Absorption-mechanical compression coupling refrigeration and cold accumulation system

A technology of mechanical compression and cold storage, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of no cold storage advantage, small circulating adsorption capacity, and large heat loss of adsorbent alternately between cold and heat, and improve isentropic efficiency. and volumetric efficiency, increase the intake pressure, and expand the application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

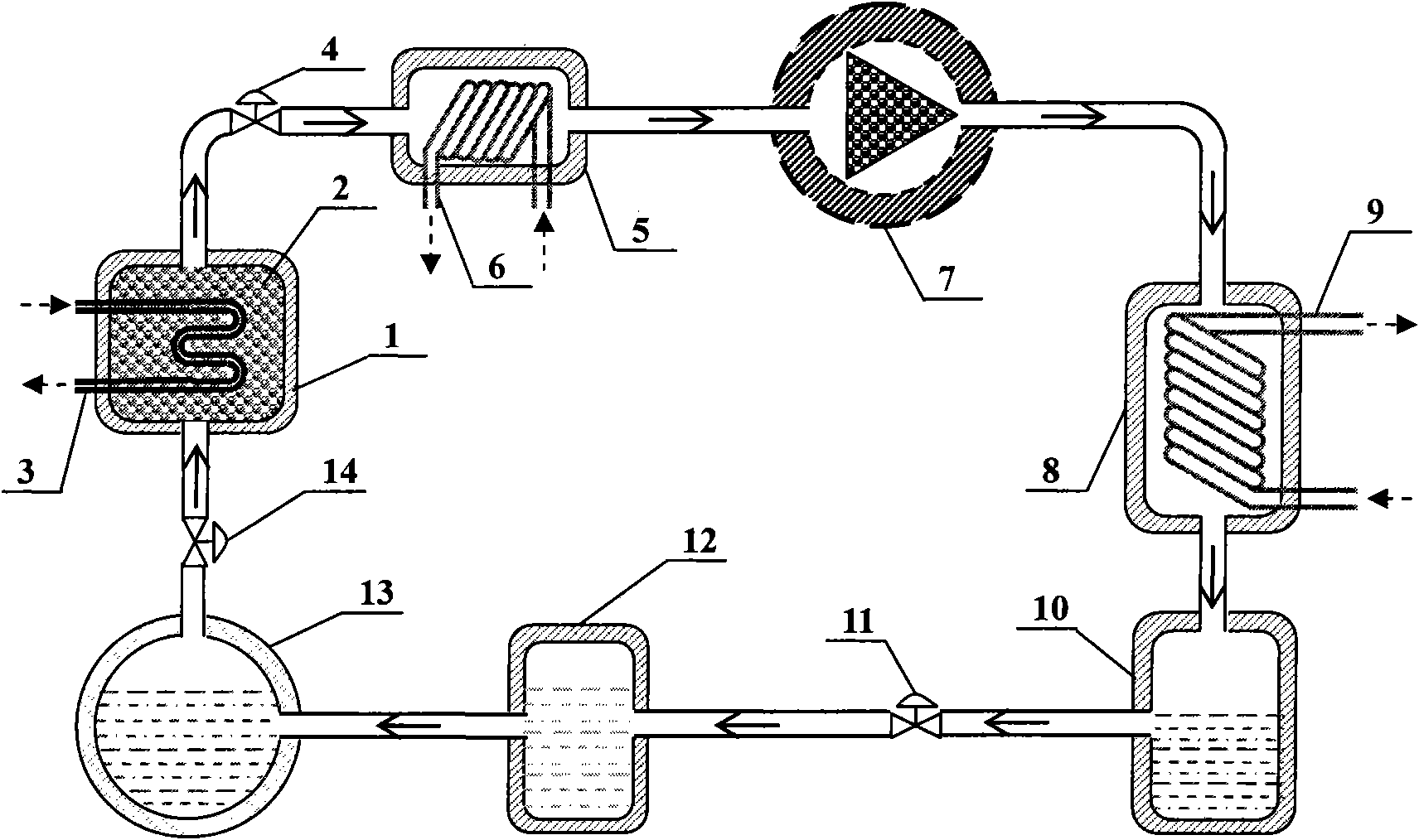

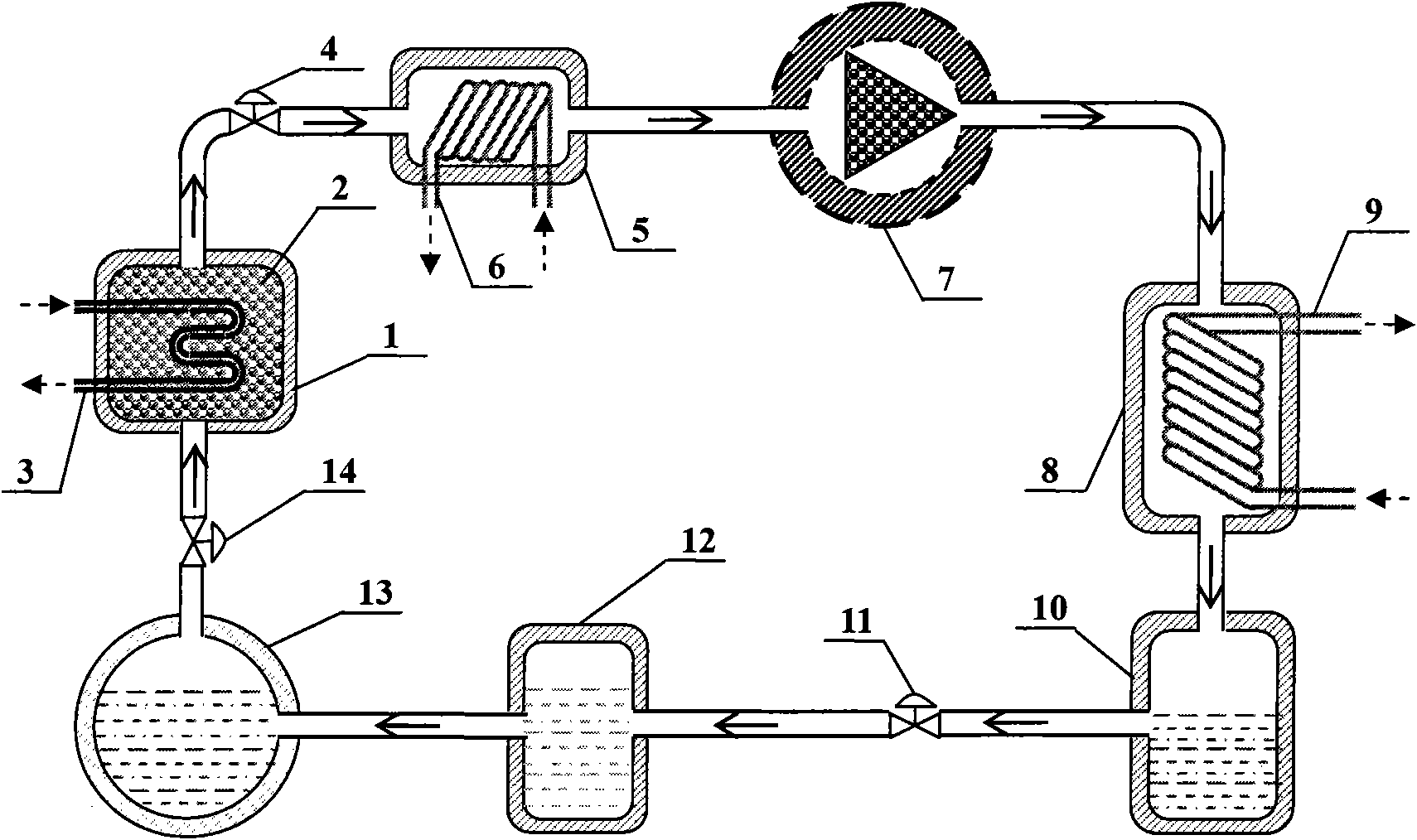

[0023] like figure 1 As shown, this embodiment includes: adsorption bed 1, adsorbent 2, adsorption bed heat exchanger 3, desorption valve 4, cooler 5, cooler heat exchange coil 6, compressor 7, condenser 8, condenser exchange Heat coil 9, high-pressure liquid storage tank 10, throttle valve 11, low-pressure liquid storage tank 12, evaporator 13, adsorption valve 14.

[0024] In this embodiment, an adsorption bed 1 is added between the evaporator and the compressor of the traditional compression refrigeration system, the outlet of the adsorption bed 1 is connected to the inlet of the desorption valve 4, the outlet of the desorption valve 4 is connected to the inlet of the cooler 5, and the outlet of the cooler 5 It is connected with the inlet of compressor 7, the outlet of compressor 7 is connected with the inlet of condenser 8, the outlet of condenser 8 is connected with the inlet of high-pressure liquid storage tank 10, the outlet of high-pressure liquid storage tank 10 is co...

Embodiment 2

[0032] In this embodiment, the number of adsorption beds is 4, and the refrigerant gas passages between different adsorption beds are connected in parallel to achieve the purpose of mass recovery; the heat exchangers of different adsorption beds are connected in series to achieve higher recovery temperature. The heat of adsorption and the purpose of controlling the rate of adsorption of refrigerant.

