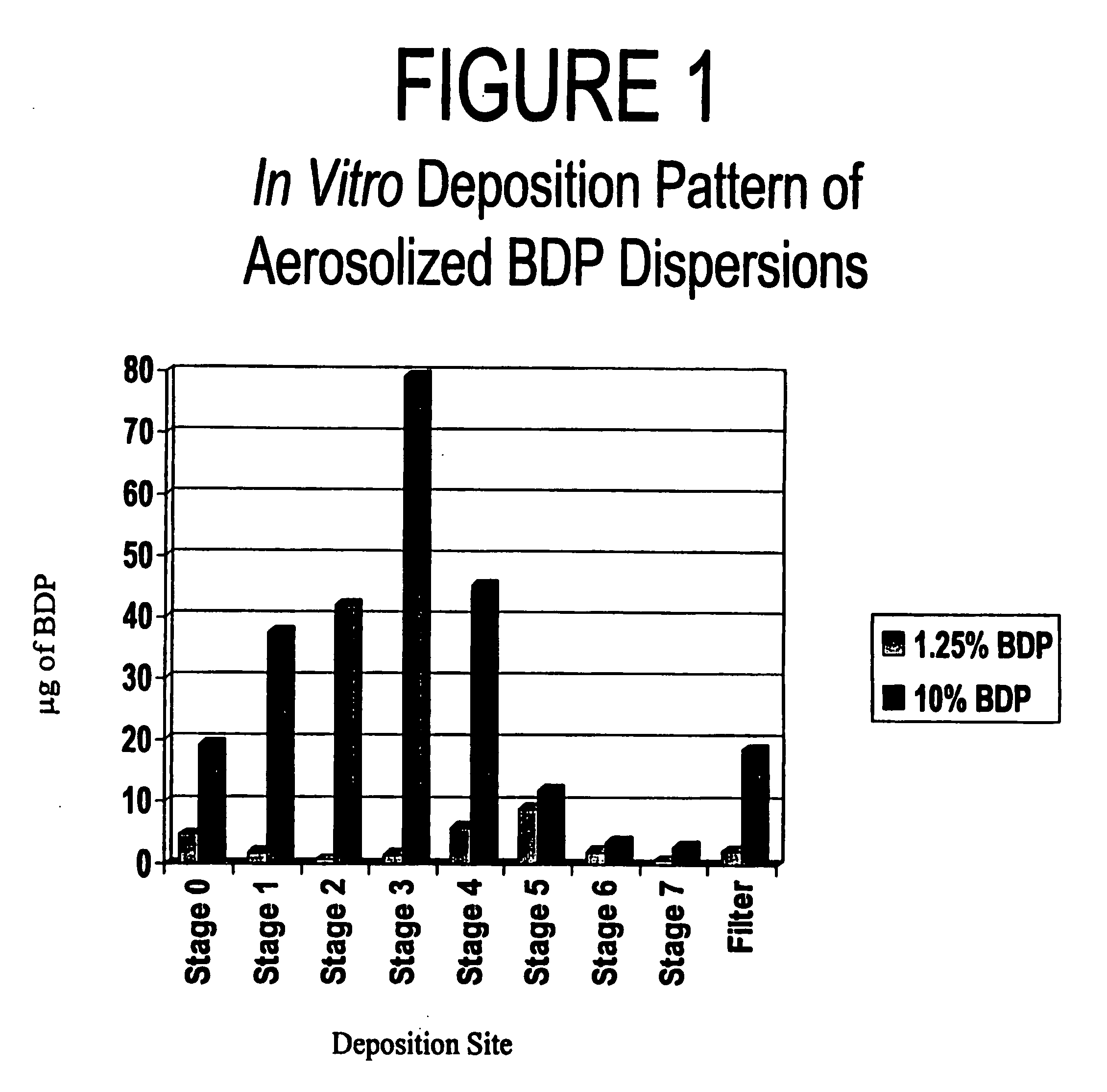

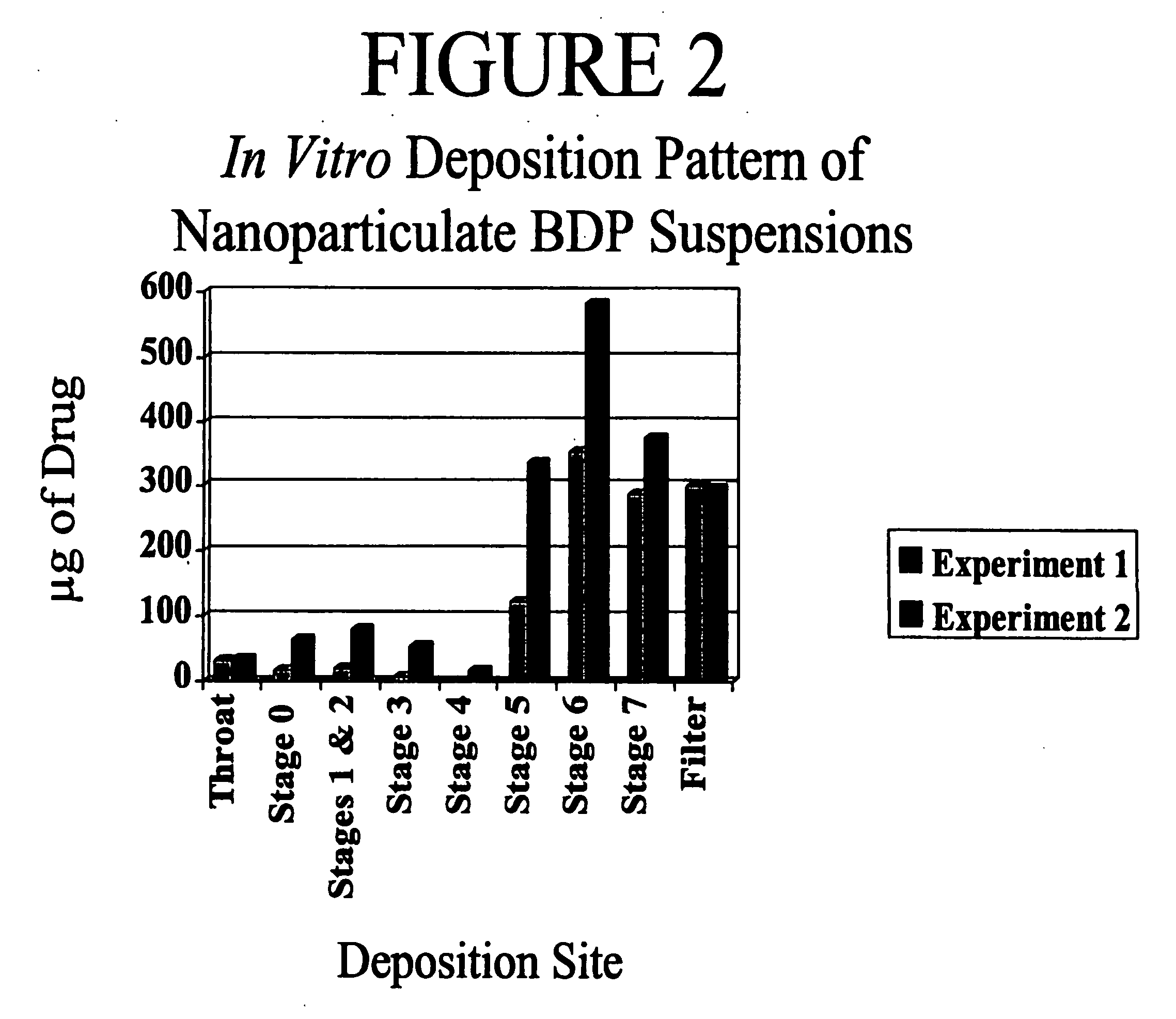

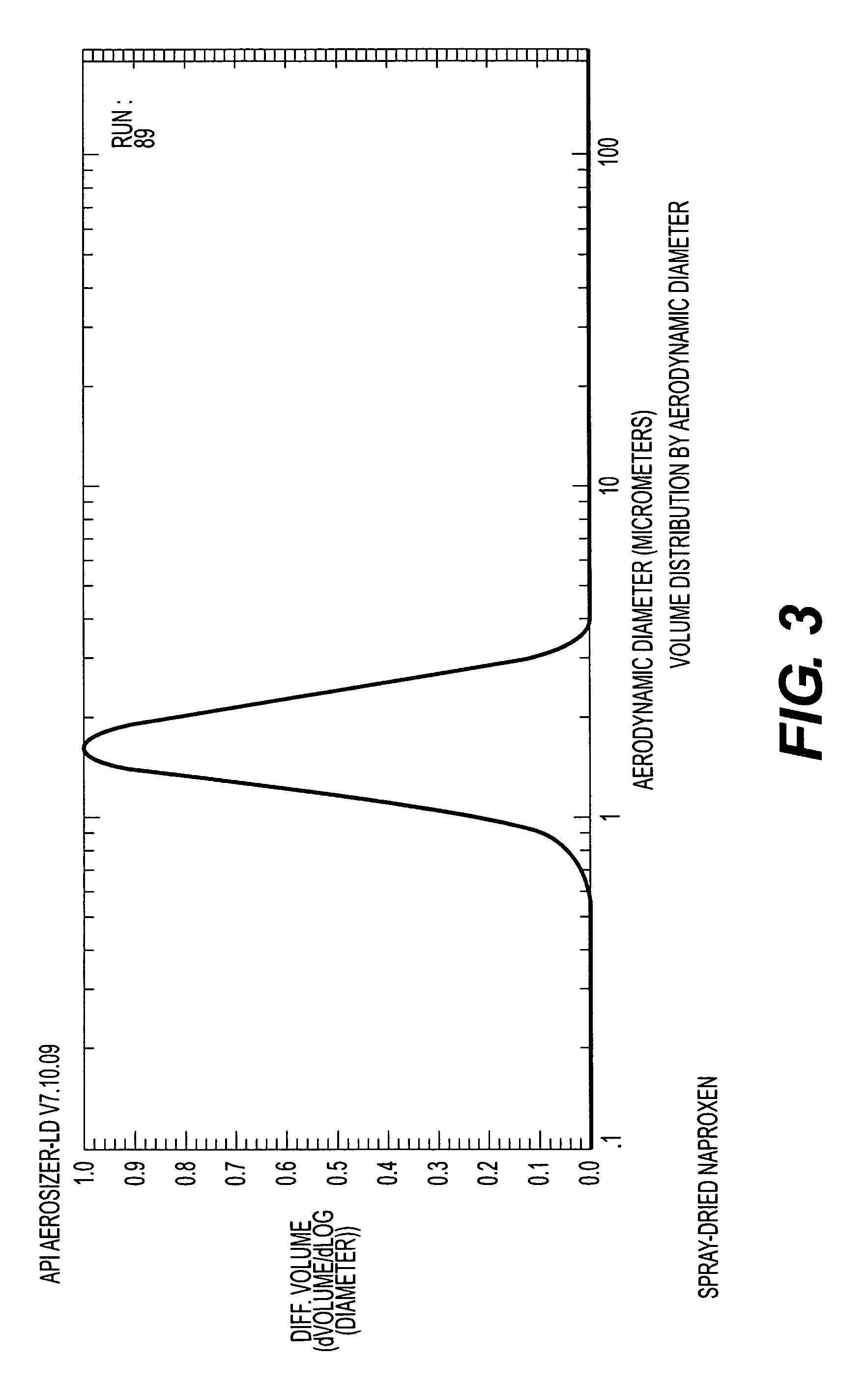

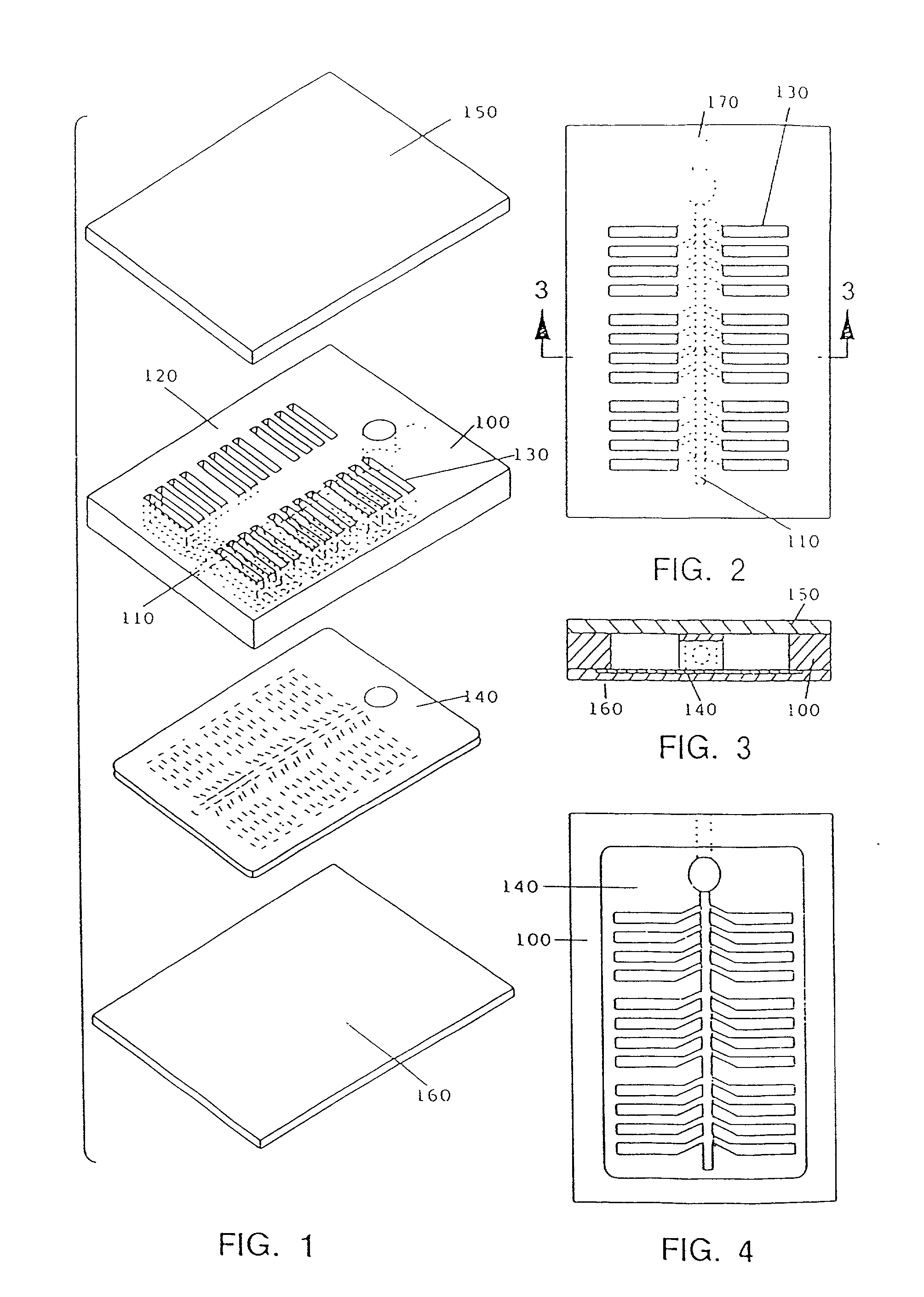

Dry powder aerosols of nanoparticulate drugs

InactiveUS7521068B2Permit deliveryEasy to atomizeAntibacterial agentsOrganic active ingredientsNanoparticleAerosol delivery

