Variable displacement dual vane pump

A displacement pump and vane pump technology, applied in the field of sliding vane pumps, can solve problems such as pollution, torque loss, and affecting reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following description of one or more preferred embodiments is merely exemplary in nature and is in no way intended to limit the present invention, its application, or uses.

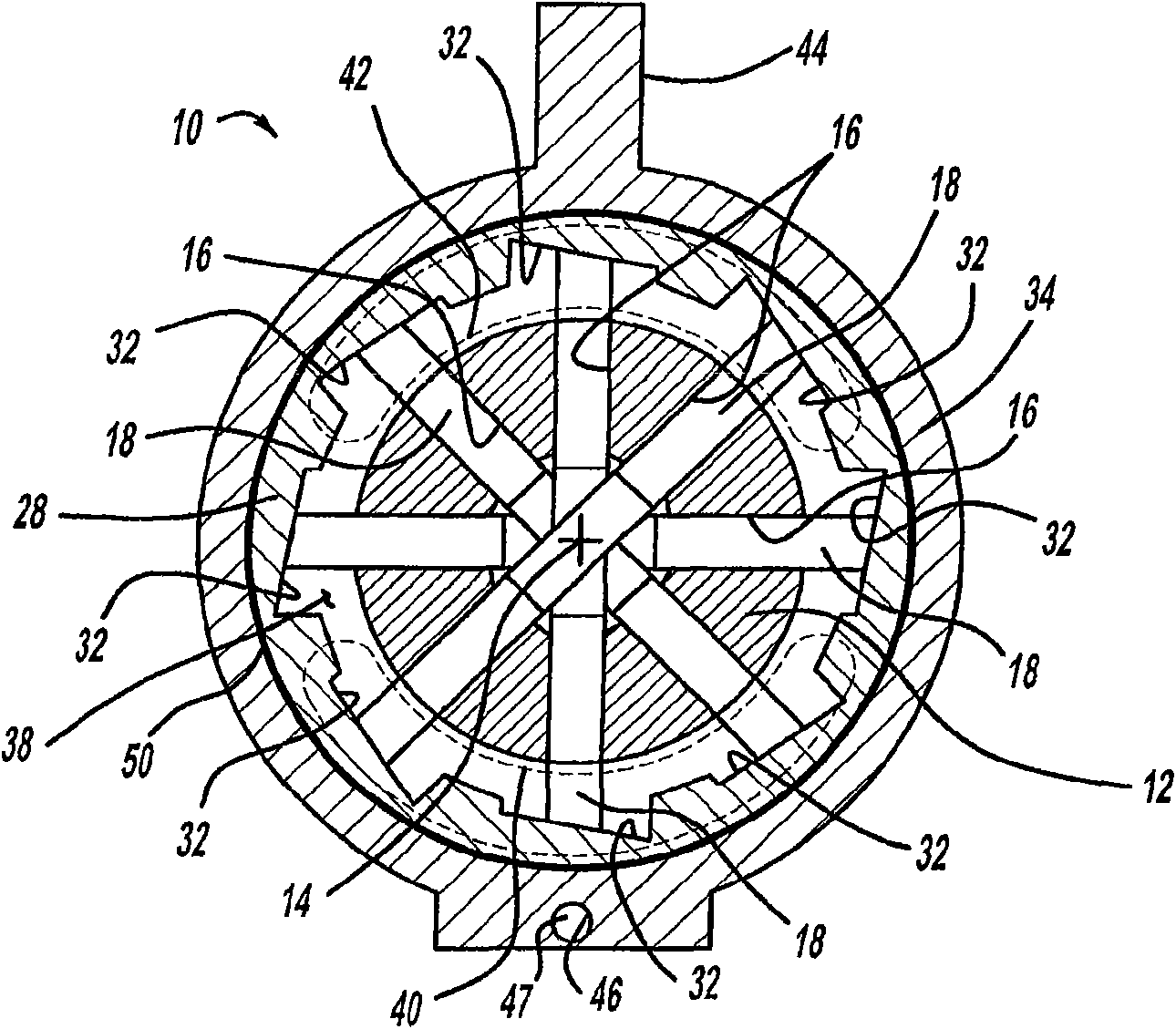