[0033] In this embodiment, the compressor 7 is an oil-containing screw compressor. In order to prevent the compressor from polluting the adsorbent with lubricating oil, an oil separator is installed at the outlet of the compressor, and an oil filter device is installed between the evaporator and the adsorption bed.

[0034] In this embodiment, during the peak, peak and normal periods when the electricity price is relatively expensive, the four adsorption beds in the system perform the evaporative refrigeration-adsorption process, and the high-pressure and normal-temperature refrig...

Embodiment 3

[0040] In this embodiment, the number of adsorption beds 1 is 10, and the refrigerant gas channels between different adsorption beds are connected in parallel to achieve the purpose of mass recovery; the heat exchangers of different adsorption beds are connected in series to achieve higher recovery. The temperature is the heat of adsorption and the purpose of controlling the rate of adsorbed refrigerant.

[0041] In this embodiment, the compressor 7 is a moving magnet linear compressor.

[0042] In this embodiment, during the peak, peak and normal periods when the electricity price is relatively expensive, the seven adsorption beds in the system perform the evaporative refrigeration-adsorption process, and the high-pressure and normal-temperature refrigerant in the high-pressure liquid storage tank 10 enters the low-pressure liquid storage through the throttle valve 11 The tank 12 then enters the evaporator 13 for evaporation and refrigeration, and is adsorbed by the adsorptio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com