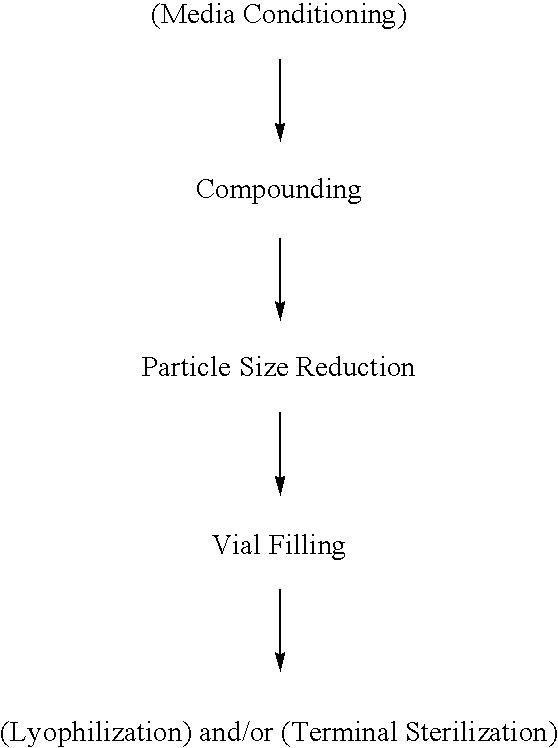

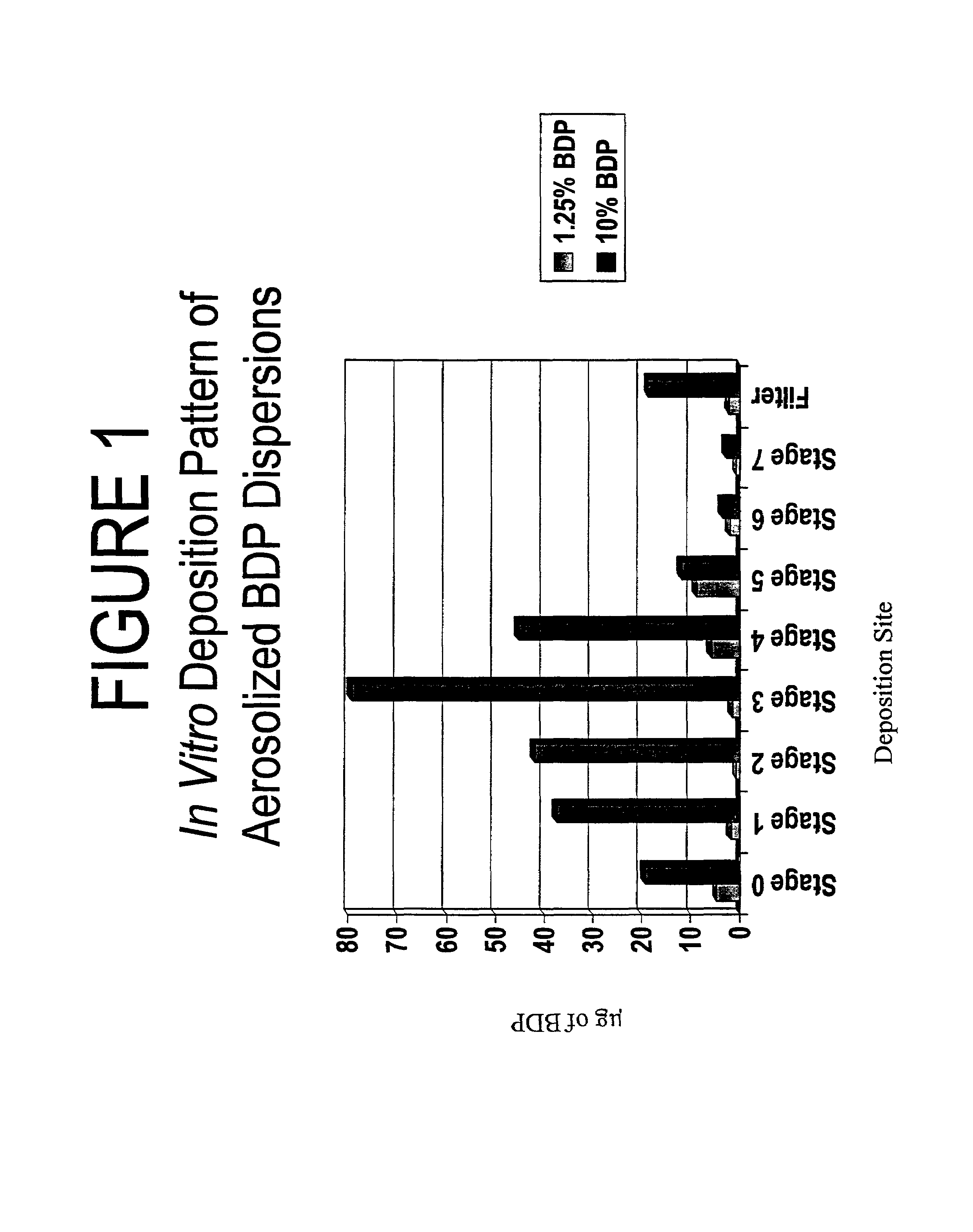

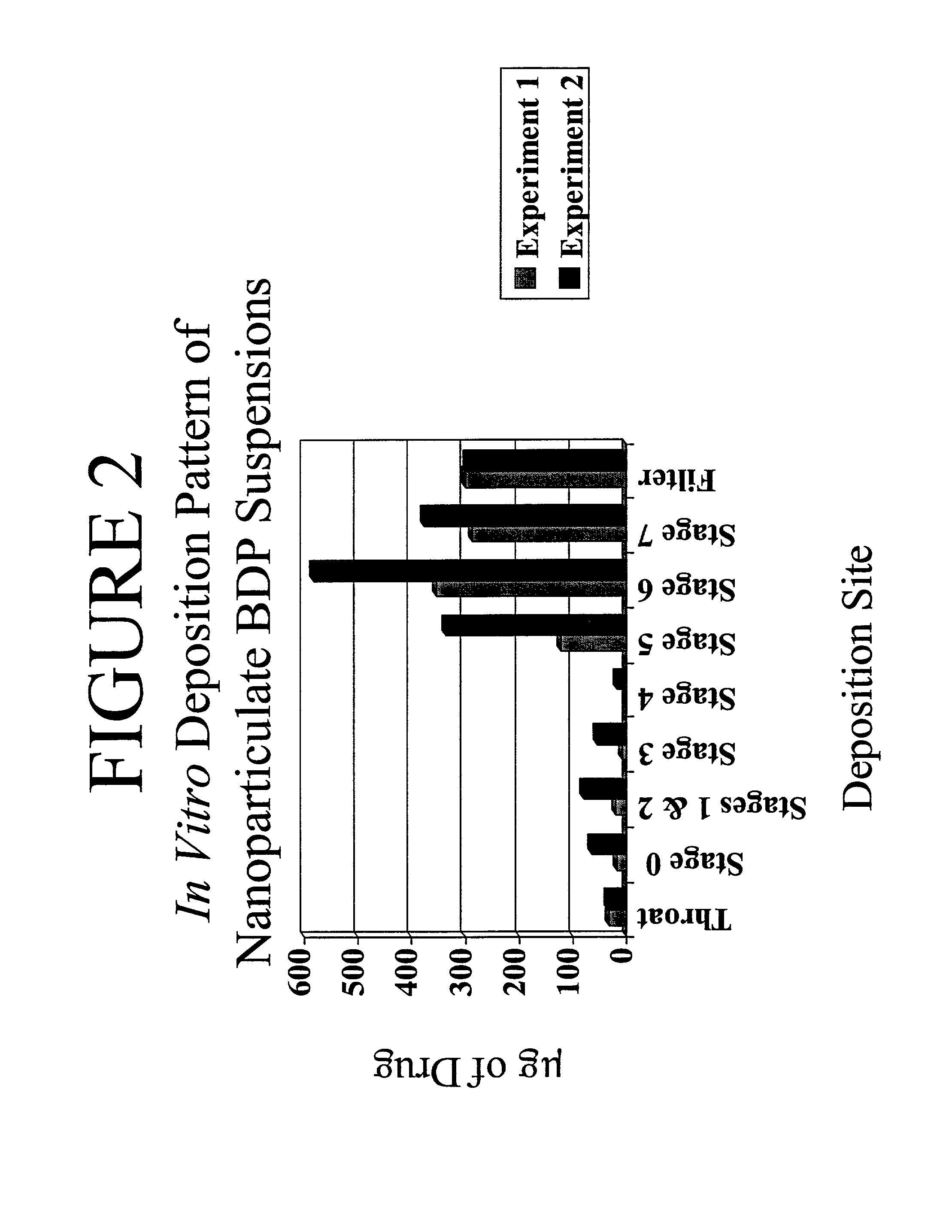

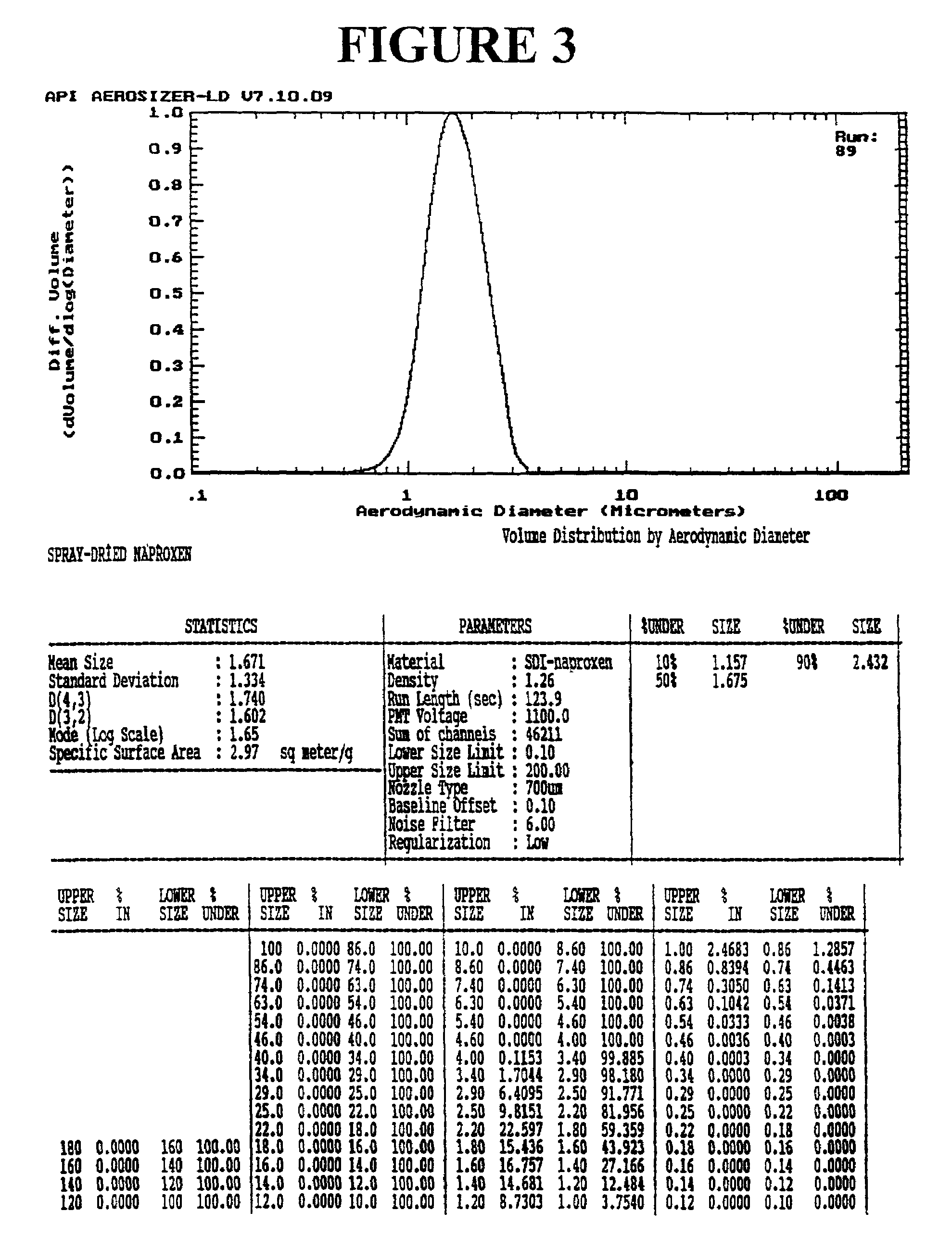

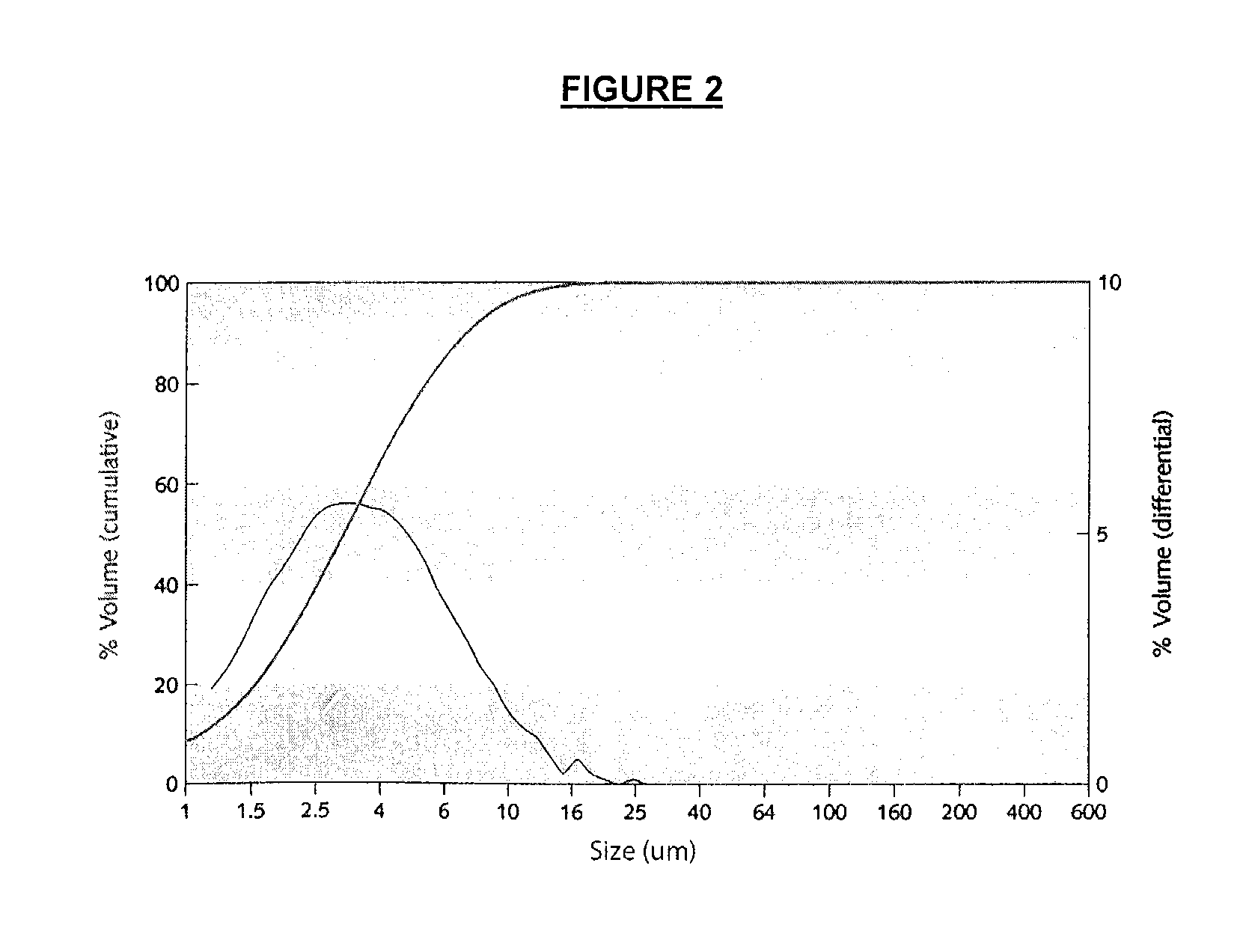

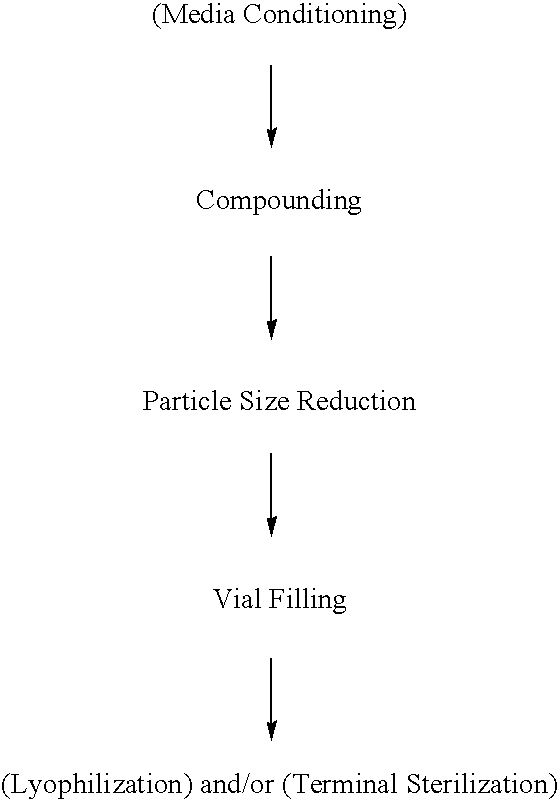

There invention discloses aqueous dispersions of nanoparticulate aerosol formulations, dry powder nanoparticulate aerosol formulation, propellant-based aerosol formulations, methods of using the formulations in aerosol delivery devices, and methods of making such formulations. The nanoparticles of the aqueous dispersions or dry powder formulations comprise insoluble drug particles having a surface modifier on the surface thereof.

Owner:ALKERMES PHARMA IRELAND LTD

Pharmaceutical composition comprising propofol

The invention provides novel pharmaceutical compositions comprising the active ingredient propofol. Preferably, propofol is dissolved in at least one semifluorinated alkane. The compositions, which are preferably liquid or gel-like, may optionally comprise further excipients. They may be used as fill material in capsules, as buccal or nasal sprays, or as aerosols for pulmonary administration. They are particularly useful for the transmucosal administration of propofol.

Owner:NOVALIQ GMBH

Method of producing a nicotine medicament and a medicament made by the method

InactiveUS20120042886A1Efficiently conveyedImprove efficiencyTobacco preparationPowder deliveryNicotineSpray drying

A method of producing a nicotine medicament for use in an inhaler comprises combining nicotine, a non-spheronized sugar and a liquid carrier including water to produce a flowable mixture and spray drying the flowable mixture at conditions to produce particles of the nicotine medicament suitable for delivery to the alveoli and lower airways of the person. Also disclosed is a nicotine medicament made by the method. The nicotine composition produced by this method is a composite particle suitable for tobacco replacement or withdrawal therapy.

Owner:SANSA BARBADOS

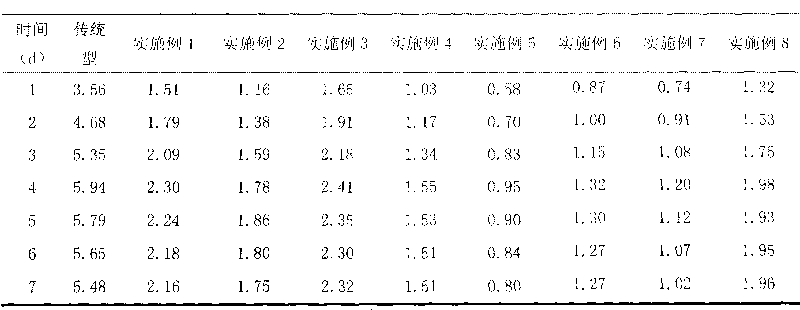

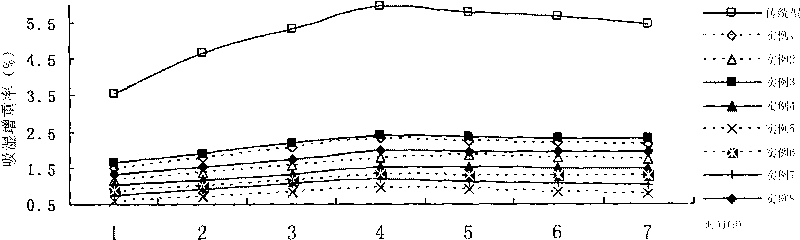

Bait added with vegetable fiber and preparation method thereof

The invention relates to bait added with vegetable fiber and a preparation method thereof. The bait added with vegetable fiber comprises the raw materials of traditional bait and vegetable fiber. The traditional bait consists of raw materials and additives, wherein the raw materials comprise seeds, bran, dregs and animal proteins; and the additives comprise oxidants, mildew preventives, adhesives, coloring agents, flavoring agents and food attractants. The plant fiber is a mixture containing one or two of wood fiber and grass fiber. The wood fiber and the grass fiber can be uniformly distributed in the fishing bait, can achieve the effects of connection, cracking resistance, strength enhancing and bait atomizing improvement, and does not cause environmental pollution; and the bait is ideal for fishermen.

Owner:刘桂雨

Aerosol and injectable formulations of nanoparticulate benzodiazepine

InactiveUS20090304801A1Easy to atomizeFacilitate depositionPowder deliveryBiocideBenzodiazepineNanoparticle

Described are nanoparticulate formulations of a benzodiazepine, such as lorazepam, that does not require the presence of polyethylene glycol and propylene glycol as stabilizers, and methods of making and using such formulations. The formulations are particularly useful in aerosol and injectable dosage forms, and comprise nanoparticulate benzodiazepine, such as lorazepam, and at least one surface stabilizer. The formulations are useful in the treatment of status epilepticus, treatment of irritable bowel syndrome, sleep induction, acute psychosis, and as a pre-anesthesia medication.

