Organosilicone polyurethane anti-fouling material with low surface energy and hydrolyzed self-polishing function and application thereof

A low surface energy, silicone technology, applied in polyurea/polyurethane coatings, antifouling/underwater coatings, biocide-containing paints, etc., can solve low surface energy, poor static antifouling performance of tin-free self-polishing coatings, Poor antifouling performance of antifouling coatings, etc., to achieve the effect of reducing adhesion and low surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

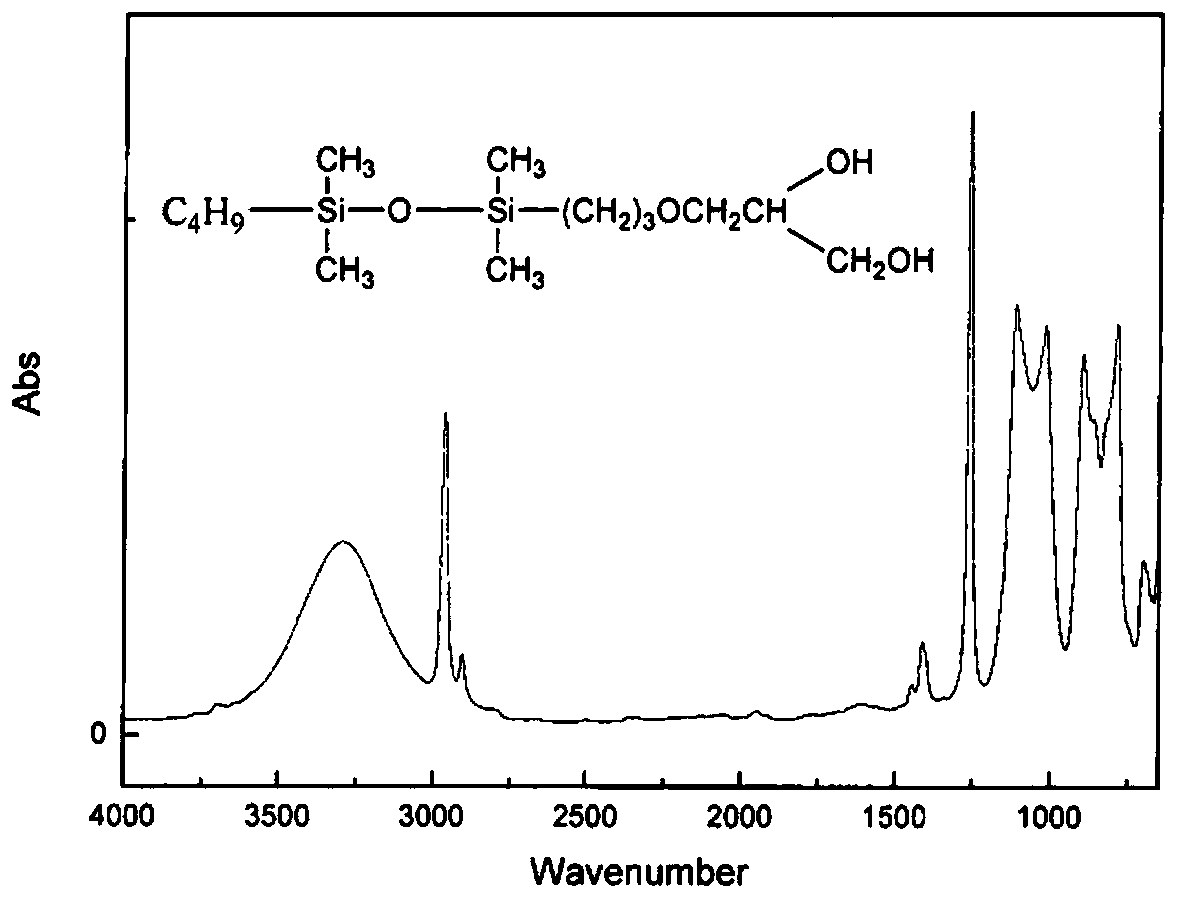

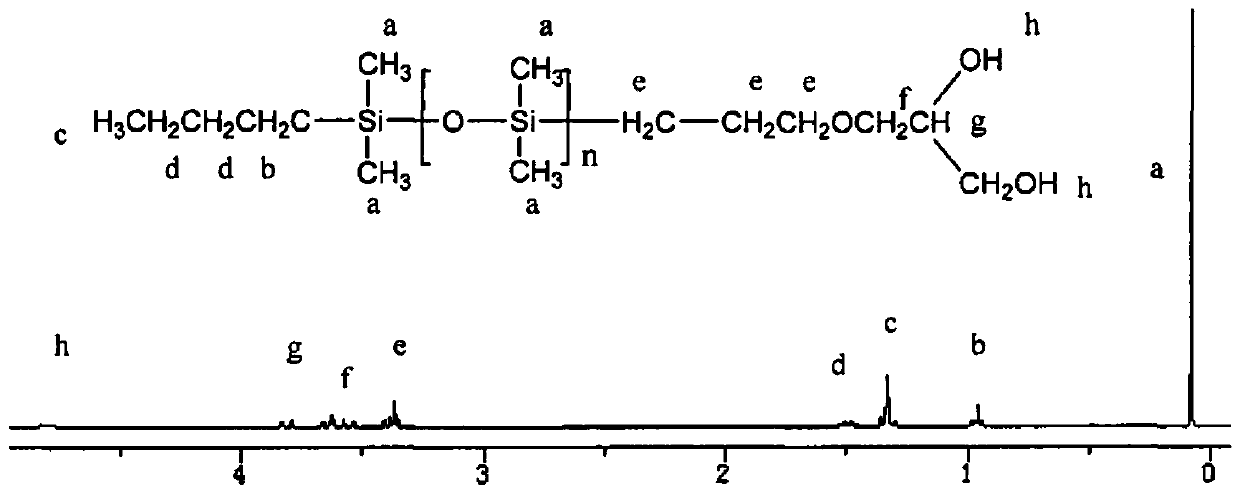

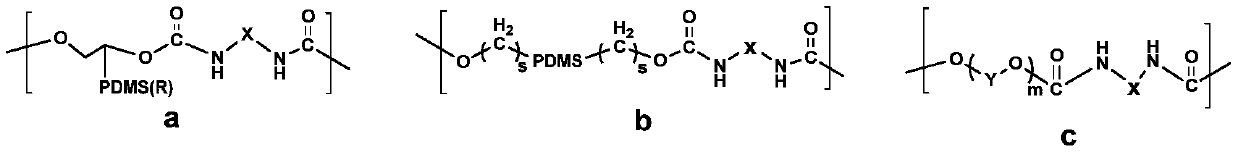

[0030] The preparation of embodiment 1 polyurethane material

[0031] Dissolve 10g PDMS(R) (molecular weight 1330), 7.5g double-terminated hydroxyl PDMS (molecular weight 365), 35g polyethylene glycol (molecular weight 1000), and 5g HDI in 100g butyl acetate, and then add them to a 250ml single-necked flask for use Stir with a magnet, raise the temperature to 75°C, and add 3 drops of dibutyltin dilaurate dropwise to react. The product is obtained after reacting for 4 hours, and a certain solvent is volatilized to adjust the solid content to 50%. According to 60 parts of the product, 15 parts of cuprous oxide, 10 parts of red iron oxide, 12 parts of PM200 (crosslinking agent), processing aids (leveling agent, Defoamer and other mixtures) 3 parts are formulated into antifouling paint for marine coating.

Embodiment 2

[0032] The preparation of embodiment 2 polyurethane materials