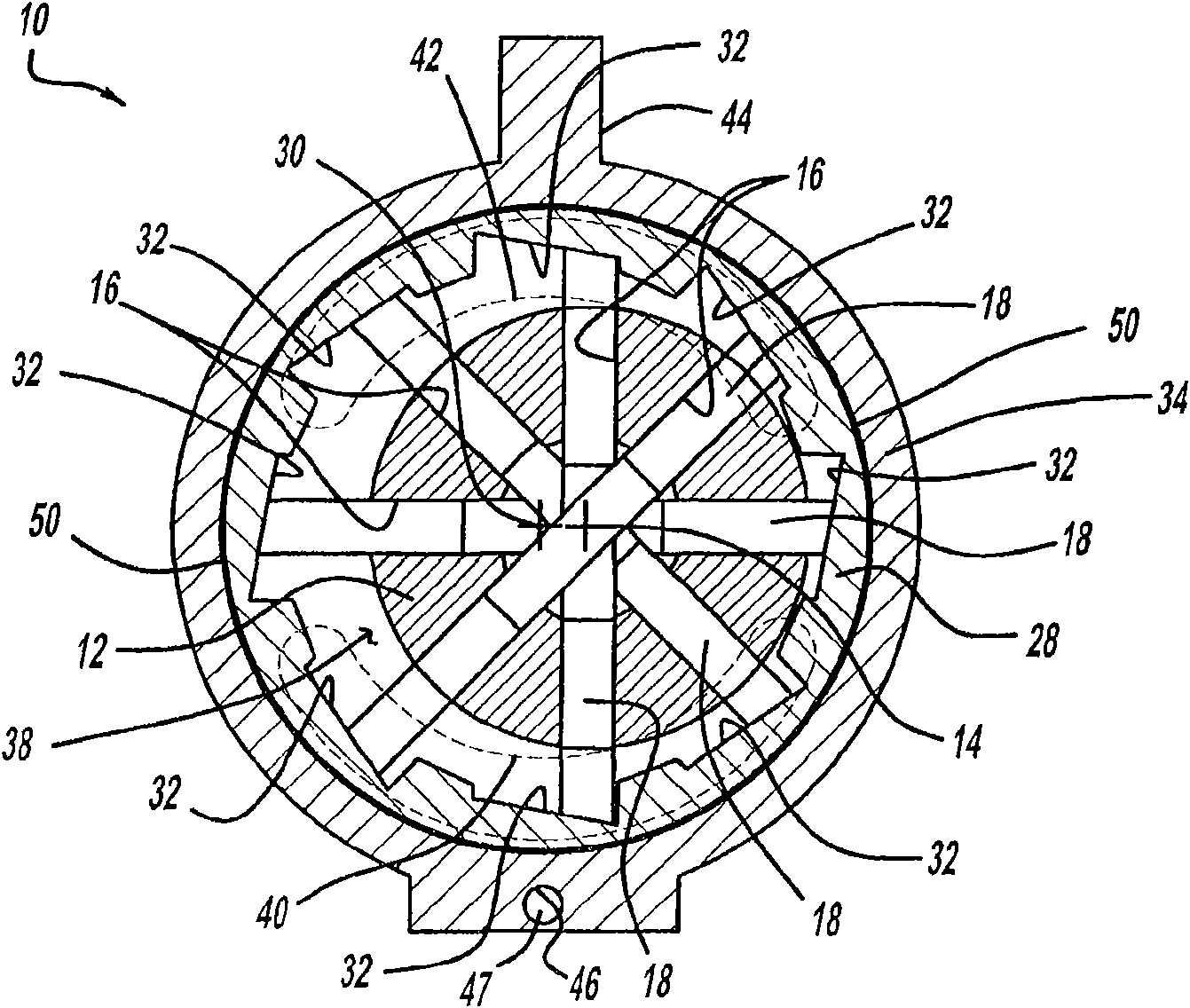

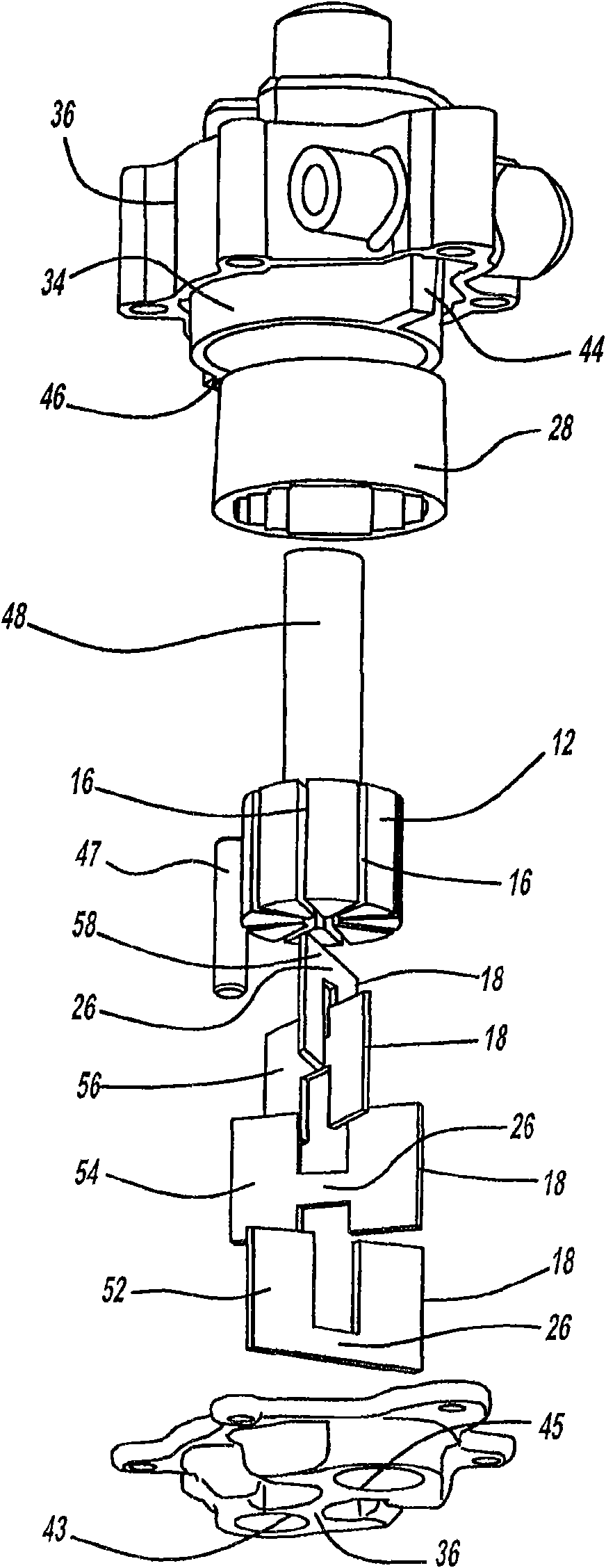

[0021] Referring generally to these drawings, a sliding vane pump according to the present invention is generally indicated by 10. The pump 10 has an inner rotor 12 that rotates about a first axis 14. The inner rotor 12 also has a series of slits 16 for receiving a plurality of blades 18. The blades 18 have a first side 20 which is offset from and parallel to a second side 22. The blades 18 also have a third side 21 which is parallel to a fourth side 23 and is equal in length compared to it. Both the third side 21 and the fourth side 23 serve as a flat joint surface 24. The blade 18 also includes an extension 26 which has a reduced width compared to the rest of the blade 18. The pump 10 also has an outer rotor 28 that rotates about a second axis 30 and has recesses 32 for receiving the flat joint s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com