Owner:ELAN PHRMA INT LTD

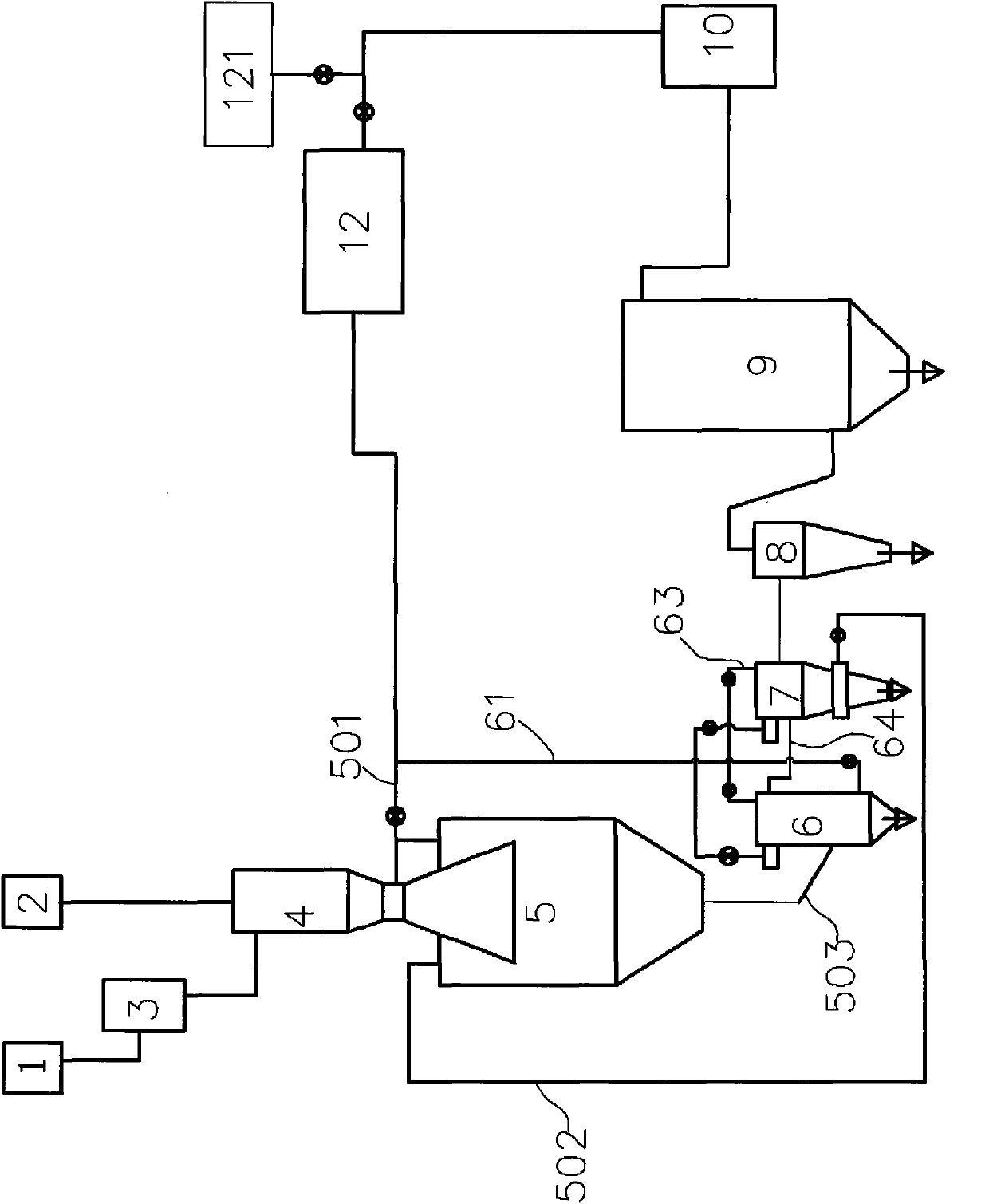

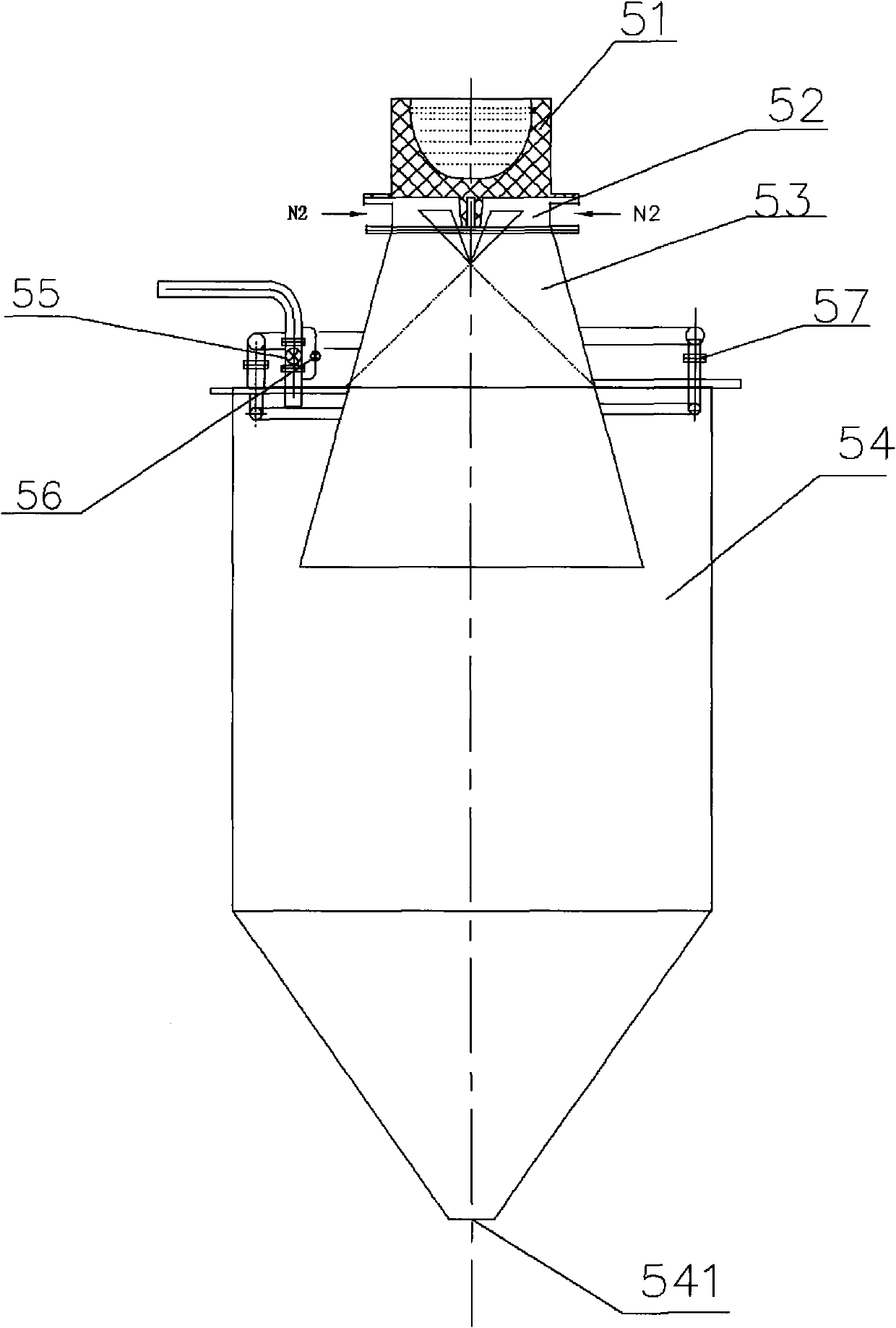

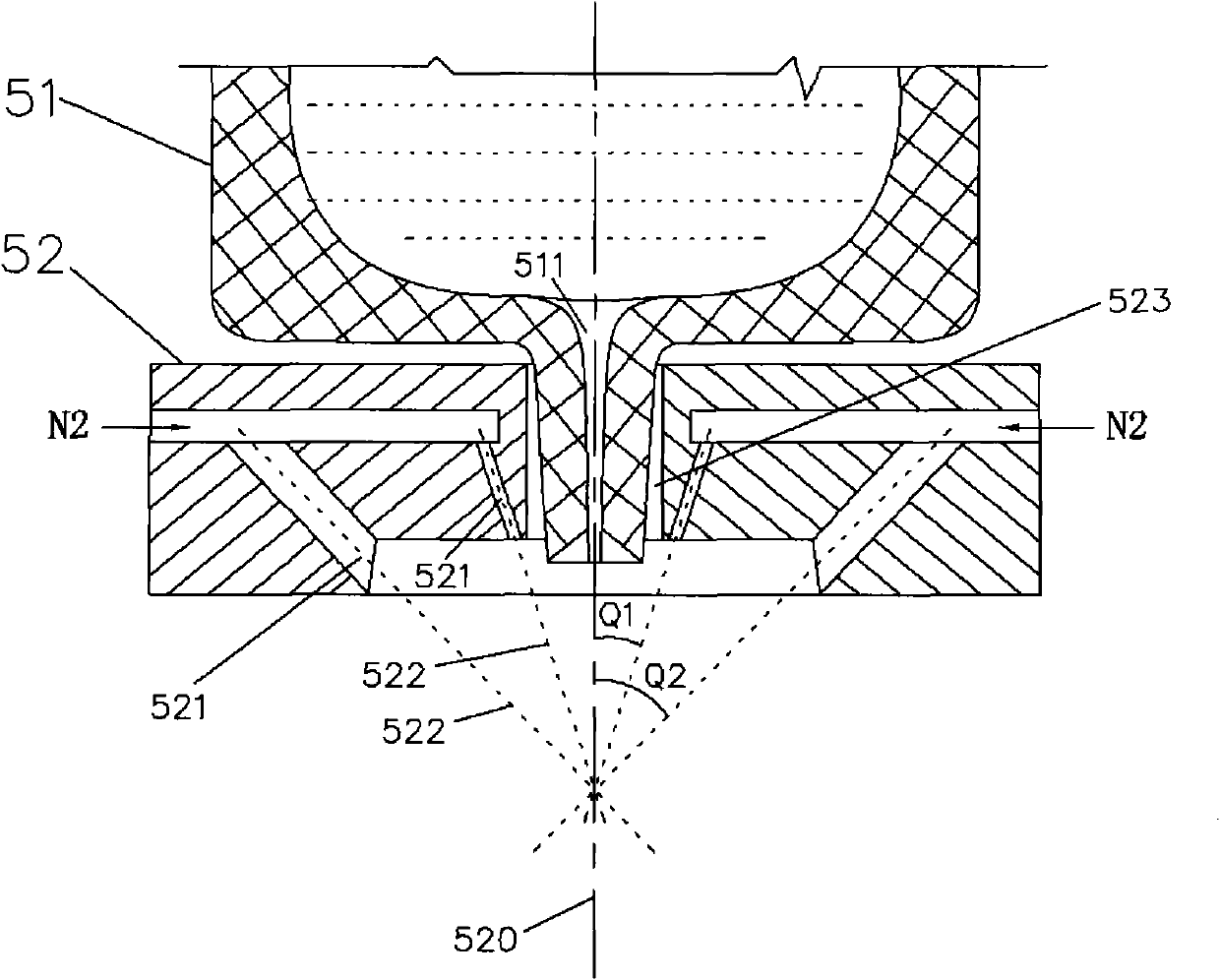

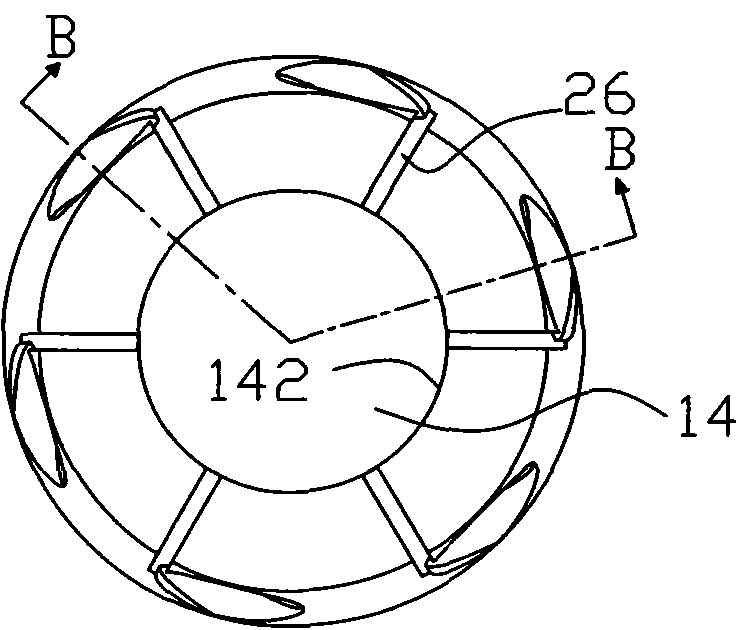

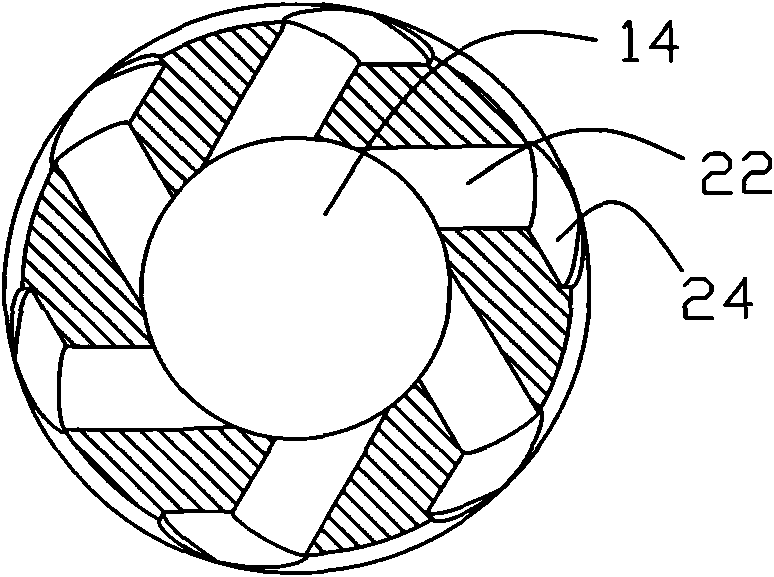

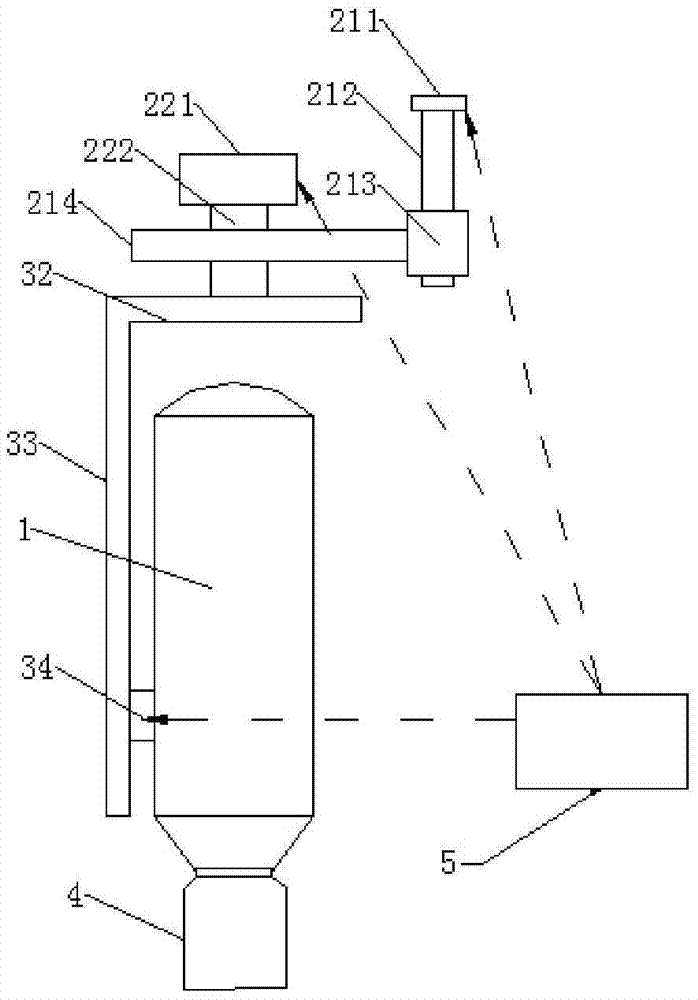

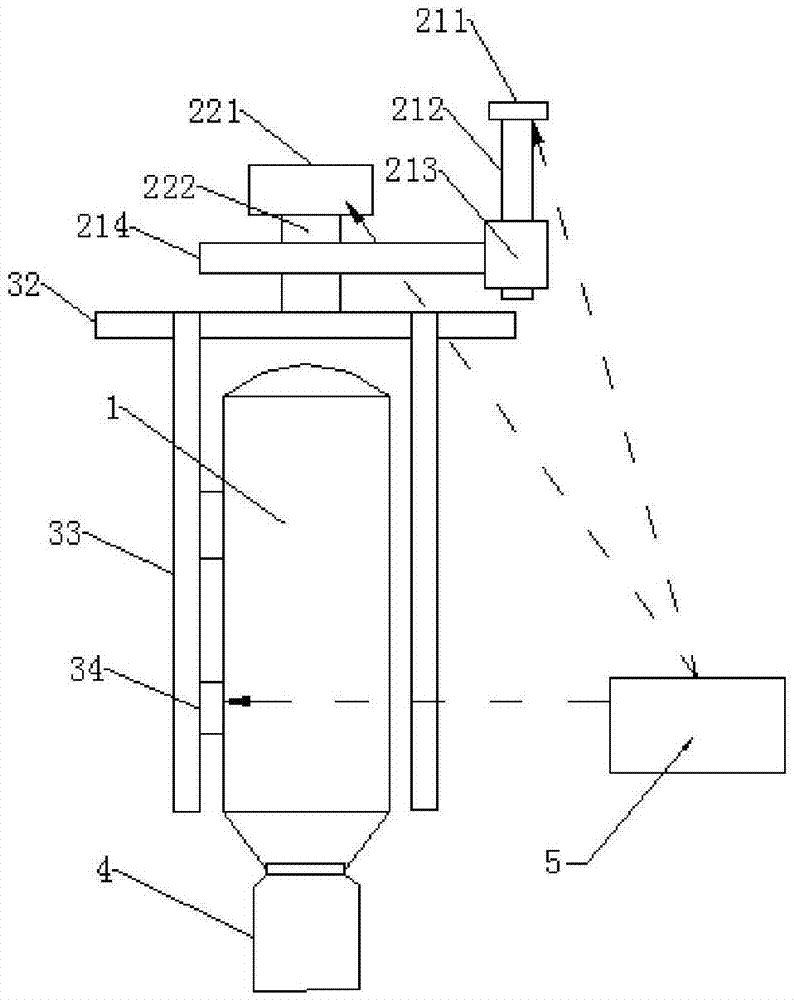

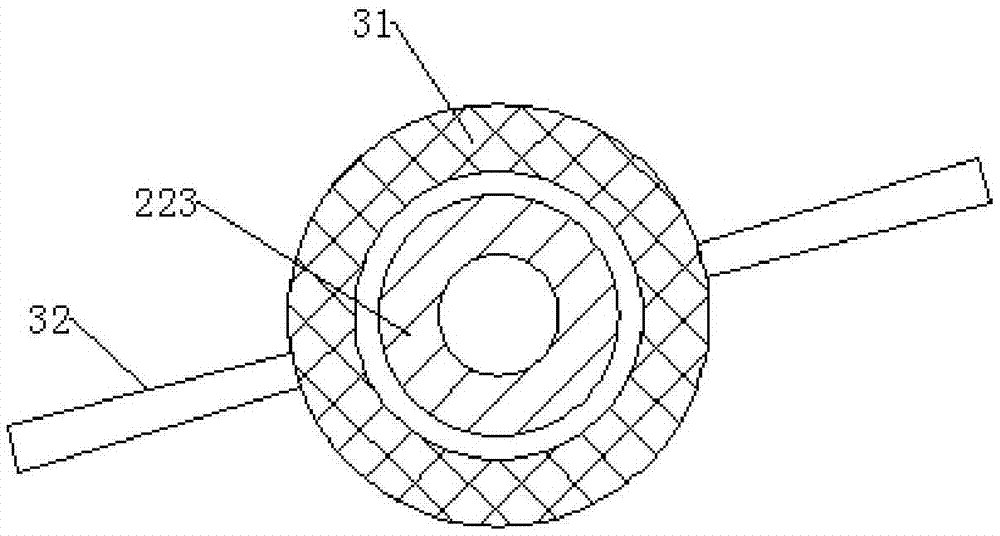

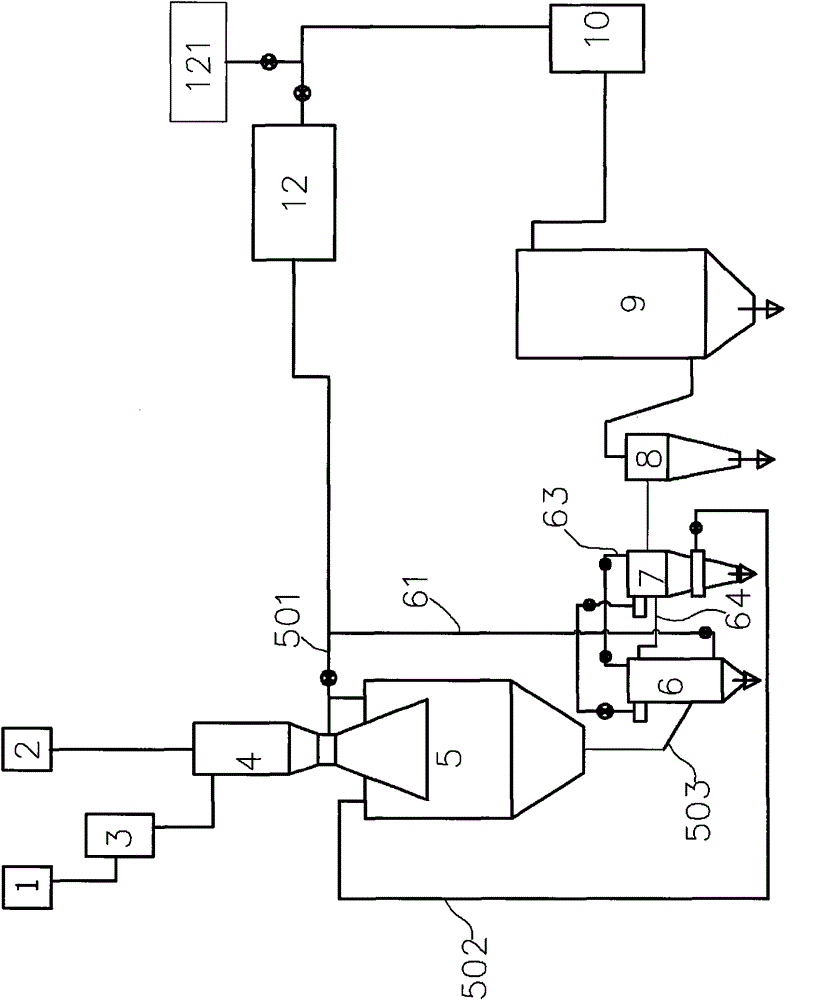

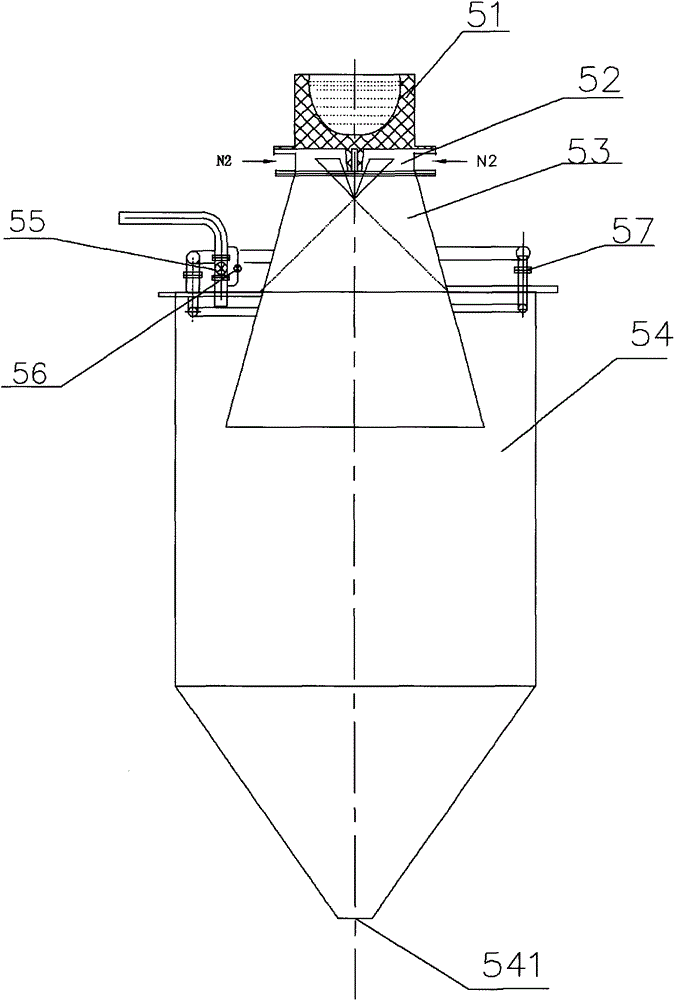

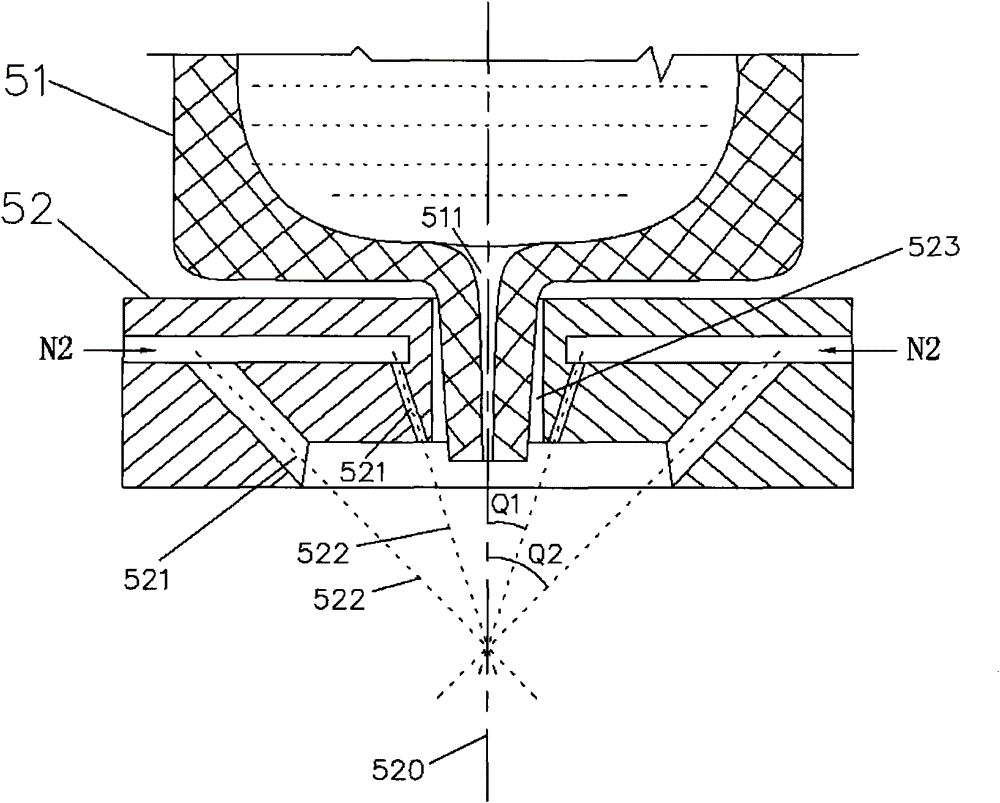

Metal ultrafine atomizing, crushing and grading system and metal atomizing device thereof

The invention provides a metal ultrafine atomizing, crushing and grading system, comprising a metal smelting furnace, a metal hydrogen-discharging and heating furnace, a metal atomizing device, a fluidized bed depolymerization grader, a second precise grader, at least one collector, a filter and a compressor. The invention also provides a metal atomizing device, comprising a crucible, a spray disc, a spray cover and a cylindrical spray cylinder, wherein a circle of evenly distributed inclined holes is respectively arranged on at least two circumferences with different diameters of the spray disc; each inclined hole is provided with a Laval nozzle; and the extension line of each Laval nozzle is intersected with the central axis of the spray disc at the same point. Through the airflow with ultrasonic velocity, ultralow temperature and large velocity pressure generated by the nozzle in the metal atomizing device, the liquid metal or alloy is directly crushed, or rapidly cooled into atomized powder and then depolymerized by a fluidized bed and precisely graded by the precise grader to obtain metal fine powder and ultrafine powder with finer granularity, more even granularity and better granularity sphericity.