[0033] 52g PDMS (R), 36g double-terminated hydroxyl PDMS, 88g polyethylene glycol (molecular weight 600), 14.16g HDI and 7.48g IPDI were dissolved in 400g xylene, then added to a 1000ml three-necked flask and stirred with a stirring paddle, The temperature was raised to 75°C, and 12 drops of dibutyltin dilaurate were added dropwise to react. The product was obtained after reacting for 6 hours, and a certain amount of solvent was volatilized to adjust the solid content to 50%. According to 60 parts of the product, 15 parts of cuprous oxide, 10 parts of red iron oxide, 12 parts of PM200 (crosslinking agent), and 3 parts of processing aids, it was formulated into an anti- Dirty paint for marine coated panels.

Embodiment 3

[0034] The preparation of embodiment 3 polyurethane materials

[0035] Dissolve 10g PDMS(R), 7.5g double-terminated hydroxyl PDMS, 35g polyethylene glycol (molecular weight 1000), 3.75g HDI and 1.65g IPDI in 100g xylene, then add them to a 250ml single-necked flask and stir with a magnet , heated up to 75°C, and 3 drops of dibutyltin dilaurate were added dropwise to react. The product was obtained after reacting for 1.5 hours, and a certain amount of solvent was volatilized to adjust the solid content to 50%. According to 60 parts of the product, 15 parts of cuprous oxide, 10 parts of red iron oxide, 12 parts of PM200 (crosslinking agent), and 3 parts of processing aids, it was formulated into Antifouling paint for marine coated panels.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com