Metal ultrafine atomizing, crushing and grading system and metal atomizing device thereof

An atomization device, pulverization and classification technology, which is applied in the field of production and preparation of metal ultra-fine atomization and pulverization, can solve the problems of few ultra-fine powder devices and low output rate of fine powder, etc. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the present invention better understood, it will be described below in conjunction with the accompanying drawings.

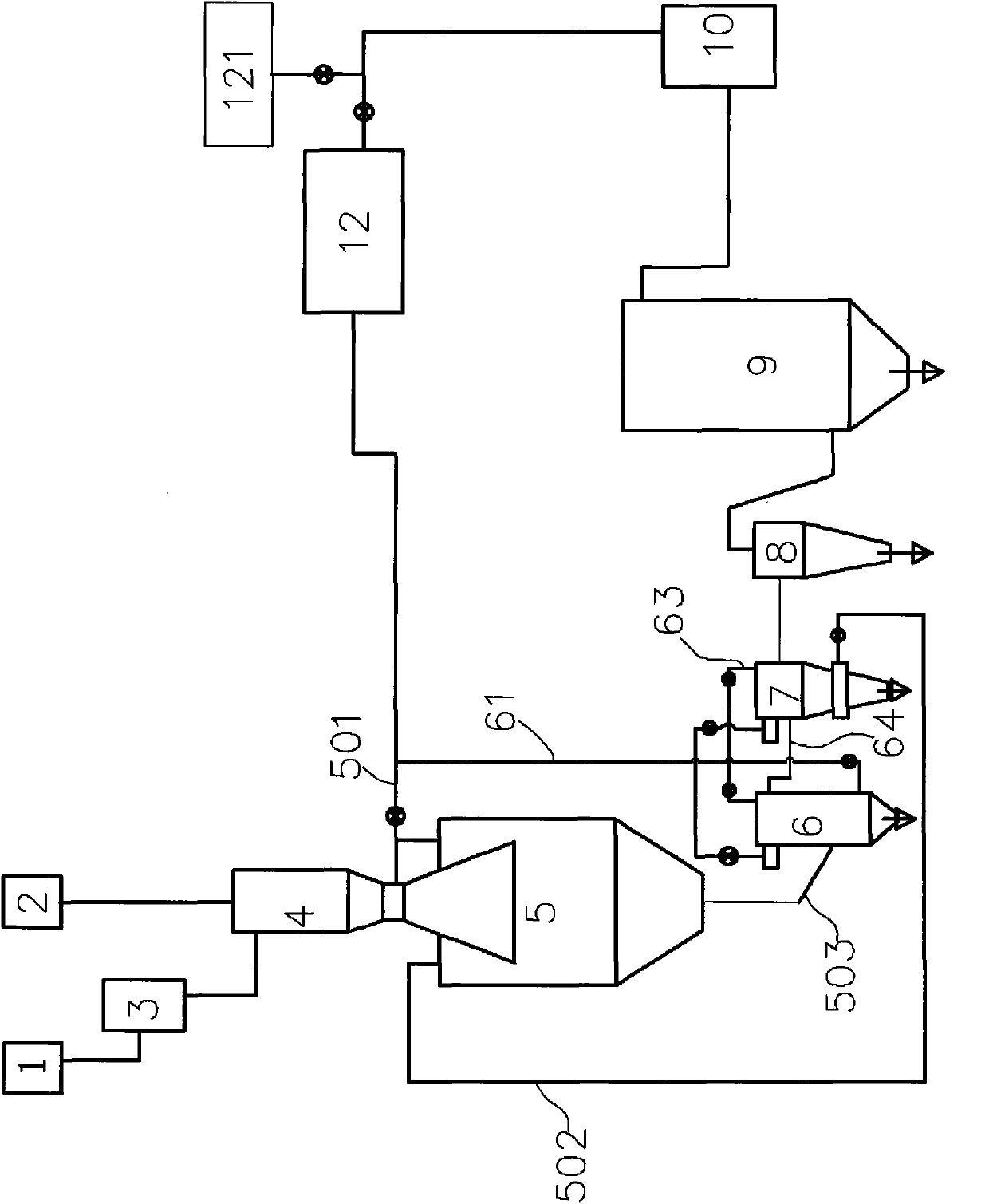

[0043] figure 1 It is a schematic composition diagram of the metal ultrafine atomization pulverization classification system provided by the present invention. This system includes:

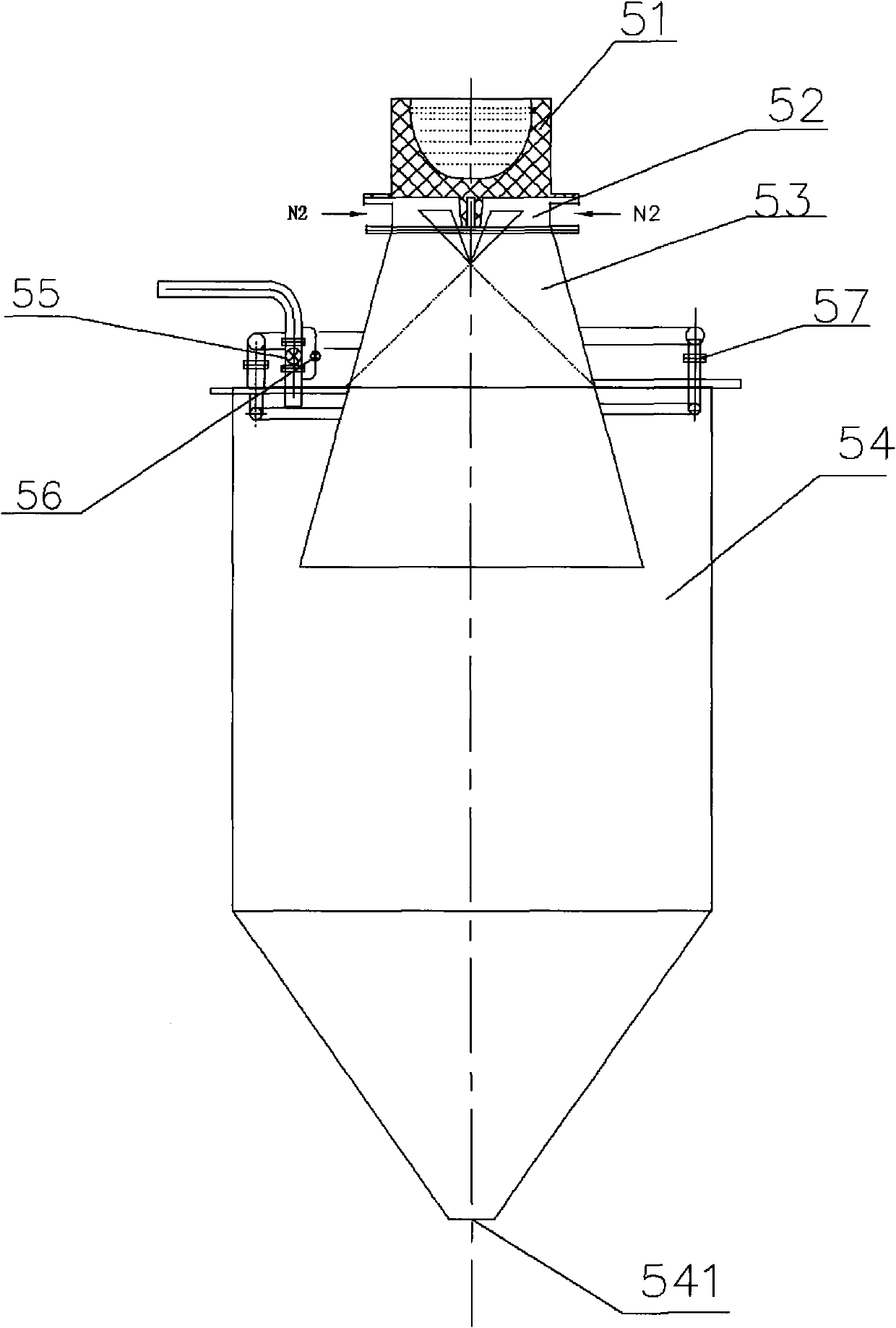

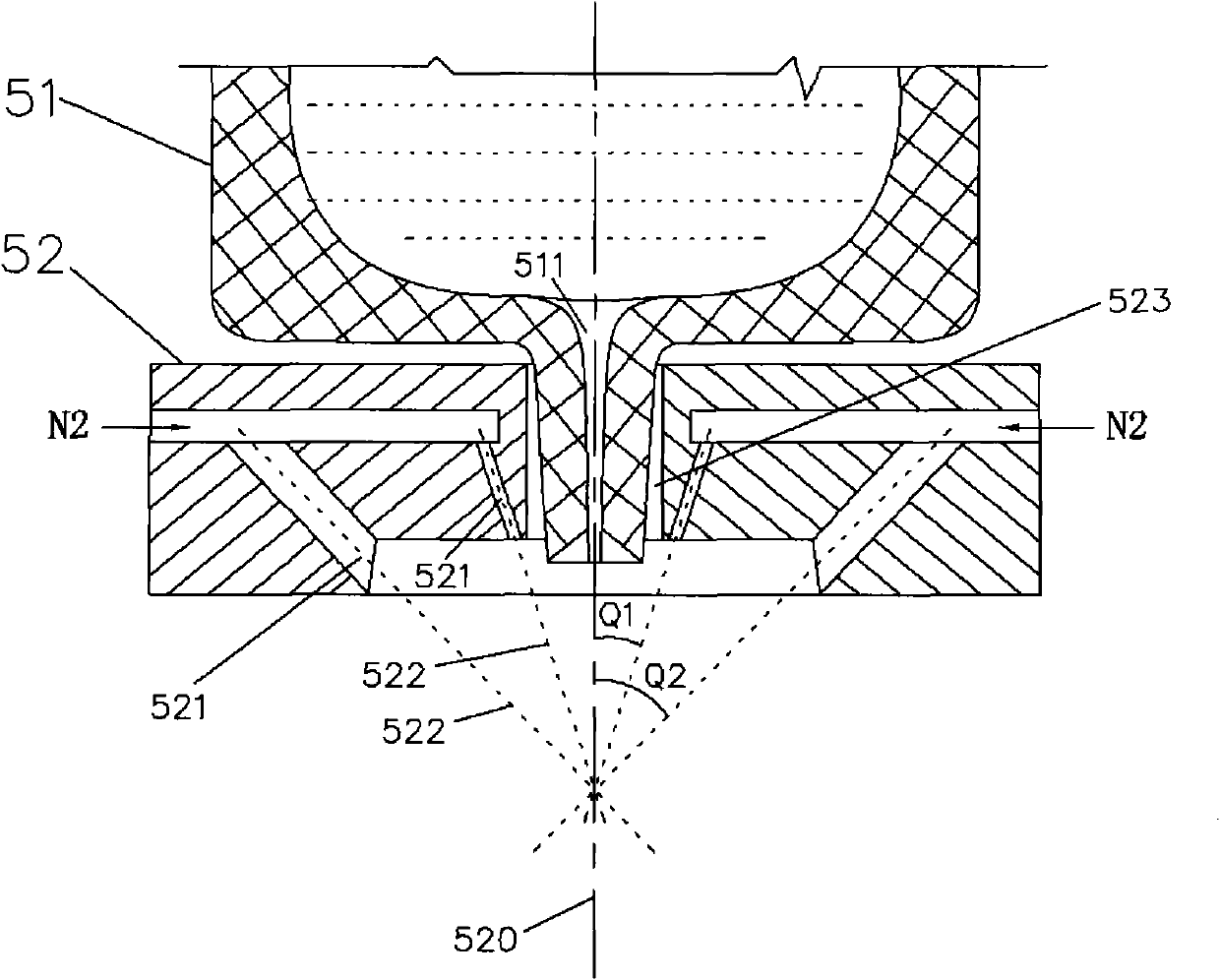

[0044] The metal smelting furnace 3 is powered by the metal smelting furnace power supply 1, and metal (such as metal pure aluminum or other metals and alloys) is melted in an oxygen-free state through two groups of electrodes; in this embodiment, the metal Aluminum (ingot) is melted into a liquid state and injected into the crucible 51 of the metal atomization device 5;

[0045] The metal hydrogen exhaust heating furnace 4 is powered by the metal hydrogen exhaust heating furnace power supply 2 and connected to the output end of the metal smelting furnace 3 to discharge the hydrogen and oxygen contained in the molten metal and heat the metal to atomized me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com