Owner:宁波中物力拓超微材料有限公司

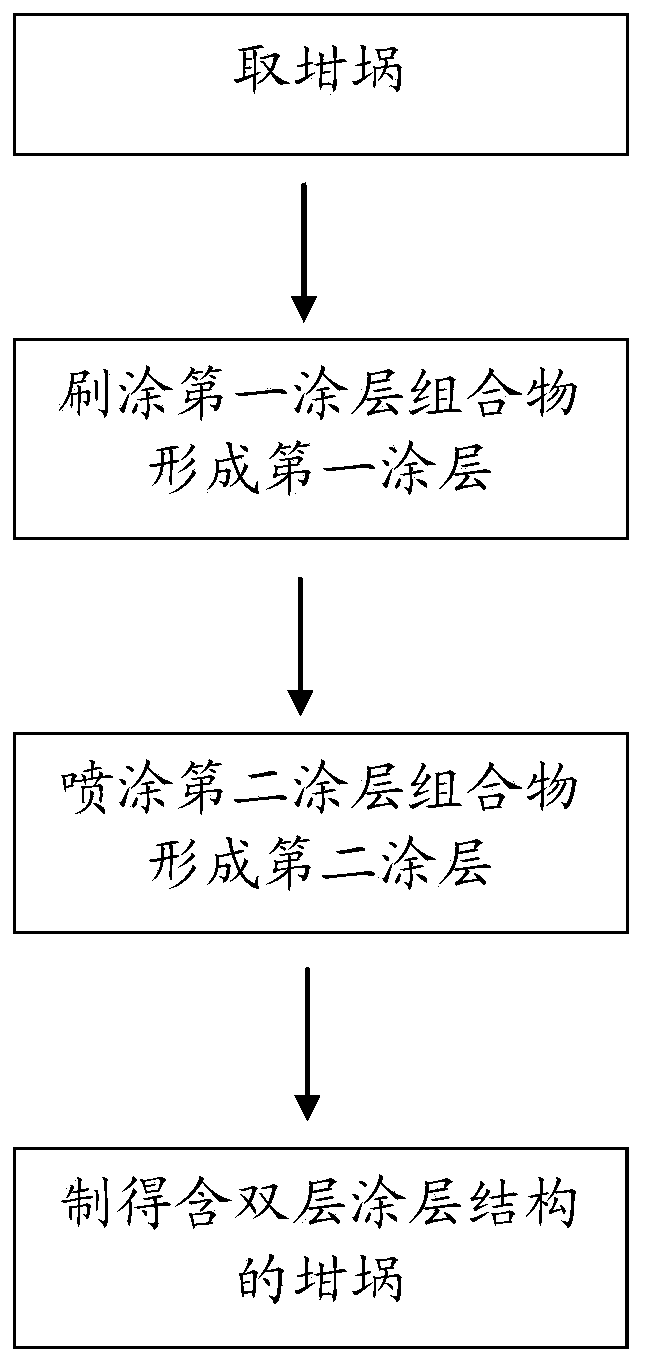

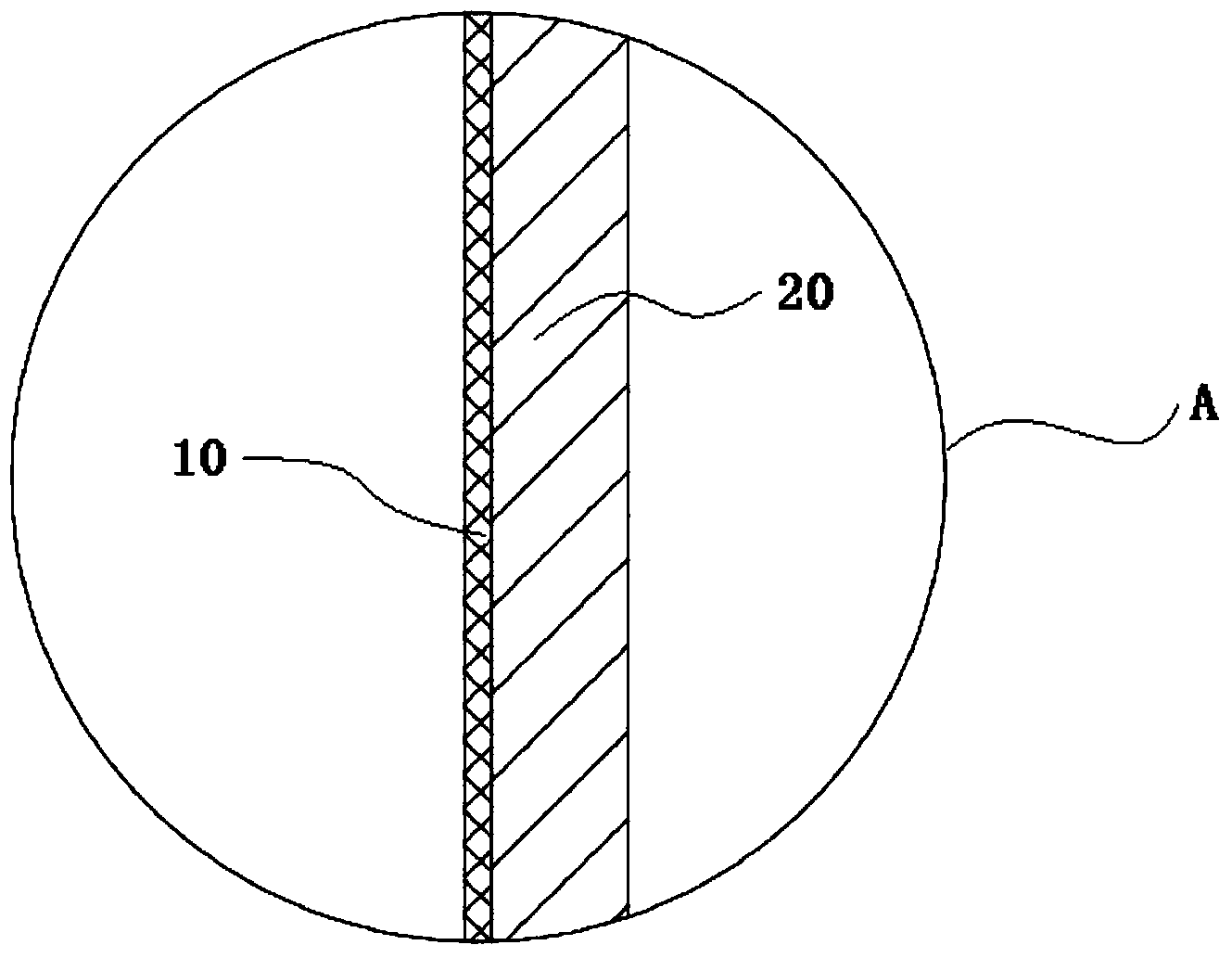

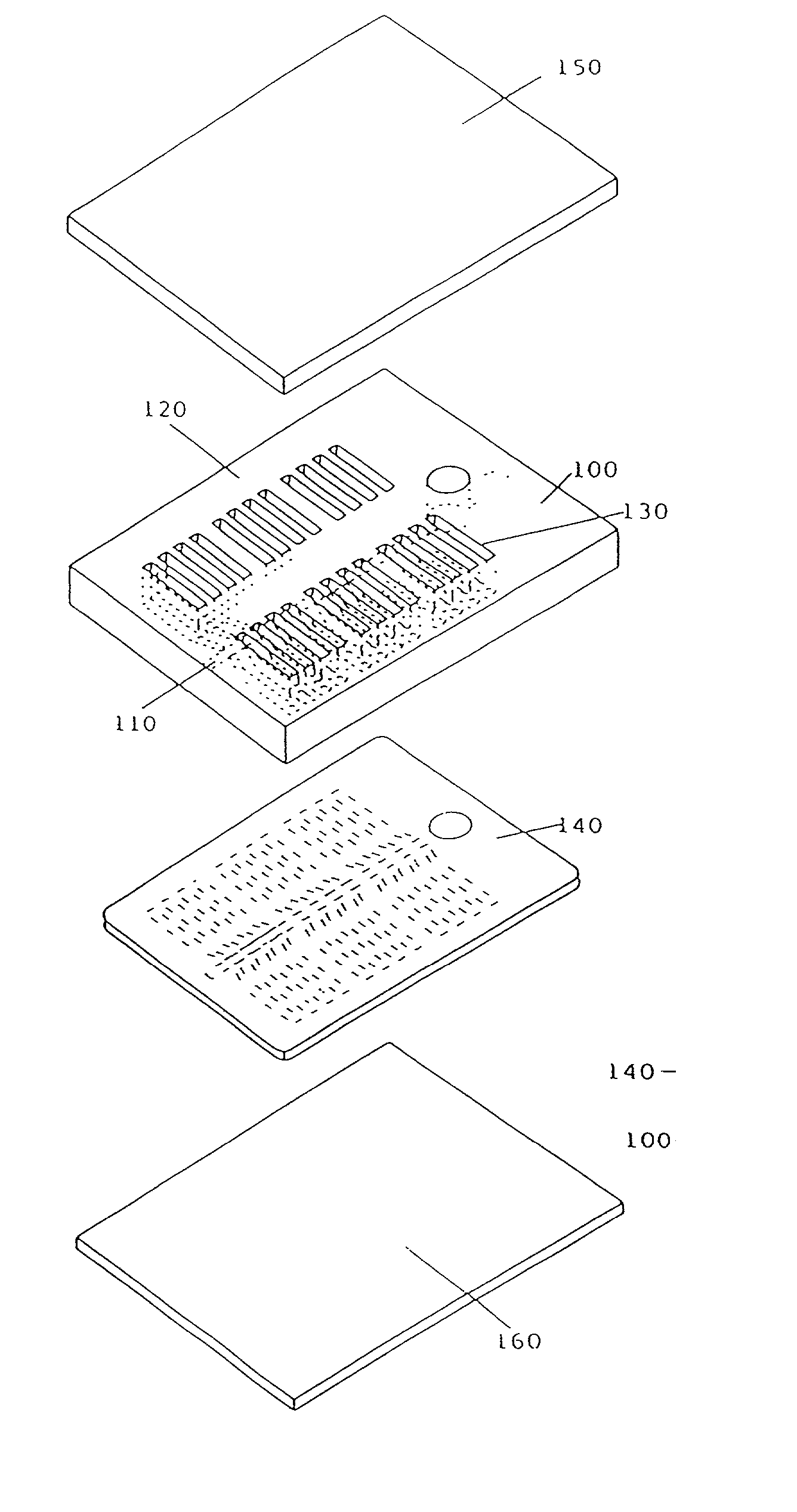

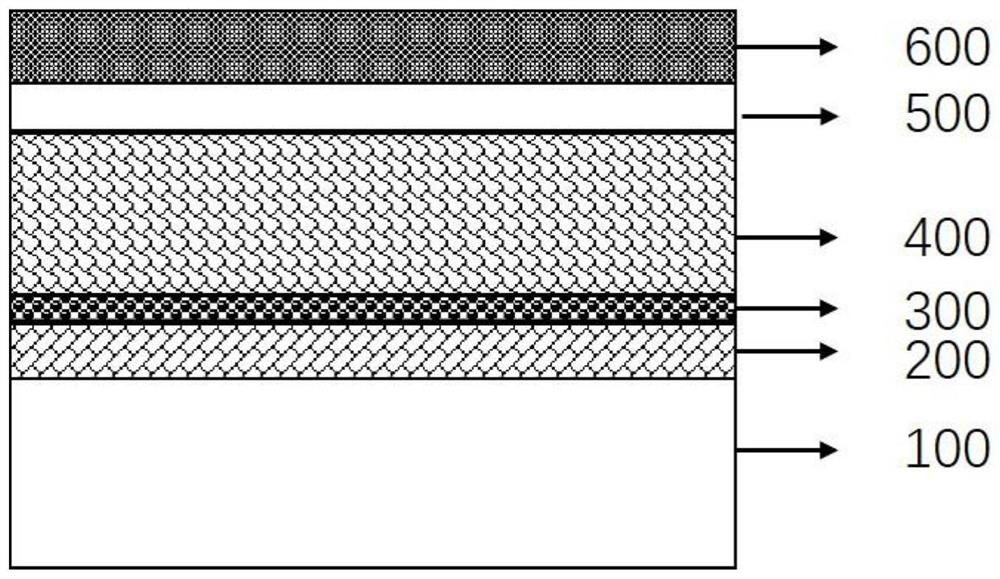

Crucible for polysilicon ingot casting, coating structure of crucible and coating preparation method

InactiveCN104109902AImprove bindingNot easy to fall offPolycrystalline material growthSingle crystal growth detailsCrucibleIngot casting

The invention provides a crucible for polysilicon ingot casting, a coating structure of the crucible and a coating preparation method. The coating structure of the crucible for polysilicon ingot casting comprises a first coating arranged on the inner side wall of the crucible and a second coating arranged on the first coating. The first coating is formed from a first coating composition by brush coating. The first coating composition comprises silicon nitride and a solvent. The second coating is formed from a second coating composition by spray coating. The second coating composition comprises silicon nitride and a solvent. The coating structure of the crucible for polysilicon ingot casting has uniform thickness, does not crack easily, has high bonding force to the inner wall of the quartz ceramic crucible, and strong bonding force between silicon nitride particles, does not spall easily in an ingot casting technology and has a low rate of adhesion to the crucible.

Owner:JIANGXI SAI WEI LDK SOLAR HI TECH CO LTD

Film-coating premixing auxiliary material and preparation method thereof

ActiveCN101691429AGood dispersionGood flexibilityPharmaceutical delivery mechanismMethacrylic acid-ethyl acrylate copolymerPolyethylene glycol

The invention relates to a film-coating premixing auxiliary material which mainly comprises hydroxypropyl methylcellulose, polyvinylpyrrolidone-vinyl acetate copolymer (6:4), polyvinyl alcohol-polyethylene glycol copolymer, methacrylic acid-ethyl acrylate copolymer (1:1), polyethylene glycol, talcum powder and a colorant. The film-coating premixing auxiliary material has the advantages of favorable dampproof and anti-cracking properties, can disintegrate at a suitable time and uses water as dissolvent.

Owner:浙江瓯伦包衣技术有限公司

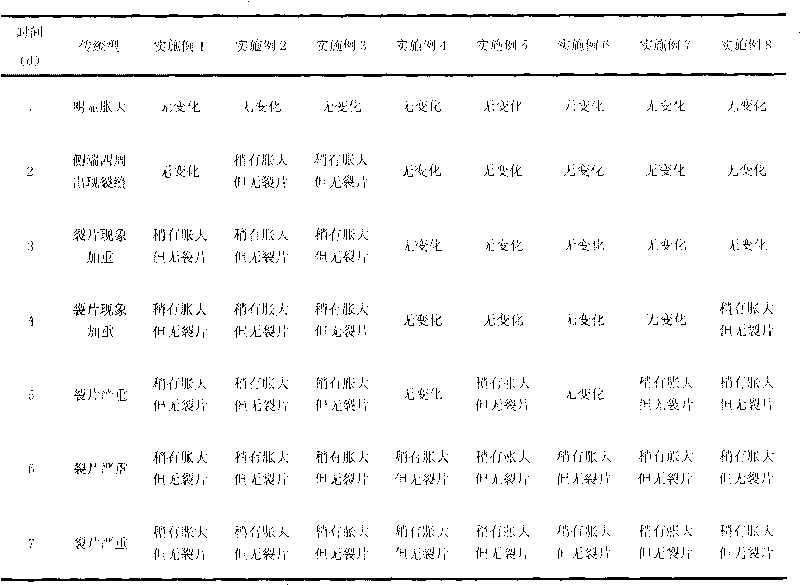

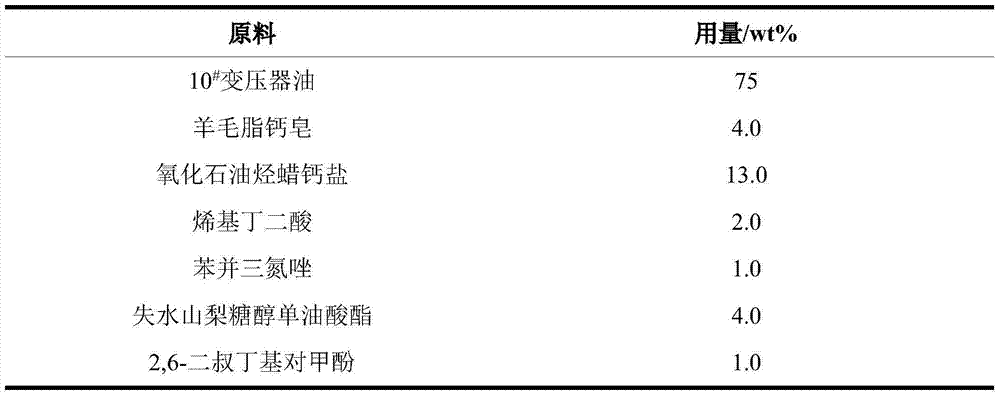

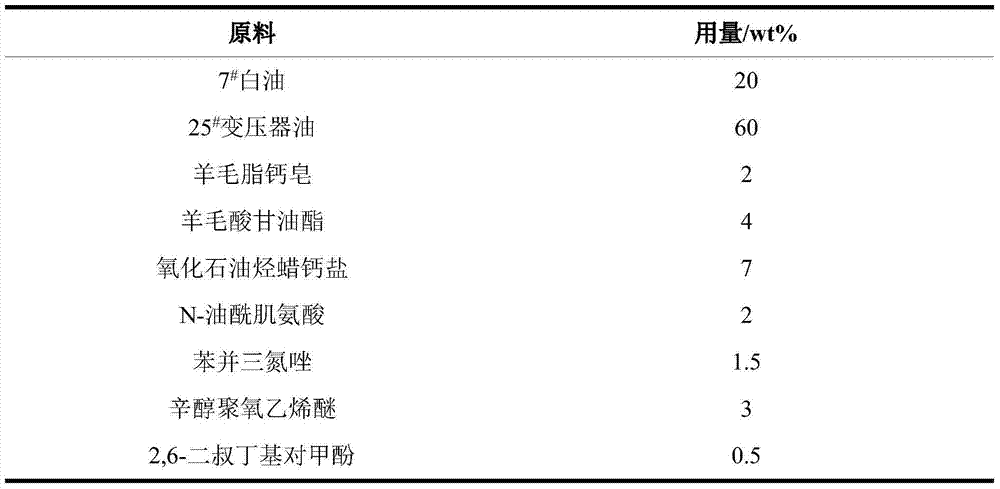

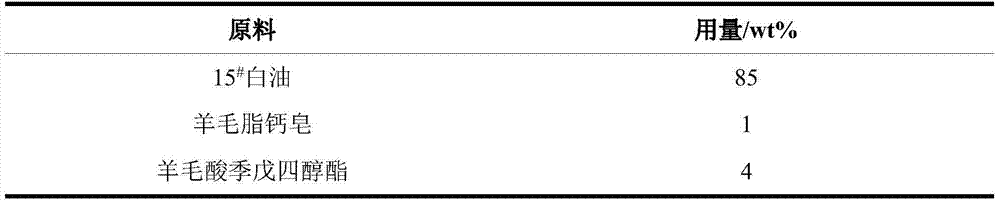

Environment-friendly electrostatic spraying antirust oil and preparation method thereof

The invention discloses an environment-friendly electrostatic spraying antirust oil which is prepared from the following raw materials in percentage by mass: 70.0-90.0% of base oil, 5.0-25.0% of rust inhibitor, 1.0-5.0% of surfactant and 0.5-5.0% of antioxidant. The preparation method of the environment-friendly electrostatic spraying antirust oil comprises the following steps: mixing the measured base oil, rust inhibitor, surfactant and antioxidant, heating, and stirring uniformly to obtain the environment-friendly electrostatic spraying antirust oil. The antirust oil has the advantages of higher breakdown voltage, high safety, high atomization tendency of the oil product and low viscosity, and is convenient for cleaning; and the antirust oil can satisfy the requirement for antirust properties and conform to the requirement for environmental protection.

