Urea duplex double-scroll SCR mixer of diesel vehicle

A double-screw and mixer technology, which is used in machines/engines, exhaust gas treatment, mechanical equipment, etc., can solve the problems of insufficient hydrolysis and large back pressure, and achieve the effects of easy hydrolysis, low back pressure and large cross-sectional area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

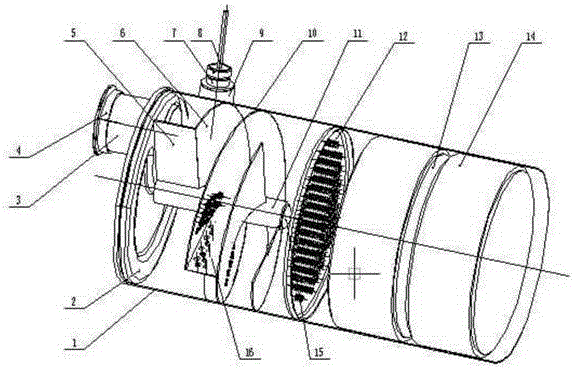

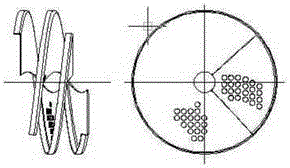

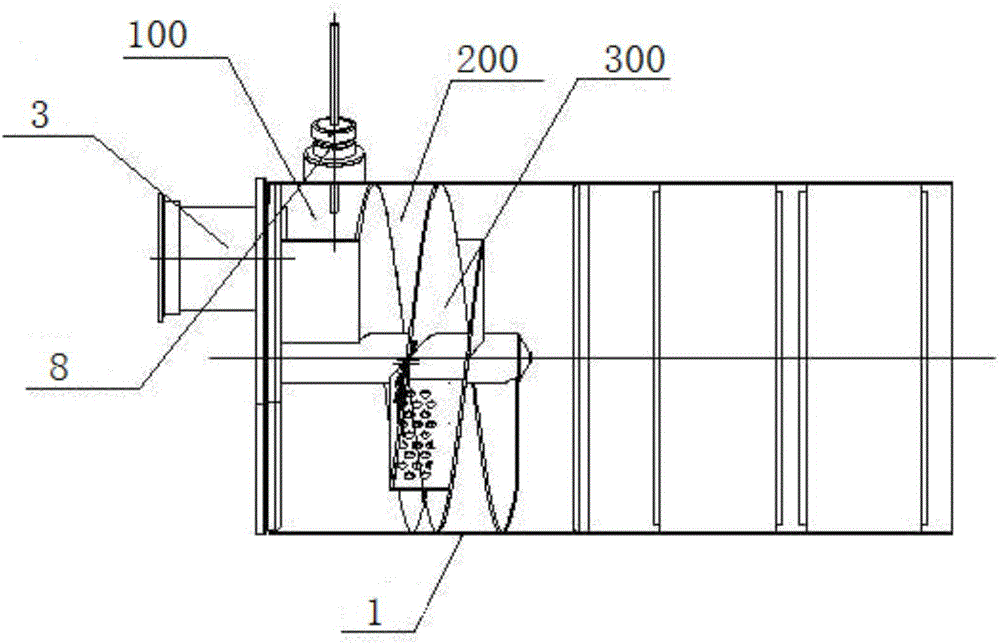

[0022] Below in conjunction with specific embodiment and accompanying drawing, the best embodiment of the present invention is described in detail: for example: the flow direction of air flow through each channel, and how the injection urea is atomized in the inside of the mixer and other working principles are described in detail.

[0023] The urea double helix double vortex SCR mixer for diesel vehicles in the embodiment of the present invention consists of 2 sets of helical blades, the air flow first passes through the main helical channel, and then the air flow is divided into two groups, which are mixed and passed through the two sets of helical blades to form two sets of double vortex Swirling air flow; the two air streams hit together, the urea is further broken, hydrolyzed, and finally further hydrolyzed and atomized by hitting the cylinder to form ammonia gas, so that the exhaust gas and ammonia gas are evenly mixed together; due to the double helix double vortex SCR T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com