Compressor oil injector having gas suction function

A technology of compressors and fuel injectors, which is applied in the direction of machines/engines, mechanical equipment, climate sustainability, etc., and can solve problems such as reducing compressor efficiency and liquid hammer loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

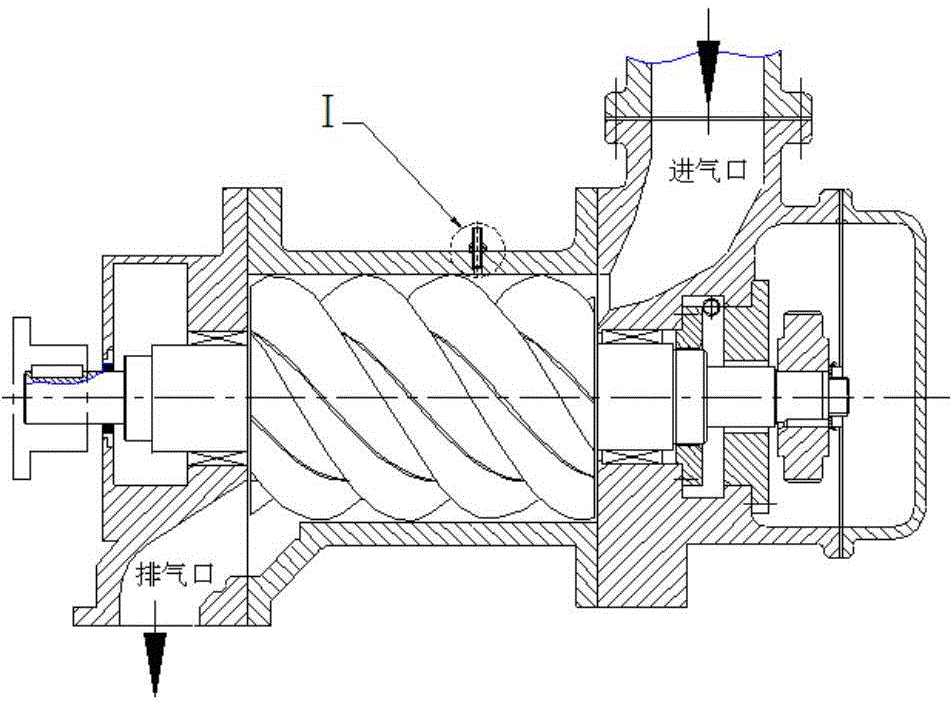

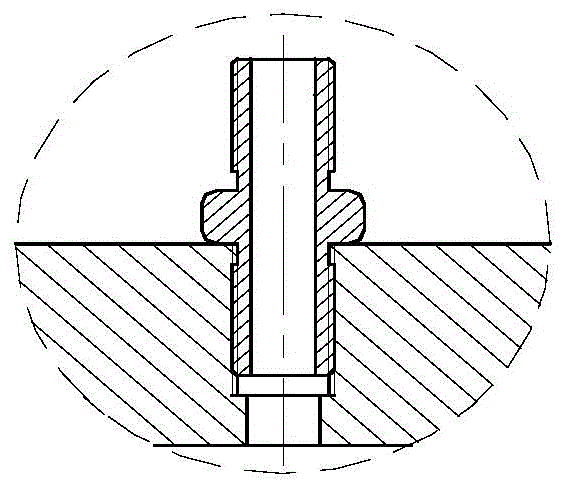

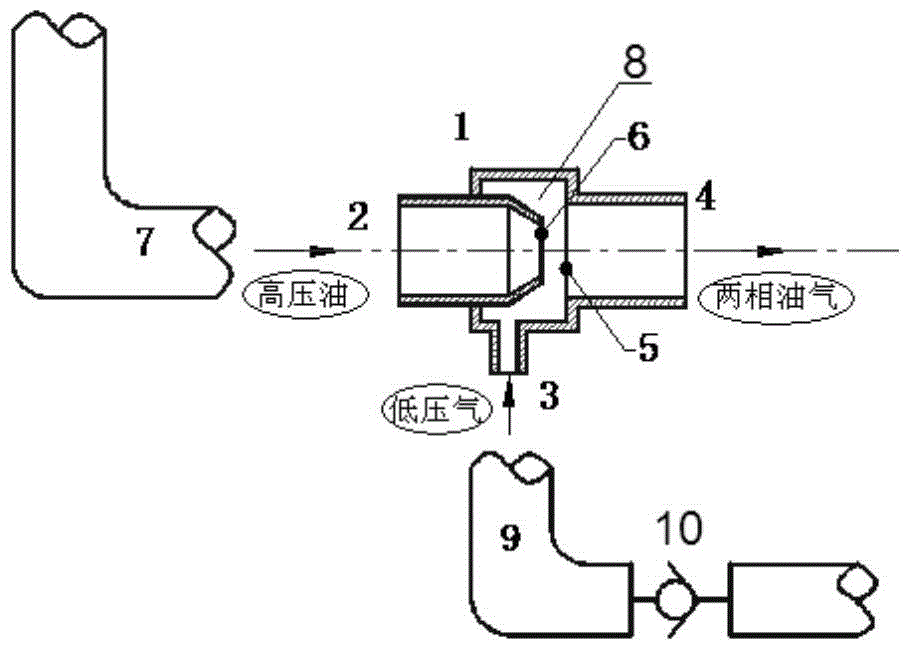

[0021] Install an injector 1 before the oil injection port of the rotary compressor, such as figure 1 As shown, the fuel injector includes a secondary nozzle 5 with a mixing chamber 8 at the rear end, a primary nozzle 6 set in the secondary nozzle mixing chamber 8, the rear end of the primary nozzle is an oil inlet 2, and the secondary nozzle The front end of the cylinder is an oil and gas outlet 4, which is connected to the oil injection port of the compressor. The cylinder wall of the secondary nozzle mixing chamber is provided with an air suction inlet 3 connected to a low-pressure air pipe 9 . The oil inlet 2 is connected to the high-pressure oil pipe 7, and the high-pressure oil cooled by the oil cooler is introduced from the oil inlet 2, and sprayed from the first-stage nozzle 6 into the second-stage nozzle 5. At this time, the suction inlet 3 sucks the low-pressure air into the mixing chamber 8 , mixed with high-pressure oil, sprayed into the compression chamber of the...

Embodiment 2

[0026] refer to Figure 5 , the secondary nozzle 5 of the injector 1 is set on the casing 11 of the compressor, and is integrated with the compressor casing 11, the mixing chamber 8 of the secondary nozzle is connected to the primary nozzle 6, and the pipe wall of the primary nozzle An air suction pipe 13 parallel to the axis of the nozzle is provided on the top, which communicates the mixing chamber with the air suction inlet 3, and the air suction inlet communicates with the air inlet of the compressor or with the atmosphere. After the high-pressure oil enters the mixing chamber 8 through the inlet 2 of the primary nozzle, the gas is inhaled from the suction pipe 13 through the suction inlet. into the compression chamber of the compressor.

[0027] The characteristic of this embodiment is that the suction pipe 13 is directly arranged on the primary nozzle 6 .

Embodiment 3

[0029] refer to Figure 5 , this embodiment is basically the same as Embodiment 2, and the feature of this embodiment is that the suction pipe 13 is directly arranged on the compressor casing 11, parallel to the axial direction of the compressor, and connects the mixing chamber 8 to the suction of the compressor. The mouth is connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com