Owner:广州中机实业有限公司 +1

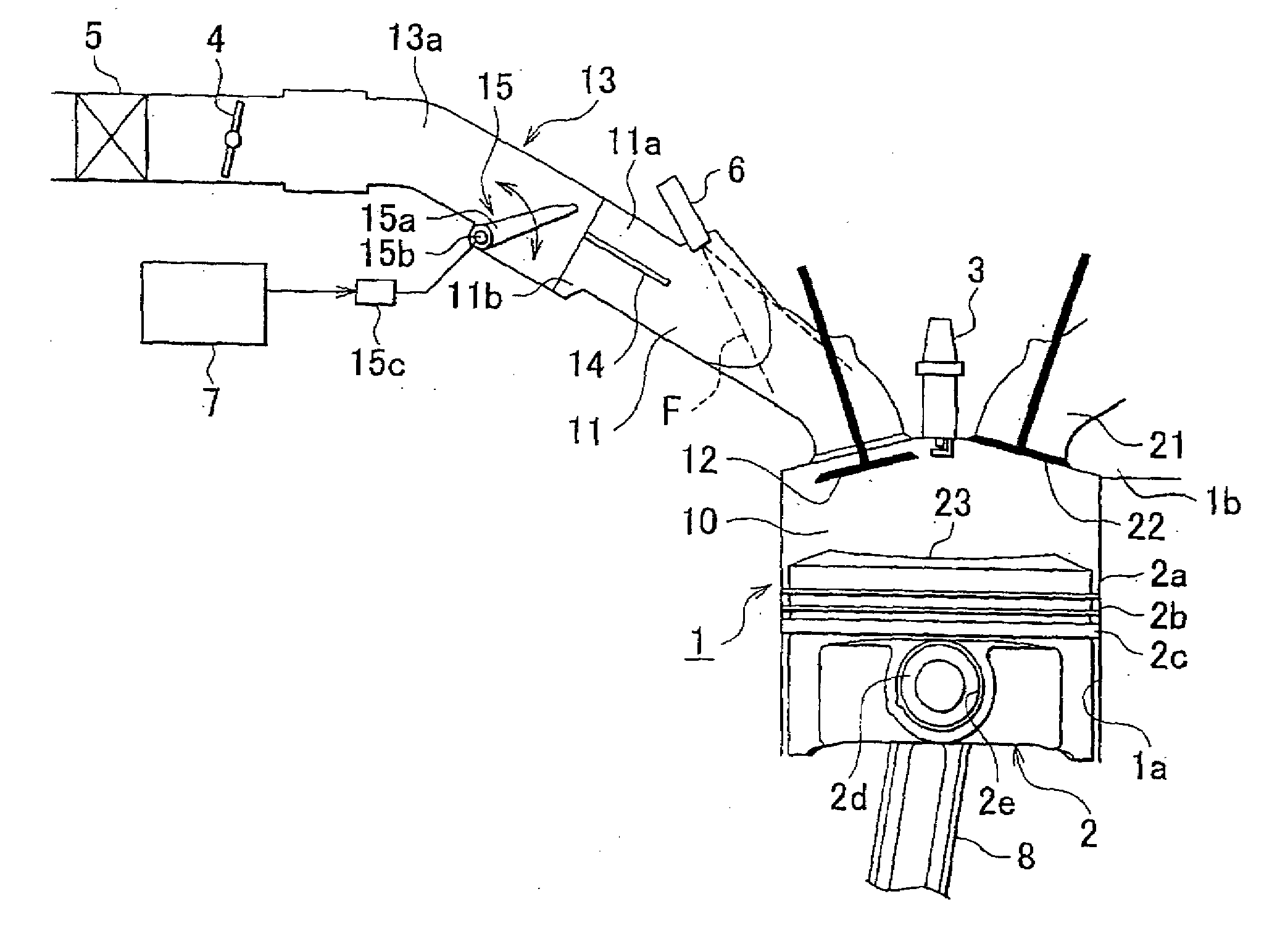

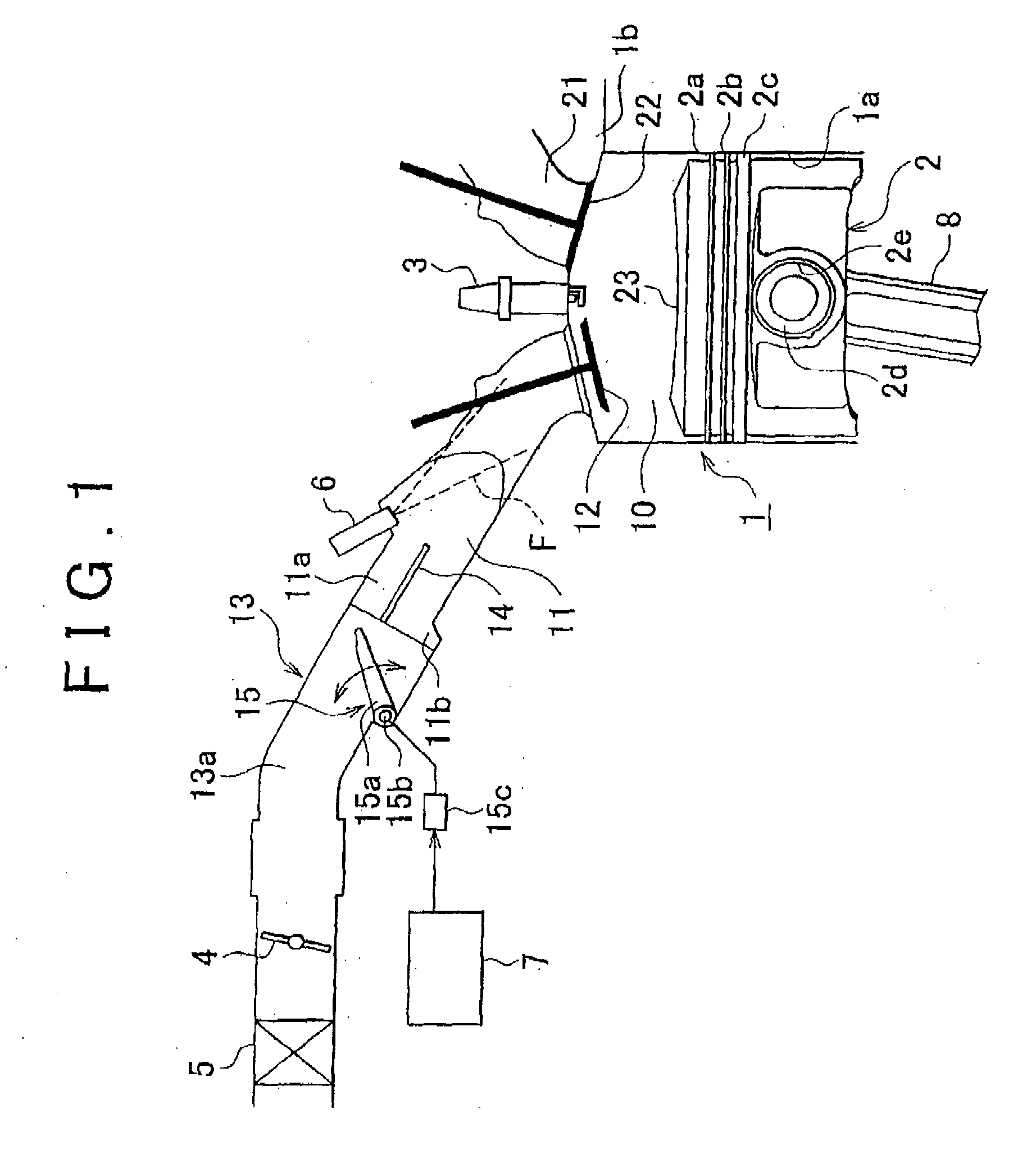

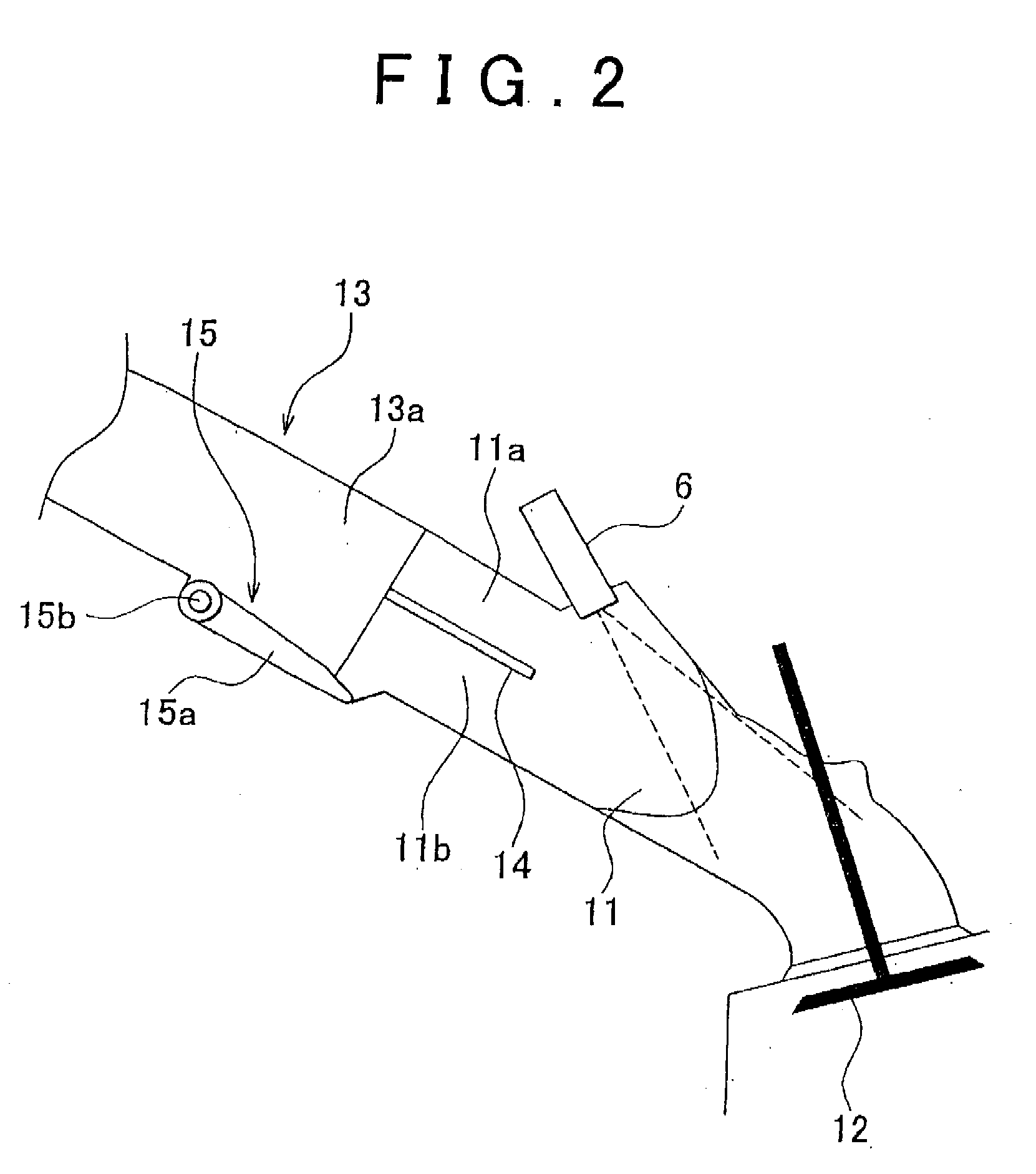

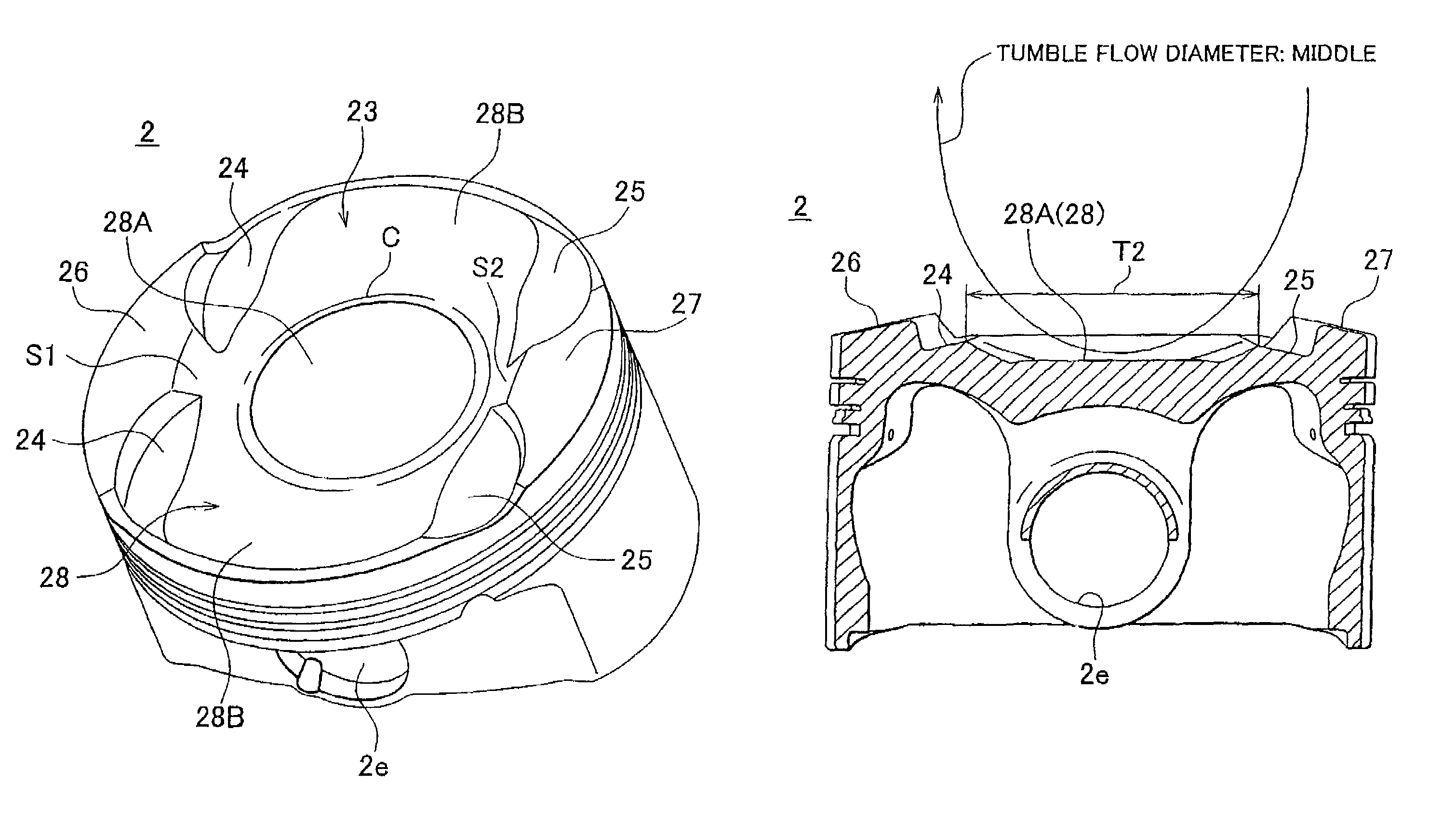

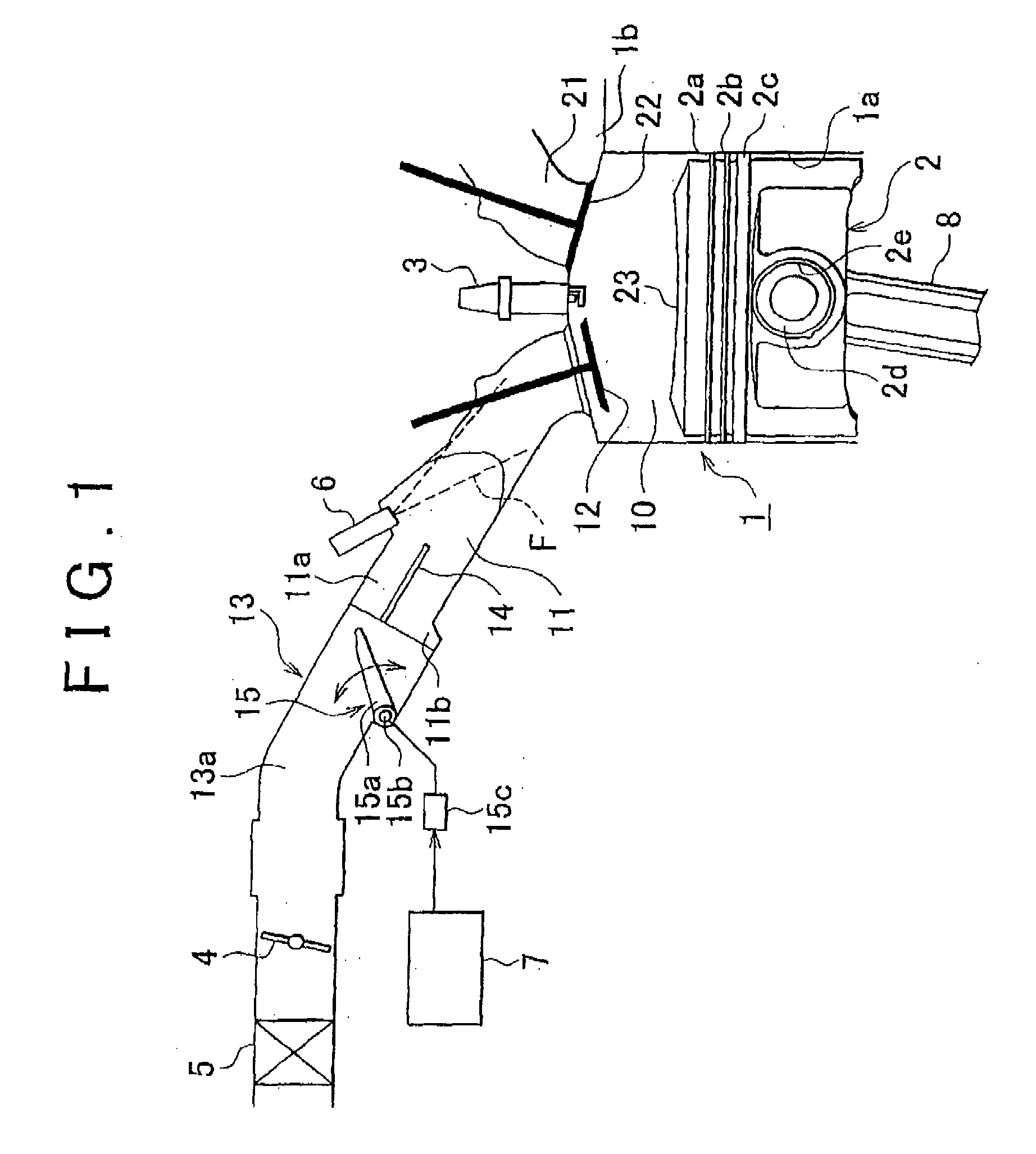

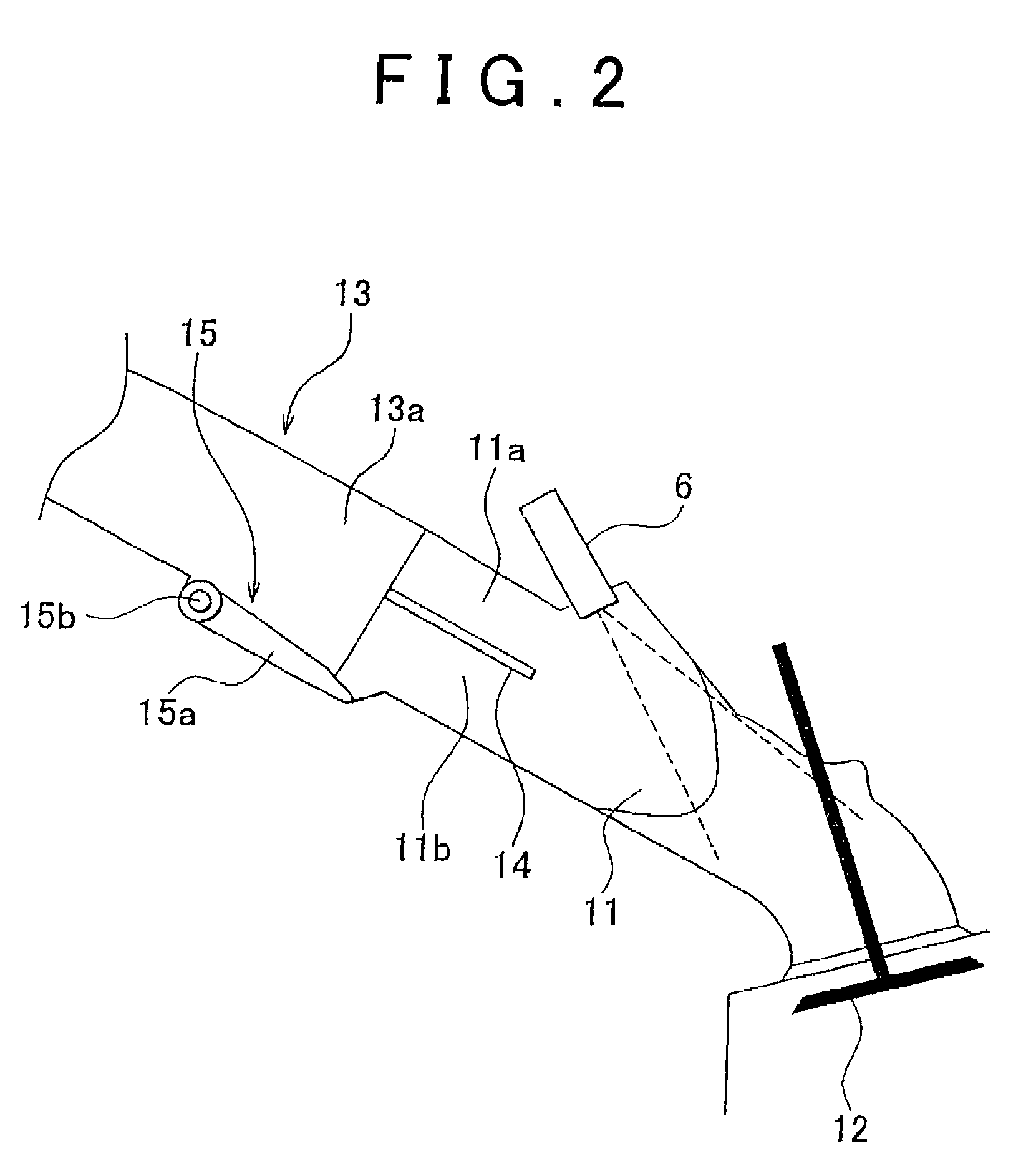

Piston for internal combustion engine, and internal combustion engine using the piston

InactiveUS20100059016A1Promote evaporation and atomization of fuelEasy to evaporateInternal combustion piston enginesCombustion-air/fuel-air treatmentPistonEngineering

A piston top surface (23) has a depression. A center region (28A) is formed at the center of the depression to secure the diameter of a center tumble flow to be large. A side region (28B) is formed on both sides of the piston top surface to generate a side tumble flow that is not influenced by a cylinder bore inner wall and has a flow line generally parallel to that of the center tumble flow.

Owner:TOYOTA JIDOSHA KK

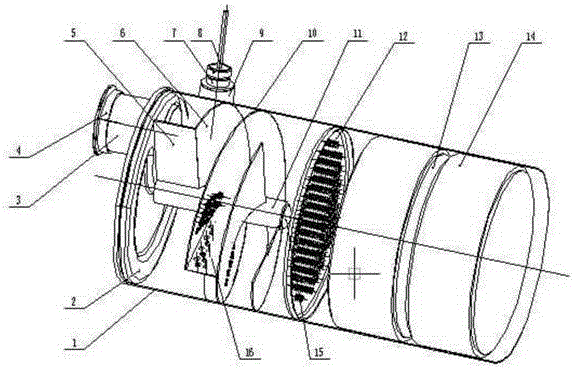

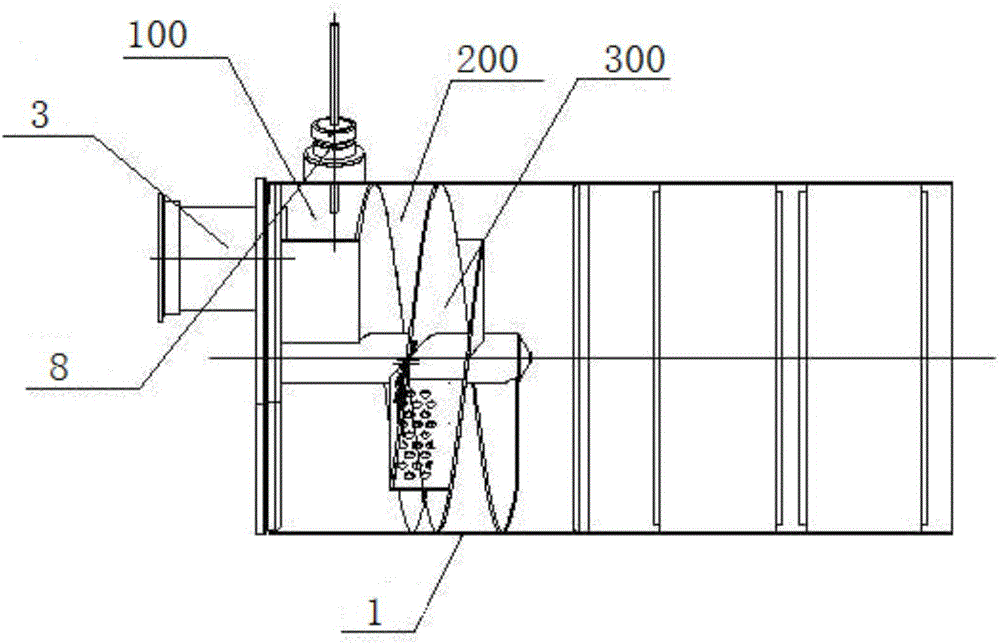

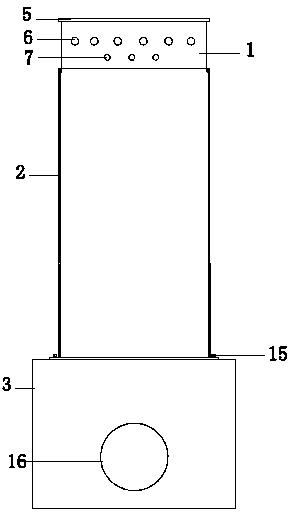

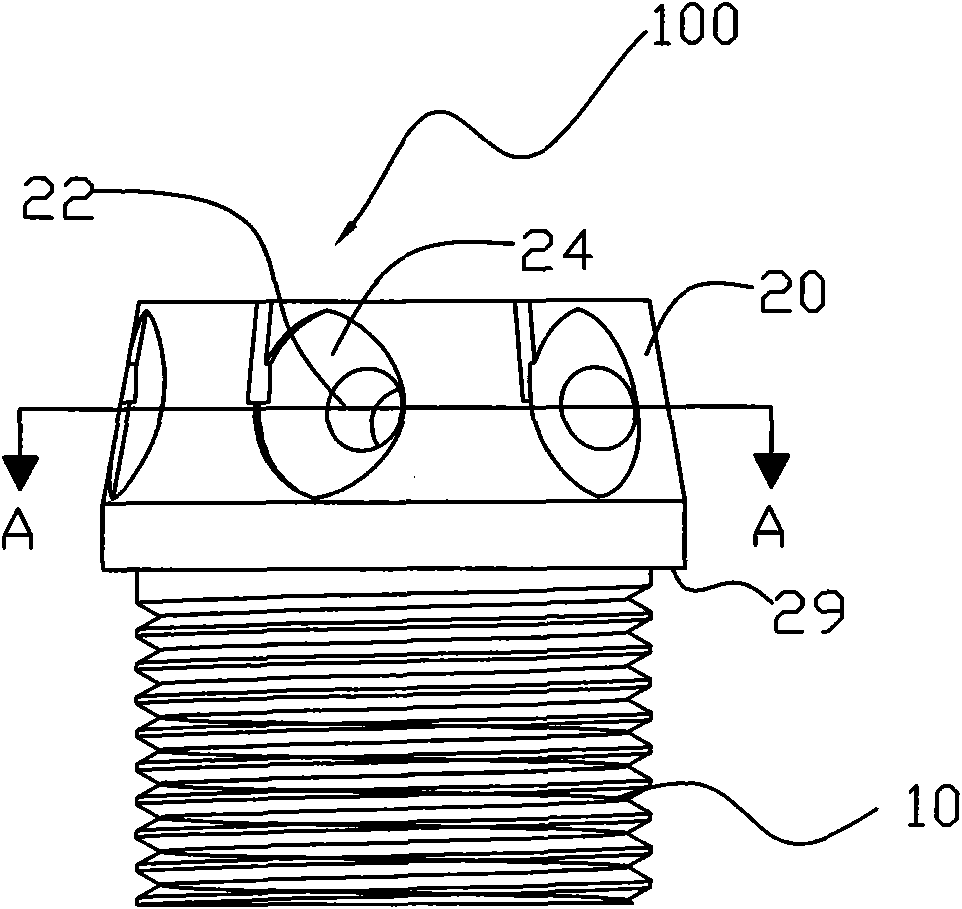

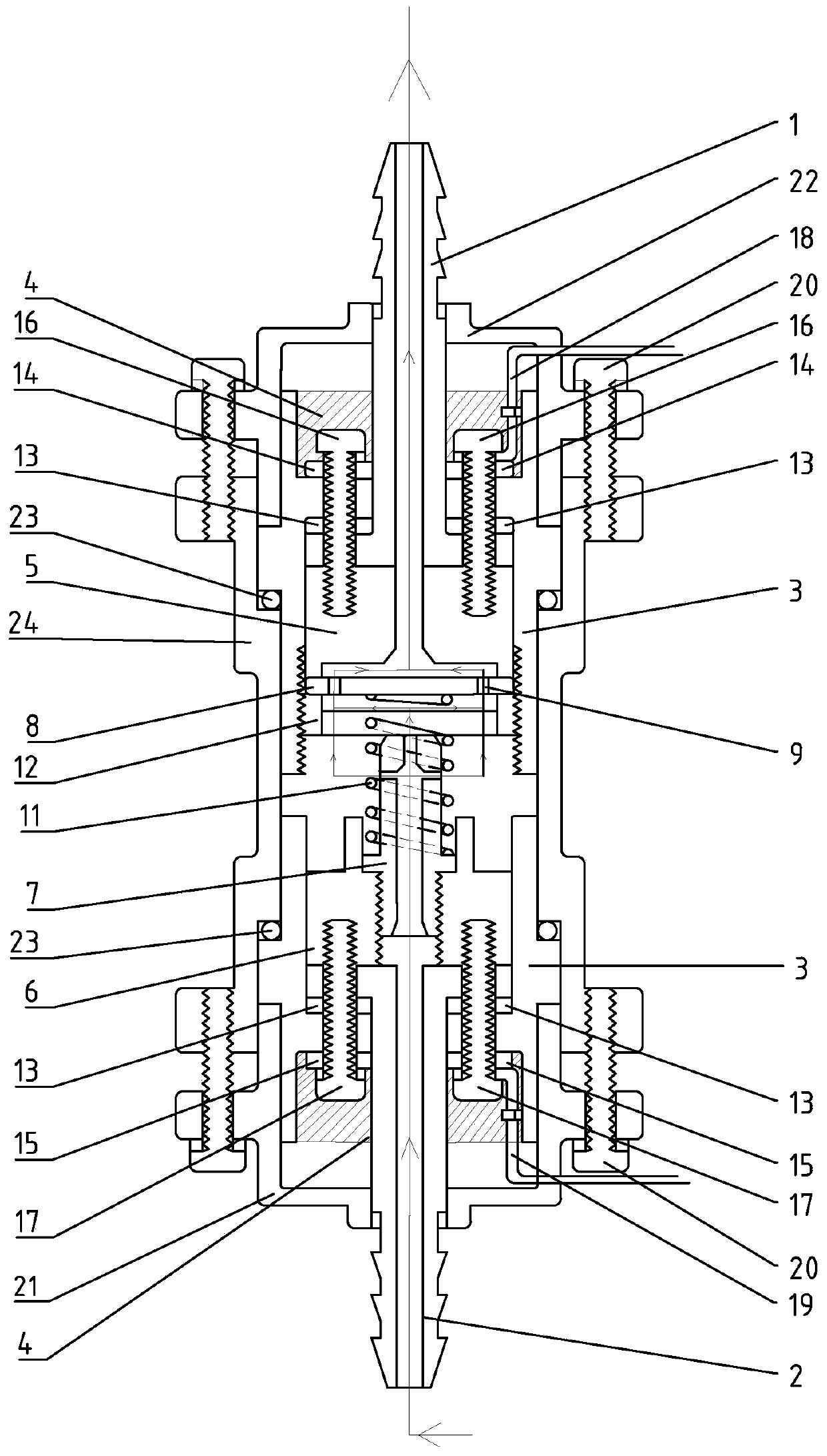

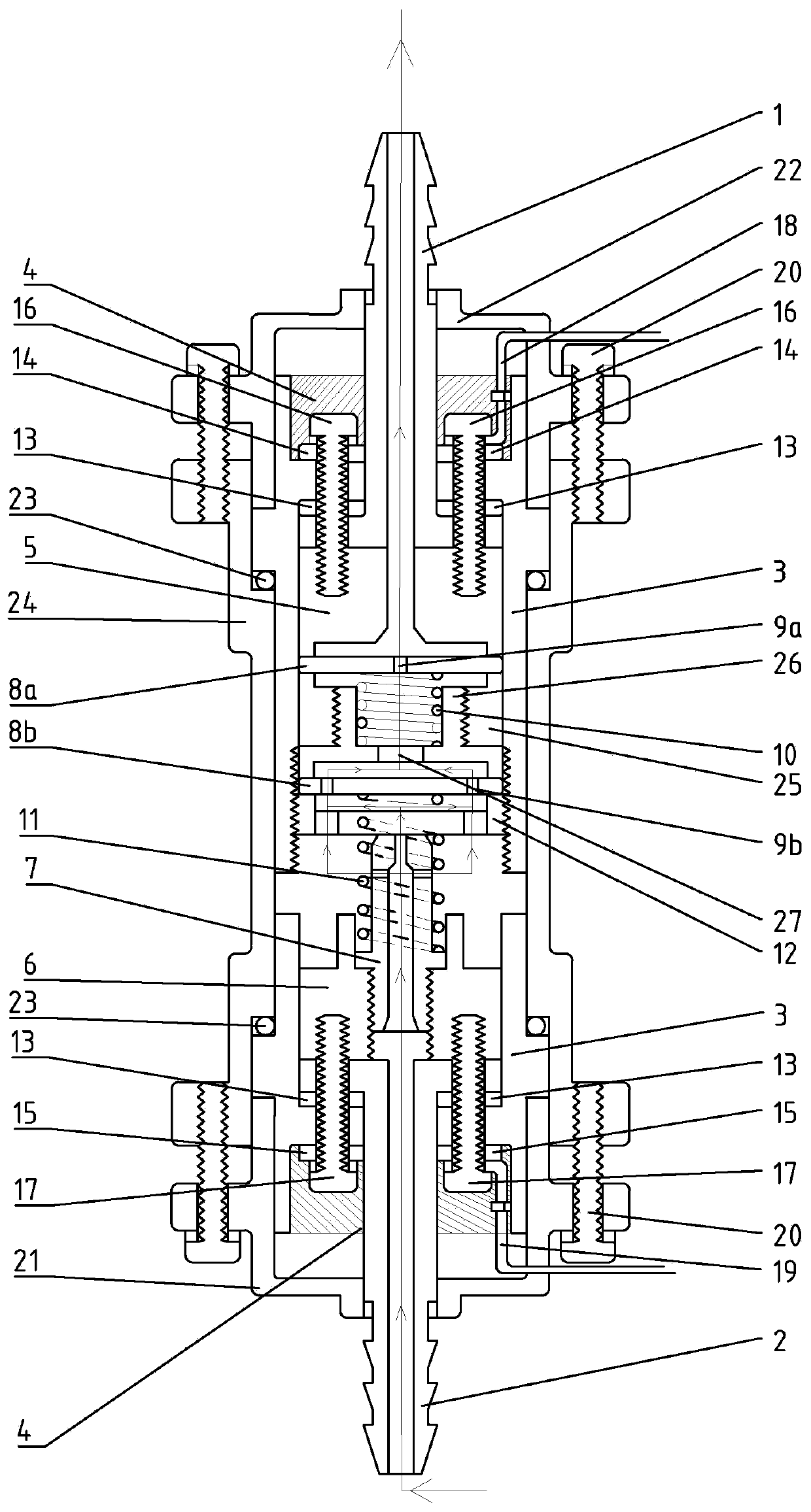

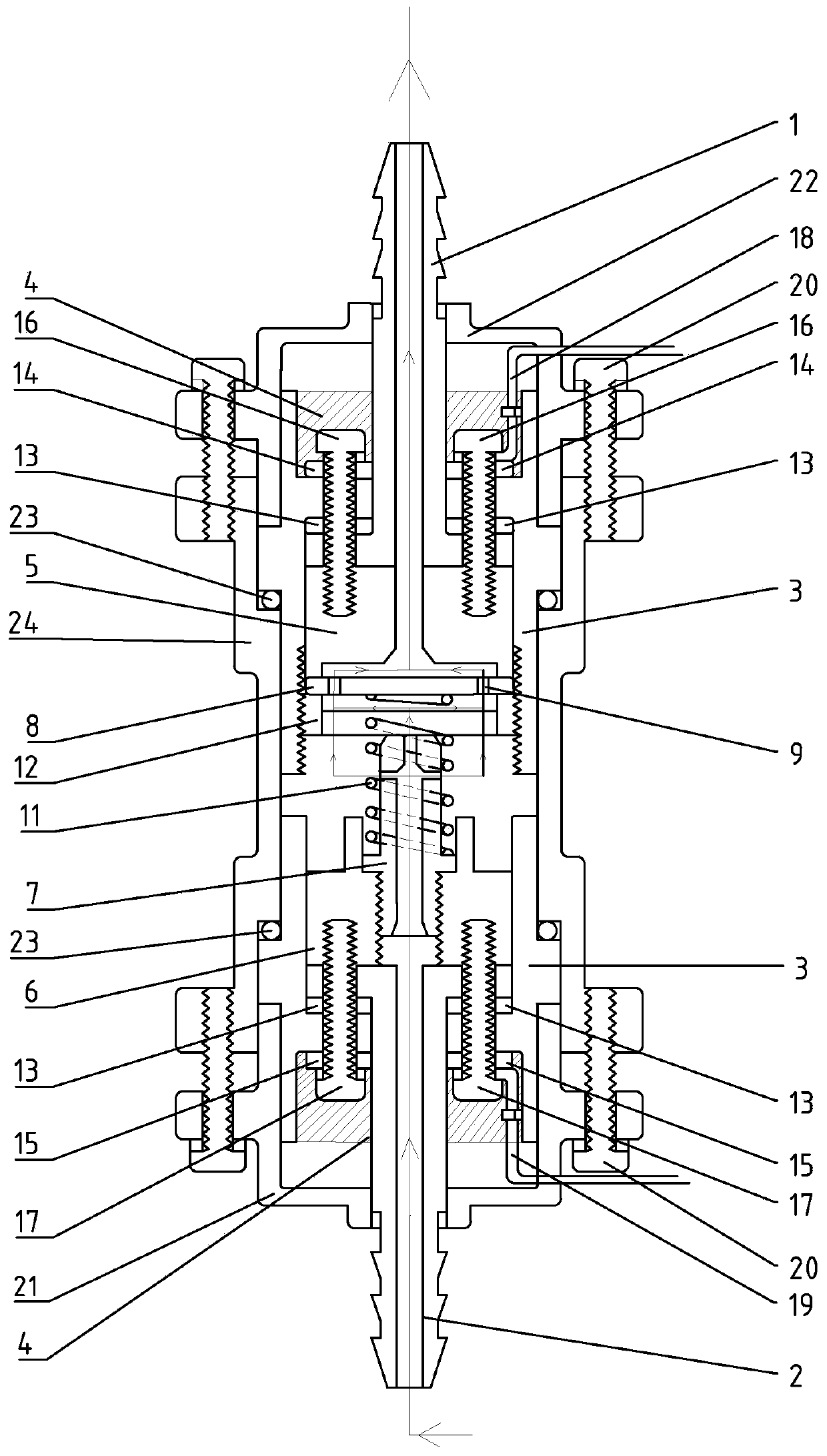

Urea duplex double-scroll SCR mixer of diesel vehicle

ActiveCN106285863AEasily hydrolyzedEasy to atomizeInternal combustion piston enginesExhaust apparatusUreaBack pressure

The invention discloses a urea duplex double-scroll SCR mixer of a diesel vehicle. The urea duplex double-scroll SCR mixer comprises a barrel (1), a guide column (11), an end cover (2), a front helical blade (6), a rear helical blade (10), a front baffle plate (5), a urea nozzle (8) and a distributing baffle plate (16); the front helical blade (6) and the rear helical blade (10) are installed on the guide column (11); the barrel (1), the front baffle plate (5), the front helical blade (6) and the end cover (2) form a single-direction main passage; the distributing baffle plate (16) is installed between the front helical blade (6) and the rear helical blade (10); and the urea nozzle (8) is arranged on the single-direction main passage. The duplex double-scroll SCR mixer is arranged inside the barrel, so that the back pressure is small, the space is compact, and the urea is uniformly atomized; the contradiction between the back pressure and the urea atomizing can be solved; and the problem of urea atomizing in the compact space can be solved.

Owner:NANJING IKAKAT EMISSIONS TECH CO LTD

Dry powder aerosols of Nanoparticulate drugs

InactiveUS20090181100A1Permit deliveryEasy to atomizeAntibacterial agentsOrganic active ingredientsNanoparticleAerosol delivery

There invention discloses aqueous dispersions of nanoparticulate aerosol formulations, dry powder nanoparticulate aerosol formulation, propellant-based aerosol formulations, methods of using the formulations in aerosol delivery devices, and methods of making such formulations. The nanoparticles of the aqueous dispersions or dry powder formulations comprise insoluble drug particles having a surface modifier on the surface thereof.

Owner:ALKERMES PHARMA IRELAND LTD

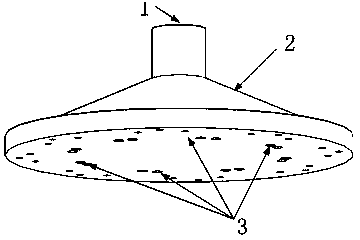

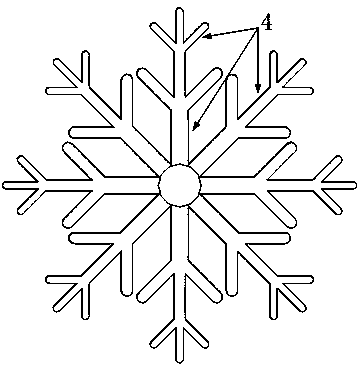

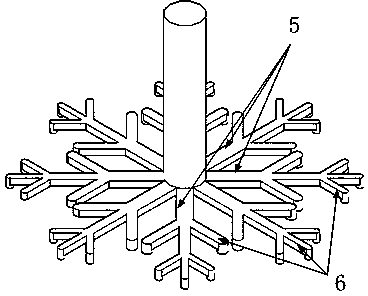

Blade skeleton type atomizing sprayer

ActiveCN104028410ALarge coverage areaReduce trafficSpray nozzlesLiquid spraying apparatusSprayerStructural engineering

The invention discloses a blade skeleton type atomizer. The blade skeleton type atomizer consists of a sprayer body and an ultrasonic atomizer, wherein the sprayer body comprises a liquid delivery channel and a liquid outlet; the liquid outlet is positioned in the tail end of the liquid delivery channel and is used for atomizing and spraying liquid through the ultrasonic atomizer; the liquid delivery channel is a blade skeleton type channel and consists of a main delivery channel and (i) m ( / i) forked blade skeleton channels; each forked blade skeleton channel comprises a main channel and branch channels; each main channel comprises at least two grading channels with different diameters; and the grading channels comprise high-level channels and low-level channels connected to the high-level channels end to end. The blade skeleton type channel comprises the main channels and the branch channels; the diameters of the main channels are gradually reduced; and the multi-level grading channels extend outwards, the forked channels are distributed in a radiating manner, channel outlets are formed in limited space to the great extent, the flow of the liquid is gradually reduced, the liquid can be uniformly distributed within the limited range, the atomizing effect is improved, and the liquid is easily atomized.

Owner:SOUTHEAST UNIV

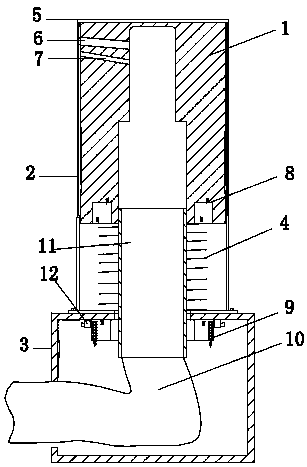

Embedded extension nozzle

PendingCN110124888AMove upwards against resistanceEasy to atomizeSpray nozzlesRoad cleaningEmbedded systemNozzle

The invention discloses an embedded extension nozzle in the technical field of pavement spraying. The embedded extension nozzle comprises an inner-layer cylinder, an outer-layer sleeve, an annular spring and a bottom fixed bin; multiple upper-layer spraying holes and multiple lower-layer spraying holes communicating with an inner cavity of the inner-layer cylinder are formed in the outer wall of the inner-layer cylinder; after the power failure of an electromagnet, the inner-layer cylinder slides down to the upper-layer spraying holes and the lower-layer spraying holes for closing in the outer-layer sleeve; and after the electromagnet is electrified, the inner-layer cylinder upwards slides to the upper-layer spraying holes and the lower-layer spraying holes for extension out of the outer-layer sleeve. The nozzle shrinks underground in an idle state; the spraying holes automatically extend out of the ground during working; liquid is sprayed near the ground to achieve lower influence ontraffic; and the embedded extension nozzle is wide in spraying coverage and suitable for such length distances as four lanes, six lanes and eight lanes.

Owner:SHANDONG JIAOTONG UNIV

Piston for internal combustion engine, and internal combustion engine using the piston

InactiveUS7856958B2Easy to evaporateEasy to atomizeInternal combustion piston enginesCombustion-air/fuel-air treatmentEngineeringInternal combustion engine

Owner:TOYOTA JIDOSHA KK

Spray nozzle

The invention relates to a spray nozzle which comprises a thread connection part and a spray head, wherein the spray head is larger than the diameter of the thread connection part, a flow control hole is axially formed in the thread connection part, an accumulated water bulk cavity which is communicated with the flow control hole and defined by an annular inner wall is further formed along the axial direction facing to the spray head in the thread connection part, the diameter of the accumulated water bulk cavity is larger than that of the flow control hole, the accumulated water bulk cavity is further connected with the flow control hole through a conical wall, and the accumulated water bulk cavity extends into the spray head; a conical surface which is convex to the accumulated water bulk cavity is formed in the spray head, a plurality of whirl holes which are communicated with the accumulated water bulk cavity and diffusion conical holes which are respectively communicated with each whirl hole and penetrate a circumferential outer wall of the spray head; and the conical surface extends to each whirl hole. As the spray nozzle uses the larger main flow control hole and comprises the whirl holes, the spray nozzle is less prone to being blocked. Simultaneously, a plurality of gaps are formed on the spray nozzle, the spray nozzle is easy to atomize liquid; in addition, the spray nozzle has simple structure and convenient manufacture.

Owner:深圳市利源水务设计咨询有限公司

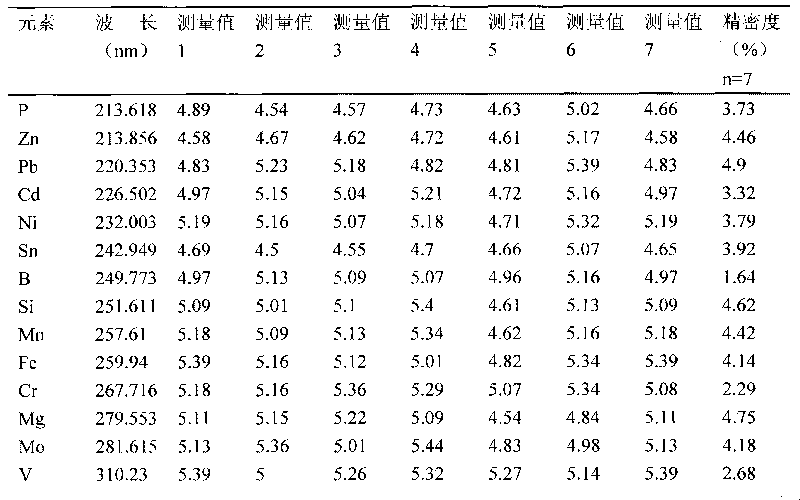

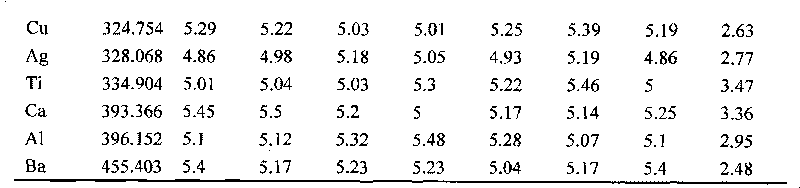

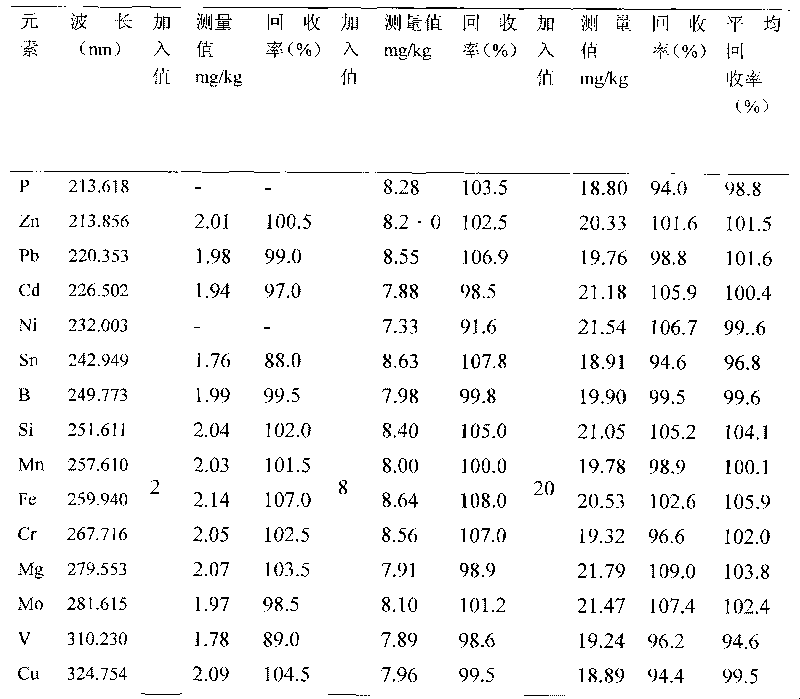

Method for detecting content of elements in oil with inductively coupled plasma (ICP) spectrometer

InactiveCN101726482AReduce formationInhibitionAnalysis by thermal excitationInductively coupled plasmaQuartz

The invention discloses a method for detecting the content of elements in oil with an inductively coupled plasma (ICP) spectrometer. The ICP spectrometer comprises a torque tube, and the torque tube is formed by three layers of concentric quartz tubes. Cooling gas is guided into the quartz tube of the outer layer, oxygen is guided into the quartz tube of the middle layer and gasoloid of the oil which is diluted by organic solution is injected into the quartz tube of the outer layer. The method for detecting the content of elements in oil with the ICP spectrometer makes up the deficiency of the prior art.

Owner:JIANGSU SKYRAY INSTR

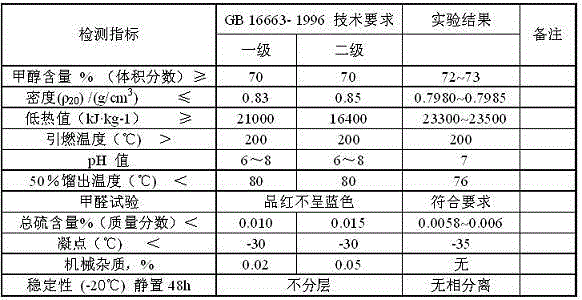

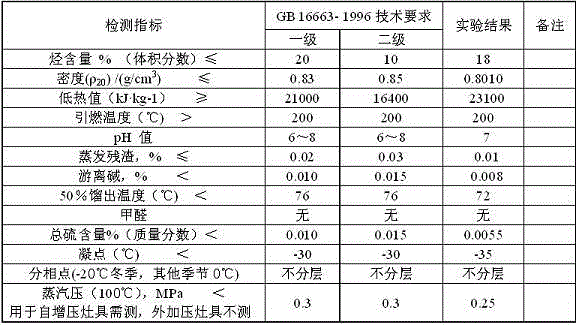

Alcohol-based fuel without eye fumigation in use

InactiveCN107723036AStable combustionBoost octaneLiquid carbonaceous fuelsFuel additivesDistillationOil phase

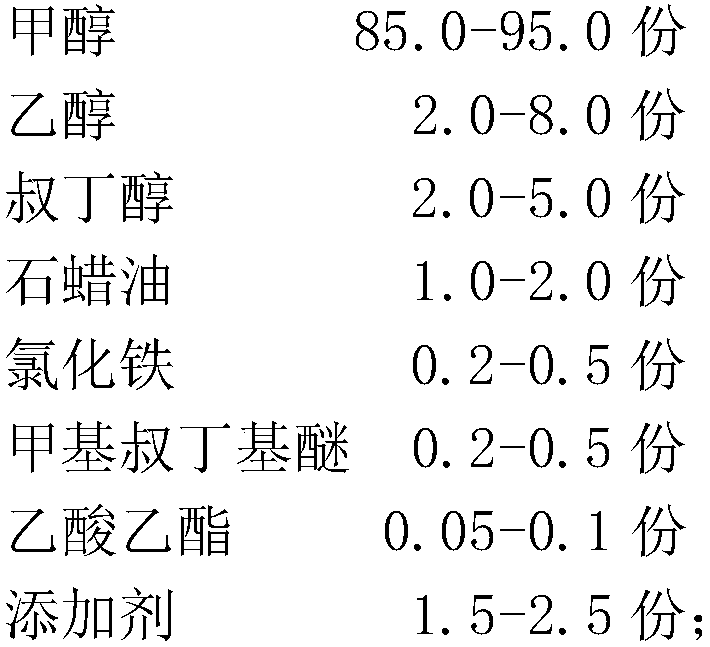

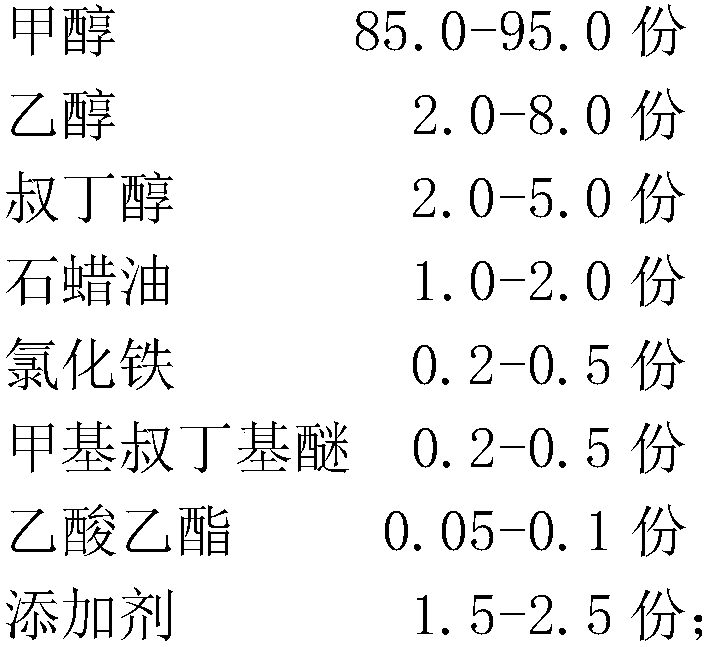

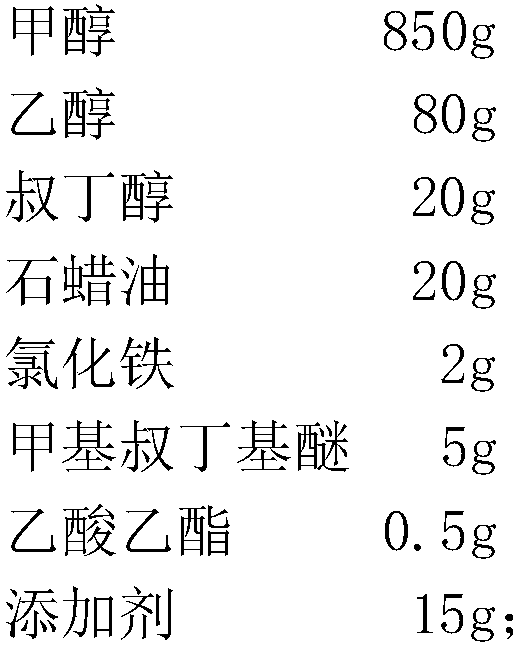

The invention discloses alcohol-based fuel without eye fumigation in use. The alcohol-based fuel is characterized by being prepared from the following ingredients in parts by weight: 85.0 to 95.0 parts of methyl alcohol, 2.0 to 8.0 parts of ethyl alcohol, 2.0 to 5.0 parts of tertiary butanol, 1.0 to 2.0 parts of paroline, 0.2 to 0.5 part of ferric chloride, 0.2 to 0.5 part of methyl tertiary butylether, 0.05 to 0.1 part of ethyl acetate and 1.5 to 2.5 parts of additive. The additive is prepared from the following preparation method which comprises the steps: (1) forcing treatment: putting water-extracted folium eriobotryae residues into a high-pressure tank, forcing to 3kg / cm<2> to enable pressure to be even, maintaining and then releasing the pressure instantly; (2) distillation treatment: putting the materials obtained in the step (1) into a distiller, heating, burning or introducing steam at the bottom of the distiller, guiding the steam into a condenser through a condensing pipe when the distiller is full of the hot steam and then collecting an oil phase through an oil-water separator; (3) high-shear homogenizer treatment: processing the oil phase obtained in the step (2) by ahigh-shear homogenizer to be prepared into nanoemulsion to obtain the additive.

Owner:桂林淦隆环保设备有限责任公司

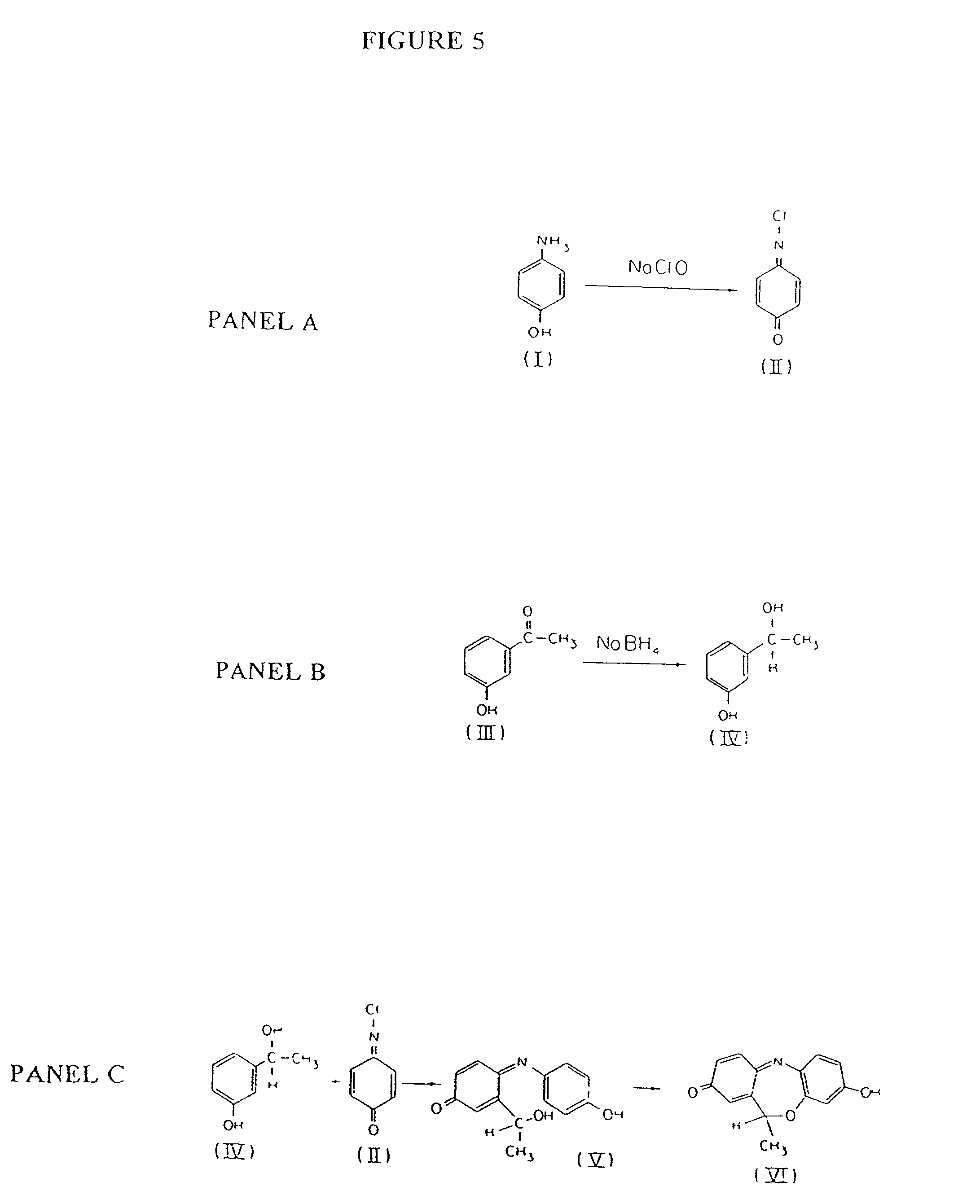

Comparative phenotype analysis

InactiveUS20020110848A1Easy to atomizeReduce chanceMicrobiological testing/measurementBiological material analysisEscherichia coliMammal

Owner:BIOLOG

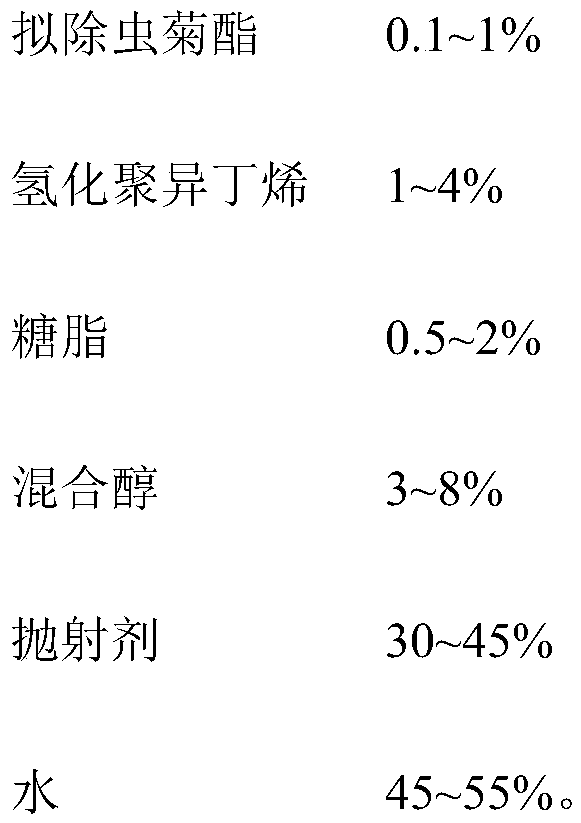

Insecticidal aerosol and preparation method thereof

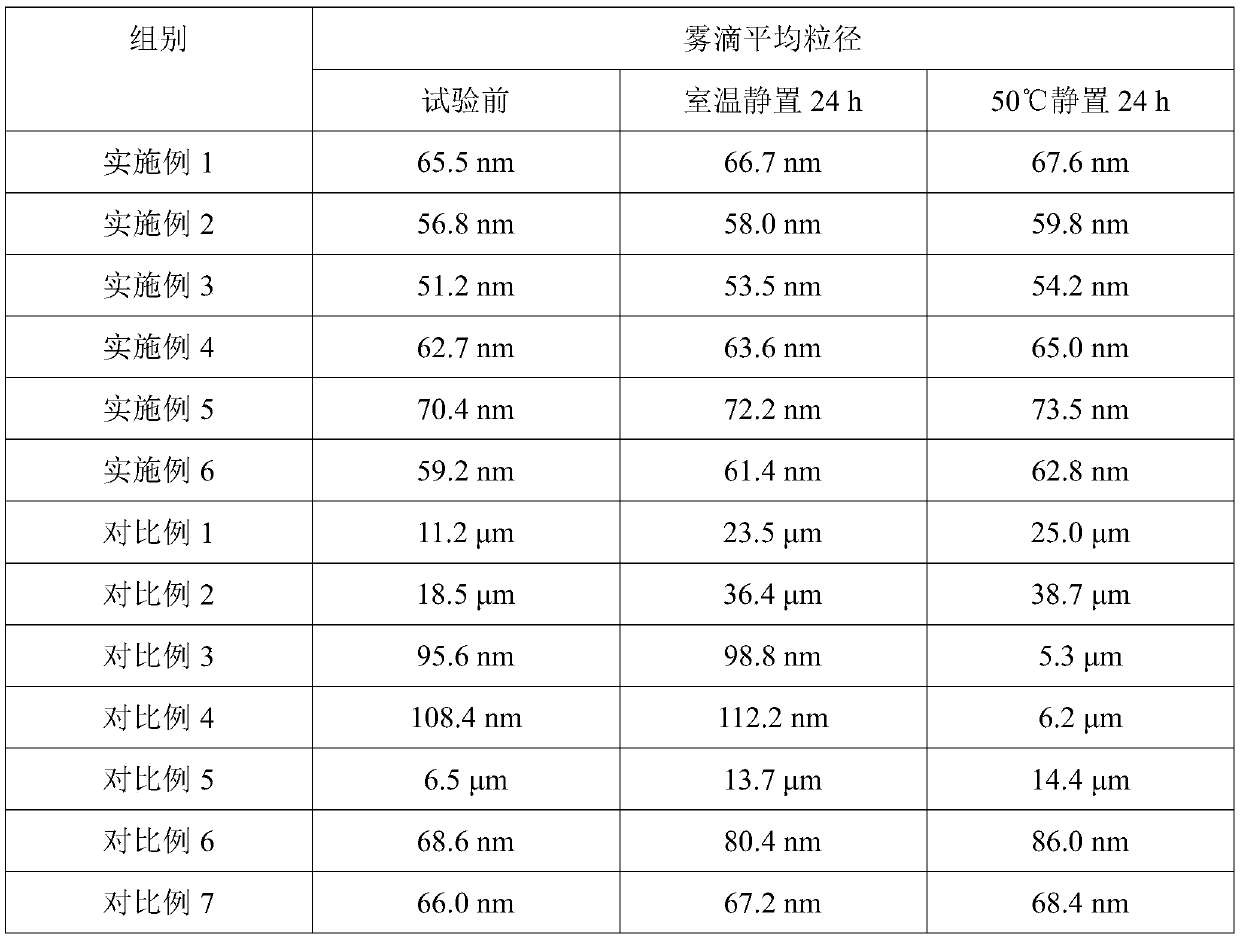

ActiveCN110384091AImprove permeabilityImprove thermal stabilityBiocideAnimal repellantsWater basedAlcohol

The invention discloses an insecticidal aerosol and a preparation method thereof. The insecticidal aerosol comprises the following components in percentage by mass: 0.1-1% of pyrethroid, 1-4% of hydrogenated polyisobutene, 0.5-2% of glycolipid, 3-8% of mixed alcohol, 0.1-0.5% of a synergist, 0.05-0.3% of an essence, 30-45% of a propellant and 45-55% of water. The insecticidal aerosol disclosed bythe invention is a thermodynamically stable water-based microemulsion system, has a particle size in a range of 10-100 nm, has transparent appearance, is not layered after being stood for a long time,has good stability, and can be directly sprayed without shaking. In addition, the insecticidal aerosol has an insecticidal effect close to an oil-based product, and has fast killing effects on mosquitoes, flies and cockroaches.

Owner:LOOBI GUANGZHOU HEALTH IND CO LTD

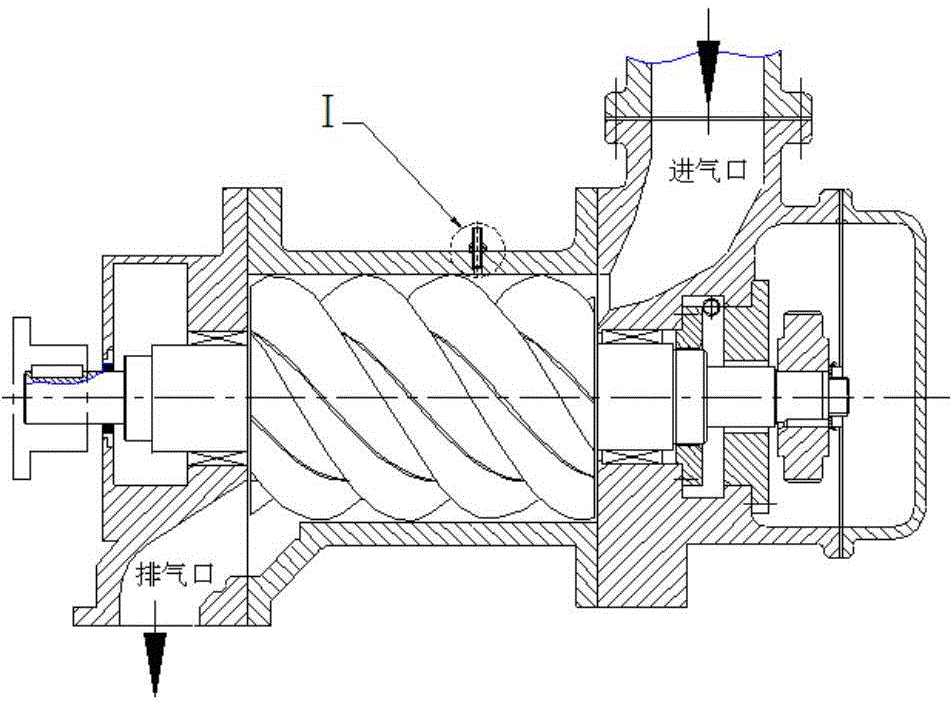

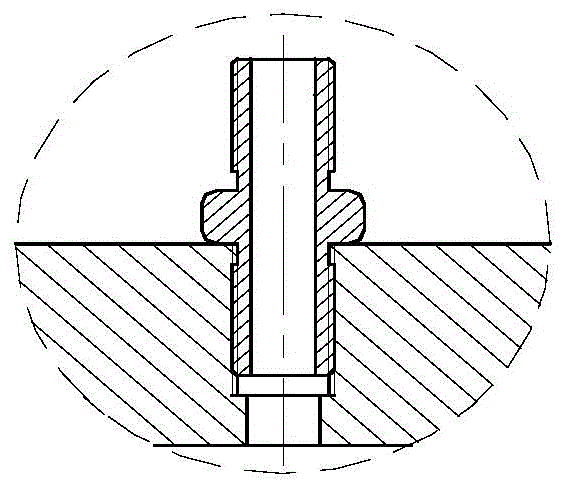

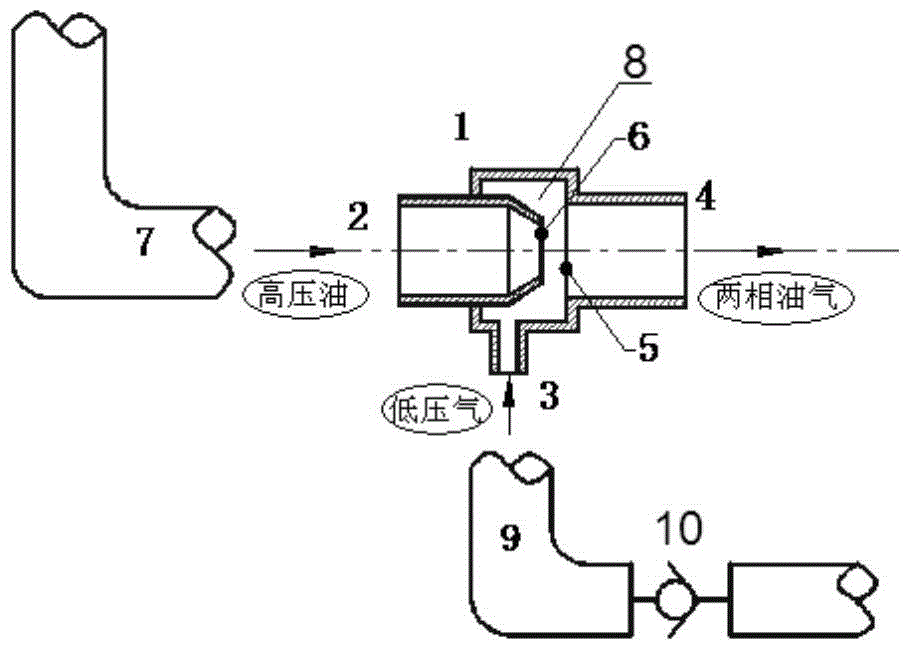

Compressor oil injector having gas suction function

ActiveCN104454545AImprove volumetric efficiencyImprove insulation efficiencyChemical industryRotary/oscillating piston pump componentsInjectorHigh pressure

The invention discloses a compressor oil injector having a gas suction function. The compressor oil injector is characterized by comprising a first-stage nozzle, a second-stage nozzle and a low-pressure gas suction inlet, wherein a cavity is formed between the first-stage nozzle and the second-stage nozzle and is communicated with the low-pressure gas suction inlet. High-pressure oil is injected in from the first-stage nozzle, then gas is sucked in from the low-pressure gas suction inlet, and a two-phase oil and gas mixture is formed, injected into the second-stage nozzle and finally injected into a compression cavity. The function of gas suction of the compression cavity is realized, and the efficiency of a compressor is increased.

Owner:XI AN JIAOTONG UNIV

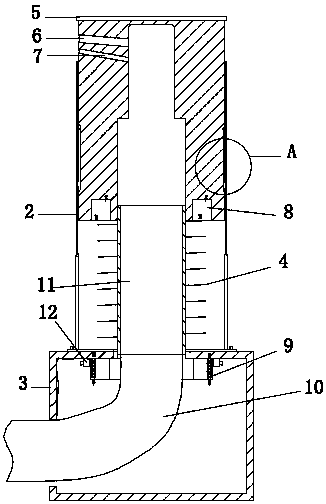

Intelligent vibration dust removing device for reaction tower

InactiveCN106914458ASolve problems that affect the performance of the reactionEasy to atomizeHollow article cleaningEngineeringTower

The invention provides an intelligent vibration dust removing device for a reaction tower. The intelligent vibration dust removing device for the reaction tower comprises a drive mechanism, a fixing mechanism, movable arms, vibrators and a controller. The fixing mechanism is arranged on the upper side of the reaction tower and connected with the drive mechanism. The fixing mechanism comprises a fixing ring connected with the drive mechanism and fixed arms arranged on the periphery of the fixing ring. The movable arms are in a strip shape. One end of each movable arm is connected with the corresponding fixed arm. The side, opposite to the reaction tower, of each fixed arm is provided with at least one vibrator. The drive mechanism comprises a vertical moving portion and a rotating portion. The vertical moving portion, the rotating portion and the vibrators are all connected with the controller. The controller controls the vibrators to vibrate so that accumulated dust on the inner wall of the reactor tower cracks and falls; the vertical moving portion and the rotating portion enable the vibrators to rise during vibration, vibration is conducted on the reaction tower at different positions, so that later-period atomization treatment is convenient, and matter attached to the inner wall is completely removed.

Owner:TIANJIN HEAD HAOTIAN TECH DEV CO LTD

Metal ultrafine atomizing, crushing and grading system and metal atomizing device thereof

The invention provides a metal ultrafine atomizing, crushing and grading system, comprising a metal smelting furnace, a metal hydrogen-discharging and heating furnace, a metal atomizing device, a fluidized bed depolymerization grader, a second precise grader, at least one collector, a filter and a compressor. The invention also provides a metal atomizing device, comprising a crucible, a spray disc, a spray cover and a cylindrical spray cylinder, wherein a circle of evenly distributed inclined holes is respectively arranged on at least two circumferences with different diameters of the spray disc; each inclined hole is provided with a Laval nozzle; and the extension line of each Laval nozzle is intersected with the central axis of the spray disc at the same point. Through the airflow with ultrasonic velocity, ultralow temperature and large velocity pressure generated by the nozzle in the metal atomizing device, the liquid metal or alloy is directly crushed, or rapidly cooled into atomized powder and then depolymerized by a fluidized bed and precisely graded by the precise grader to obtain metal fine powder and ultrafine powder with finer granularity, more even granularity and better granularity sphericity.

Owner:宁波中物力拓超微材料有限公司

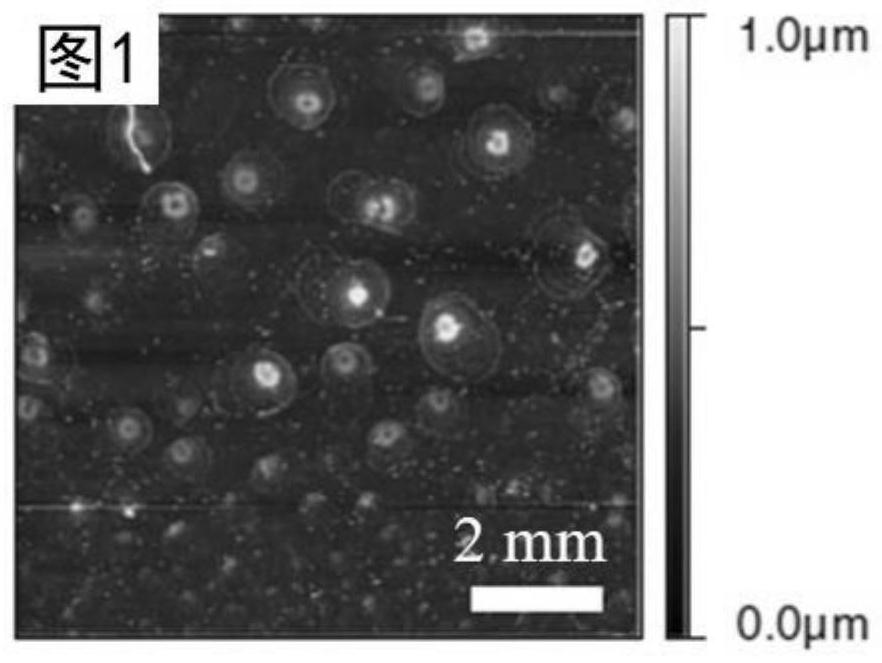

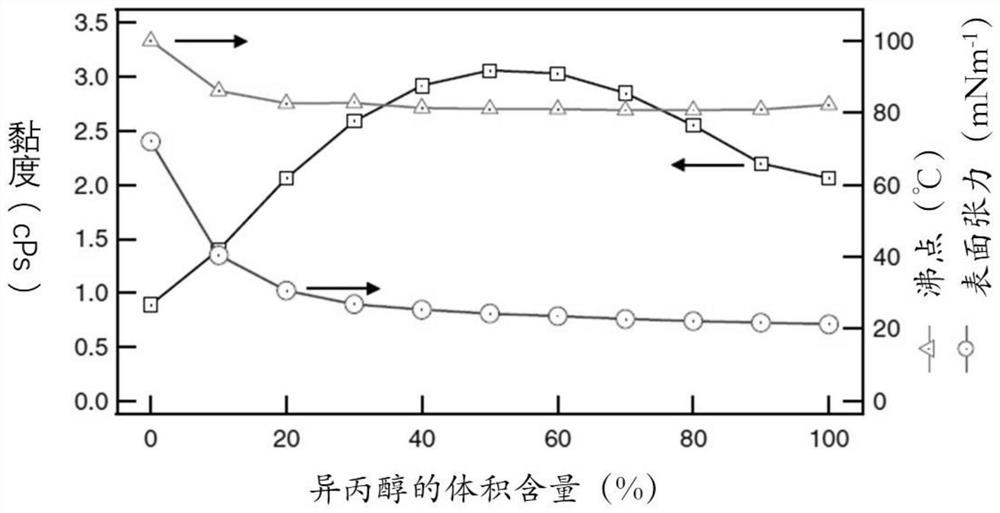

Spray pyrolysis method of nickel oxide and perovskite solar cell

PendingCN114715958AEasy to atomizeImprove uniformityMaterial nanotechnologyFinal product manufactureNickel saltPerovskite solar cell

The invention provides a nickel oxide spray pyrolysis method which comprises the following steps: S1) mixing nickel salt with water to obtain a nickel salt solution; s2) mixing the nickel salt solution with a precipitant solution to obtain a precipitate; s3) calcining the precipitate to obtain nickel oxide nanoparticles; s4) mixing the nickel oxide nanoparticles with water and / or isopropanol, and performing ultrasonic treatment to obtain a nickel oxide precursor solution; and S5) carrying out spray deposition on the nickel oxide precursor solution, and then carrying out annealing treatment to obtain the nickel oxide film. Compared with the prior art, the method has the advantages that the surface tension and the viscosity of the nickel oxide spraying solution are adjusted by adjusting different solvents and the volume ratio of the solvents, so that the nickel oxide spraying solution is more easily atomized into small particles during spray pyrolysis, and the uniformity of a film is better.

Owner:HUANENG NEW ENERGY CO LTD +1

Ultrasonic fuel excitation device

PendingCN110030127AEasy to atomizeIncrease profitInternal combustion piston enginesCombustion-air/fuel-air treatmentEngineeringLiquid fuel

The invention discloses an ultrasonic fuel excitation device. The ultrasonic fuel excitation device comprises a shell, wherein the shell comprises an outer metal shell and an inner insulating layer, and an inner cavity filled with insulating liquid fuel, at least one fuel inlet and at least one fuel outlet are formed in the shell. The inner cavity of the shell at least comprises an ultrasonic transduction unit, a first electrode conductive connection block, a first conductive screw, a conductive spring, a second electrode conductive connection block and a second conductive screw. According tothe ultrasonic fuel excitation device, the fuel utilization rate can be increased, equipment power is enhanced, fuel is saved, emission of harmful gas is reduced, environment is protected, equipment running noise is reduced, oil paths are cleaned, carbon deposition is reduced, and installation and maintenance are easy. The ultrasonic fuel excitation device can be widely applied to equipment for acquiring energy through various fuels, and has strong adaptability.

Owner:方荣武 +2

Methanol fuel additive for cold plateau region and methanol fuel containing the additive

The invention relates to a methanol fuel additive for cold plateau region. The additive is prepped by adding 3-20 wt.% of an oxidant hydrogen peroxide with mass concentration of 30%, 1-6% of an antifreeze, 0.2-3% of an antioxidant antigum agent 2,6-butylated hydroxytoluene, 0.05-0.6% of a metal passivator N,N-bis(salicylidene)-1,2-propanediamine, 0.008-0.06% of a detergent dispersant, 1-6% of a preservative and 1-20% of a emulsifier into 10-83.742% of aqueous solution, mixing evenly by pump circulation, then successively adding 3-20% of naphtha, 3-10% of toluene, 2-10% of xylene, 2-10% of C5H12-C7H16 in weight ratio of 1:1, and mixing homogeneously by pump circulation. At the same time, the invention also discloses a ratio and a preparation method of a methanol fuel containing the methanol fuel additive for cold plateau region. The methanol fuel additive for cold plateau region provided by the invention has good and stable performance, and solves the problems of low temperature fluidity, high altitude hypoxia burning property, low sulfur, low nitrogen and dynamic stability.

Owner:GANSU ZHONGAO PETROCHEM CO LTD

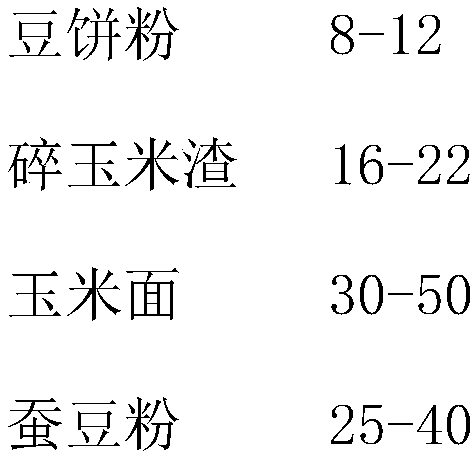

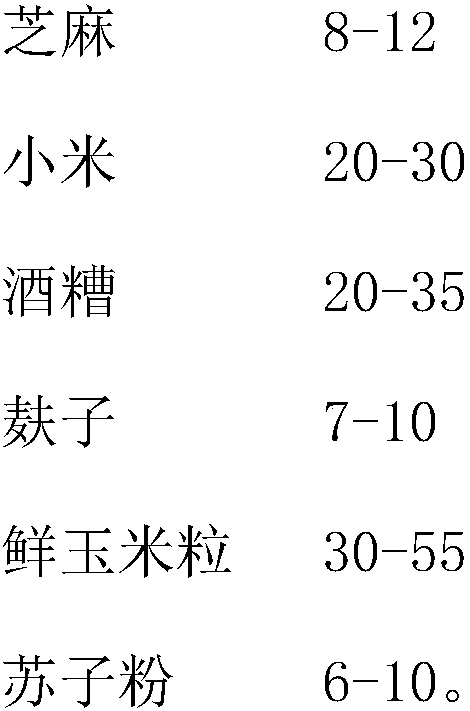

Bait for explosive hook and preparation method thereof

InactiveCN108739704AIncrease aromaHas the ability to lure fishOther angling devicesSesamum orientaleCorn flour

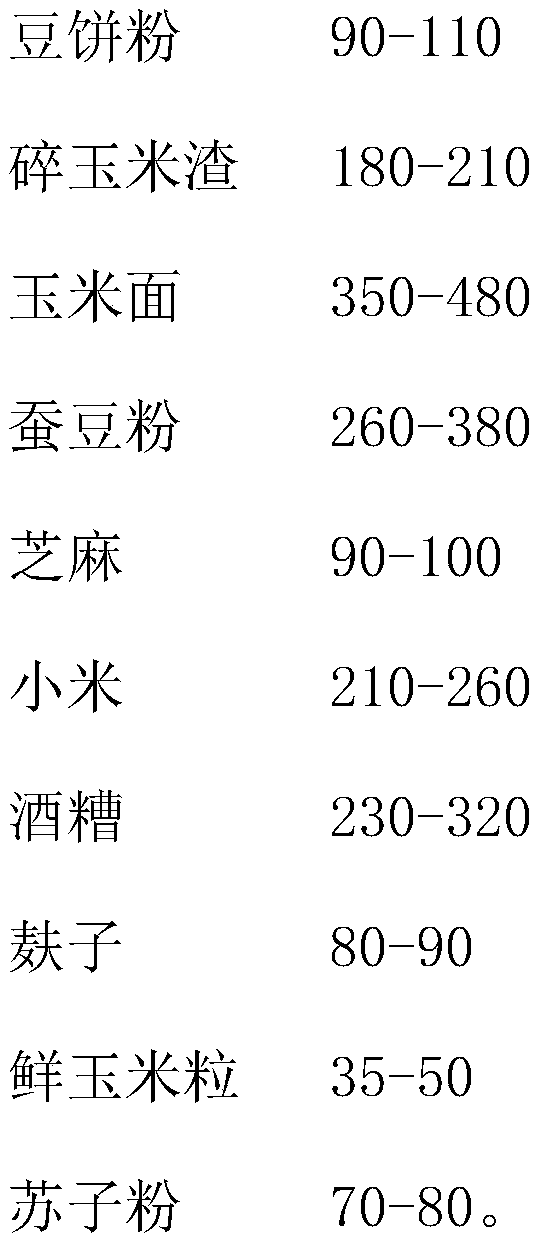

The invention discloses bait for explosive hook and relates to the technical field of bait preparation. Raw materials of the invention comprise, by weight, 8 to 12 parts of bean cake powder, 16 to 22parts of crushed corn dregs, 30 to 50 parts of corn flour, 25 to 40 parts of broad bean powder, 8 to 12 parts of sesame, 20 to 30 parts of millet, 20 to 35 parts ofvinasse, 7 to 10 parts of bran seed,30 to 55 parts of fresh corn kernel and 6 to 10 parts of perilla seed powder. By utilizing a reasonable ratio and preparation method, the bait provided by the invention can satisfy the use requirement of the explosion hook and fish luring function, and solves the problem that the prior bait is easy to spread when throwing or easy to atomize and cannot cover the hook after entering the water.

Owner:合肥正特垂钓用品有限公司

Paper plastic package anti-fluffing sealing and coating process and paper plastic package

PendingCN110420815ASolve the problem of dandruffAvoid it happening againPretreated surfacesHyaluronic acid coatingsMolded pulpCellulose

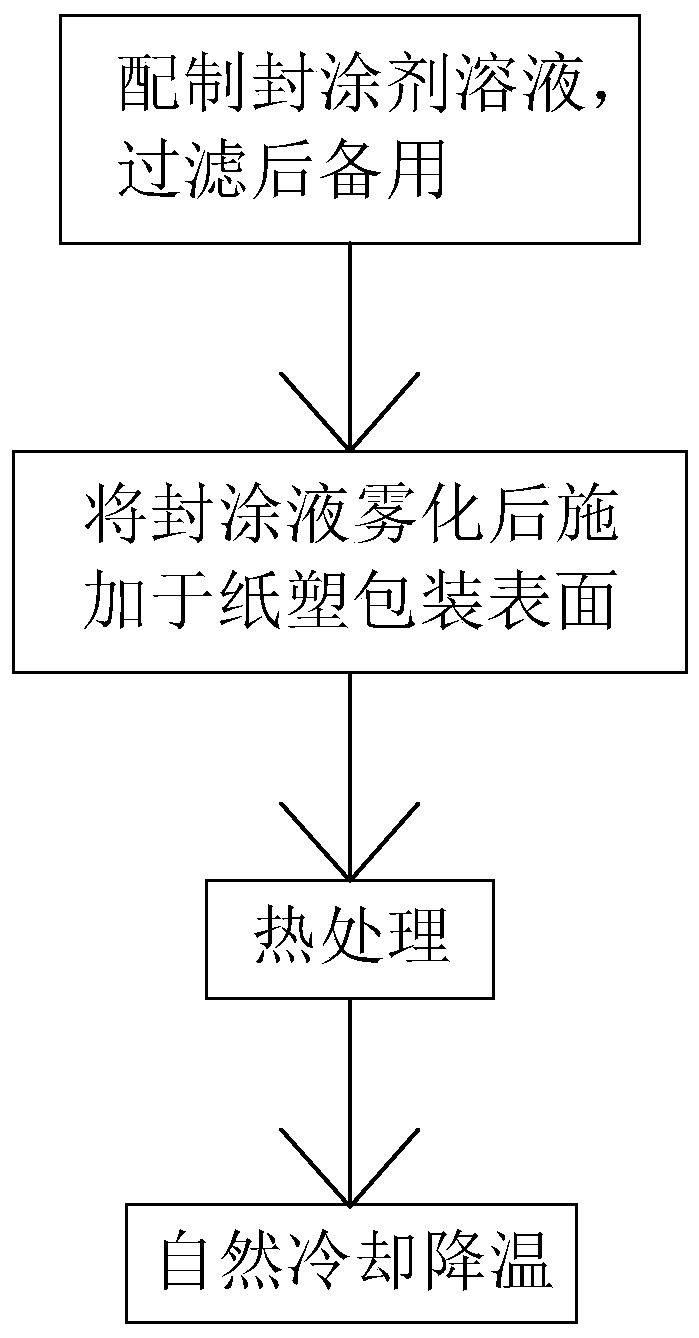

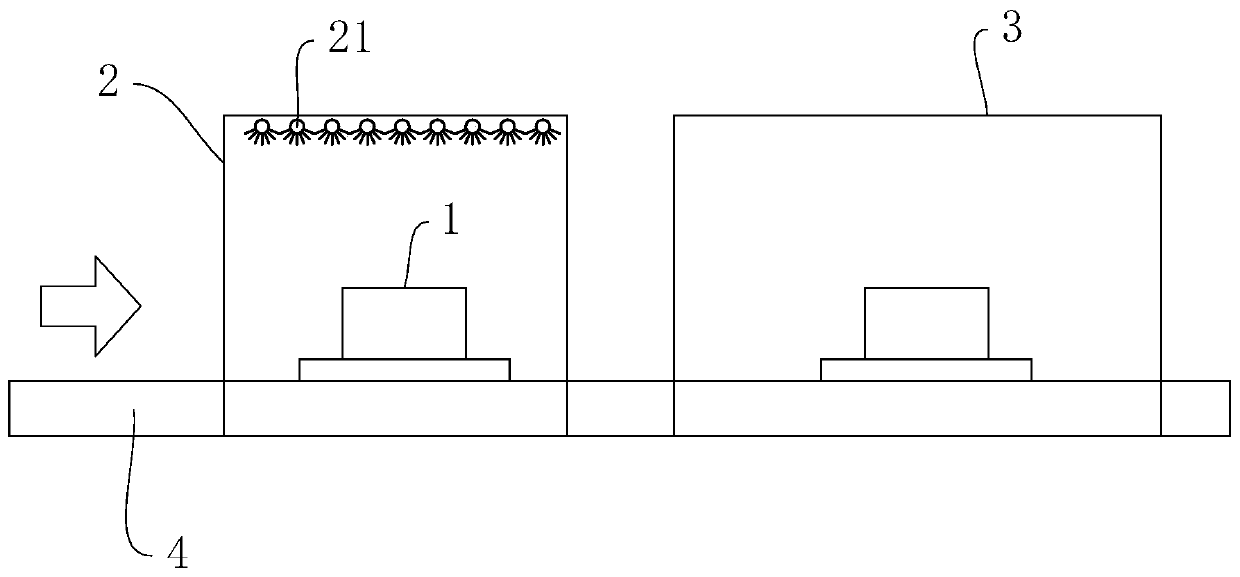

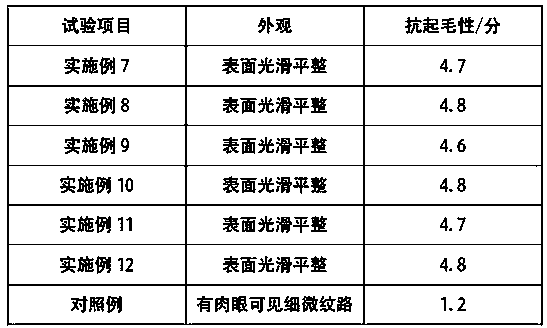

The invention discloses a paper plastic package anti-fluffing sealing and coating process, and relates to the technical field of paper-plastic package processing. According to the technical scheme, the paper plastic package anti-fluffing sealing and coating process comprises the following steps of preparing sealing and coating liquid, wherein a sealing and coating agent is prepared into an aqueoussolution to obtain the sealing and coating liquid, and the sealing and coating agent is selected from one or more of chitin, derivatives of the chitin, water-soluble cellulose ether, derivatives of the water-soluble cellulose ether, water-soluble bioglue or water-soluble synthetic high molecular polymer; conducting spraying, wherein a spraying manner is adopted for evenly applying the sealing andcoating liquid to the paper-plastic package surface; and conducting heat treatment, wherein a paper-plastic package treated by spraying is heated at 200 DEG C to 230 DEG C for 5 s to 90 s. A paper-plastic product treated by the process has a smooth surface, and fine debris is not prone to being generated in the storage and transportation processes. Another object of the invention is to provide the paper-plastic package. After sealing and coating treatment with the paper plastic package anti-fluffing sealing and coating process, the advantage that the fine debris is not prone to being caused by friction is achieved.

Owner:SUZHOU SHENGLIN PAPER PROD CO LTD

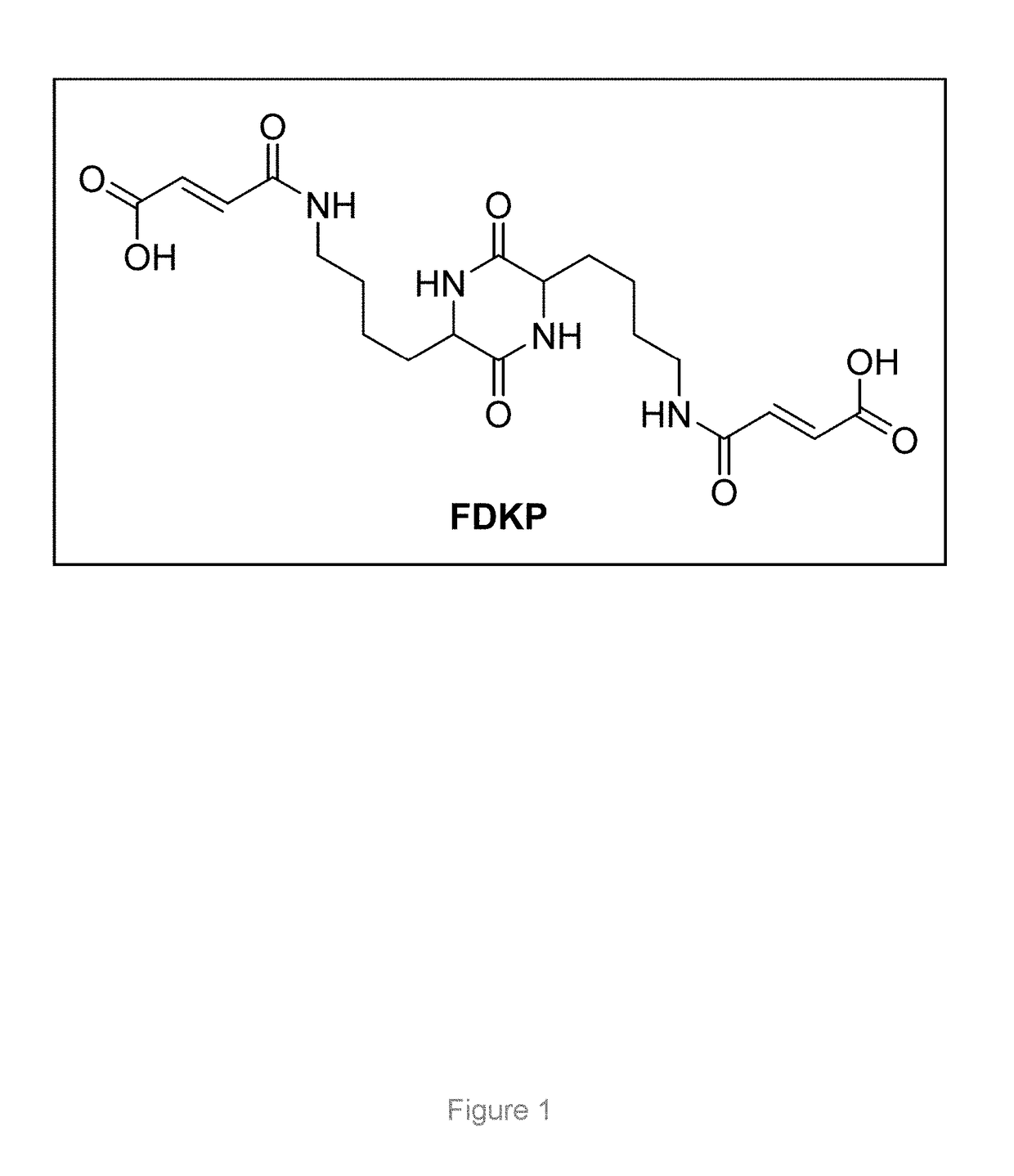

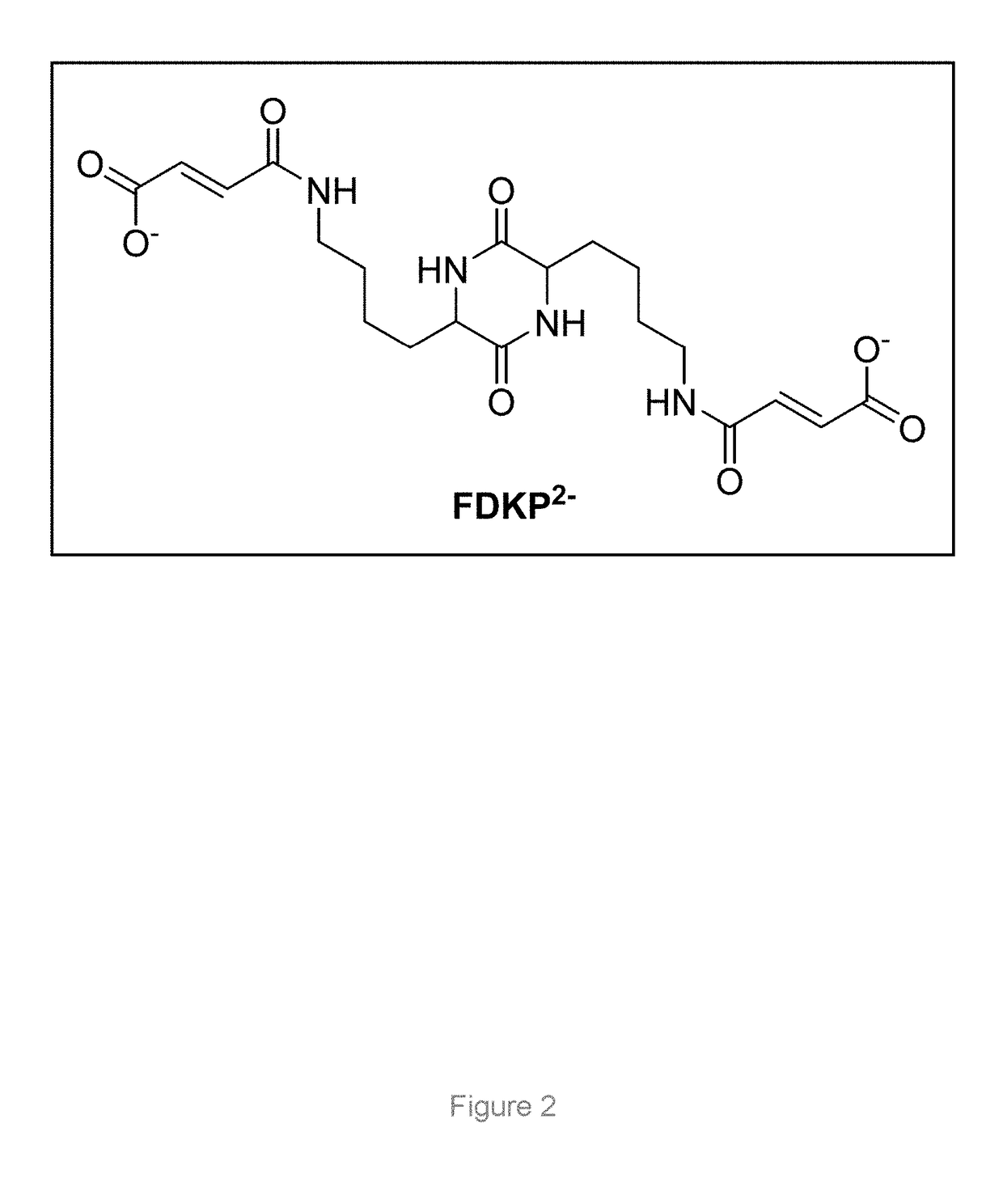

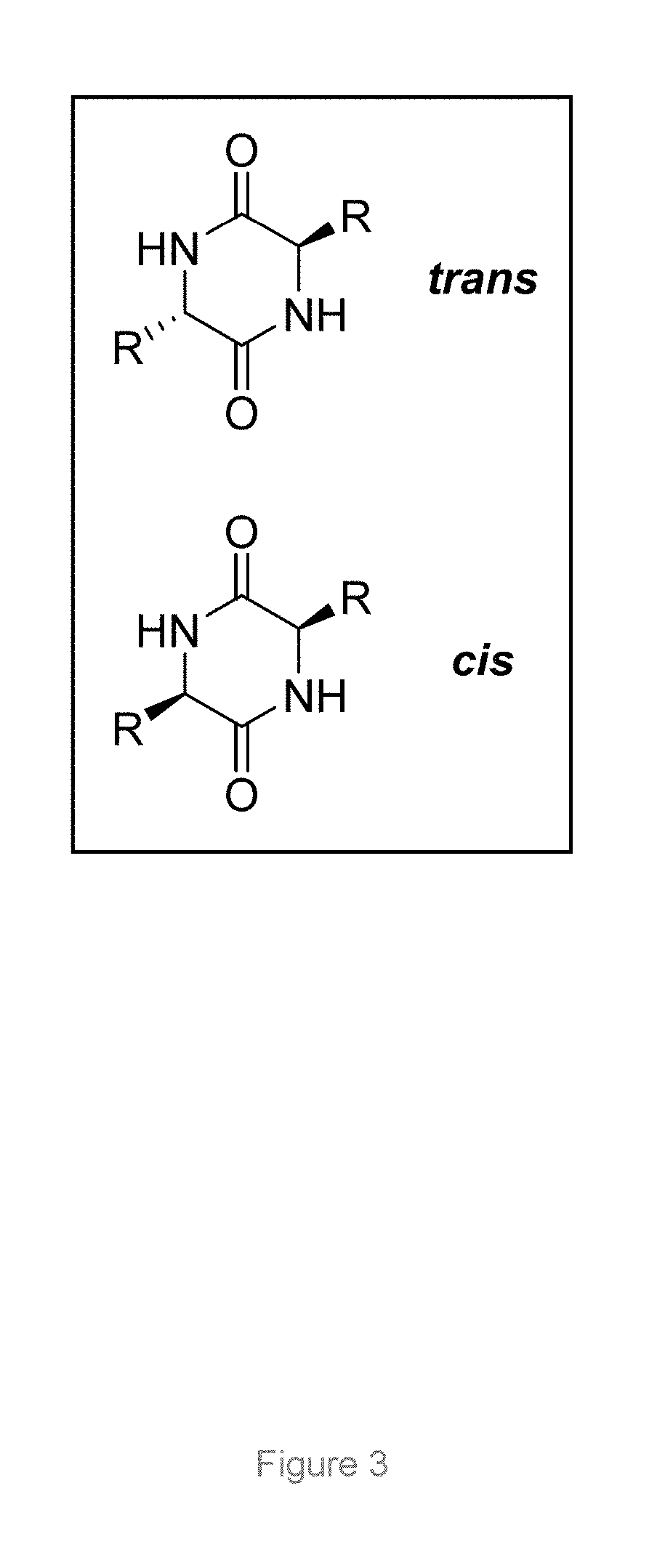

Nicotine—diketopiperazine microparticle formulations and methods of making the same

ActiveUS9968125B2Improve efficiencyReduce aggregationPowder deliveryTobacco treatmentTobacco withdrawalDiketopiperazines

This invention relates to nicotine microparticles formulations made with the help of a diketopiperazine compound, in particular fumaryl diketopiperazine (FDKP). The invention relates to the various types of microparticles that can be made, in particular nicotine-coated and nicotine-loaded microparticles. The invention further relates to the various methods that can be used in making the microparticles. One particular method involves making FDKP microparticles which are further surface-coated with nicotine. Another particular method involves mixing nicotine with FDKP2− and / or FDKP and then forming microparticles which contain nicotine throughout their volume. The invention also relates to the use of this microparticles in tobacco related therapies, such as tobacco replacement or tobacco withdrawal.

Owner:PHILIP MORRIS PROD SA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com